Patents

Literature

31results about How to "Save construction consumables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

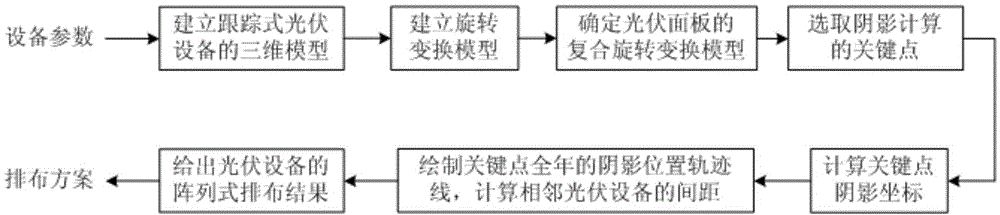

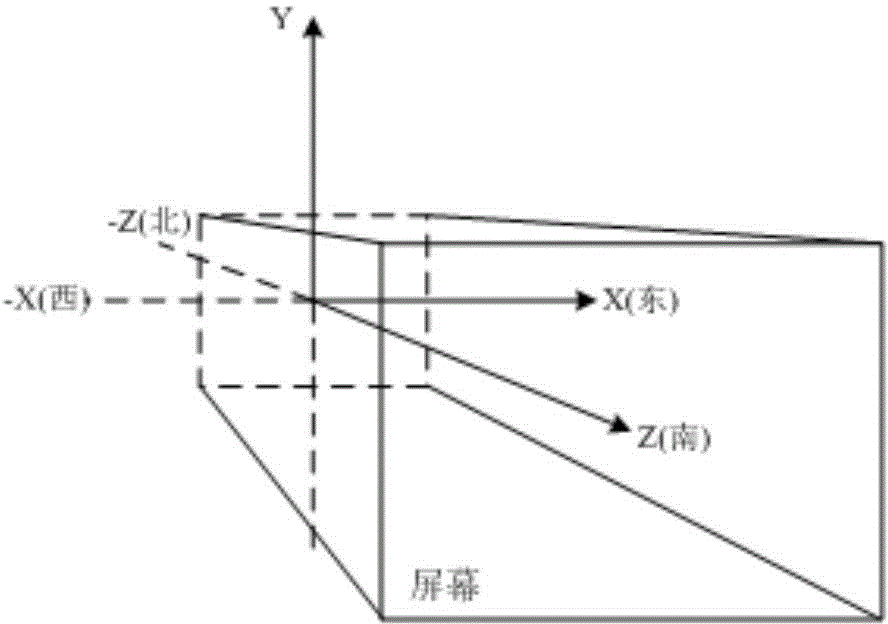

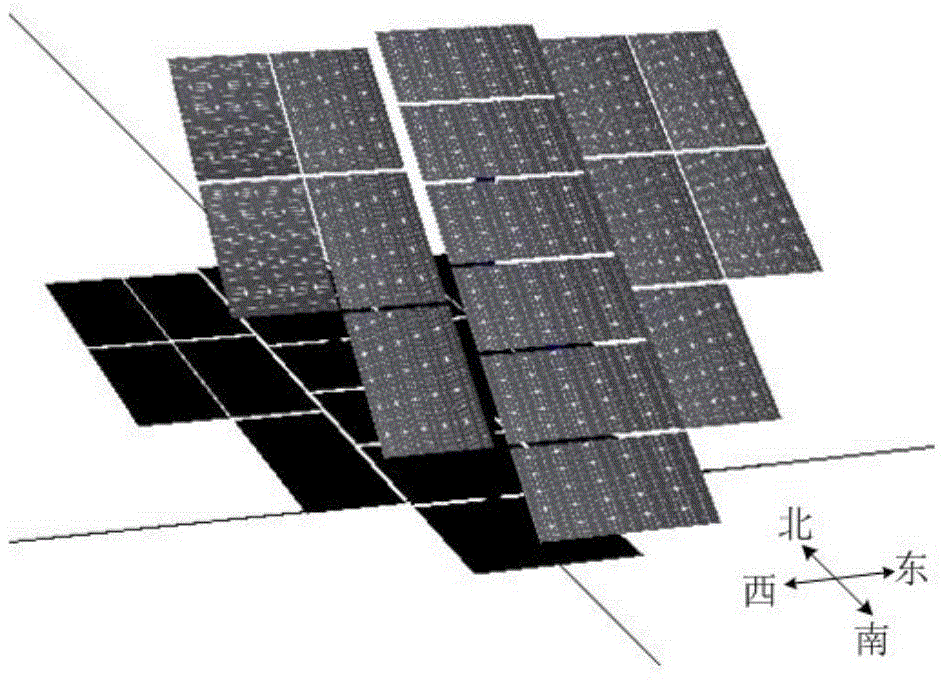

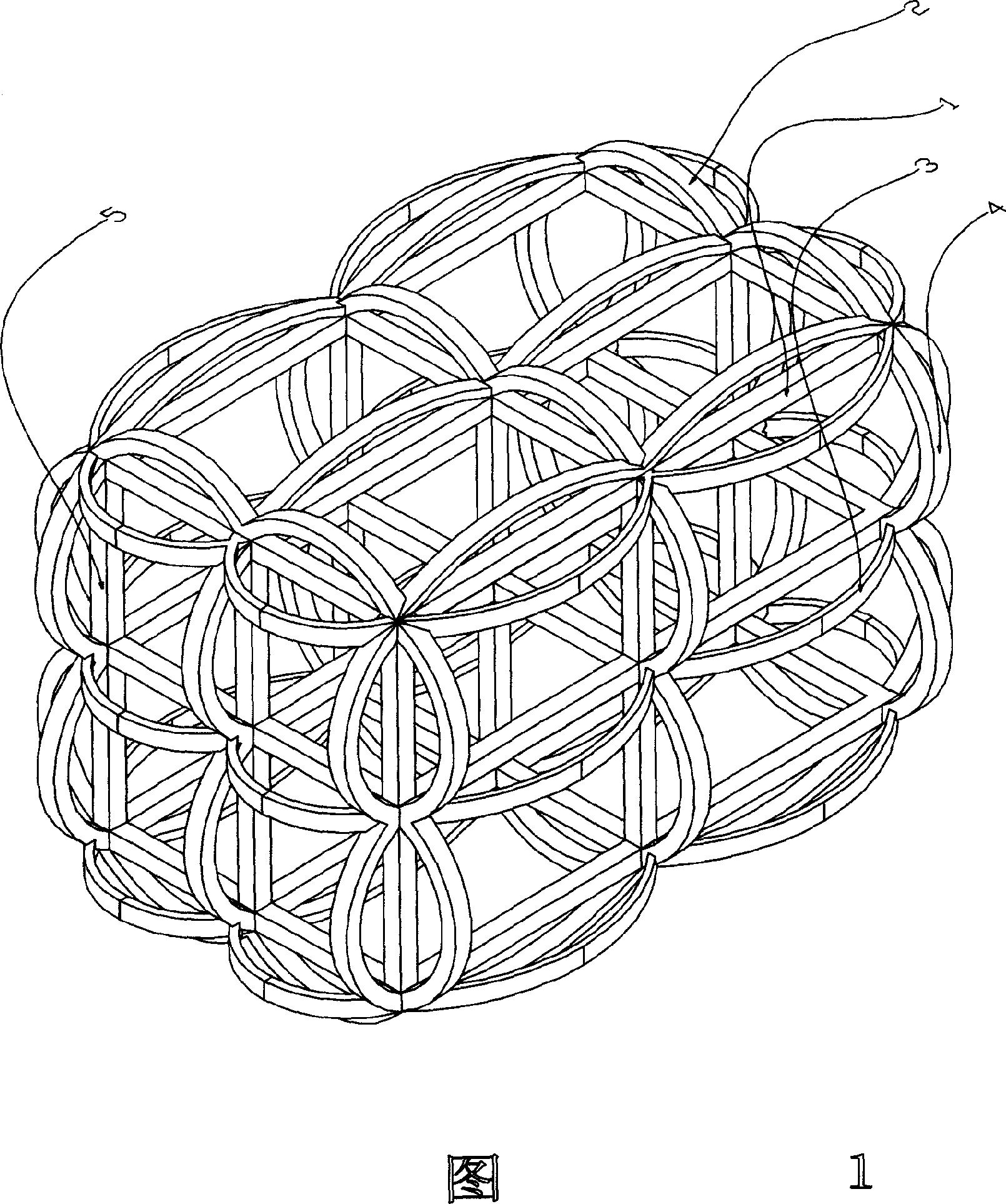

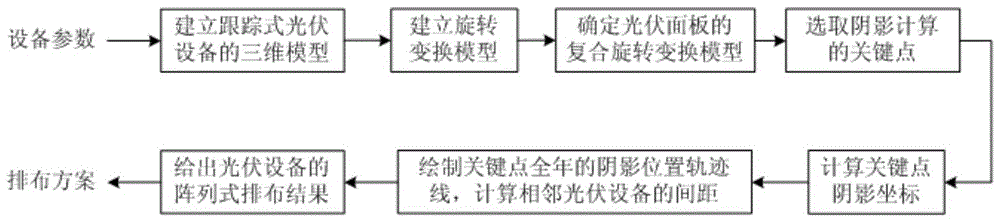

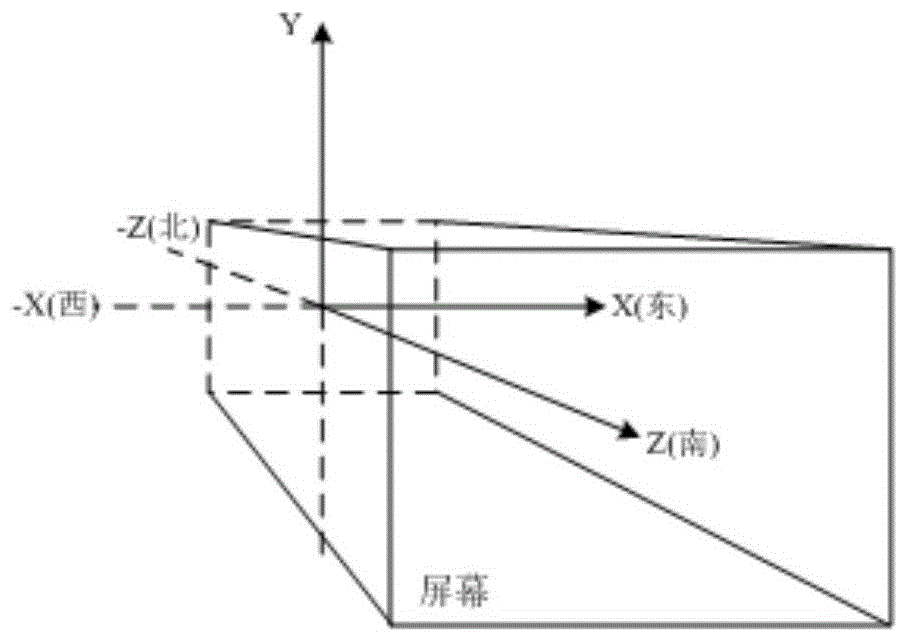

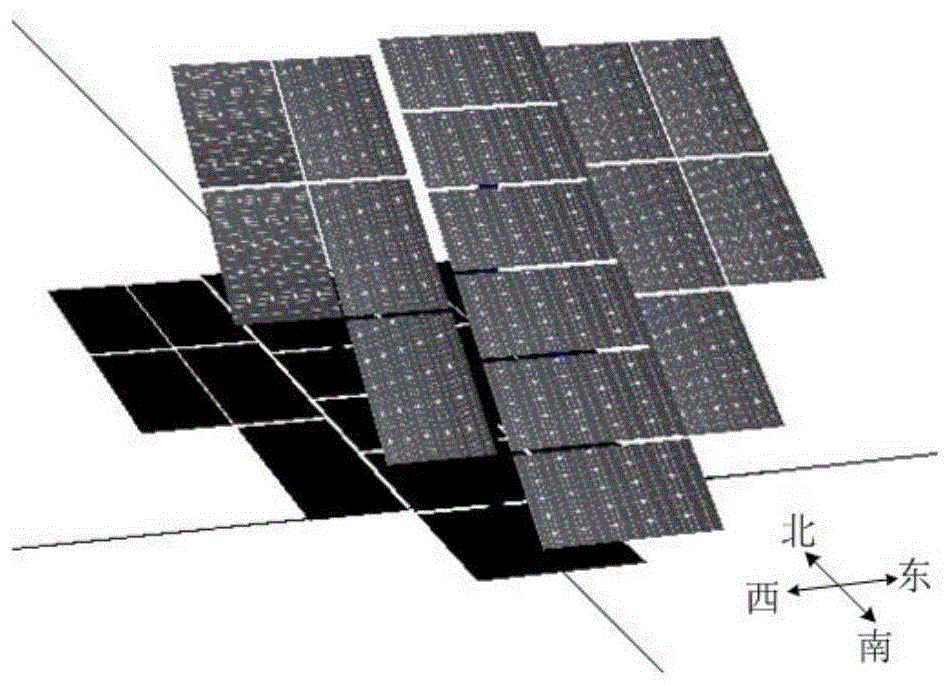

Array-type configuration method for tracking-type photovoltaic devices

ActiveCN103823927ASolving Dynamic Computing ProblemsImprove calculation accuracySpecial data processing applications3D modellingPhotovoltaic power stationComputer science

The invention discloses an array-type configuration method for tracking-type photovoltaic devices. The array-type configuration method includes the steps of 1), establishing three-dimensional models of the tracking-type photovoltaic devices; 2), establishing rotation transformation models; 3), determining composite rotation transformation models of photovoltaic panels; 4), selecting shadow calculation key points; 5), calculating shadow coordinates of the key points; 6), drawing annual shadow position track lines of the key points and calculating configuration spaces among neighboring photovoltaic devices; 7), acquiring array configuration results of the photovoltaic devices. Complexity in shadow calculation of the tracking-type photovoltaic devices is taken into consideration, shadow transformation matrix models under shining of the sun are structured, the annual shadow position track lines of the key points of the tracking-type photovoltaic devices are calculated and drawn, the minimum configuration spaces among the neighboring photovoltaic devices without shading of shadows are acquired, land occupation area and consumption of building materials for construction of a photovoltaic power station are reduced, and installed capacity and generating efficiency of the photovoltaic power station can be improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

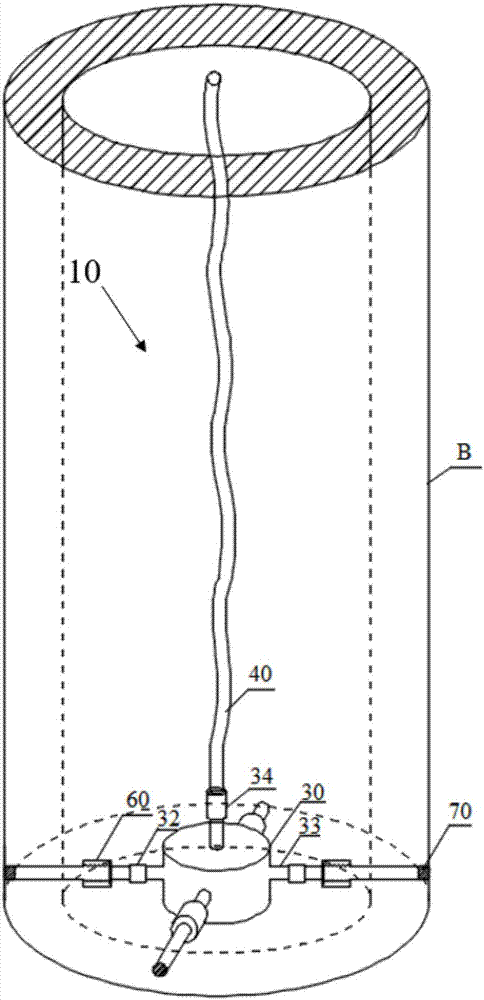

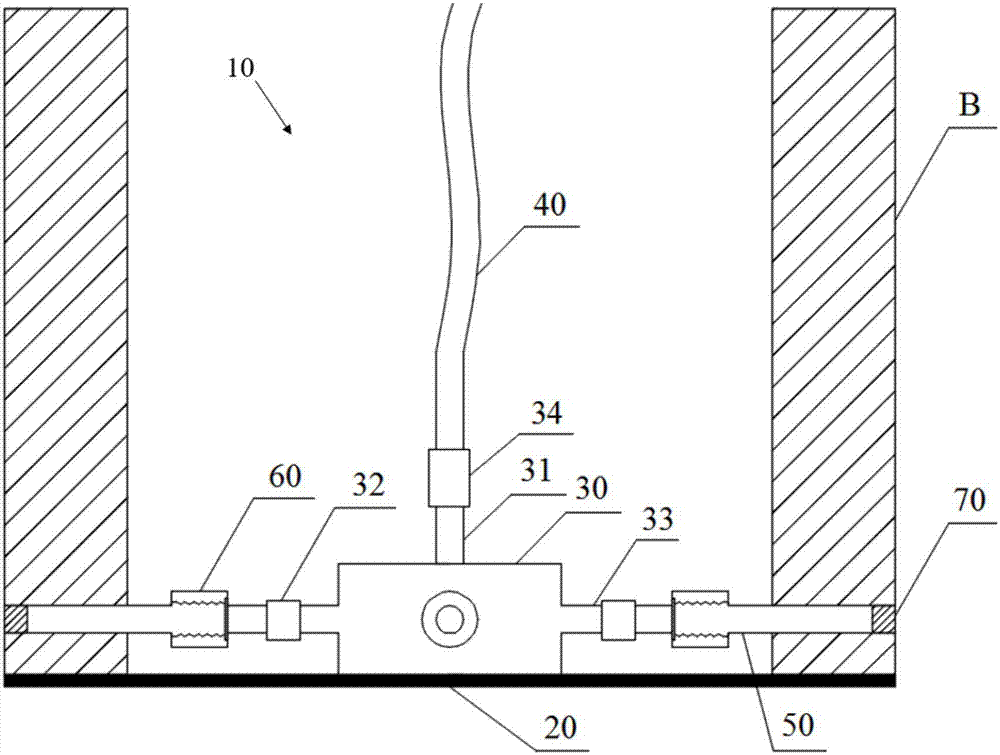

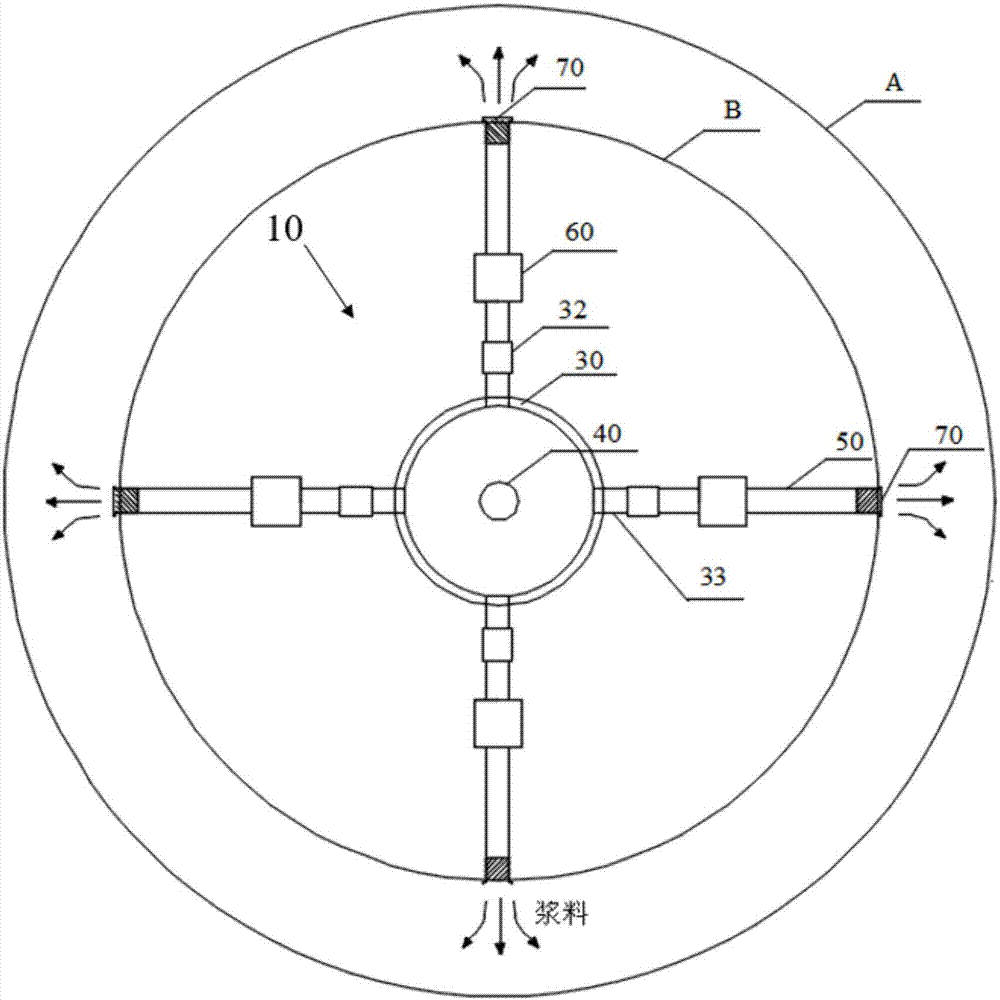

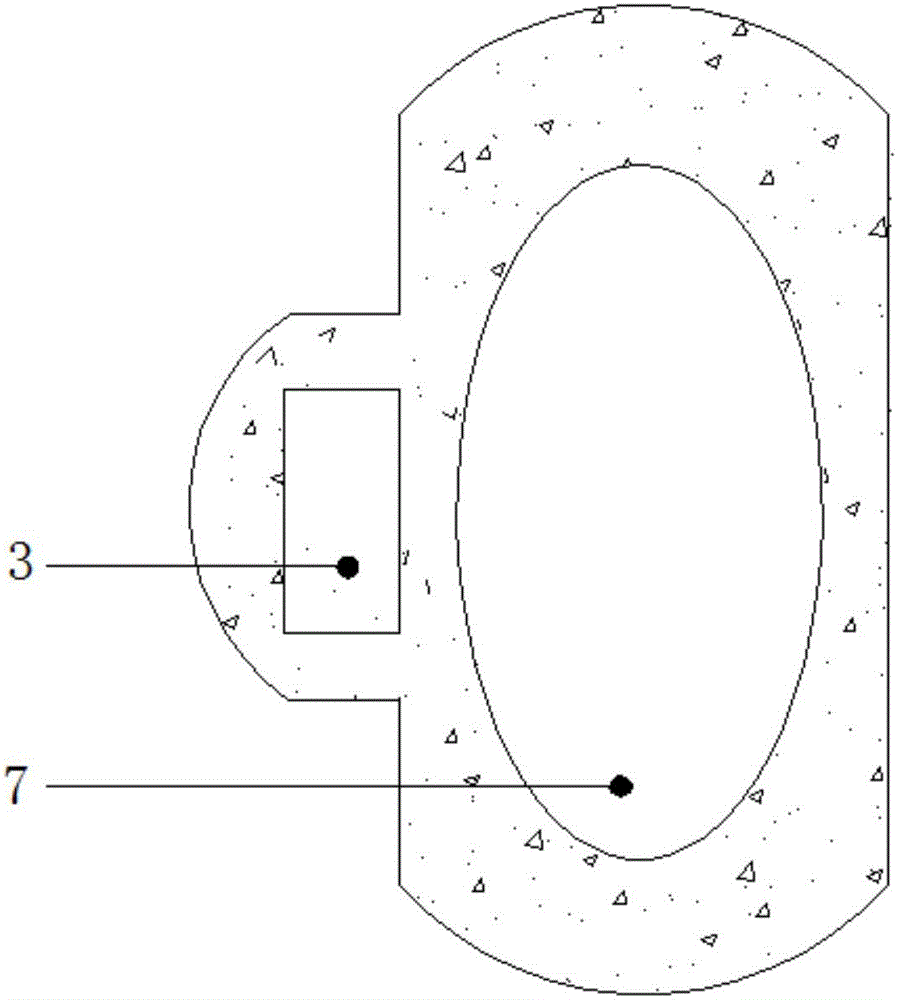

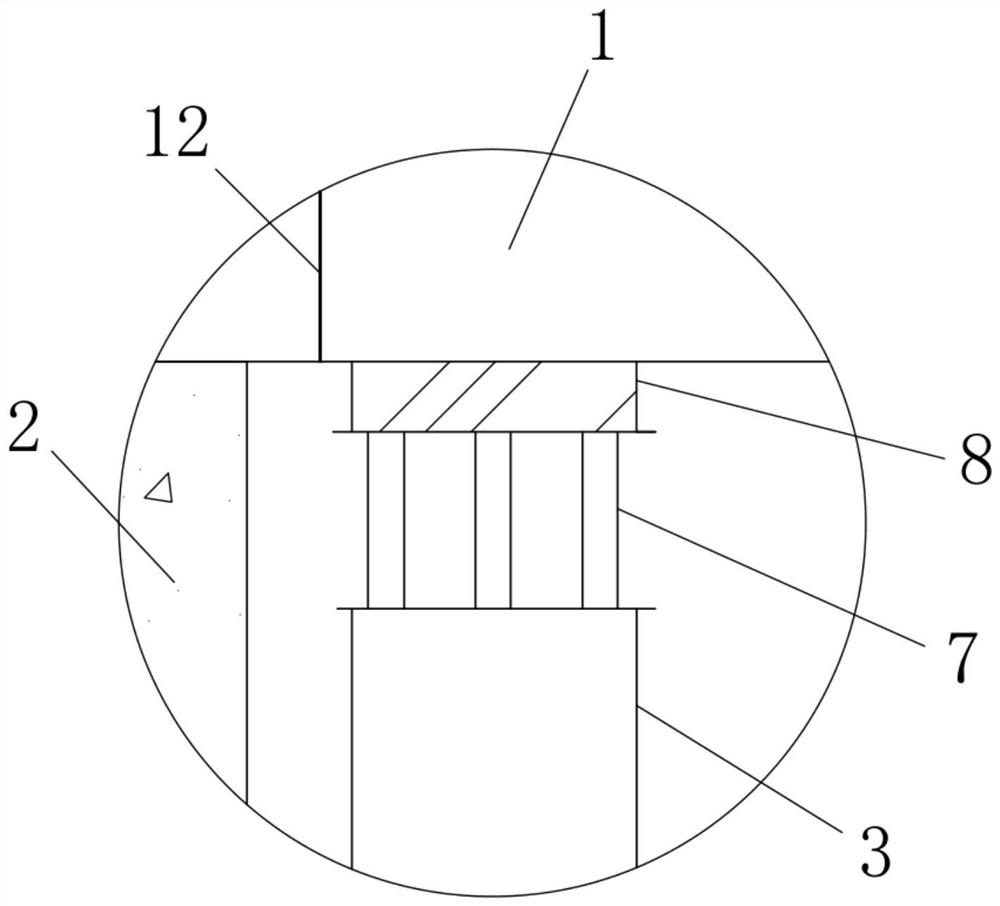

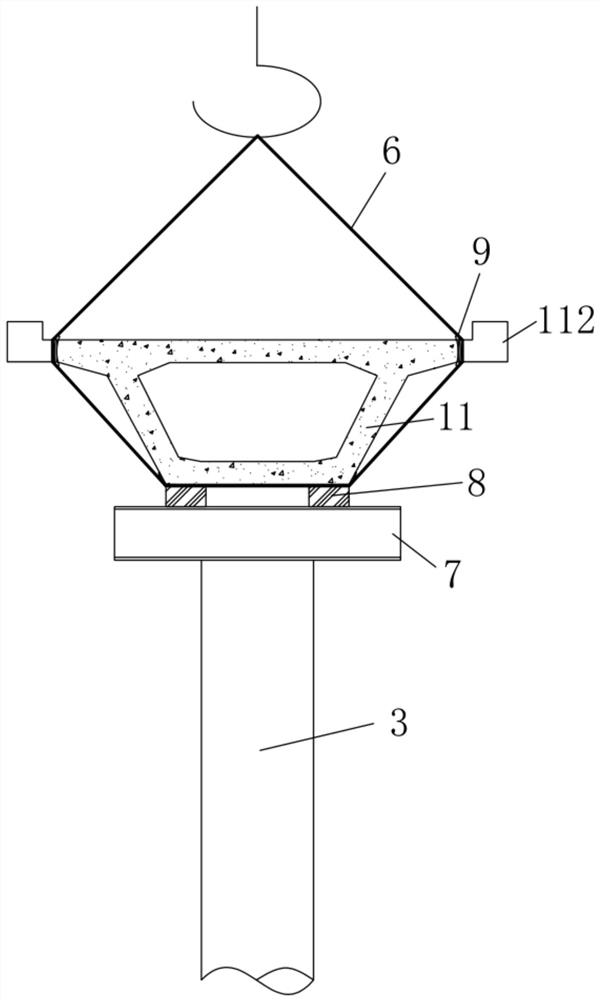

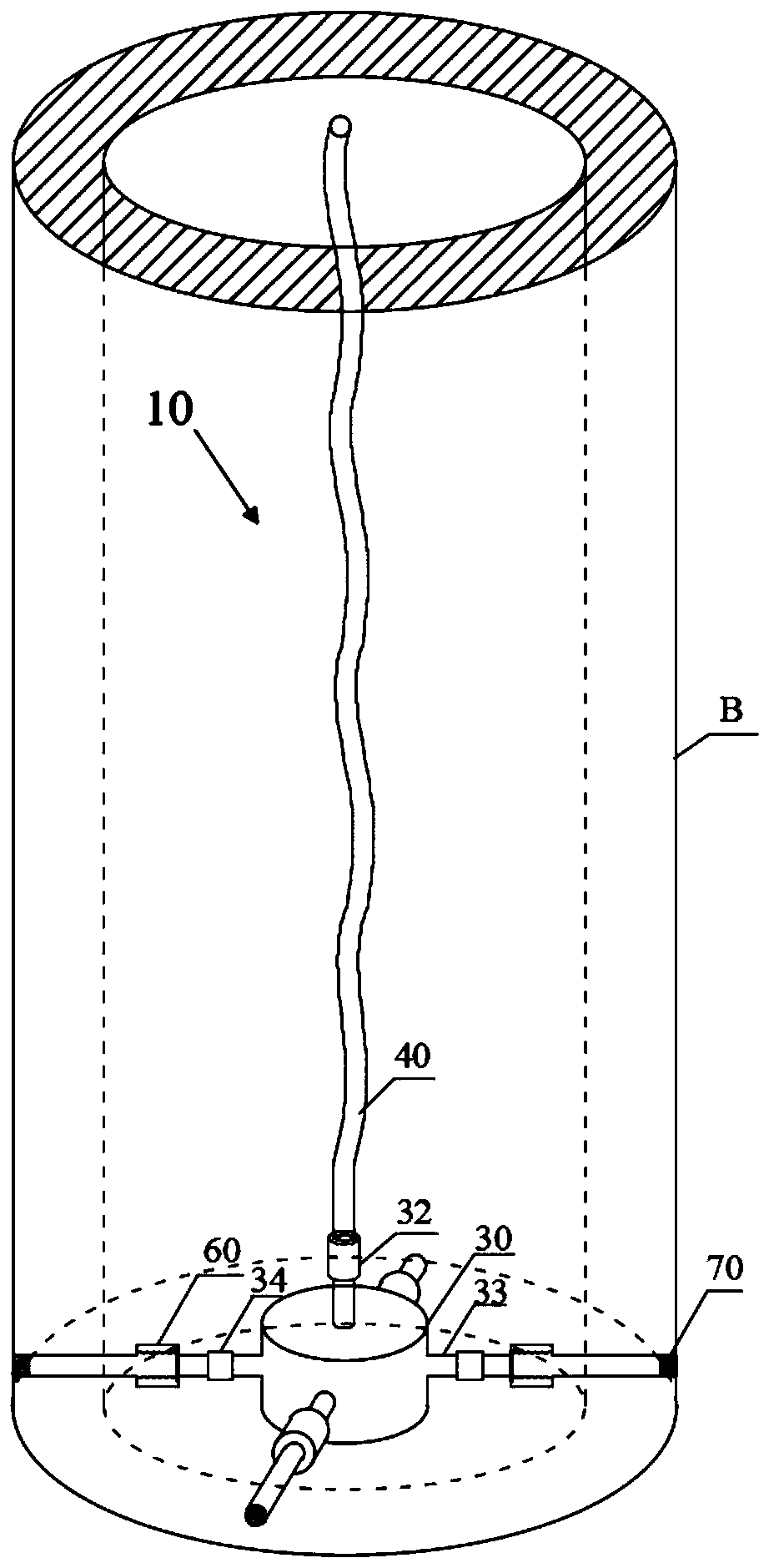

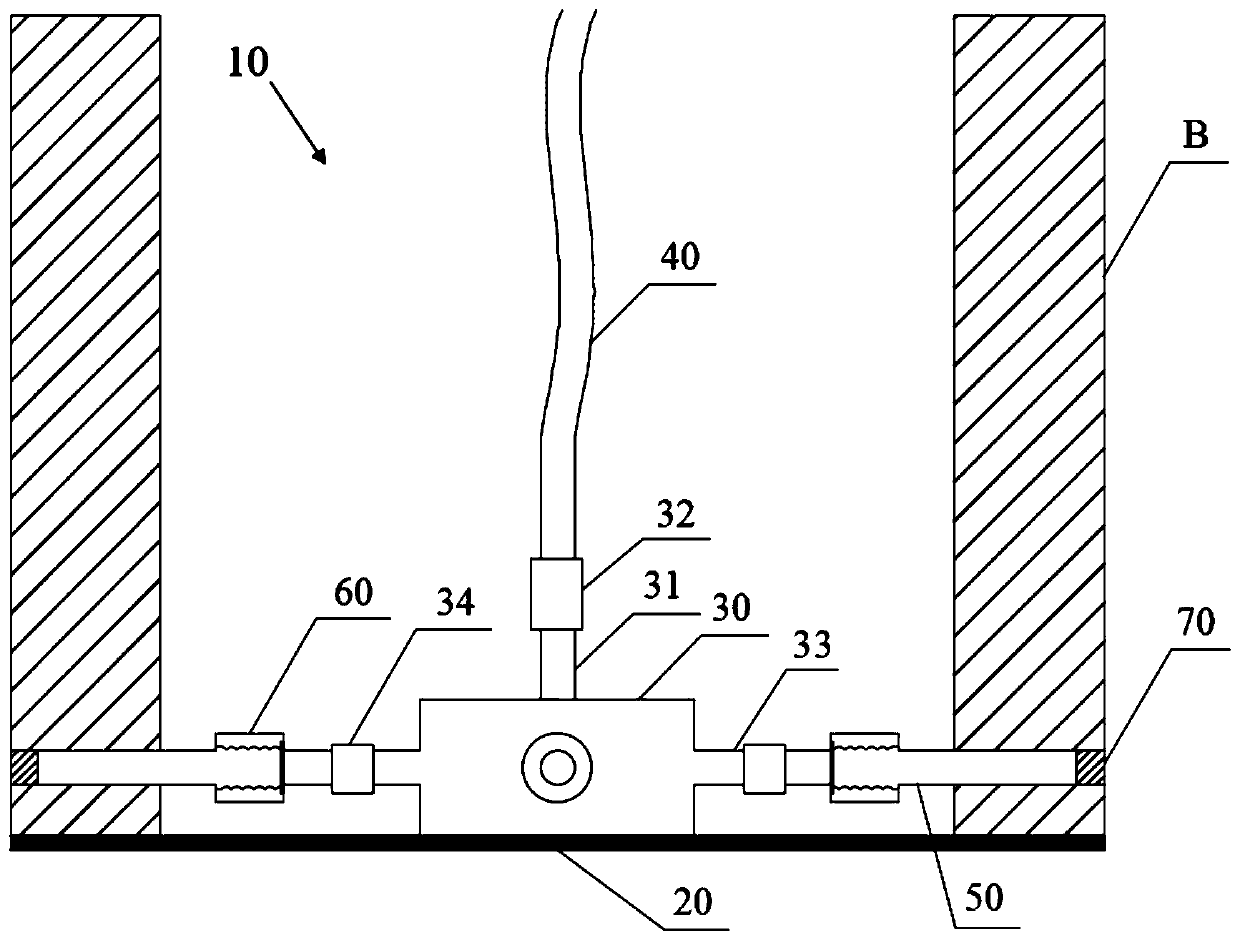

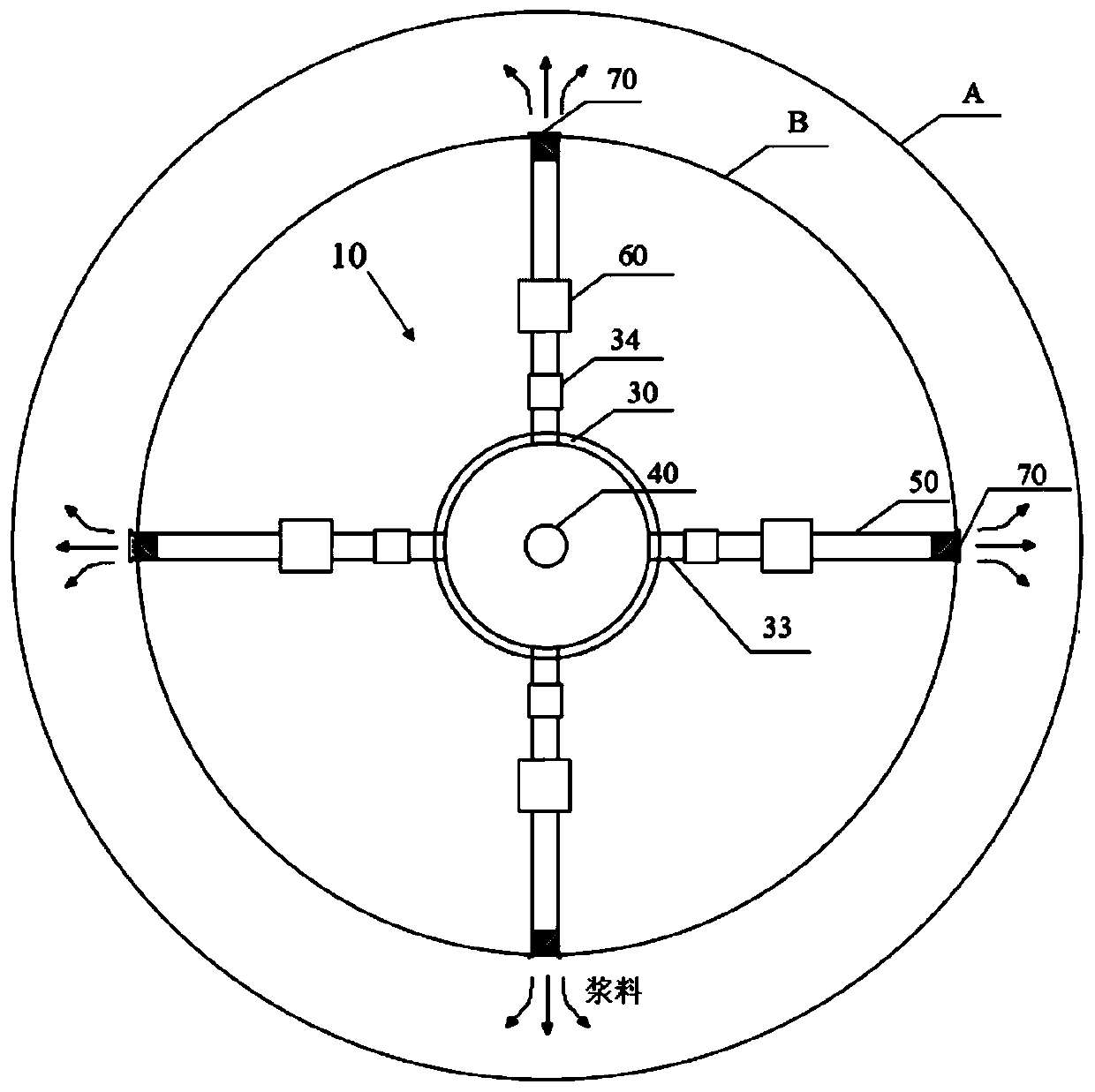

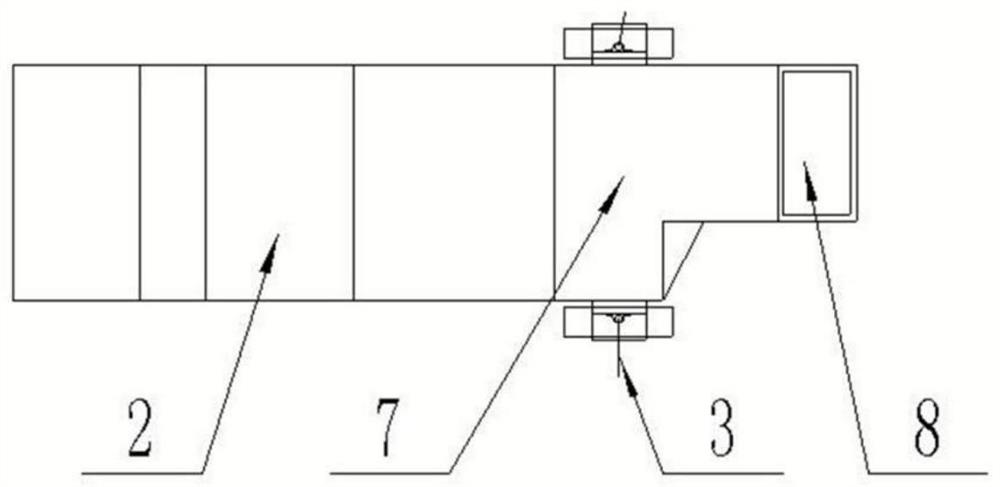

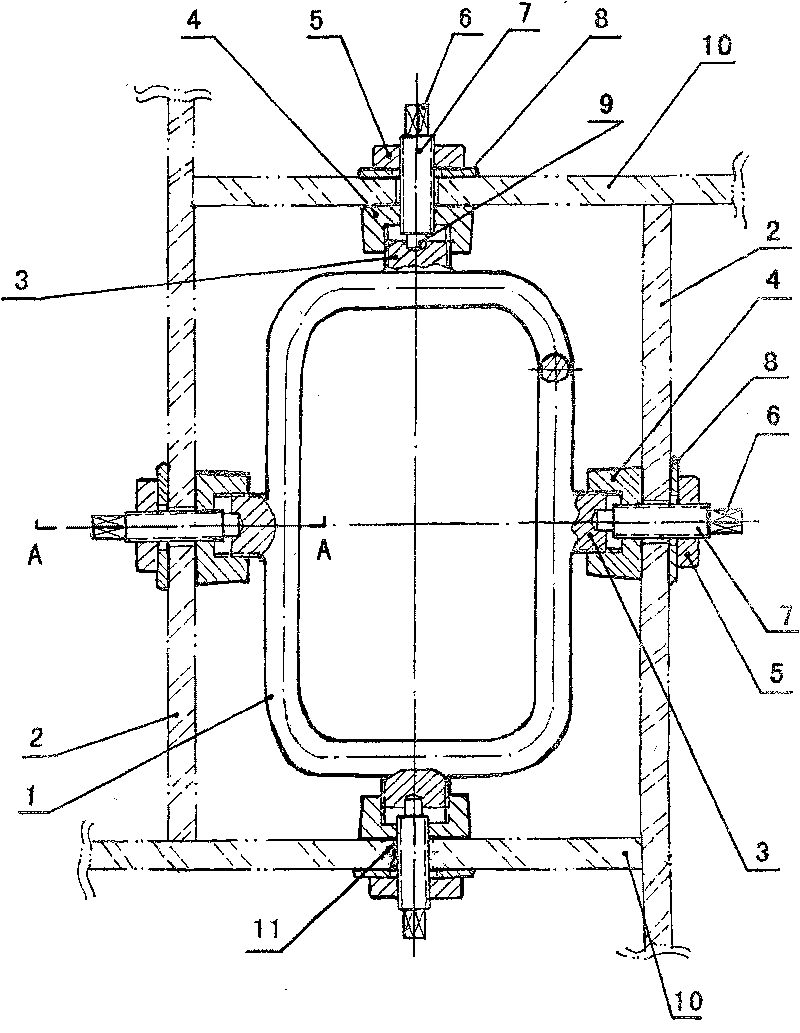

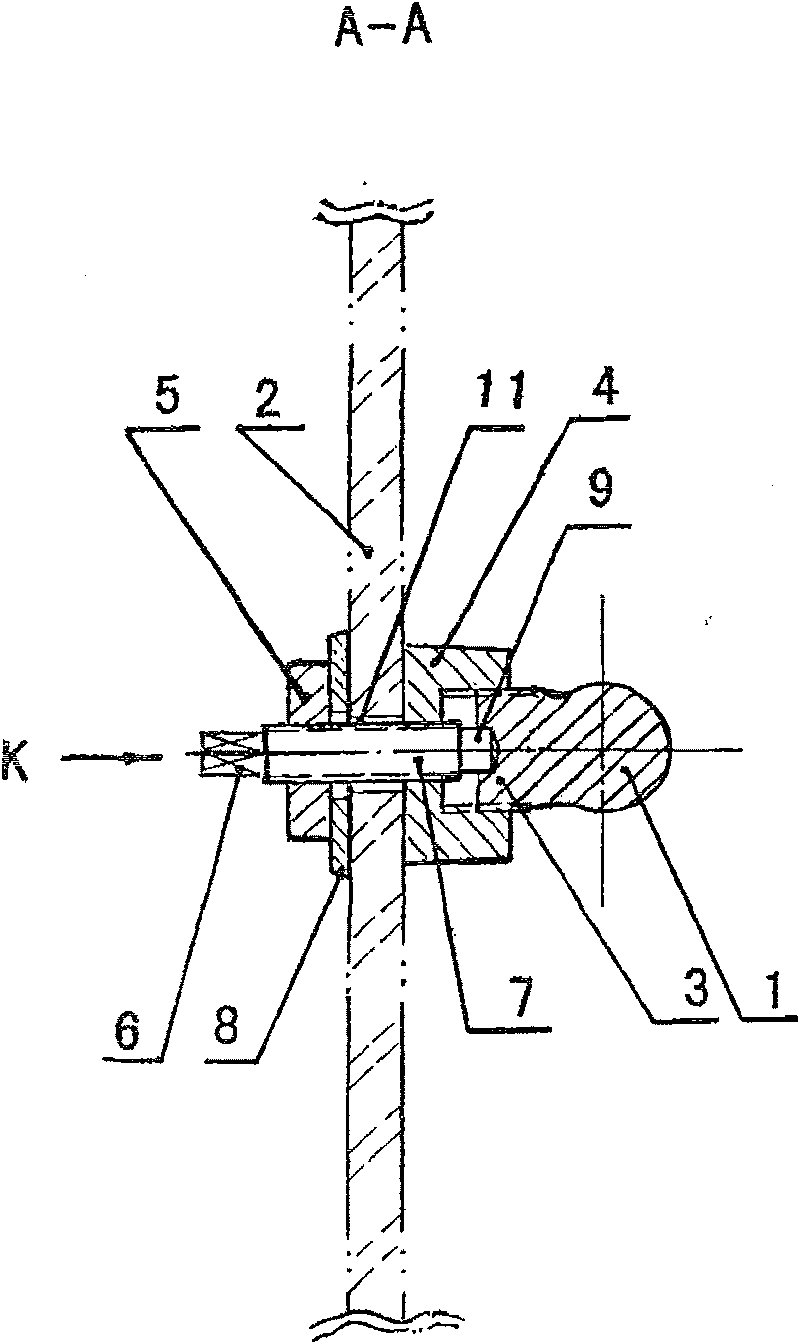

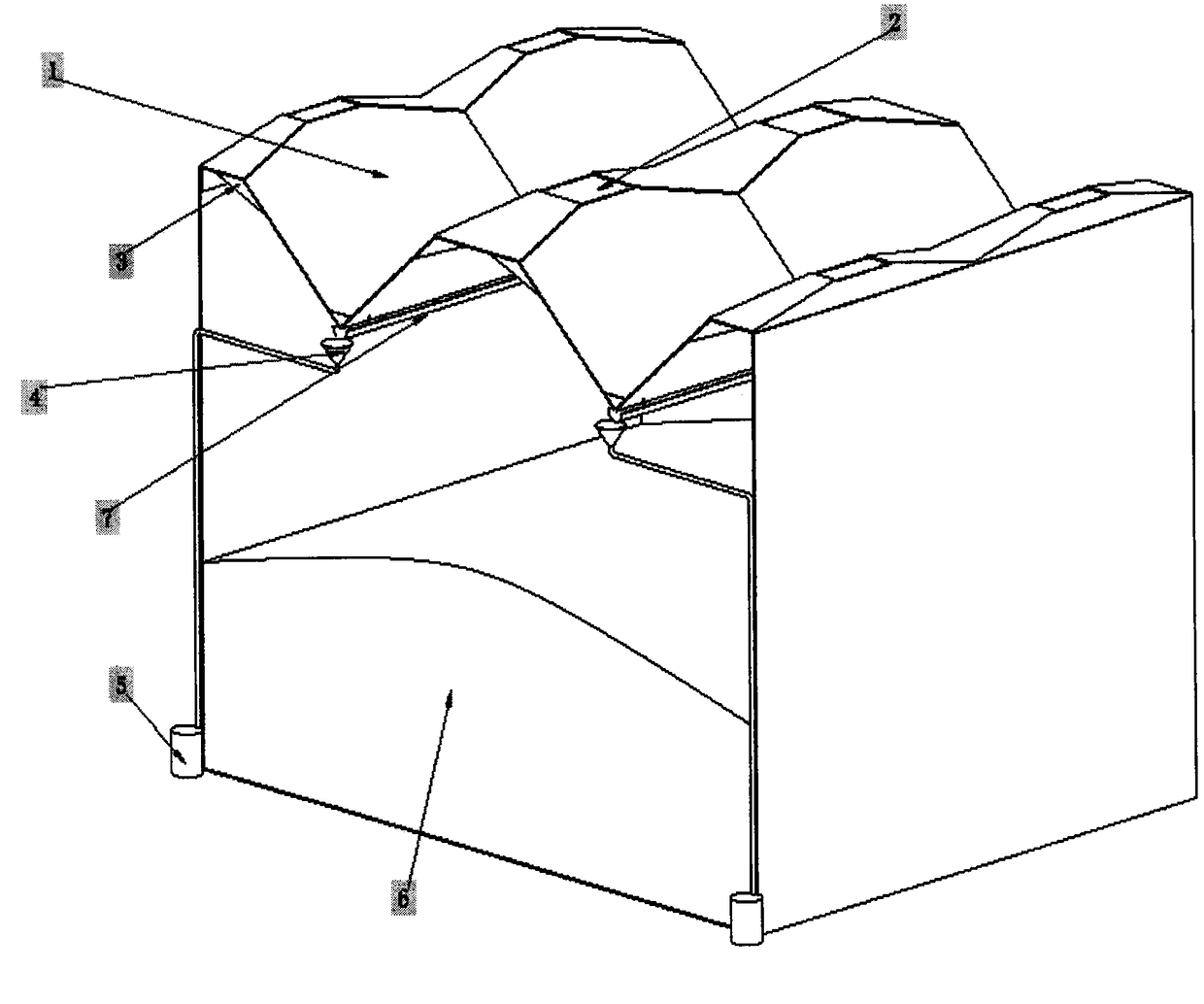

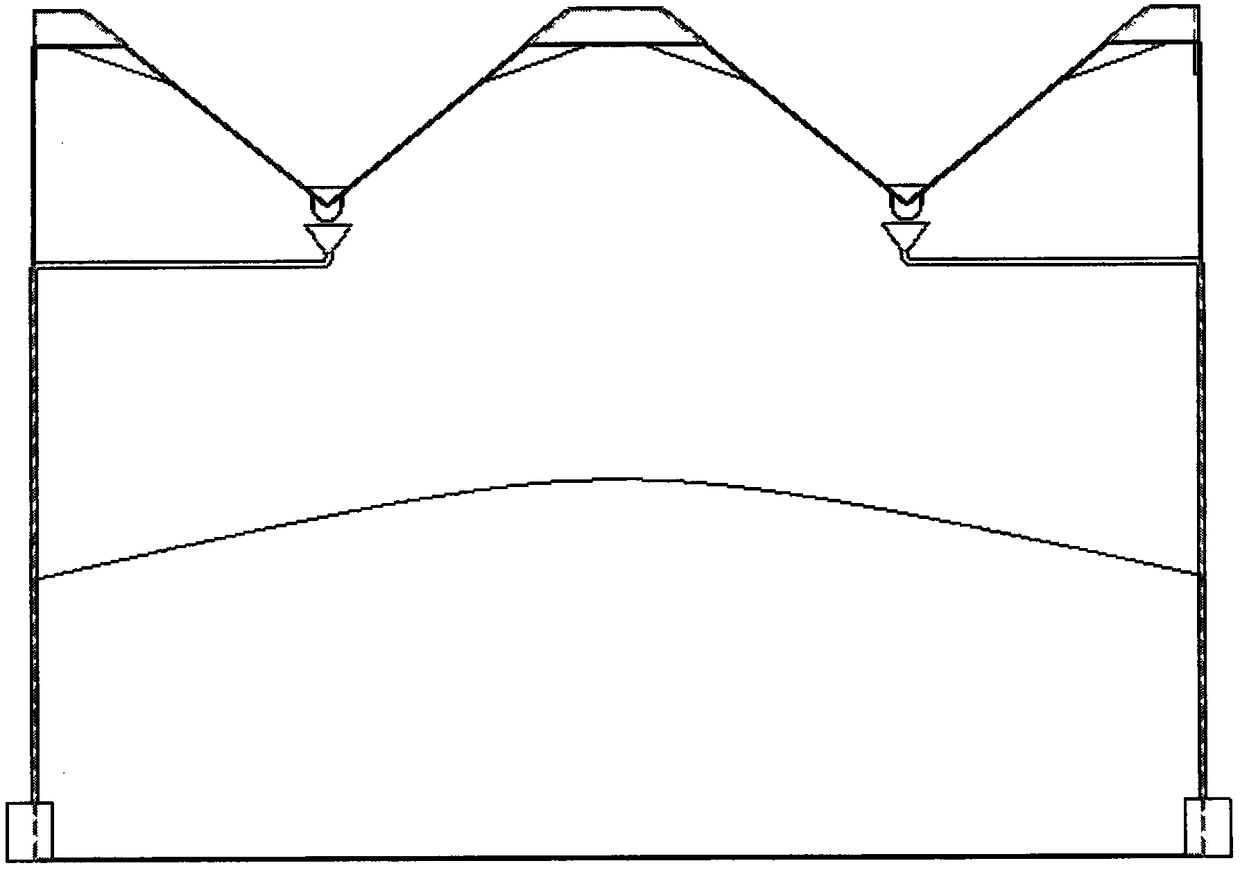

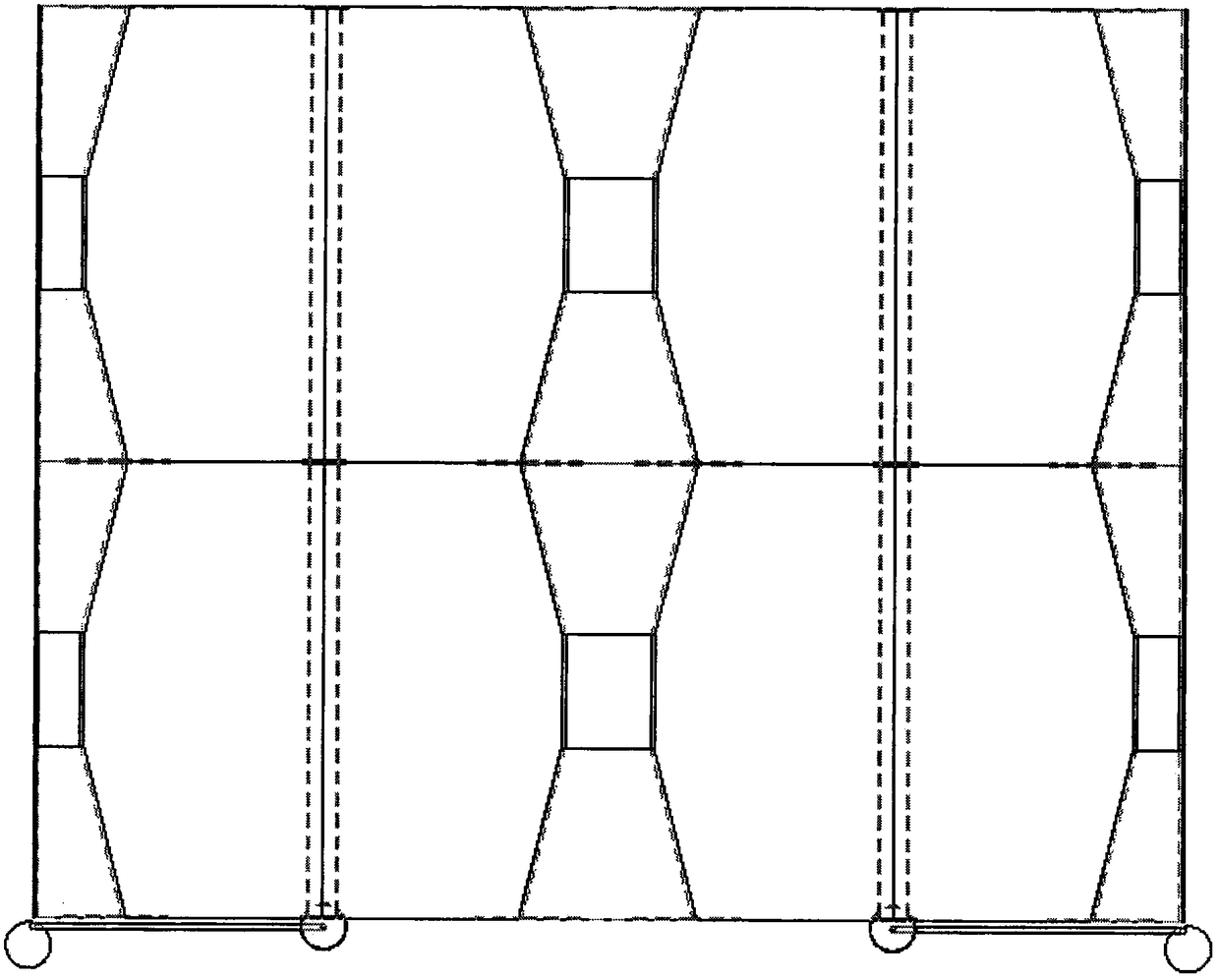

Grouting device and grouting method

ActiveCN107237329ASolve post-grouting construction problemsIncrease frictionBulkheads/pilesPipeGrout

The invention provides a grouting device which is high in construction speed, simple in structure, convenient to operate, high in efficiency and economical and a corresponding grouting method. The grouting device is characterized by being matched with a prefabricated pipe pile, and the grouting device carries out grouting after the prefabricated pipe pile is put into a pile hole with a larger diameter; the grouting device comprises an end plate which is used for sealing the bottom end of the prefabricated pipe pile, a grouting cushion chamber which is arranged in the end plate and is hollow inside, a grouting pipe, a plurality of grout outlet pipes, a plurality of reversing grout stopping valves and a plurality of end caps, wherein a grouting opening is formed in the upper end of the grouting pipe, and the lower end of the grouting pipe communicates with the grouting cushion chamber; the multiple grout outlet pipes are evenly arranged on the periphery of the grouting cushion chamber, a grout inlet of each grout outlet pipe communicates with the grouting cushion chamber, grout outlets can penetrate reserved holes in the side wall of the prefabricated pipe pile and face the space to be grouted on the outer side of the prefabricated pipe pile; the multiple reversing grout stopping valves are arranged on the grout outlet pipes correspondingly and stop grout from reversely flowing in the direction from the grout outlets to the grout inlets; and the multiple end caps block the grout outlets.

Owner:WUHAN UNIV

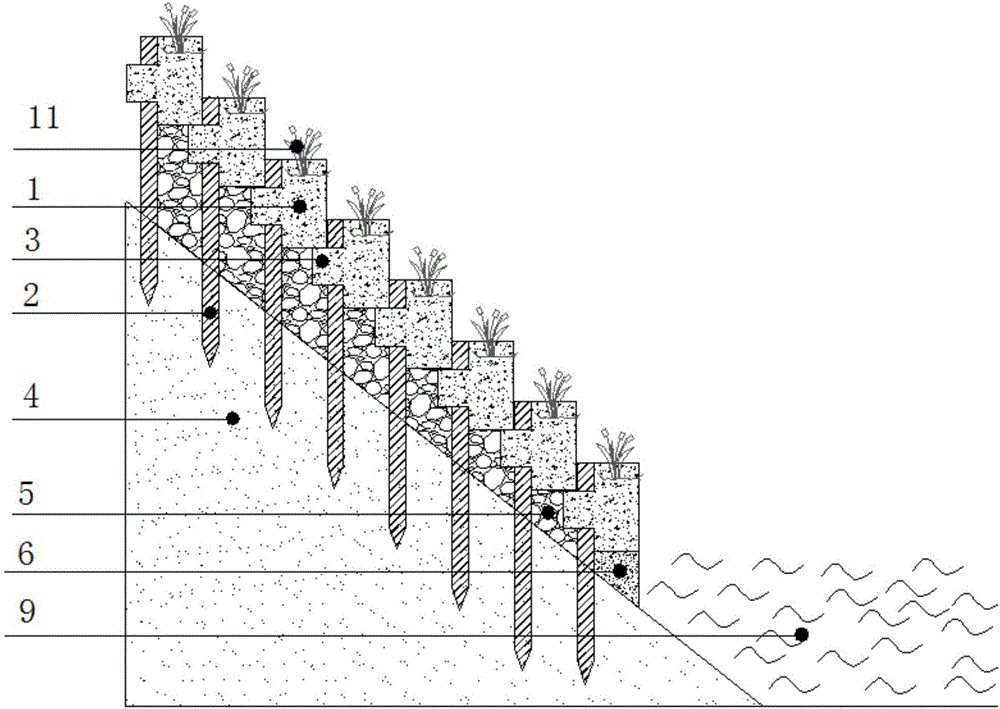

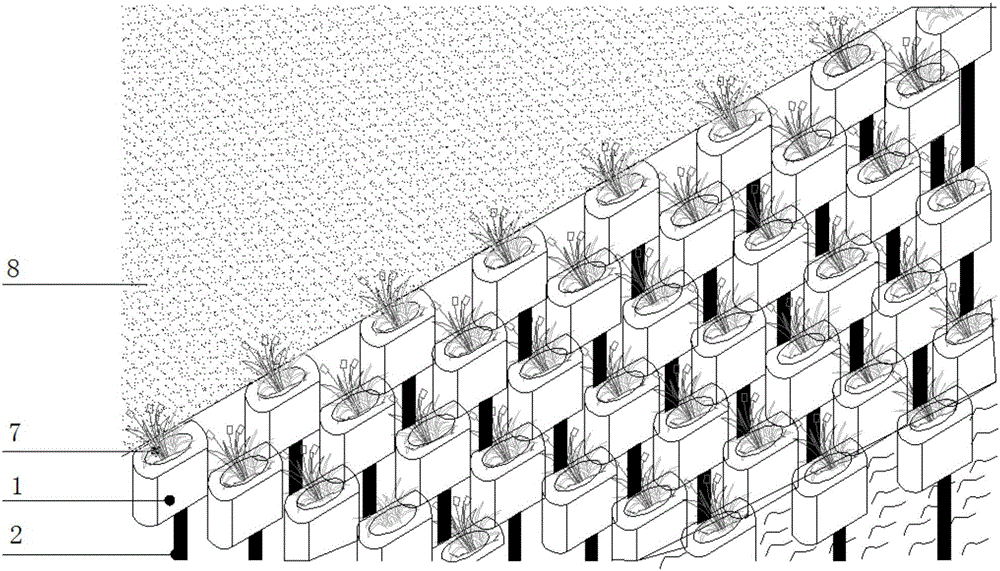

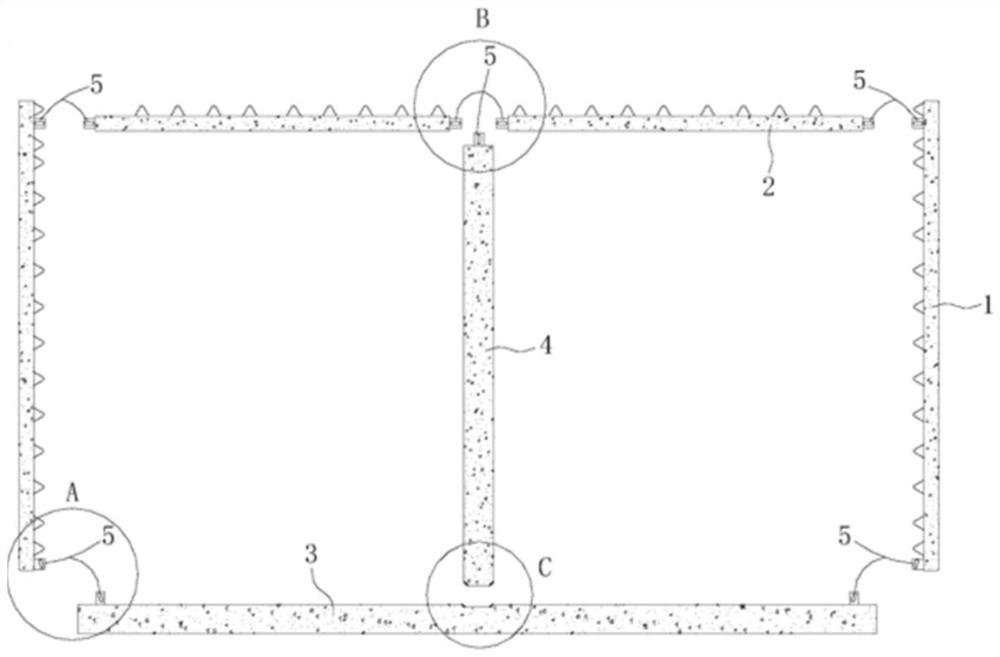

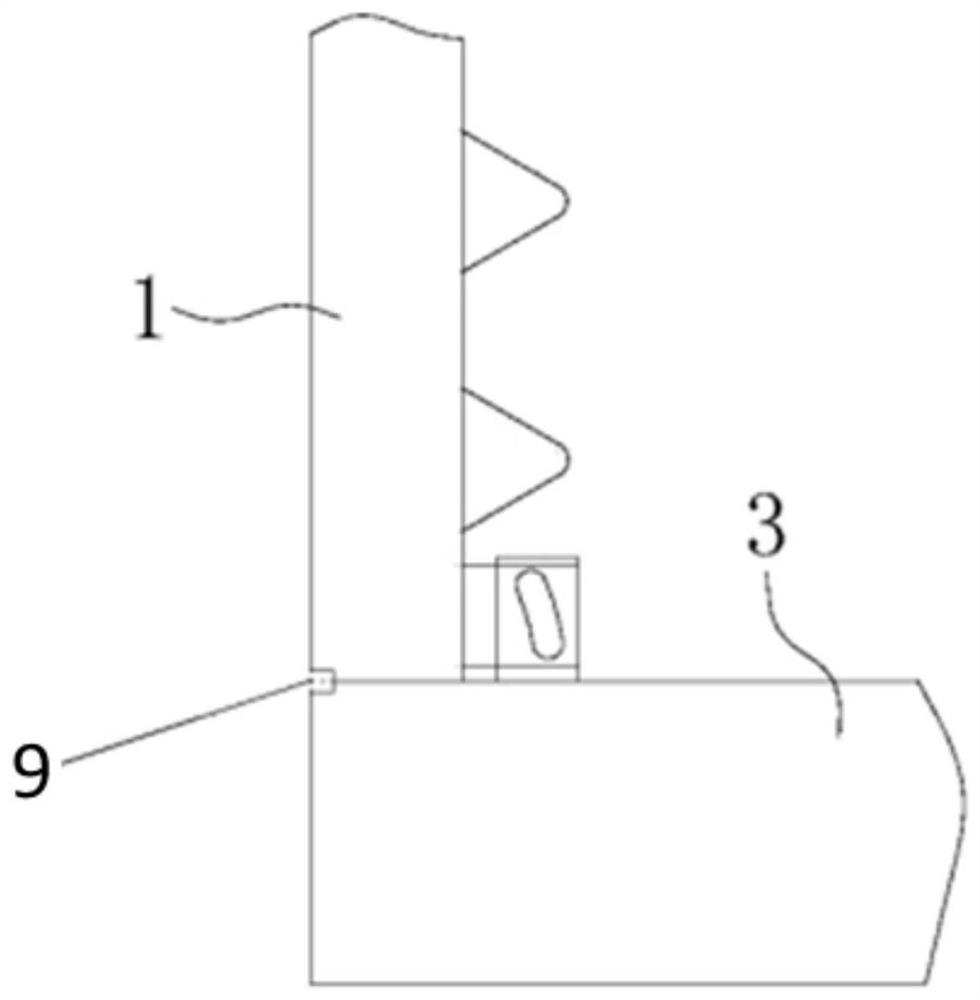

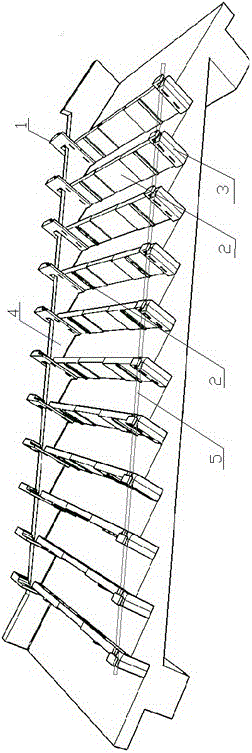

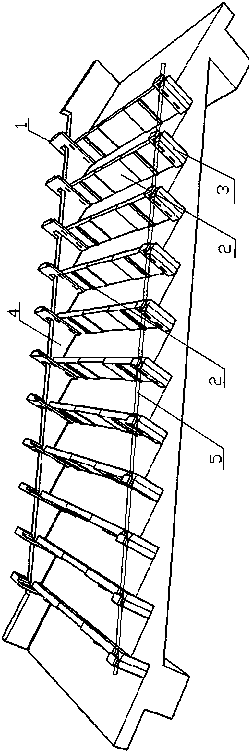

Soldier pile overlapping arrangement type ecological revetment and construction method thereof

InactiveCN106120651AStable structureGuaranteed build stabilityClimate change adaptationCoastlines protectionEngineeringRevetment

The invention provides a soldier pile overlapping arrangement type ecological revetment and a construction method thereof. The soldier pile overlapping arrangement type ecological revetment comprises a plurality of ecological revetment building blocks and a plurality of corresponding fixing piles, wherein plant growing grooves are formed in the ecological revetment building blocks; fixing grooves are connected to the outer parts of the ecological revetment building blocks; the ecological revetment building blocks are fixed to the corresponding fixing piles through the corresponding fixing grooves; the fixing piles are arranged into a plurality of rows and fixed to a river bank; the ecological revetment building blocks are fixed to the river bank in a combination manner of overlapping the plurality of rows of fixing piles in upper layers and lower layers along the height of the river bank; every two adjacent rows of fixing piles are staggered. According to the soldier pile overlapping arrangement type ecological revetment, the fixing piles are directly arranged and overlapped in the upper layers and the lower layers, and a pebble layer is used for supporting, so that the whole structure is firm and stable; the soldier pile overlapping arrangement type ecological revetment is stable in structure, and convenient and quick to construct; in addition, the building material consumption is reduced; the plant growing grooves are completely exposed, so that plants are completely under the light, and the individually-built plant growing grooves are large in space.

Owner:BEJING SUNSHINE LANDSCAPE CO LTD

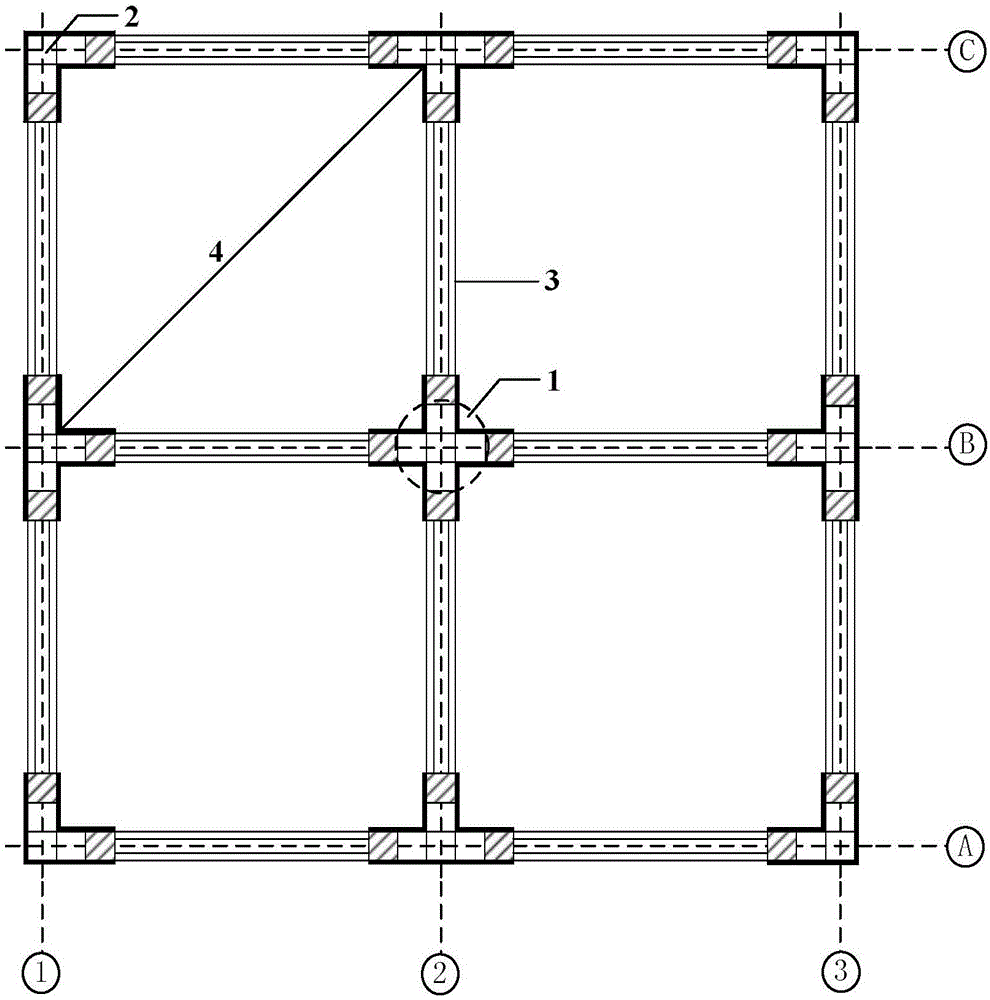

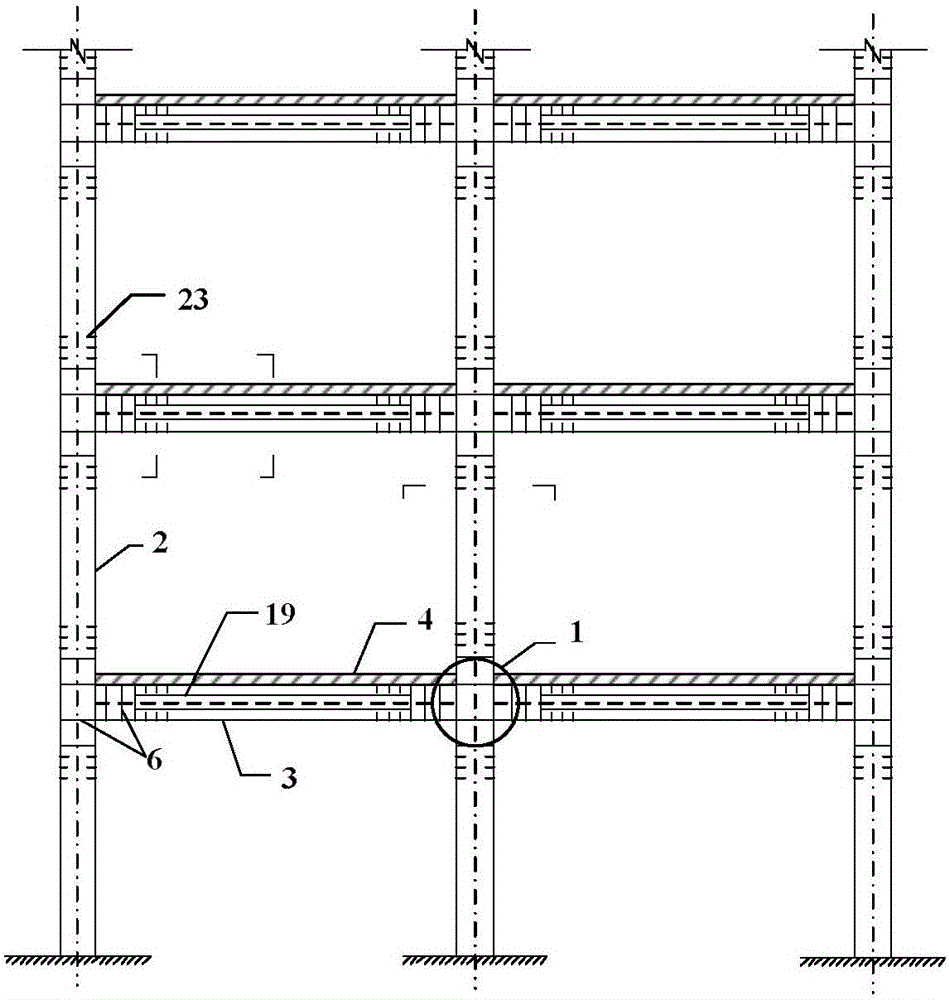

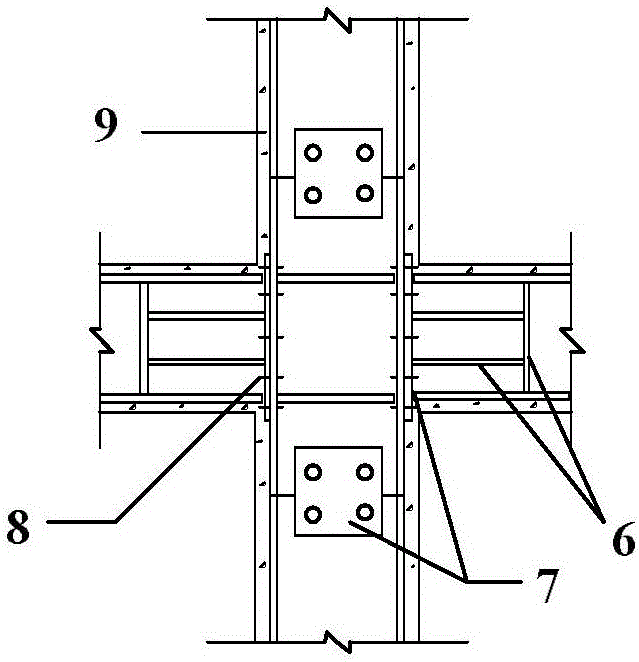

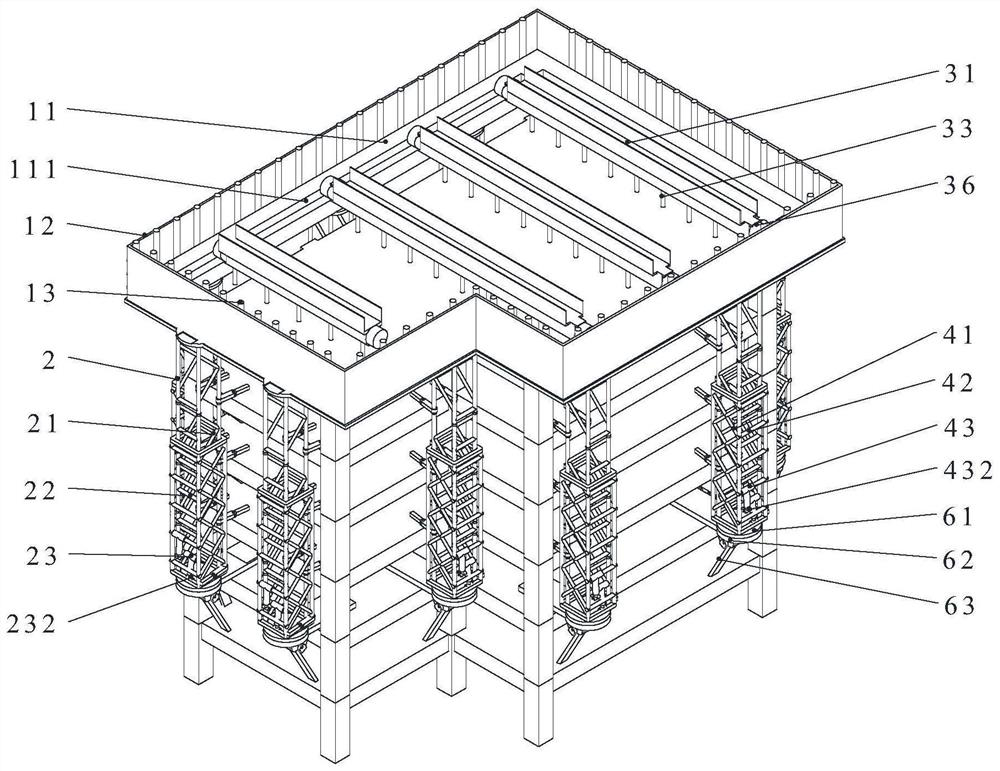

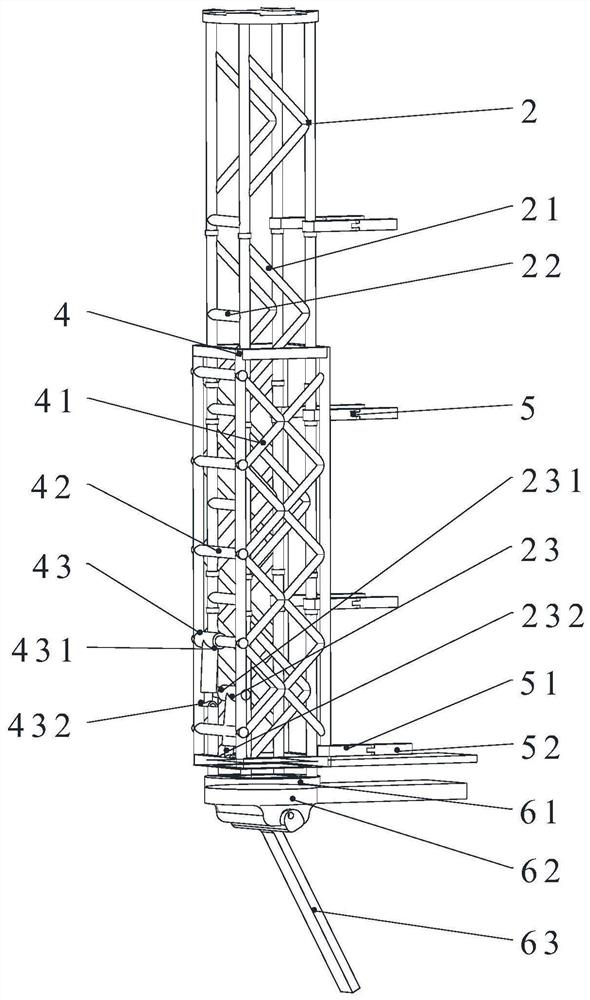

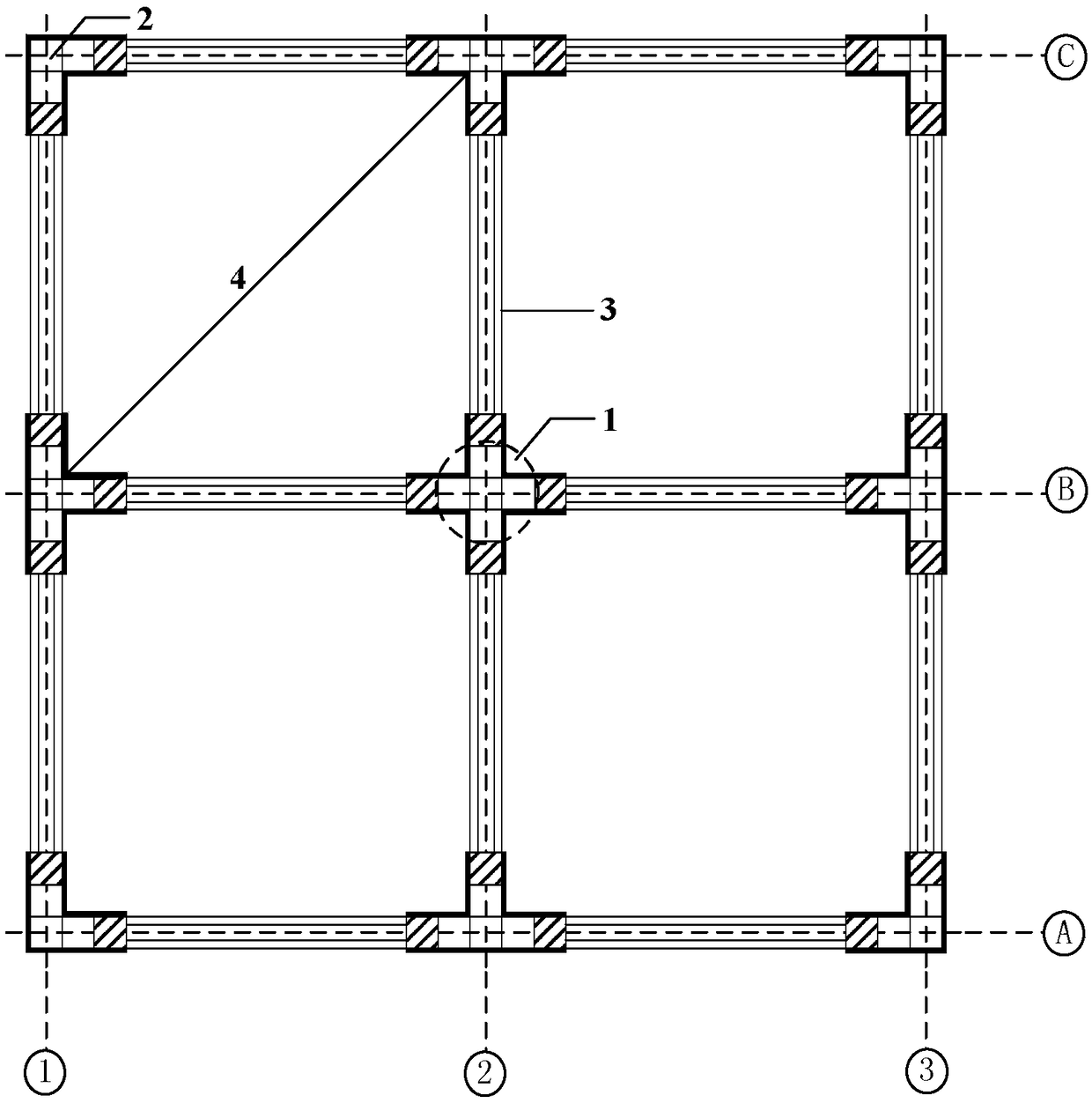

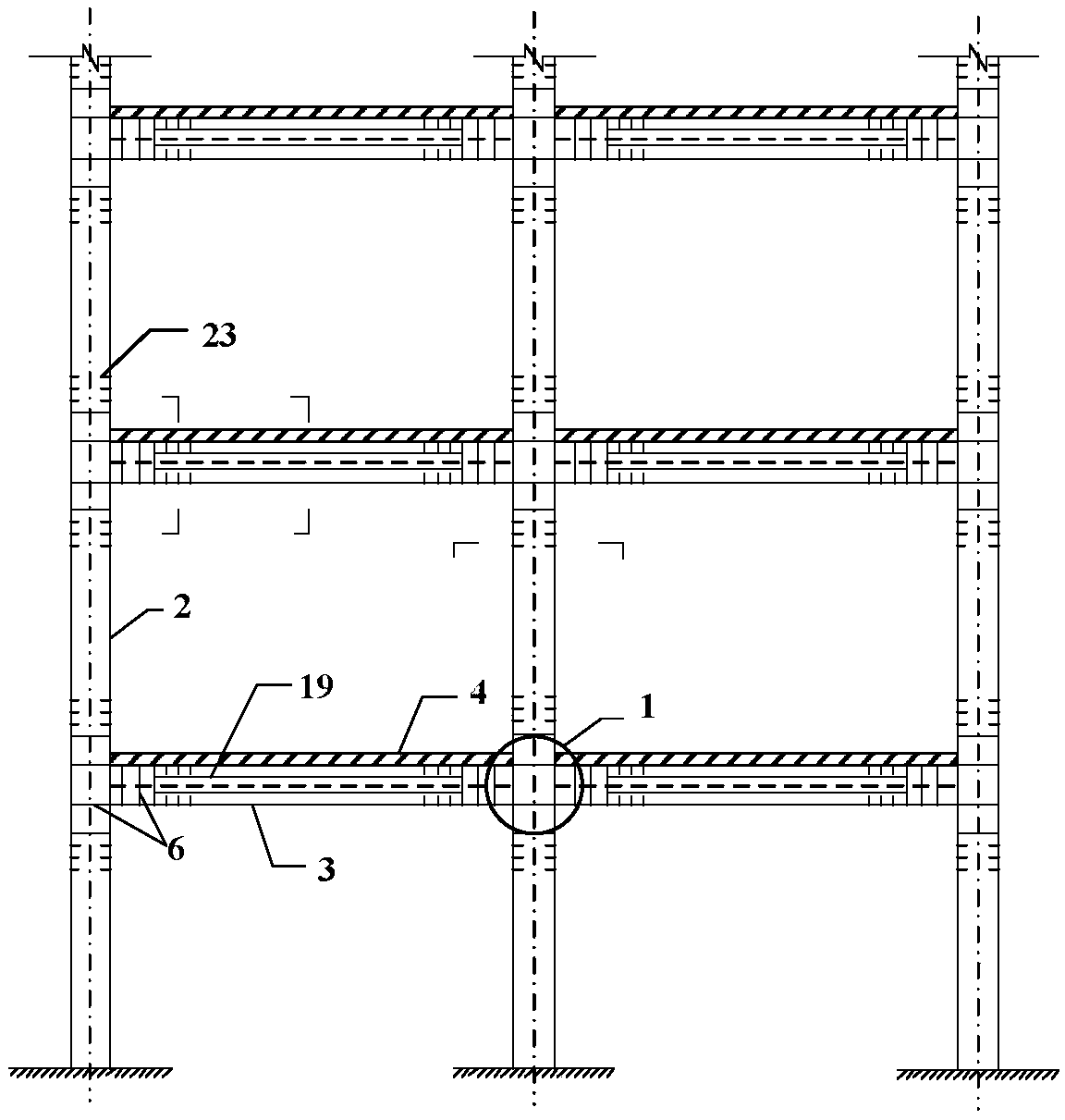

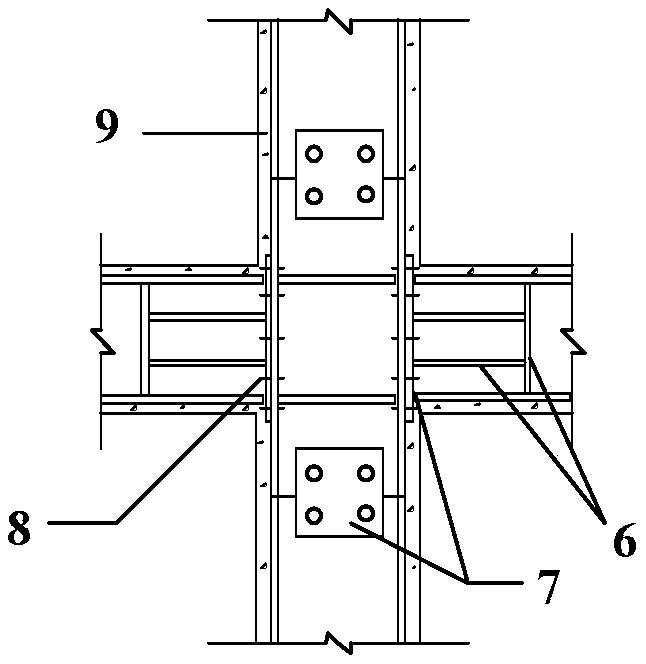

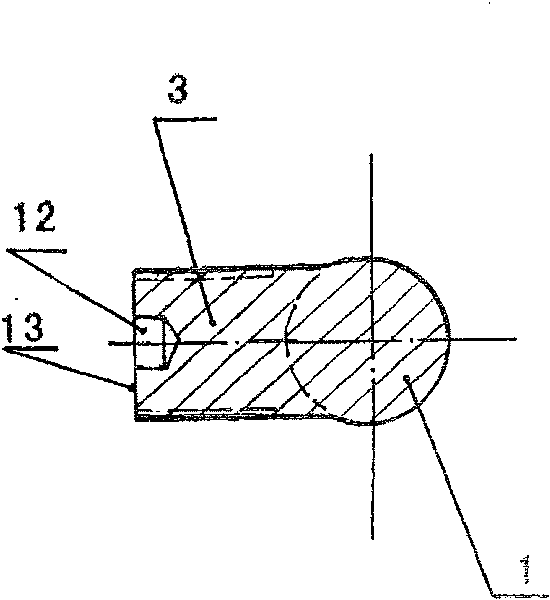

Assembly type steel-concrete combined beam column frame structure system

ActiveCN106567458AImprove anti-corrosion and fire performanceSave materialBuilding constructionsConcrete beamsRebar

The invention discloses an assembly type steel-concrete combined beam column frame structure system. The assembly type steel-concrete combined beam column frame structure system comprises a steel joint, a steel-concrete combined column, a steel-concrete combined beam and a laminated slab. The steel joint comprises profile steel, a stiffening rib, a connection plate and a bolt, and a concrete protection layer is poured outside the steel joint. The steel-concrete combined column comprises a concrete column, a steel-concrete combined section, a short steel column, a rebar, a drilling device, a finish-rolled deformed bar and an anchoring nut. The steel-concrete combined beam comprises a concrete beam, a steel-concrete combined section, a short steel beam, a rebar, a drilling device, an anchoring device, a prestressed cable and a beam end connection plate. The laminated slab comprises a precast concrete slab and a cast-in-place layer. After the precast concrete slab is installed in place, the concrete cast-in-place layer is poured on the precast concrete slab. The assembly type steel-concrete combined beam column frame structure system combines the advantages of a cast-in-place concrete frame system and a steel structure frame system and has good mechanical performance, economic indicators and a very high prefabrication assembly rate which can reach 100%. Fast assembly construction is adopted, and the construction period is shortened effectively.

Owner:SHAOXING UNIVERSITY

Dismantling method of reinforced concrete continuous box girder overpass bridge

InactiveCN113089510AReduce disturbanceReduce noiseBuilding repairsBridge strengtheningButtressReinforced concrete

The invention discloses a dismantling method for a reinforced concrete continuous box girder overpass bridge. The method comprises the steps that: a girder body is planned in a segmented mode, temporary supports are erected corresponding to piers, the bottom of the girder body is firstly lifted and cut, and a rear pier column is cut, dismantled and moved away, so that the girder body and the piers of a to-be-dismantled bridge are dismantled in a segmented manner; and after the girder body and the piers are dismantled, bridge abutment structures on the two sides and the dismantled bridge body and the dismantled piers are crushed, and building slag generated in the crushing process is conveyed to a roadbed fill for layered filling, so that the overall dismantling work of the bridge is completed. Longitudinal segmented planning is conducted on the girder body according to the number of the piers, temporary buttress is correspondingly arranged on the side, in the longitudinal bridge direction, of each pier for supporting in a matched mode, then segmented cutting, hoisting and transferring are conducted, and the purposes of reducing noise, reducing pollution and relieving disturbance to the surrounding environment are achieved; and construction consumables are reduced while construction safety is guaranteed, the construction cost is reduced, the whole dismantling construction is convenient and rapid, the construction period is shortened, and the social influence is reduced.

Owner:SICHUAN JIAOTOU CONSTR ENG CO LTD

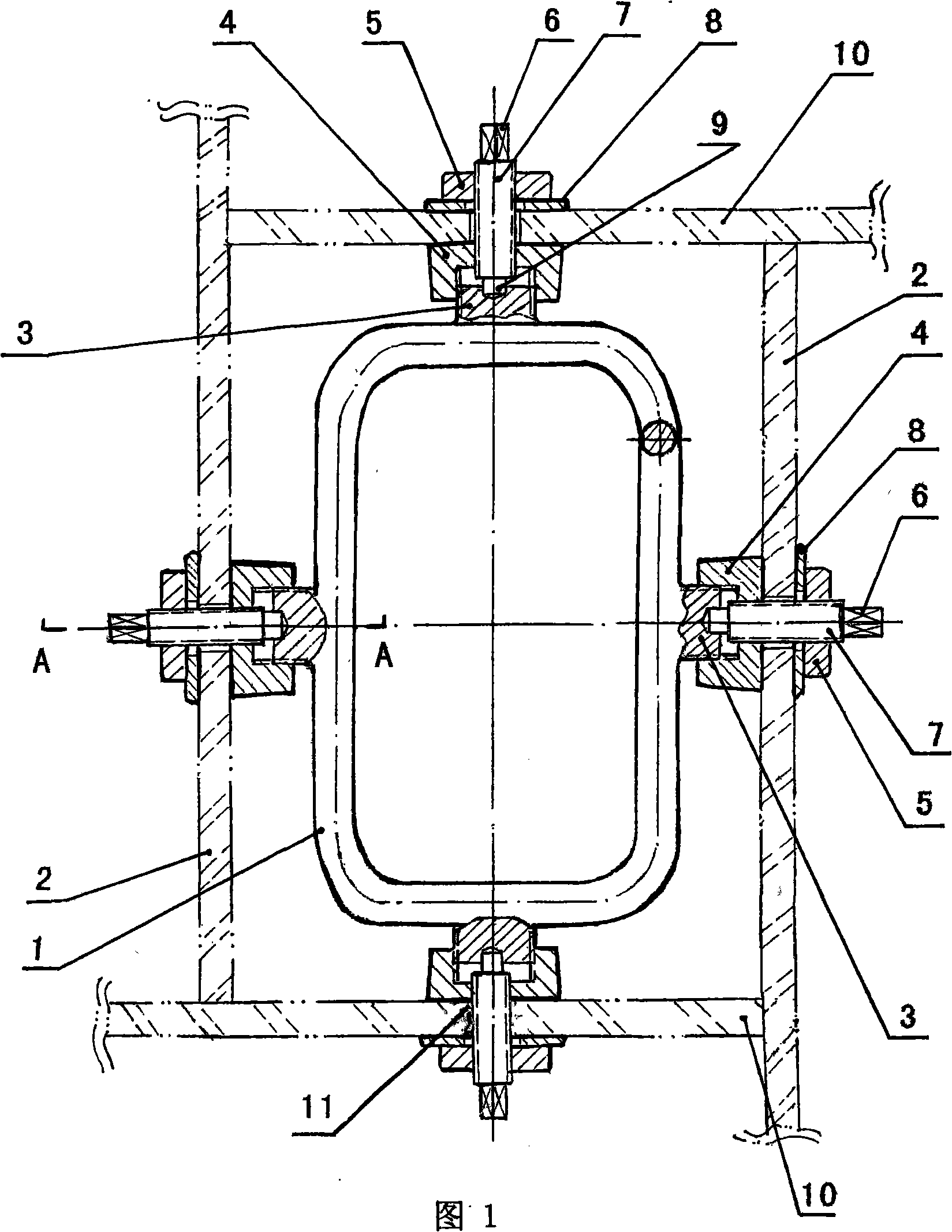

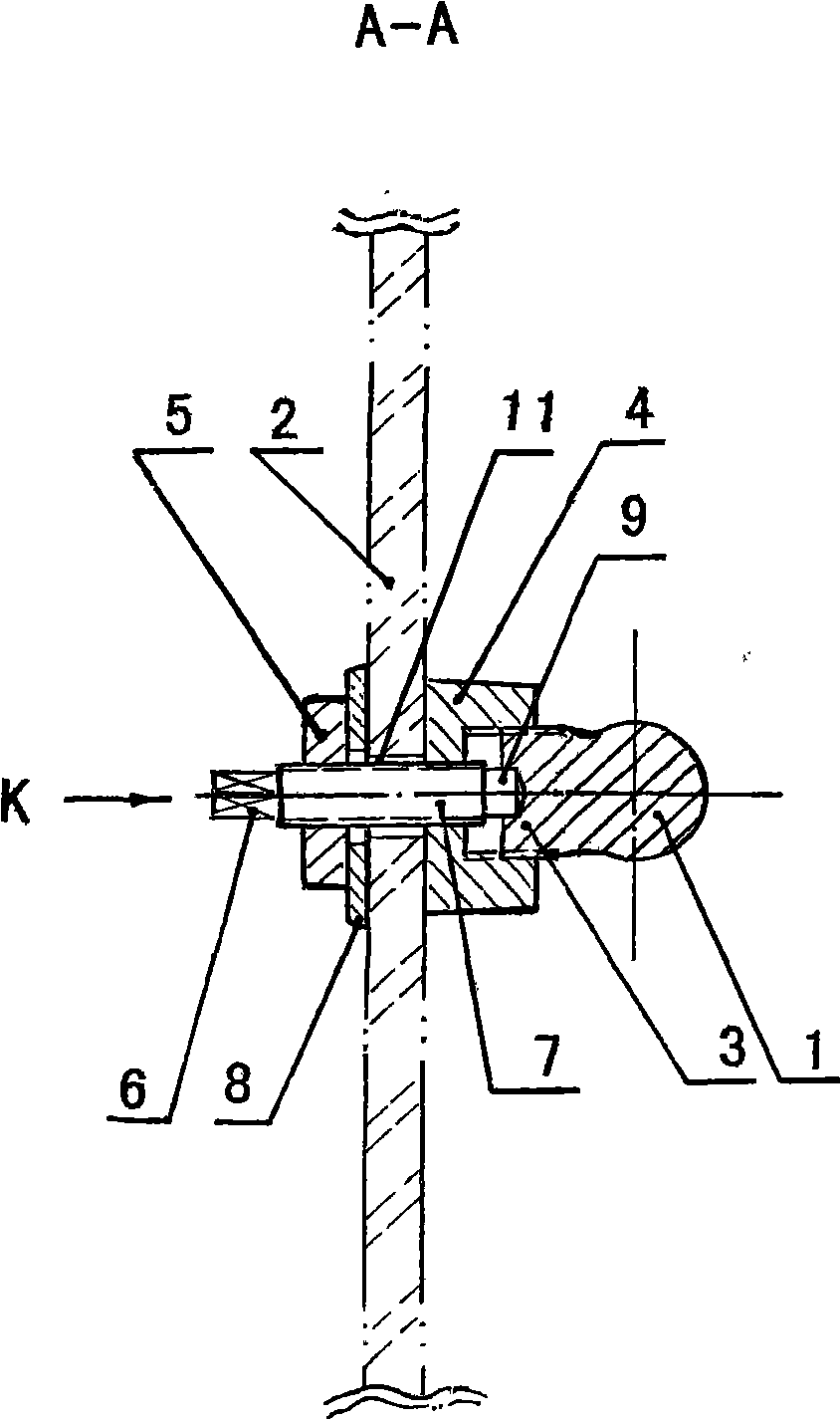

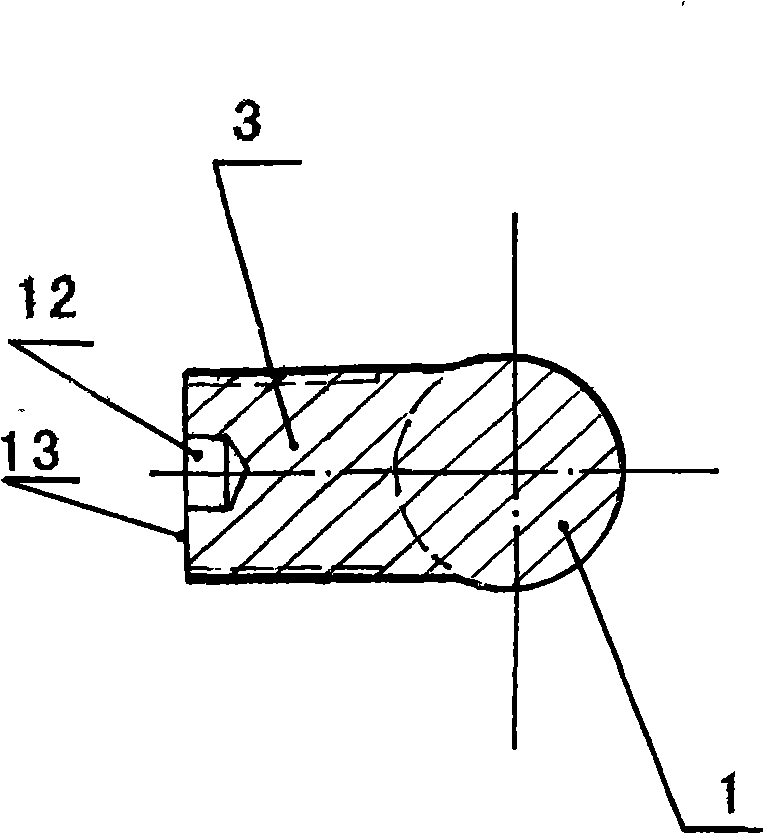

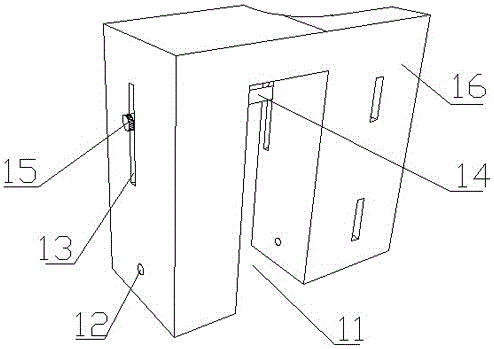

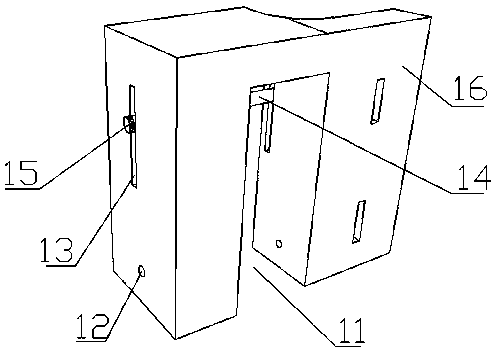

Bidirectional regulation positioning buckle device for building construction cast-in-situ concrete combined template

InactiveCN101270611AEasy to produceImprove interchangeabilityAuxillary members of forms/shuttering/falseworksArchitectural engineeringMaterial consumption

The invention discloses a double adjusting location locking device used for a cast-in-place compound template of building construction, which mainly consists of a pre-burying annular shelf provided with a convex column, an adjustable location fastener connected with the convex column in thread and an adjusting screw rod; the pre-burying annular shelf is arranged in a cast-in-place cavity formed by the template and leads the adjusting screw rod to extend out of the wall of the template to reveal an adjusting square head; adjustable location fastener can be driven to rotate and move the template to a needed position by turning the adjusting screw rod, then a locking nut is used to lock the template; the invention can simultaneously carry out double direction adjustment location to fix the compound template to form the cast-in-place cavity along the transverse and the longitudinal direction for the use of construction, has the advantages of precious adjusting location, convenient construction operation and saving construction material consumption, etc., besides, the invention has remarkable effects on improving the construction efficiency and the building engineering quality.

Owner:邹尧 +2

Grouting device and grouting method

ActiveCN107237329BSolve post-grouting construction problemsIncrease frictionBulkheads/pilesPipeGrout

The invention provides a grouting device which is high in construction speed, simple in structure, convenient to operate, high in efficiency and economical and a corresponding grouting method. The grouting device is characterized by being matched with a prefabricated pipe pile, and the grouting device carries out grouting after the prefabricated pipe pile is put into a pile hole with a larger diameter; the grouting device comprises an end plate which is used for sealing the bottom end of the prefabricated pipe pile, a grouting cushion chamber which is arranged in the end plate and is hollow inside, a grouting pipe, a plurality of grout outlet pipes, a plurality of reversing grout stopping valves and a plurality of end caps, wherein a grouting opening is formed in the upper end of the grouting pipe, and the lower end of the grouting pipe communicates with the grouting cushion chamber; the multiple grout outlet pipes are evenly arranged on the periphery of the grouting cushion chamber, a grout inlet of each grout outlet pipe communicates with the grouting cushion chamber, grout outlets can penetrate reserved holes in the side wall of the prefabricated pipe pile and face the space to be grouted on the outer side of the prefabricated pipe pile; the multiple reversing grout stopping valves are arranged on the grout outlet pipes correspondingly and stop grout from reversely flowing in the direction from the grout outlets to the grout inlets; and the multiple end caps block the grout outlets.

Owner:WUHAN UNIV

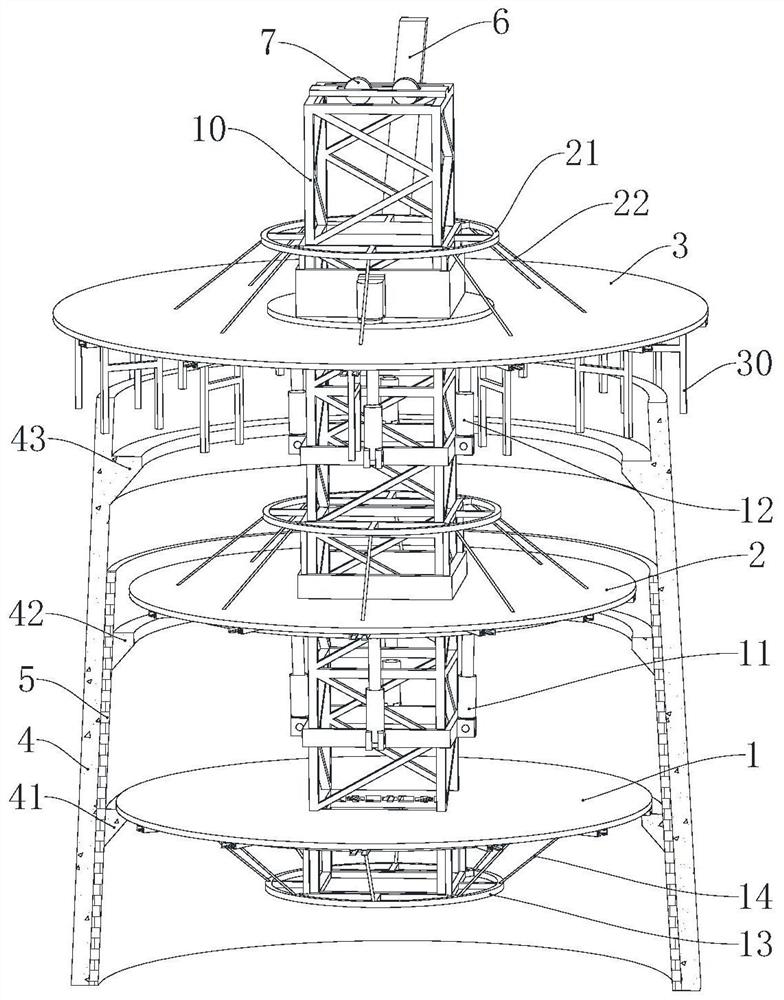

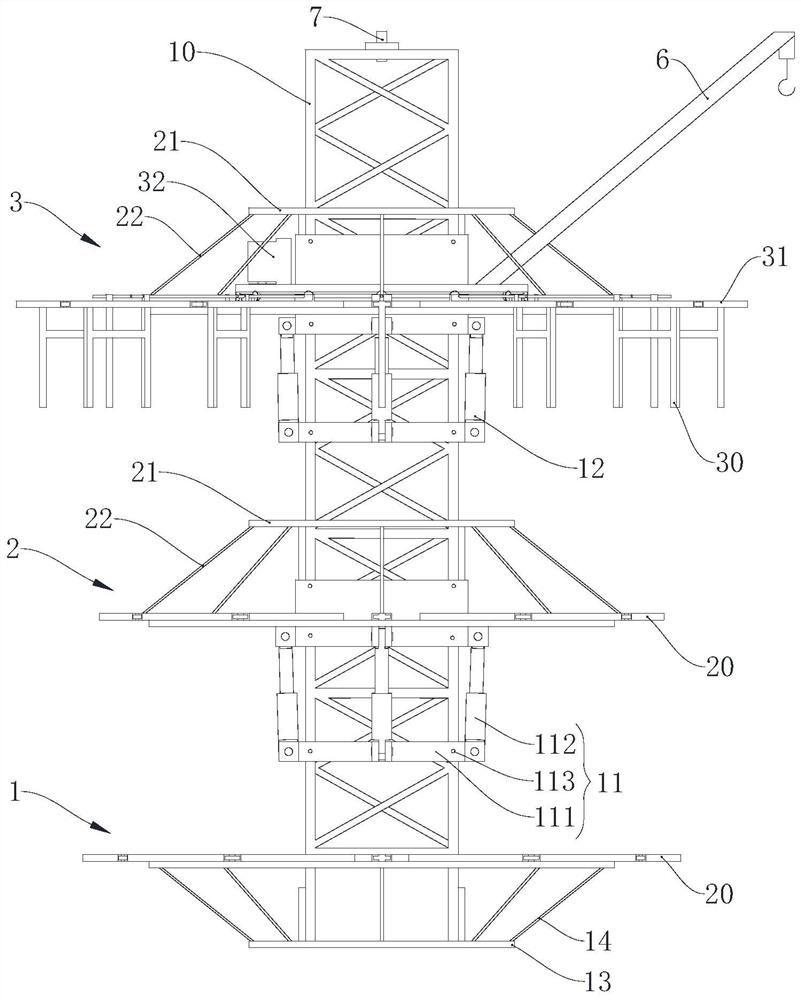

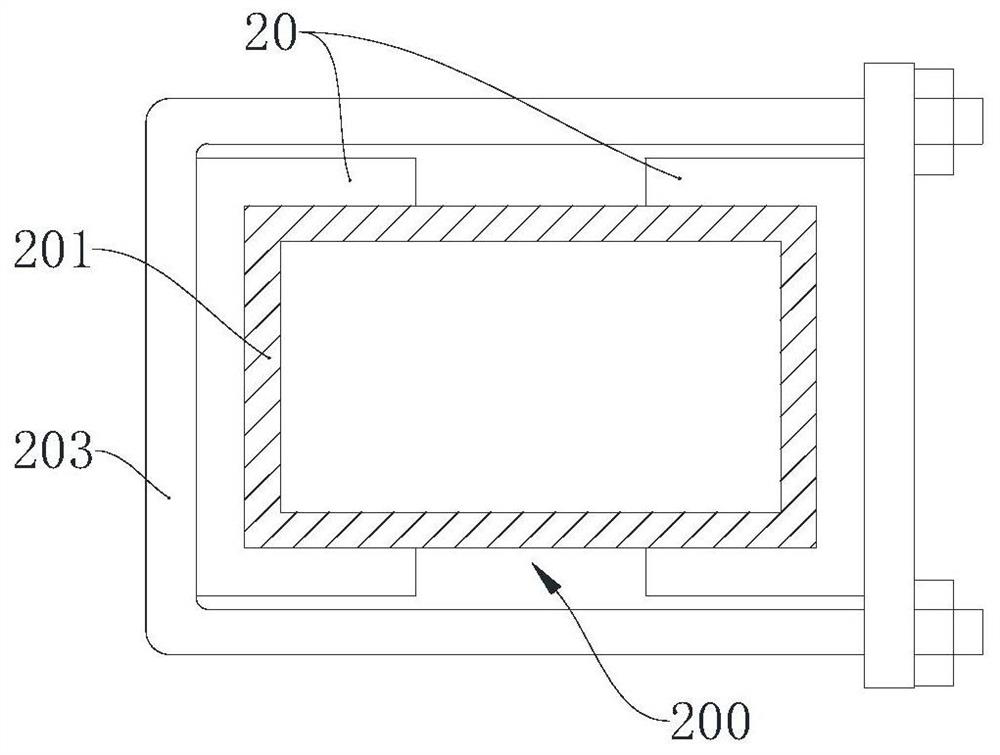

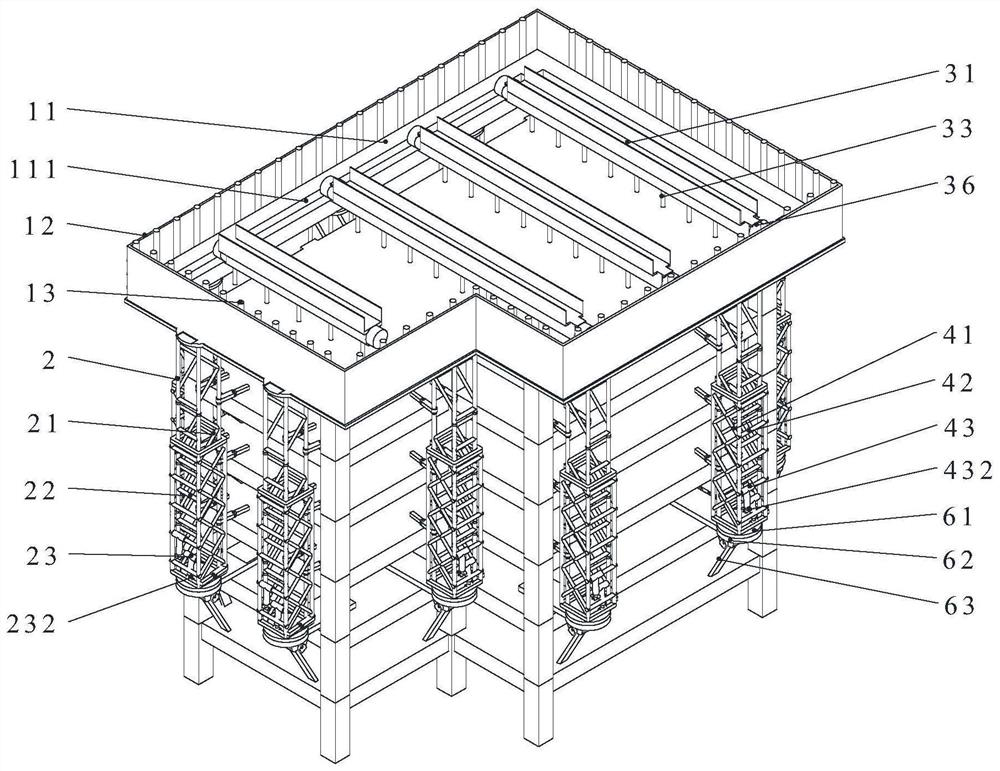

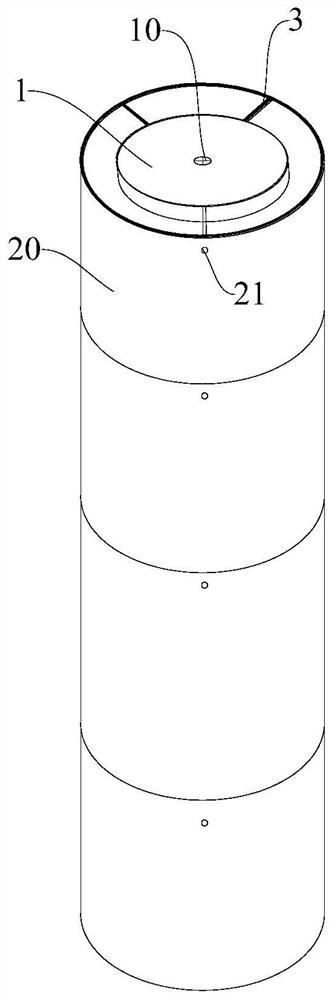

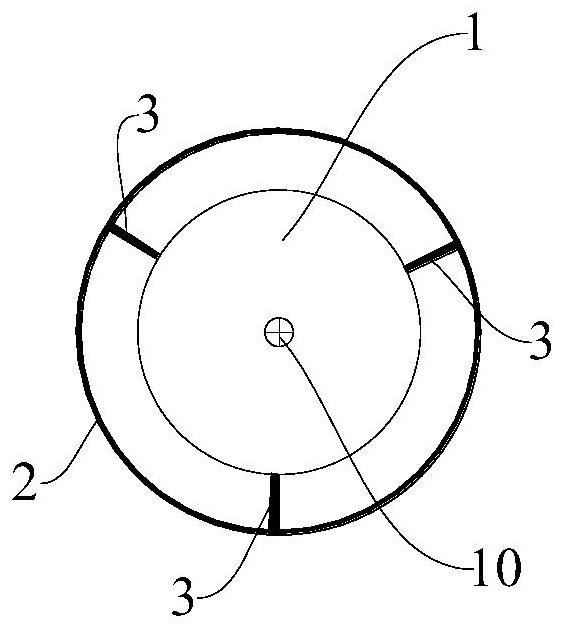

Synchronous construction platform and method for ultrahigh chimney cylinder and lining

ActiveCN113944363AReduce settlementReduce the difficulty of disassemblyForms/shuttering/falseworksTowersWhole bodyClassical mechanics

The invention provides a synchronous construction platform and method for an ultrahigh chimney barrel and a lining. The construction platform comprises a chassis, a transition platform and a top platform; the center of the chassis is fixedly connected to a supporting frame extending in the vertical direction, and the supporting frame is provided with a first climbing mechanism and a second climbing mechanism which are distributed up and down at an interval; the transition platform and the top platform are both connected to the supporting frame in an up-down sliding and sleeving mode and connected to the first climbing mechanism and the second climbing mechanism respectively; and a plurality of open frames used for fixing an inner formwork and an outer formwork in a matched mode are distributed on a bottom frame of the top platform in a circumferential array mode. According to the synchronous construction platform for the ultrahigh chimney barrel and the lining, the chassis and the transition platform can be driven by the first climbing mechanism to climb upwards in sequence, so that the chassis and the transition platform are lapped and fixed on each layer of annular bracket step by step, overall ascending is realized, a climbing supporting rod is not needed, construction consumables can be reduced, the lining is convenient to build, and the whole body can settle to the ground after construction reaches the top.

Owner:THE 13TH CONSTR CO LTD OF CHINA NAT CHEM ENG

Overall concrete stair mold

InactiveCN104005558ASimple structureEasy to installForms/shuttering/falseworksEngineeringMental detachment

Owner:JIANGSU BAIXIN PLASTIC IND

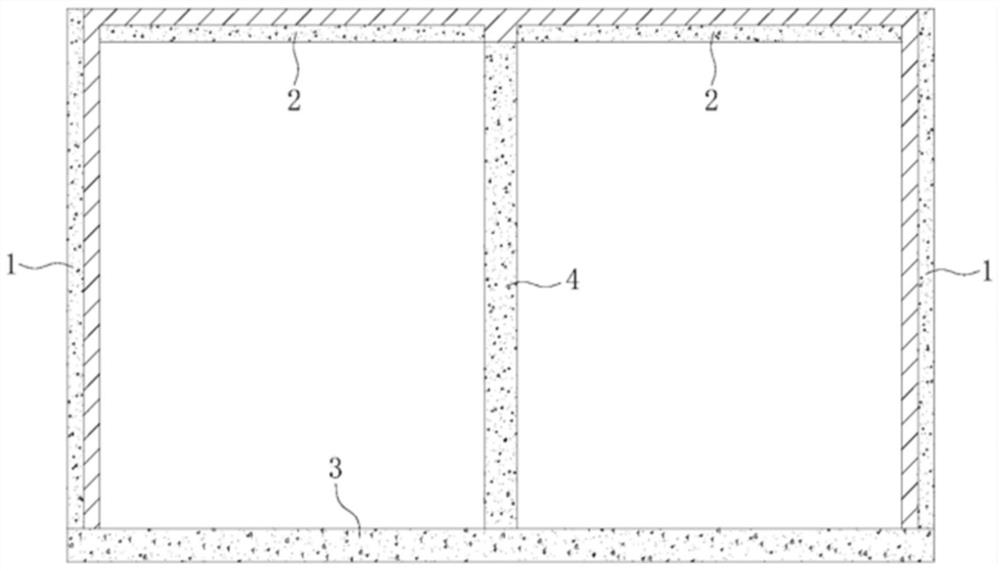

Underground excavation construction method for underground multi-cabin utility tunnel underpass buildings

InactiveCN112482435AHigh strengthNo deformationArtificial islandsUnderground chambersAdhesive cementReinforced concrete

The invention belongs to the technical field of pipe gallery construction, and particularly relates to an underground excavation construction method for underground multi-cabin utility tunnel underpass buildings. A utility tunnel is prefabricated in a factory by adopting segment prefabrication and assembly, a formwork system adopts a customized complete set of steel formwork and vertical pouring,the outer wall of a steel structure outer mold is a steel plate, the interior of the steel structure outer mold is of steel truss structure; the outer wall of a steel structure inner mold of each cabin is a steel plate, and the interior of the steel structure inner mold is of steel truss structure. According to the weight of different segments, different lifting points are adopted, a underground multi-cabin utility tunnel is formed by splicing prefabricated reinforced concrete utility tunnel segments through adhesives and tensioning the prefabricated reinforced concrete pipe gallery sections in a prestress mode, the adhesives play a role in adhesion and achieve the effects of filling, sealing, seepage resistance, leveling and the like. The method has the advantages of being high in stability, high in construction speed and the like, the construction quality can be guaranteed, the safety of existing buildings is guaranteed, and smooth proceeding of follow-up crossing construction is guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

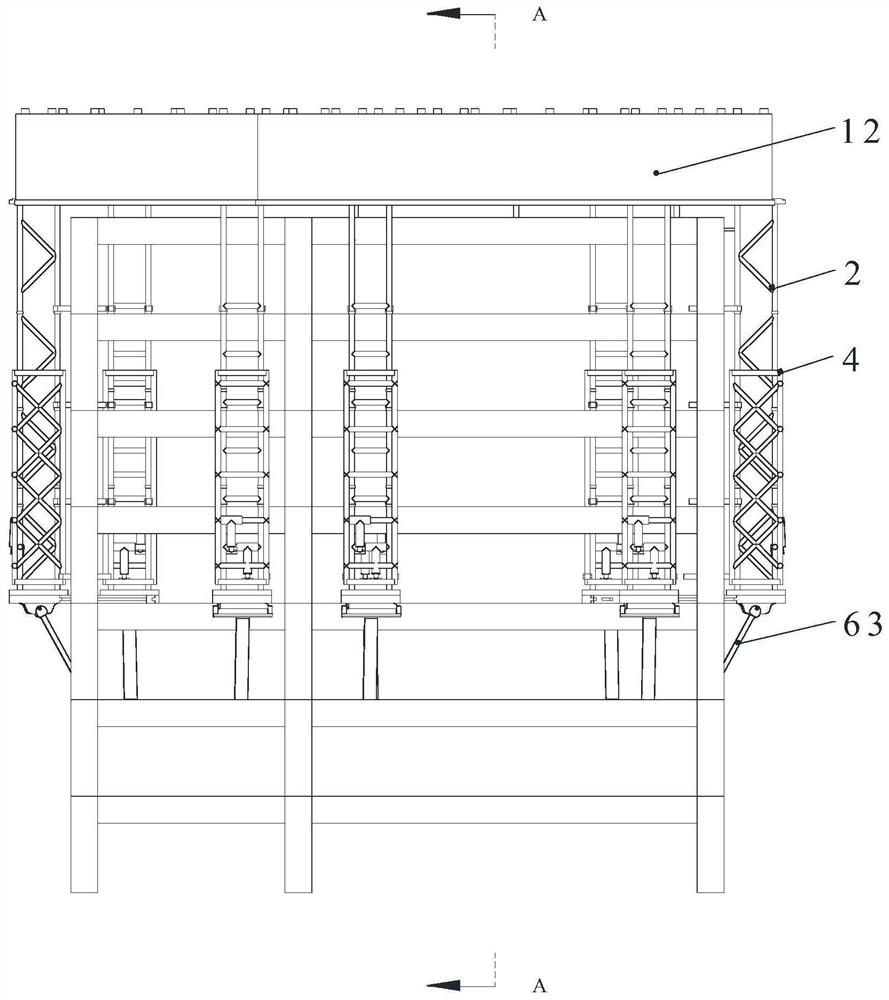

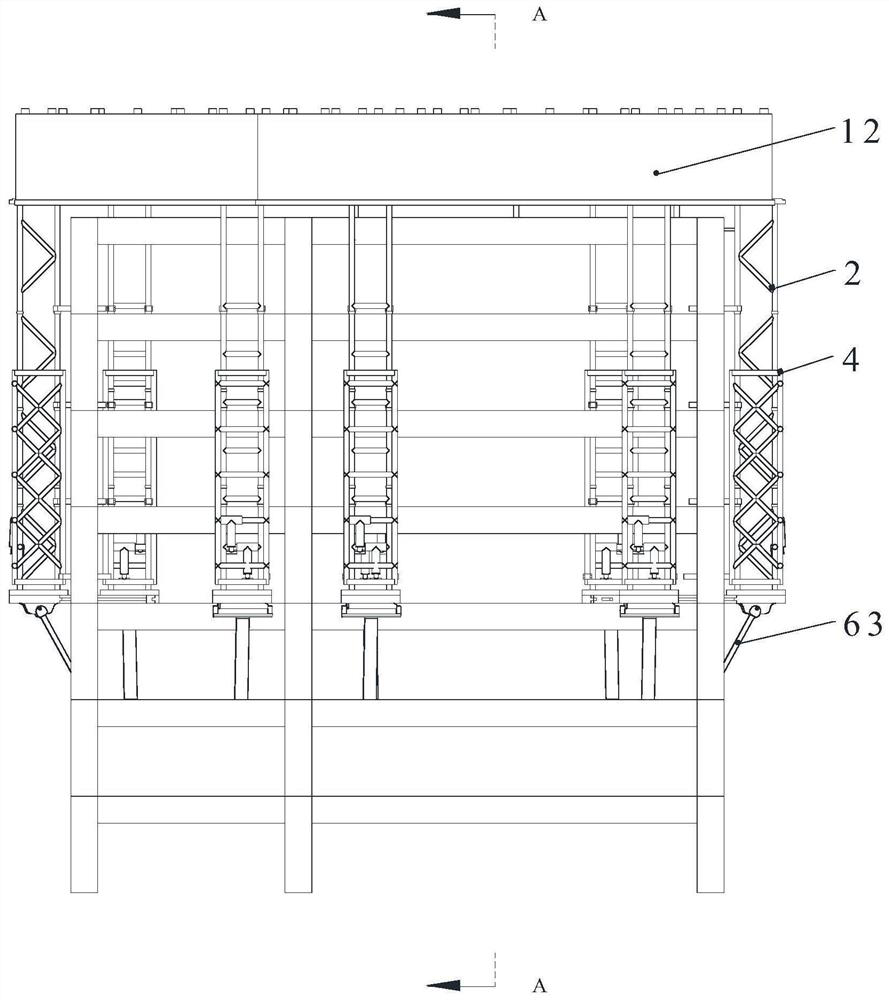

Overall lifting automatic building construction platform

ActiveCN113216650BReduce manual handlingReduce pollutionLifting devicesBuilding material handlingArchitectural engineeringAutomation

The invention belongs to the fields of construction engineering and mechanical engineering, and in particular relates to an integral lifting automatic building construction platform. The adopted technical solution is: an integral lifting automatic building construction platform, the integral lifting automatic building construction platform includes a construction platform, a lifting device, hoisting equipment and auxiliary facilities. The construction platform includes bearing beams, protective boards, and protective columns, which can move in the vertical direction; the lifting device includes steel trusses, climbing frames, holding devices, slewing seats, bases, and pillars; the hoisting equipment includes aircraft, Chutes, booms, prefabricated panels, quick release parts and moving mechanisms move on the construction platform; auxiliary facilities provide power for the lifting device; the construction method of hoisting prefabricated panels and concrete condensation is adopted. The invention provides a brand-new modularized and automatically lifted overall lifting automatic building construction platform, which reduces environmental pollution and improves construction efficiency.

Owner:SOUTHWEST PETROLEUM UNIV +1

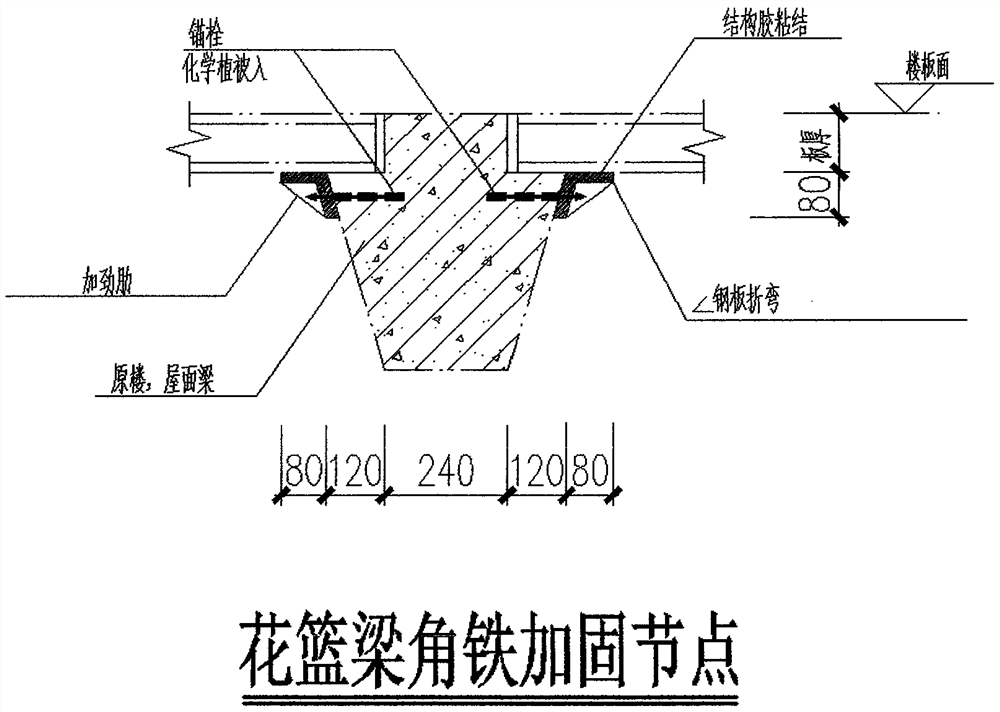

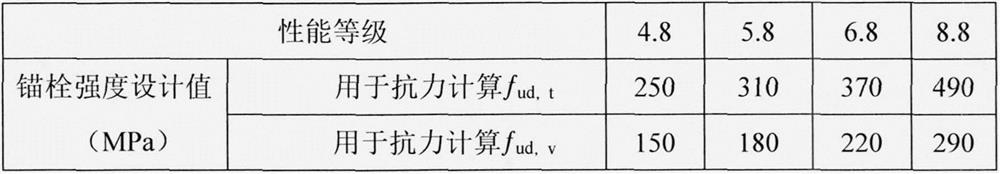

Angle iron reinforcing method for concrete ledger beam

Owner:青海恒固建筑工程有限公司

Prefabricated steel-concrete combined beam-column frame structure system

ActiveCN106567458BImprove anti-corrosion and fire performanceSave materialBuilding constructionsConcrete beamsEngineering

The invention discloses an assembly type steel-concrete combined beam column frame structure system. The assembly type steel-concrete combined beam column frame structure system comprises a steel joint, a steel-concrete combined column, a steel-concrete combined beam and a laminated slab. The steel joint comprises profile steel, a stiffening rib, a connection plate and a bolt, and a concrete protection layer is poured outside the steel joint. The steel-concrete combined column comprises a concrete column, a steel-concrete combined section, a short steel column, a rebar, a drilling device, a finish-rolled deformed bar and an anchoring nut. The steel-concrete combined beam comprises a concrete beam, a steel-concrete combined section, a short steel beam, a rebar, a drilling device, an anchoring device, a prestressed cable and a beam end connection plate. The laminated slab comprises a precast concrete slab and a cast-in-place layer. After the precast concrete slab is installed in place, the concrete cast-in-place layer is poured on the precast concrete slab. The assembly type steel-concrete combined beam column frame structure system combines the advantages of a cast-in-place concrete frame system and a steel structure frame system and has good mechanical performance, economic indicators and a very high prefabrication assembly rate which can reach 100%. Fast assembly construction is adopted, and the construction period is shortened effectively.

Owner:SHAOXING UNIVERSITY

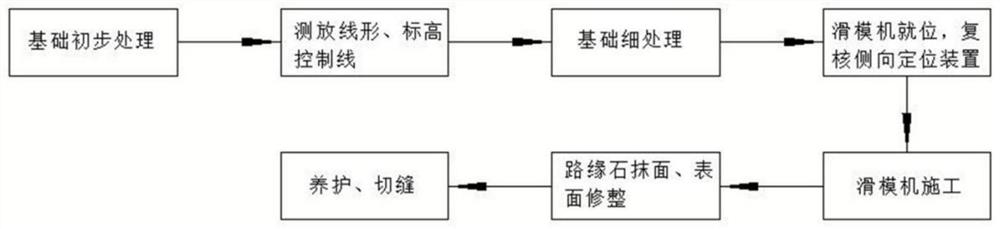

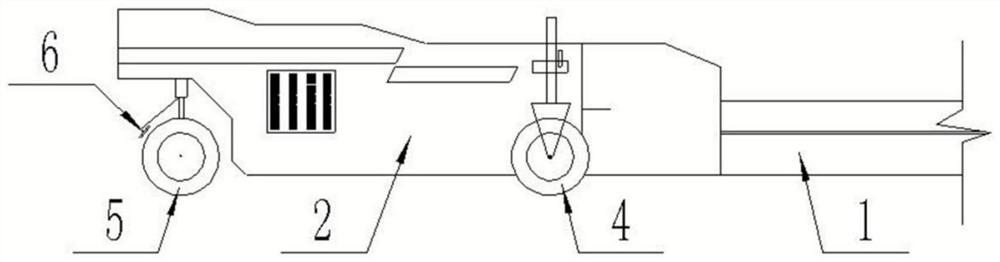

Kerb slip form construction process

InactiveCN112030680AImprove construction efficiencySave construction consumablesRoads maintainenceSmooth surfaceMechanical construction

The invention relates to a kerb slip form construction process. The process comprises the specific steps that S1, primarily treating a foundation; S2, measuring a linear and elevation control line; S3, performing basic fine treatment; S4, mounting the sliding mode machine in place; S5, performing slip form machine construction, specifically, putting concrete into a concrete groove of a slip form machine through a tank car chute, the mixed mortar is manually and continuously added into a mortar groove, an extrusion device works, the concrete is continuously extruded into a kerb mold, the mortarforms a smooth surface on the surface of an extrusion-formed kerb, and the slip form machine walks forwards through extrusion reacting force; S6, plastering the kerb; and S7, performing maintenance and joint cutting. The construction efficiency is greatly improved, construction consumables are obviously reduced, meanwhile, a large area of site is not occupied any more, and good economic benefitsare obtained; due to mechanical construction, the formed kerb has the advantages of being high in overall strength, high in anti-collision capacity, uniform and consistent in color, smooth in line type and the like, and the bonding degree of the kerb and a lower bonding layer is improved through cast-in-place.

Owner:CCCC FIRST HARBOR ENG +1

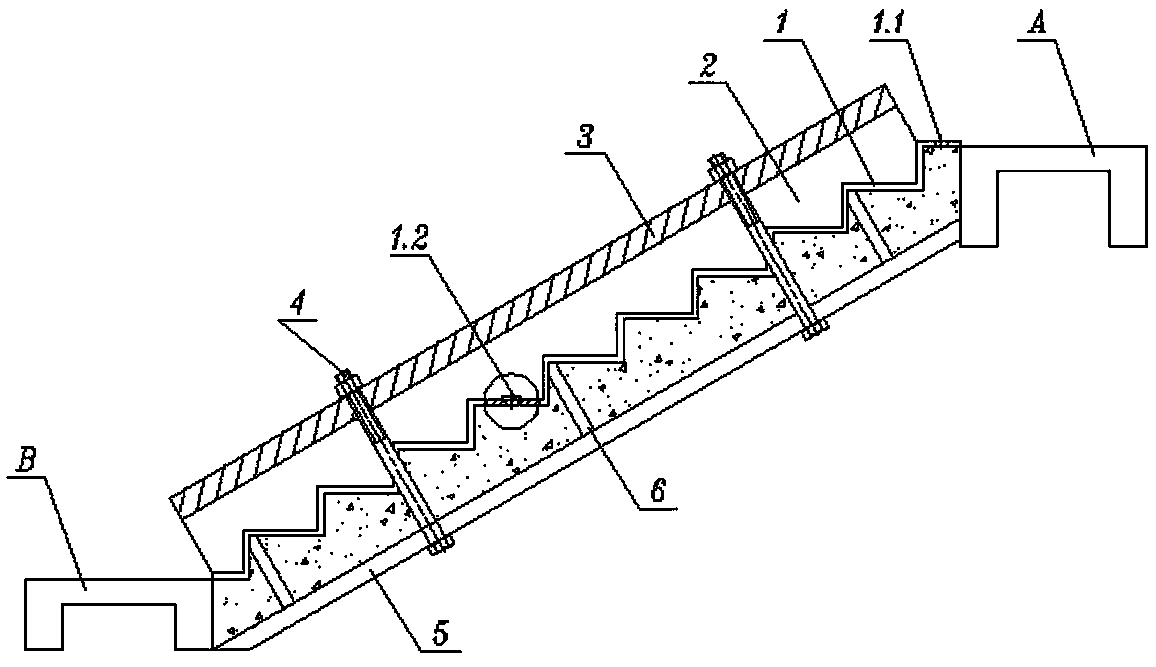

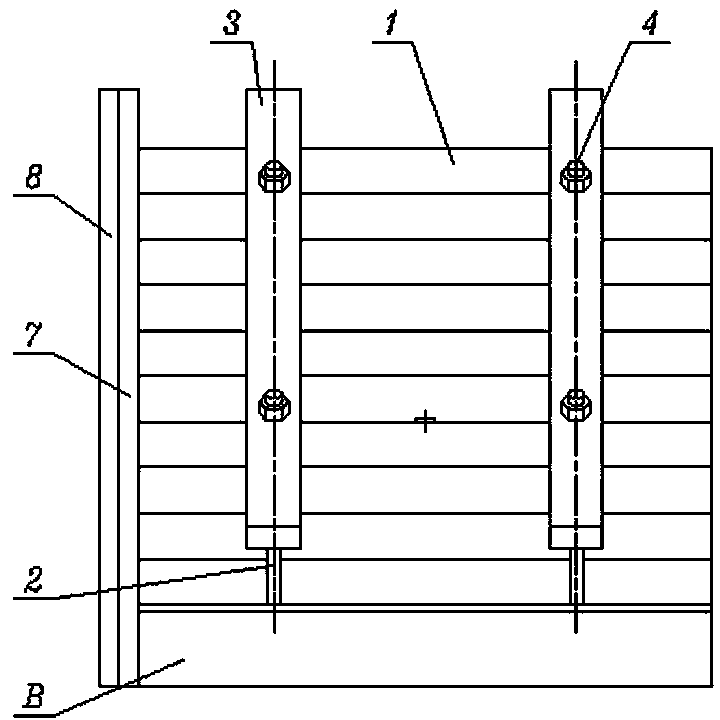

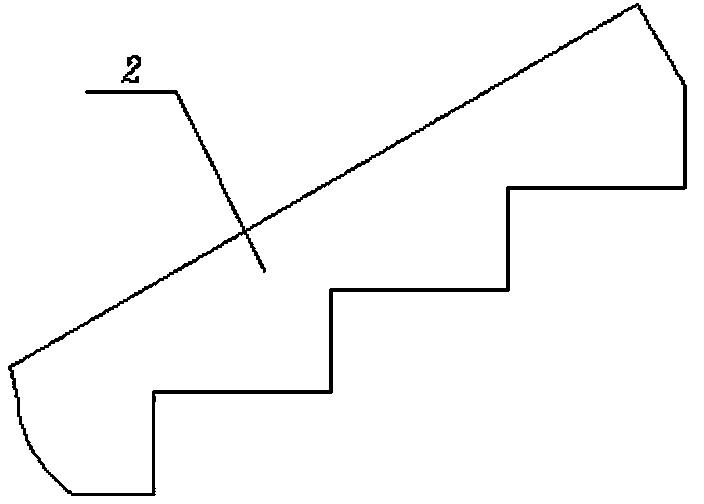

Quickly constructed stair template

Owner:山西职业技术学院

A rapid construction staircase formwork

ActiveCN106437148BSimple structureEasy to useForms/shuttering/falseworksArchitectural engineeringBuilding construction

Owner:山西职业技术学院

Bidirectional regulation positioning buckle device for building construction cast-in-situ concrete combined template

InactiveCN101270611BReduce manufacturing costSimple structureAuxillary members of forms/shuttering/falseworksMaterial consumptionScrew thread

The invention discloses a double adjusting location locking device used for a cast-in-place compound template of building construction, which mainly consists of a pre-burying annular shelf provided with a convex column, an adjustable location fastener connected with the convex column in thread and an adjusting screw rod; the pre-burying annular shelf is arranged in a cast-in-place cavity formed bythe template and leads the adjusting screw rod to extend out of the wall of the template to reveal an adjusting square head; adjustable location fastener can be driven to rotate and move the templateto a needed position by turning the adjusting screw rod, then a locking nut is used to lock the template; the invention can simultaneously carry out double direction adjustment location to fix the compound template to form the cast-in-place cavity along the transverse and the longitudinal direction for the use of construction, has the advantages of precious adjusting location, convenient construction operation and saving construction material consumption, etc., besides, the invention has remarkable effects on improving the construction efficiency and the building engineering quality.

Owner:邹尧 +2

Integral lifting type automatic building construction platform

ActiveCN113216650AReduce manual handlingReduce pollutionLifting devicesBuilding material handlingArchitectural engineeringBearing (mechanical)

The invention belongs to the field of constructional engineering and mechanical engineering, and particularly relates to an integral lifting type automatic building construction platform. According to the technical scheme, the integral lifting type automatic building construction platform comprises a construction platform body, a lifting device, hoisting equipment and subsidiary facilities, wherein, the construction platform body comprises a bearing beam, a protection plate and a protection column and can move in the vertical direction; the lifting device comprises a steel truss, a climbing frame, a holding device, a rotary seat, a base and a supporting column; the hoisting equipment comprises a crane, a sliding chute, a hoisting rod, a prefabricated slab, a quick release piece and a moving mechanism, and moves on the construction platform body; the subsidiary facilities provide power for the lifting device; and a construction method of integrally hoisting the precast slab and condensing concrete is adopted. The integral lifting type automatic building construction platform is brand new, modularized and automatically lifted, environmental pollution is reduced, and the construction efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

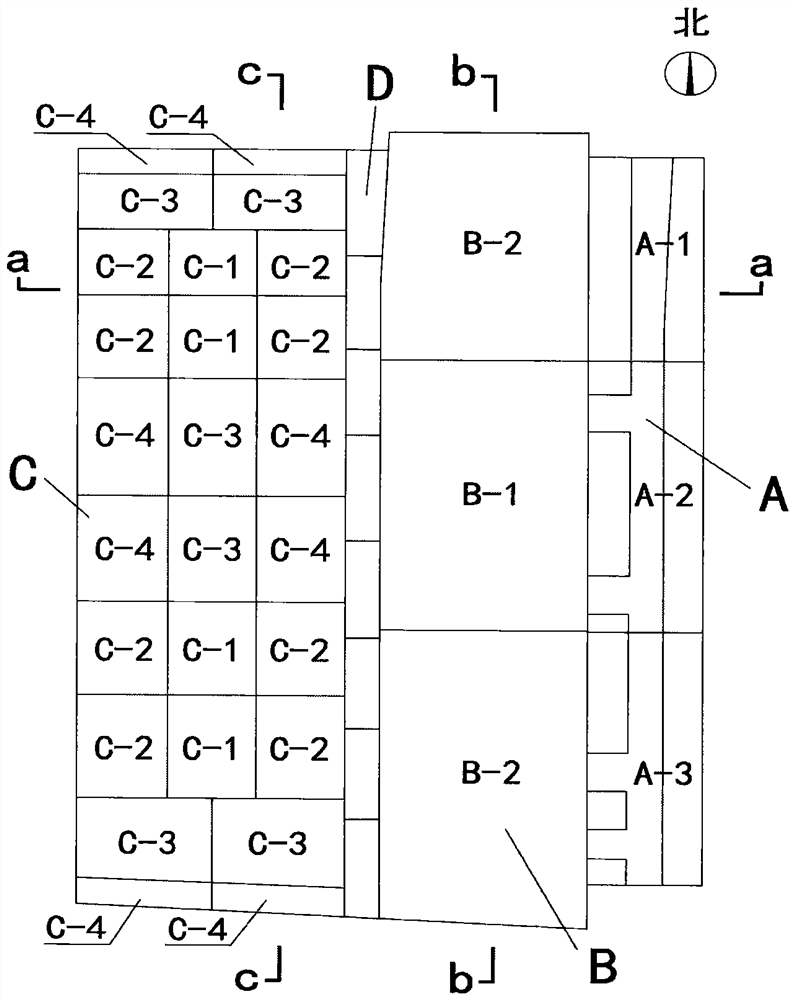

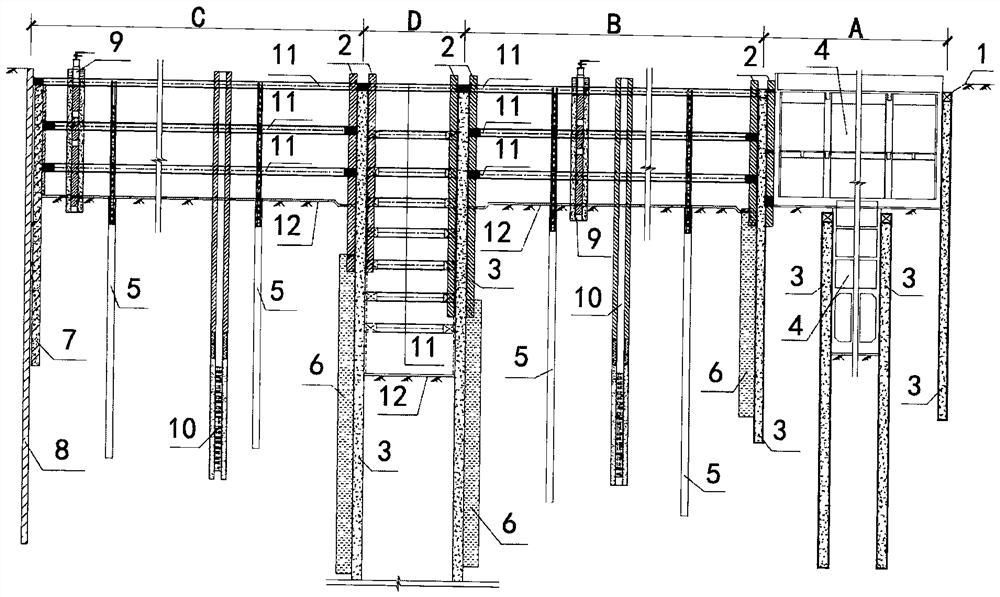

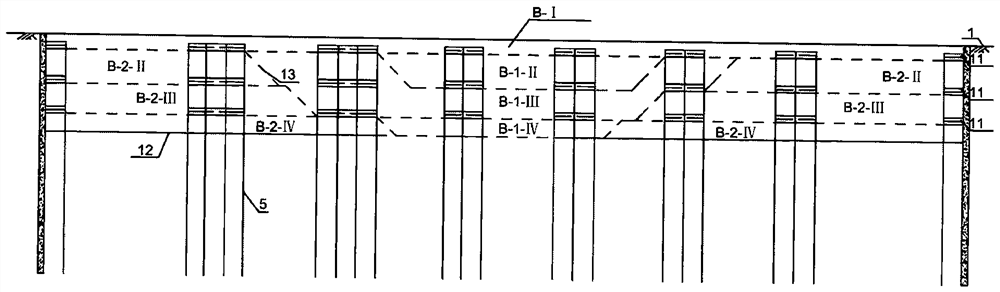

Complex foundation pit group supporting system and time-sharing excavation method

ActiveCN114016513ASave construction consumablesSpeed up the construction periodExcavationsBulkheads/pilesDeep excavationLand parcel

The invention discloses a complex foundation pit group supporting system and a time-division excavation method.The complex foundation pit group supporting system comprises a complex foundation pit group, a foundation pit group enclosure system, a dewatering system, a vertical supporting system and a horizontal supporting system.The time-division excavation method comprises the following steps that firstly, an east partition small foundation pit is excavated; meanwhile, enclosure systems and vertical supporting systems of other large foundation pits are constructed; after the east-side partitioned small foundation pit basement structure is completed, the east-side large foundation pit is divided into three land parcels to be excavated; after first-layer supporting of land parcels on the two sides of the east-side large foundation pit is completed, the west-side large foundation pit is excavated; and after the two large foundation pit basement structures are completed, the middle long and narrow subway deep foundation pit is excavated. According to the system and the time-sequence-divided excavation method, through the supporting system and excavation time sequence division, stratum disturbance is effectively reduced, dynamic interference between the foundation pits is avoided, deformation of the foundation pits is reduced, economic benefits are improved, the construction progress is accelerated, and the foundation pit group construction method is safe and efficient.

Owner:NANJING FORESTRY UNIV +1

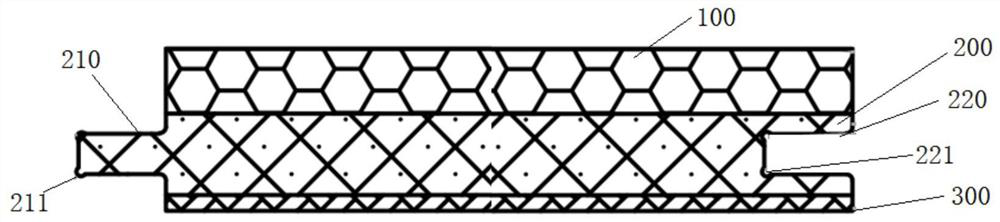

Energy-saving and environment-friendly frame assembly type building structure body

PendingCN114855995ASave construction consumablesLabor savingWallsClimate change adaptationReinforced concreteArchitectural engineering

The invention discloses an energy-saving and environment-friendly frame assembly type building structure body. The bridge-cut-off type high-strength energy-saving environment-friendly fireproof heat-preservation heat-insulation sound-insulation shear wall is composed of bridge-cut-off type high-strength energy-saving environment-friendly fireproof heat-preservation heat-insulation sound-insulation shear walls, high-strength prefabricated reinforced concrete structural columns, high-strength prefabricated reinforced concrete structural main beams, I-shaped steel secondary beams, high-strength prefabricated light steel energy-saving environment-friendly fireproof heat-preservation heat-insulation sound-insulation floor plates, foundation embedded parts, prefabricated column foundation bases and special beam body structural parts. The floor plate connecting component is composed of nine structural parts. According to the energy-saving and environment-friendly frame assembly type building structure body, assembly type construction is achieved, a large amount of building consumables are saved, and meanwhile a large amount of labor is saved; in addition, dust is not generated during assembly, pollution to the surroundings is avoided, the whole building can be detached, waste building components and building materials can be recycled, construction waste is not generated, and the building is more environmentally friendly.

Owner:华之蓝(深圳)新技术有限公司

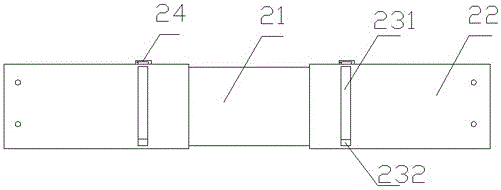

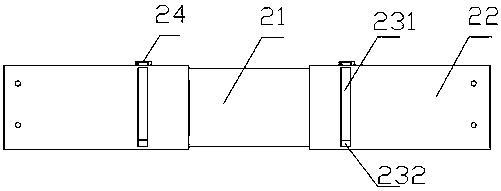

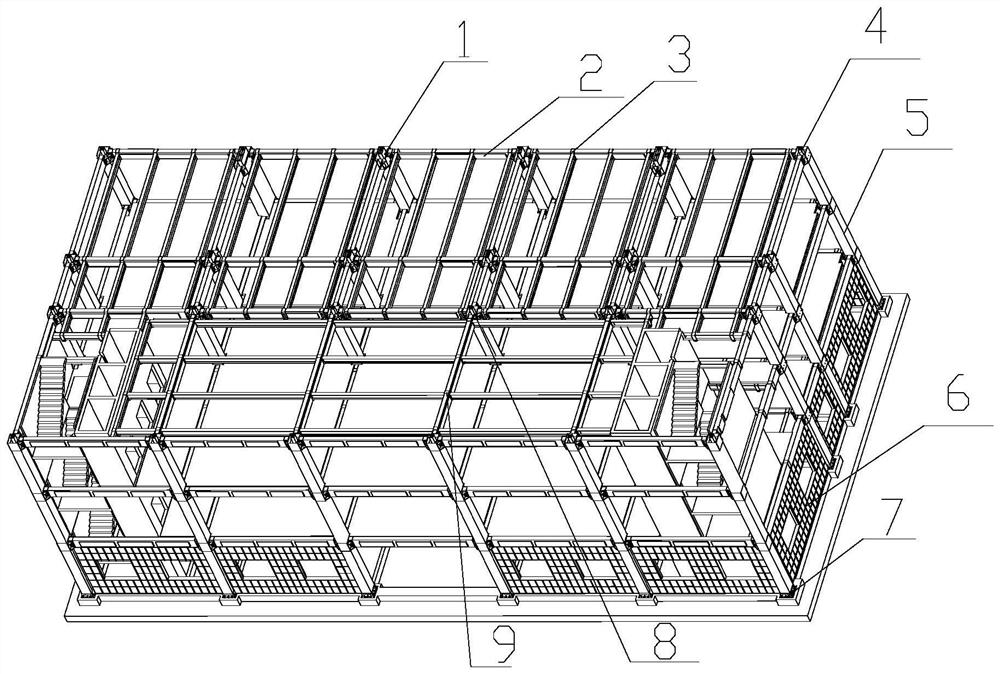

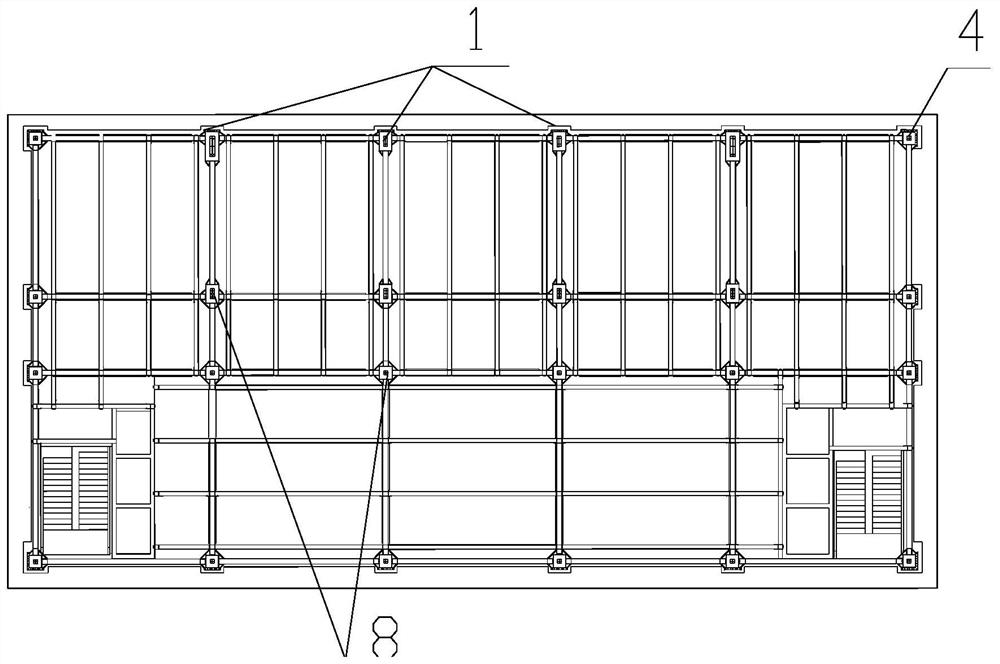

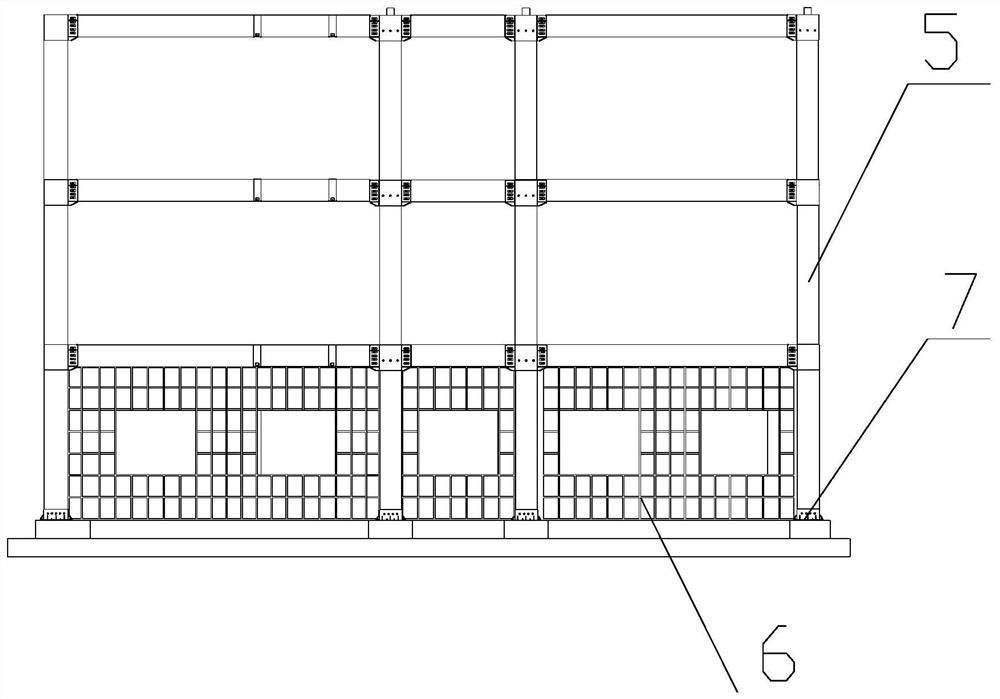

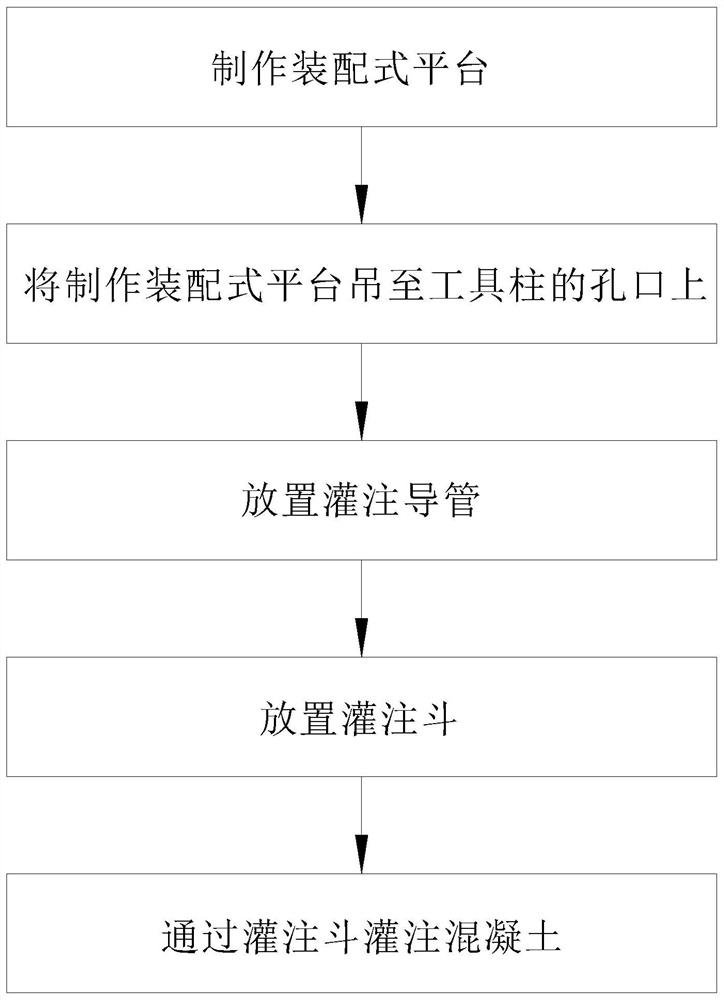

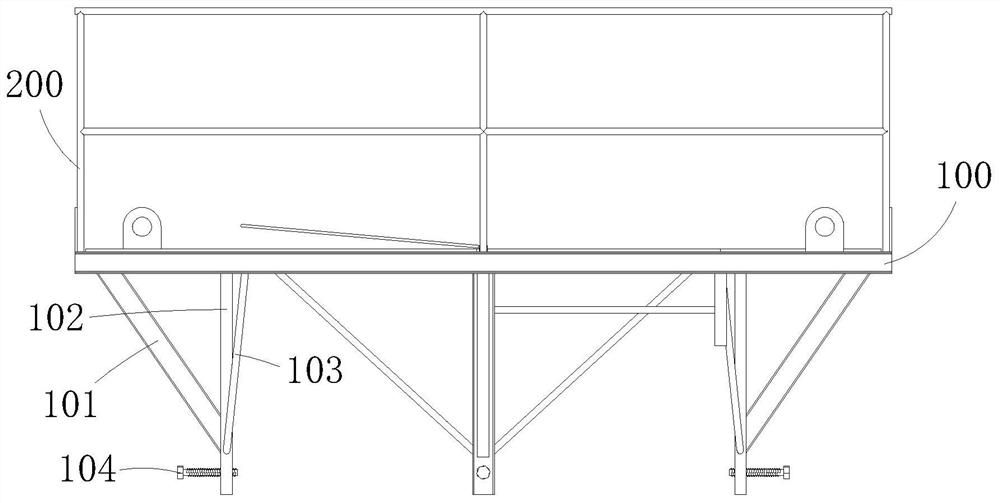

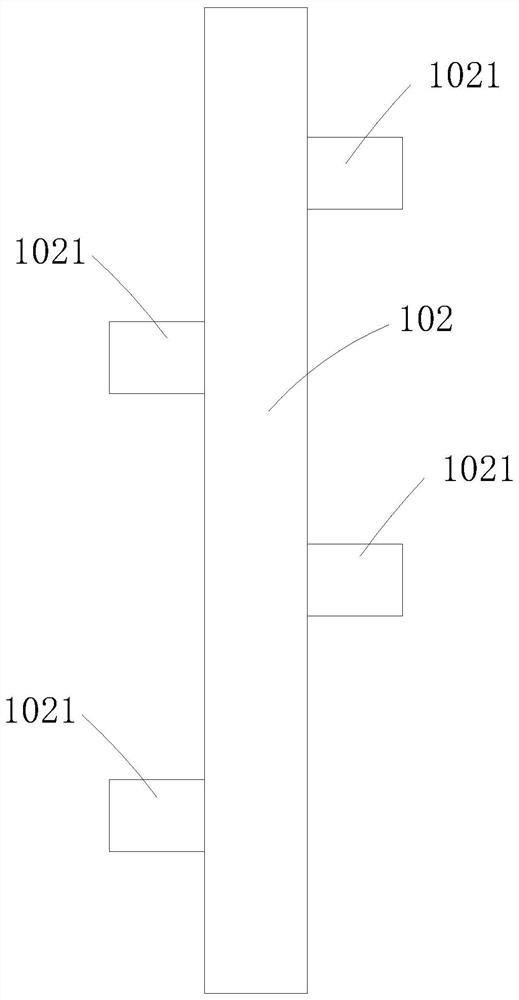

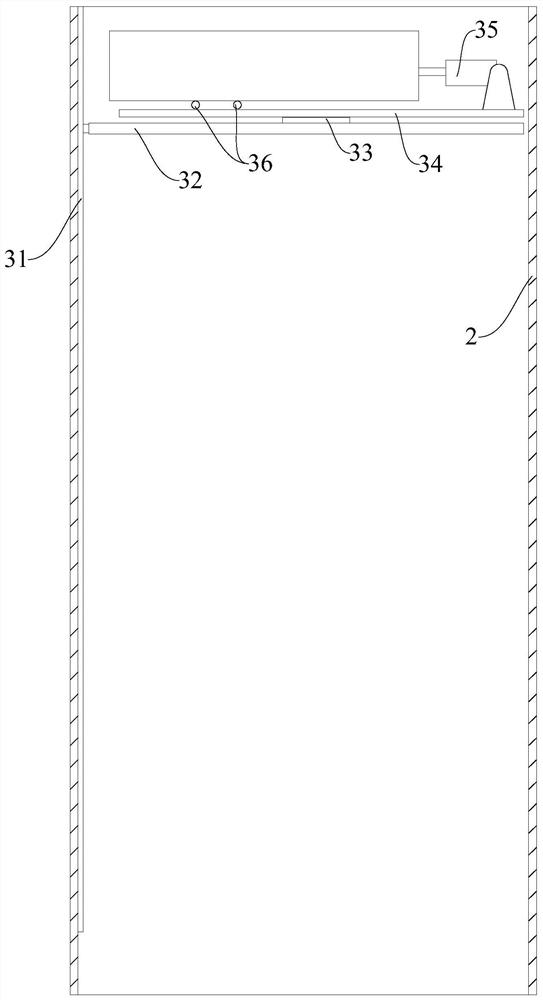

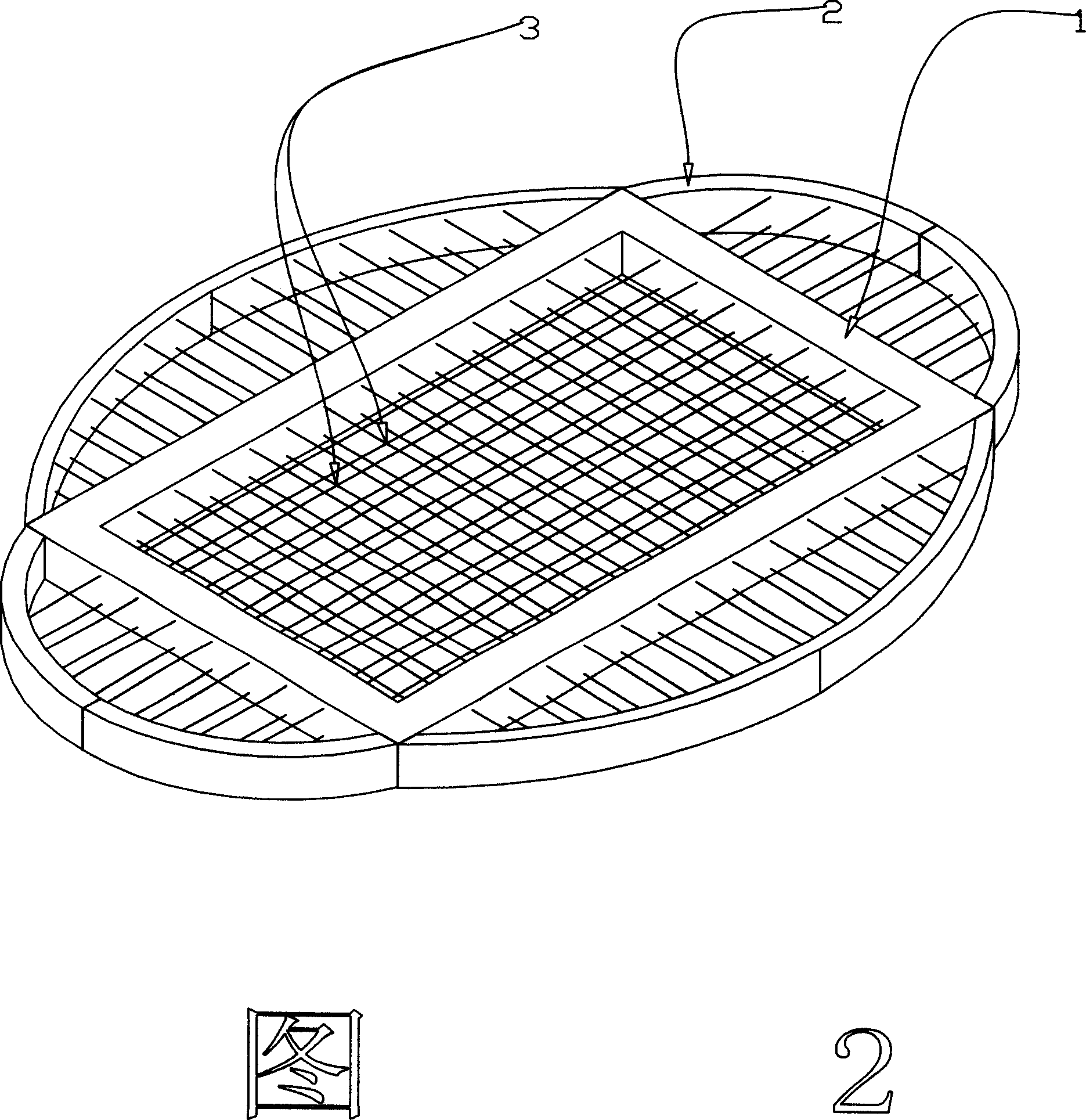

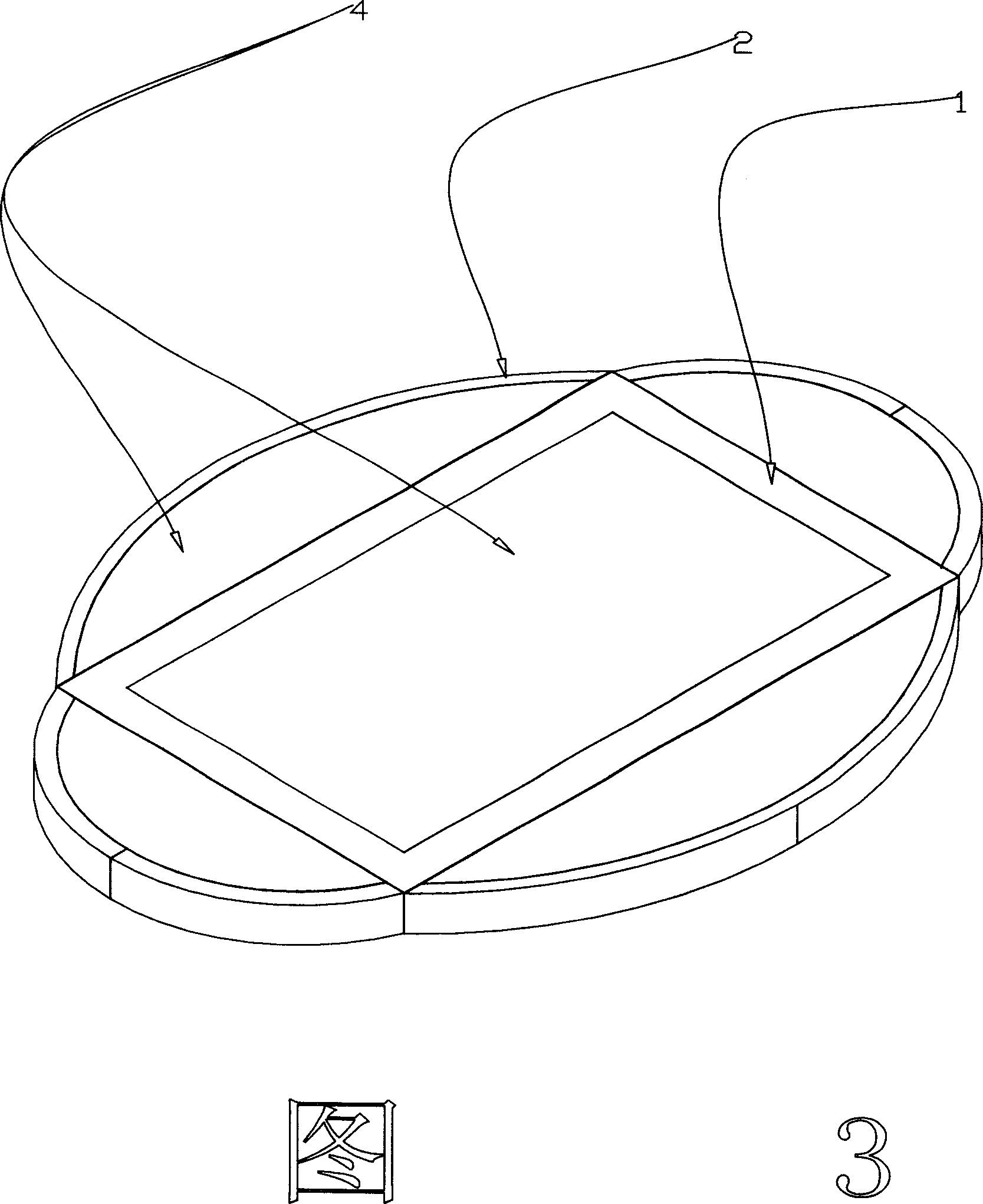

Construction method of foundation pit top-down method steel pipe structure column concrete pouring assembly type platform

ActiveCN113529795ANot affected by elevationEasy to useArtificial islandsUnderwater structuresButt jointArchitectural engineering

The invention relates to the technical field of concrete pouring, and discloses a construction method of a foundation pit top-down method steel pipe structure column concrete pouring assembly type platform. The construction method comprises the following construction steps that 1) the assembly type platform is manufactured, the assembly type platform comprises an annular frame, a supporting plate is laid on the annular frame, a plurality of longitudinal frames are connected to the lower portion of the annular frame, a protective surrounding frame is arranged on the periphery of the annular frame, and the protective surrounding frame surrounds the periphery of the annular frame; 2) the assembly type platform is hoisted to an orifice of a tool column, and the longitudinal frames and the tool column are fixedly connected through bolts; 3) a pouring guide pipe is hoisted, and the pouring guide pipe falls into the tool column from top to bottom; 4) a pouring hopper is hoisted to the annular frame, and the top of the pouring guide pipe is in butt joint and communicates with the pouring hopper; and 5) concrete is poured through the pouring hopper. The construction method of the foundation pit top-down method steel pipe structure column concrete pouring assembly type platform has the advantages that installation and use are convenient and fast, the work efficiency is improved, operation is safe and reliable, and the cost is reduced.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +2

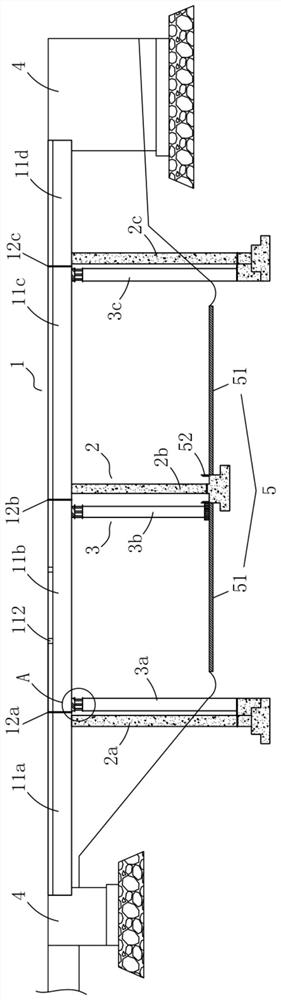

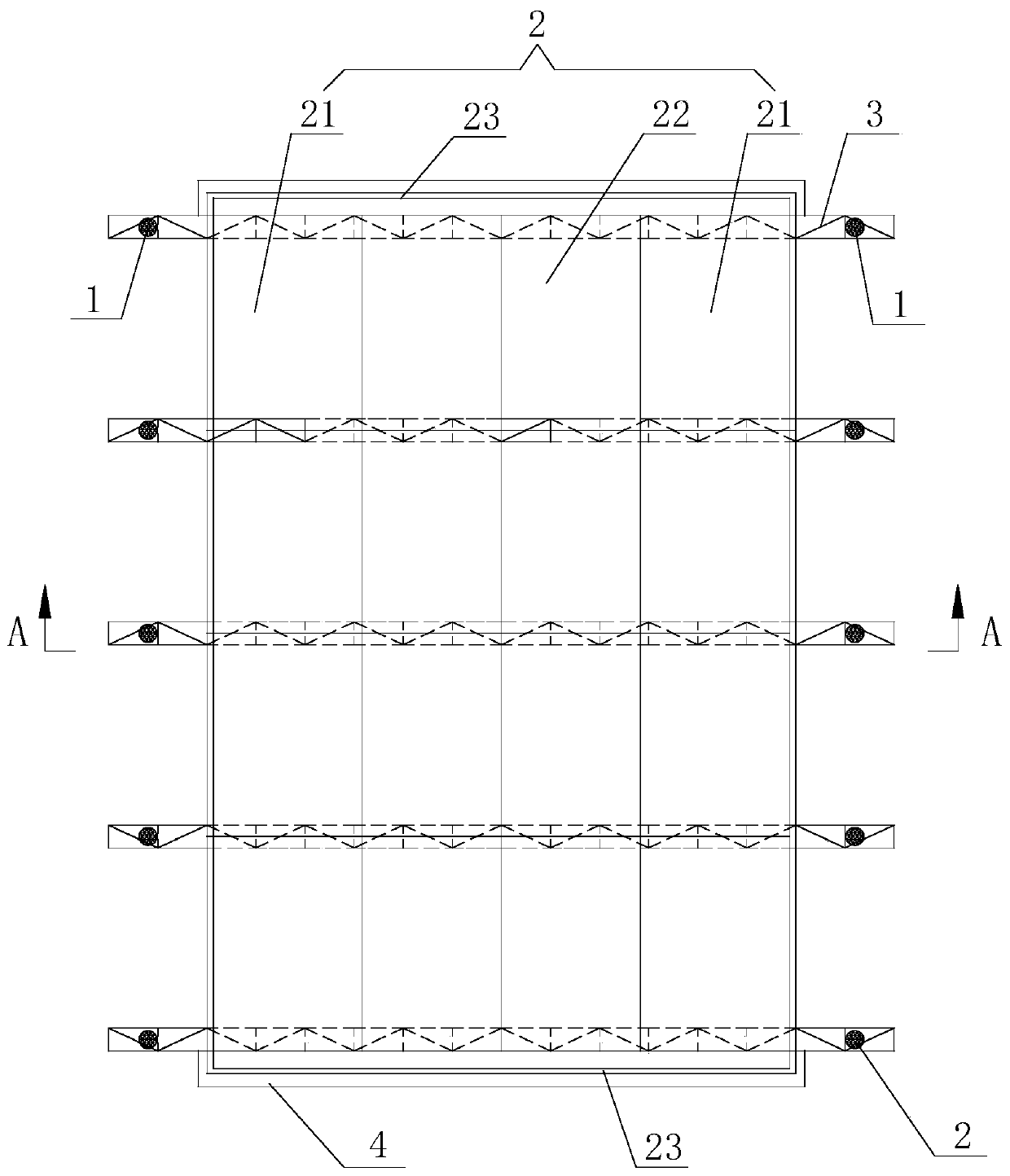

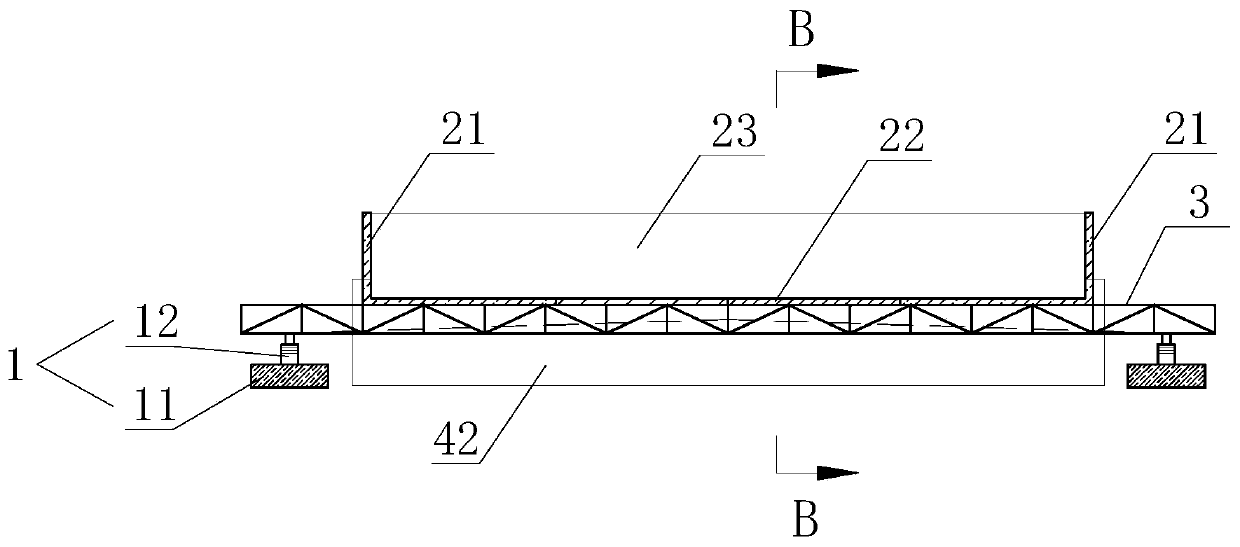

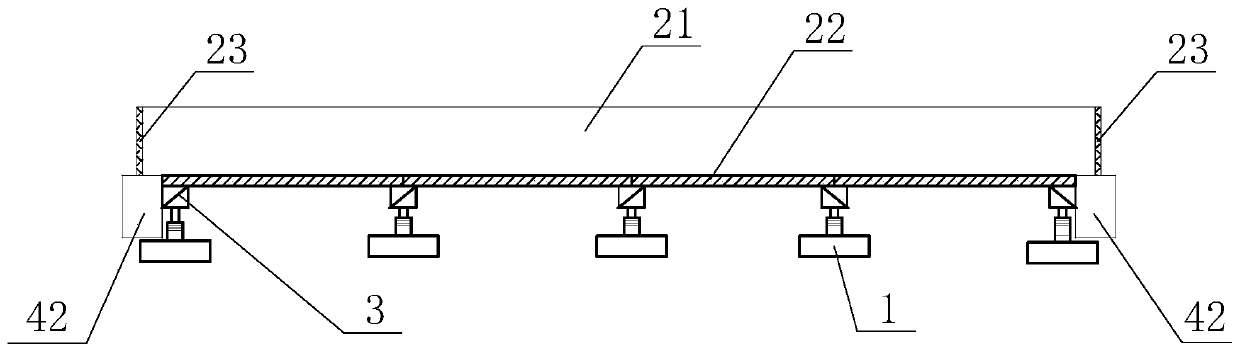

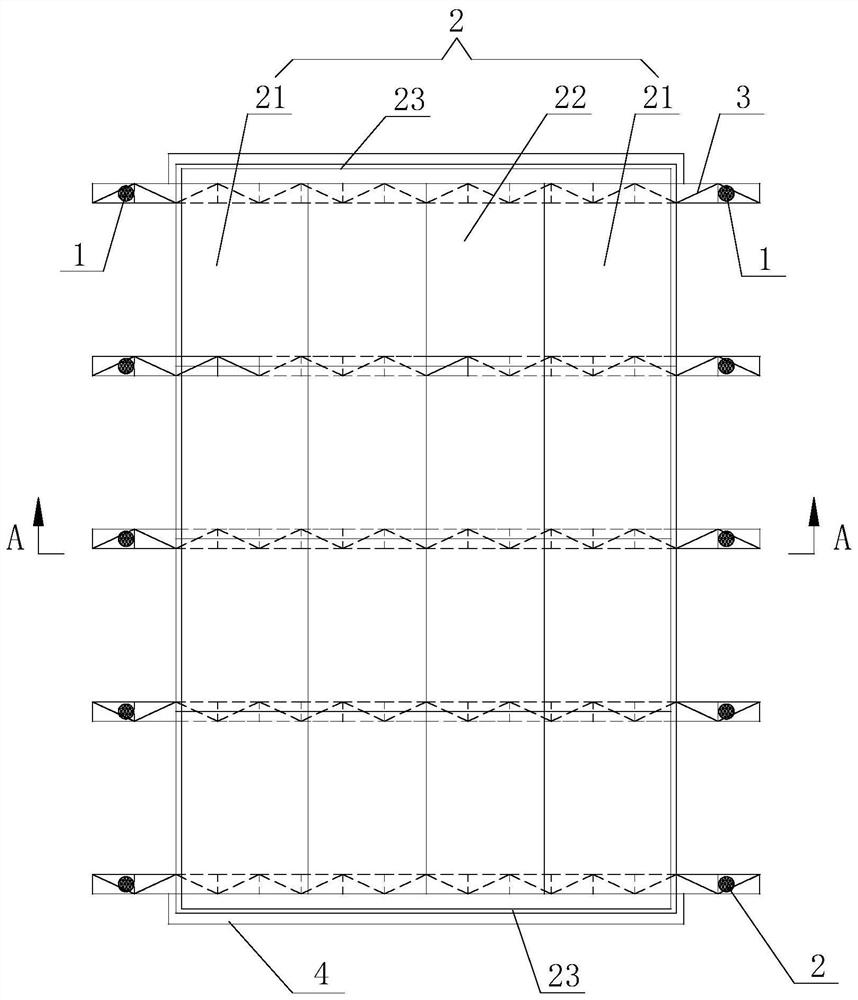

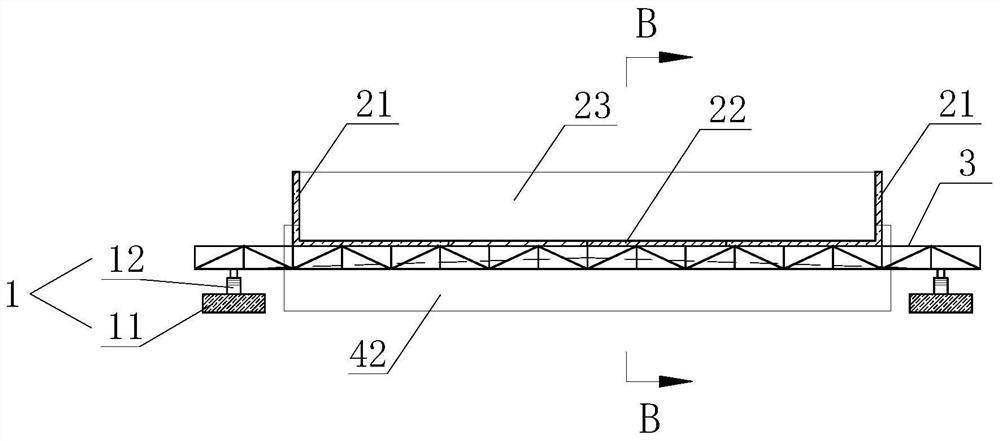

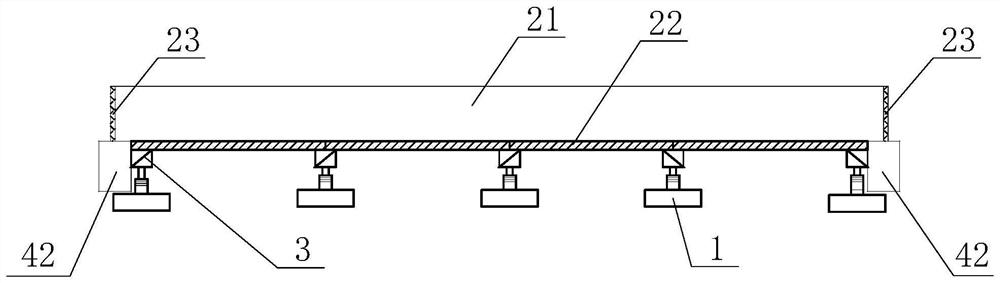

Construction device, construction system and construction method for disengaging type pile plate structure

ActiveCN111379199AAvoid passingEfficient demolitionBallastwayTrack maintainenceArchitectural engineeringBoard structure

The invention relates to the technical field of geotechnical engineering. The invention particularly relates to a construction device, a construction system and a construction method for a disengagement type pile plate structure. The constructiodevice comprises a construction template for pouring a bearing plate, and at least two truss type bearing beams are arranged at the bottom of the construction formwork. Jacking devices are arranged at the bottoms of the two ends of the truss type bearing beam correspondingly. The jacking devices are used for jacking the corresponding truss type bearingbeams, the construction formwork comprises an L-shaped steel formwork body, a plane steel formwork body and a U-shaped baffle, the plane steel formwork body is detachably connected with the L-shaped steel formwork body, the plane steel formwork body is detachably connected with the U-shaped baffle, the U-shaped baffle is detachably connected with the L-shaped steel formwork body, and the L-shapedsteel formwork body and the plane steel formwork body are both arranged on the truss type bearing beam. According to the construction device for the disengagement type pile plate structure, after pouring of the bearing plate is finished, the bearing plate can be effectively disassembled and repeatedly used, so that construction consumables are reduced, engineering investment is reduced, and the situation that foundation upheaval acting force is transmitted to the bearing plate is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction device, construction system and construction method for hollow pile structure

ActiveCN111379199BAvoid passingEfficient demolitionBallastwayTrack maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of geotechnical engineering, in particular to a construction device, a construction system and a construction method for a void-type pile-slab structure, including a construction formwork for pouring a load-bearing slab, and at least two truss-type bearing plates are arranged at the bottom of the construction formwork Beam, the bottom of both ends of the truss-type load-bearing beam are respectively equipped with jacking devices, which are used to lift the corresponding truss-type load-bearing beam. The construction formwork includes L-shaped steel formwork, plane steel formwork and U-shaped baffle, and plane steel formwork The L-shaped steel formwork is detachably connected, and the flat steel formwork is detachably connected with a U-shaped baffle. A construction device for a hollow-out pile-slab structure of the present invention can be effectively dismantled and reused after the bearing slab is poured, thereby reducing construction consumables and project investment, and avoiding the transmission of foundation uplift force to the bearing slab .

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

An identification device for measurement control points

ActiveCN112595298BLess consumablesSave construction consumablesPermanant marksBoundary marksLaser transmitterLight beam

The application discloses a marking device for measurement control points, which relates to the technical field of engineering surveying. The marking device includes: a laser emitter, which includes a small emitting hole; wherein, the small emitting hole is used to emit a laser beam; The sleeve, which is used to be vertically arranged at the measurement control point, and accommodates the laser emitter; the driving part, which is installed on the sleeve, and is detachably connected with the laser emitter; the drive The part is used to drive the emission small hole to move to the position of the reference point under different construction states. This application does not need to set additional marker stones again, moving the launch hole to the position of the reference point is equivalent to setting the marker stone again, and recycling the laser emitter when the marker stone is no longer needed, saving consumables, and using the laser emitter Perform a night calibration.

Owner:武汉致远建设集团有限公司

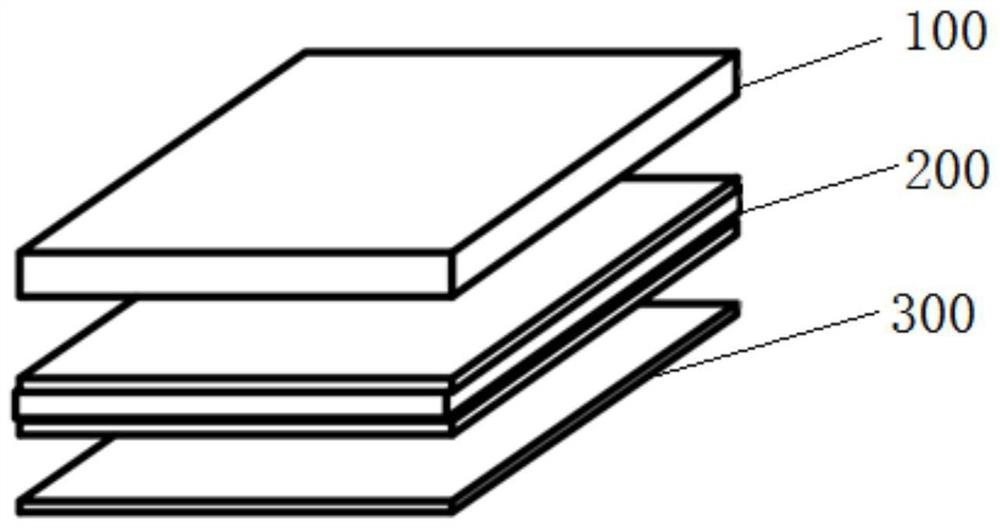

Composite floor and preparation method thereof

PendingCN114607114ASave construction consumablesReduce decoration costsFlooringMechanical engineeringCement

The invention discloses a composite floor and a preparation method thereof.The composite floor comprises a marble layer, an SPC base material layer and an EVA foaming layer, the marble layer, the SPC base material layer and the EVA foaming layer are sequentially arranged in a laminated mode, one end of the SPC base material layer is provided with a first clamping part, the other end of the SPC base material layer is provided with a second clamping part, and the first clamping part is connected with the second clamping part in a matched mode. The SPC base material layers are connected through adaptive connection of the first clamping parts and the second clamping parts, the marble layers and the SPC base material layers are arranged in a stacked mode, then the marble layers are connected, the situation that the marble layers need to be pasted through cement and gravel is avoided, and therefore building consumables and decoration cost are reduced.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

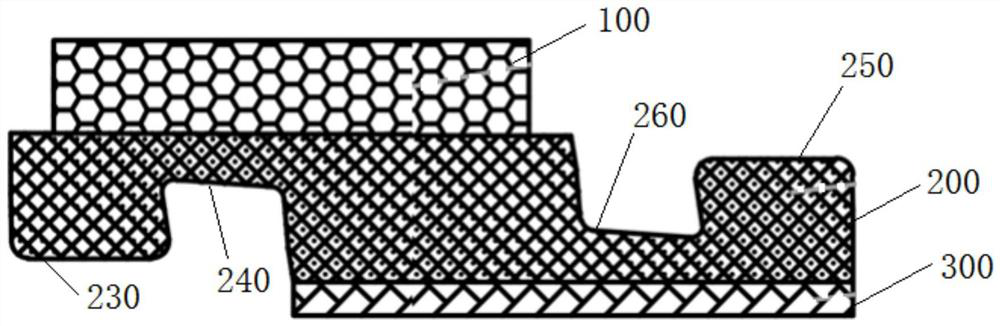

Building having integrated stress structure wall and floor slab

The construction process of building with walls and floor slabs in integral stress structure includes: tightening linear or netted material to different plane frames of beams and beams or columns to form wall or floor slab supporting members; setting sealed heat insulating and sound isolating layer between two linear or netted material layers, laying plate, etc in the outside of the linear or netted material, setting water containers or pipeline, setting transparent layer in the outmost for solar water heater, and forming arch and connecting all the linear or netted material layers to the arch.

Owner:徐林波

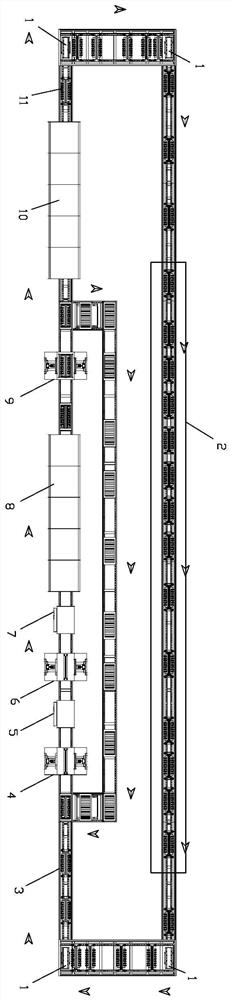

Fabricated building automatic flow production line and production process thereof

PendingCN114770720ASave construction consumablesLabor savingCeramic shaping plantsAuxillary shaping apparatusProduction lineConstruction engineering

The invention discloses a fabricated building automatic flow production line and a production process thereof. Comprising a movable template steering device, a keel upper mold area, a movable template, a primary grouting device, a primary quality inspection device, a secondary grouting device, a secondary quality inspection device, a constant-temperature hardening control device, a mold opening control device, a constant-temperature atomization maintenance control device, a finished product hoisting area and a movable template. The automatic flow production line for producing the fabricated building is energy-saving, environment-friendly, safe and standard, compared with a traditional on-site molding construction technology, the automatic flow production technology for the fabricated building saves a large amount of building consumables, meanwhile saves a large amount of labor, and compared with the traditional on-site molding construction technology, the production cost is reduced, and the production efficiency is improved. According to the assembly type building automatic flow production process, a large amount of building consumables are saved, and meanwhile a large amount of labor is saved.

Owner:华之蓝(深圳)新技术有限公司

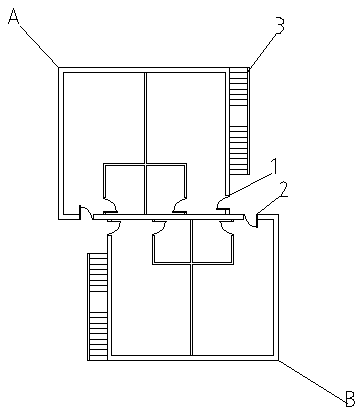

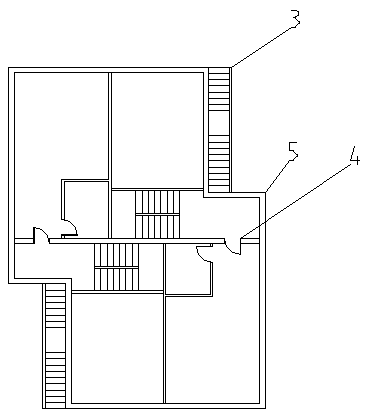

Private hotel building structure solving ventilation and lighting

PendingCN108331380ASave construction consumablesReduce energy consumptionHotelsSpecial buildingLand resourcesNatural ventilation

The invention relates to a private hotel building structure solving ventilation and lighting, and the private hotel building structure breaks a building structure in which guest rooms are connected byclosed corridors of a traditional long-strip-shaped multi-layer multi-guest-room hotel. Natural ventilation and lighting are achieved in public areas. The building consumable items are saved, the energy consumption is saved, land resources are saved, and the guest rooms have independent entrance and exit functions to increase privacy.

Owner:王升

Array arrangement method of tracking photovoltaic equipment

ActiveCN103823927BSolving Dynamic Computing ProblemsImprove calculation accuracySpecial data processing applications3D modellingPhotovoltaic power stationComputer science

The invention discloses an array-type configuration method for tracking-type photovoltaic devices. The array-type configuration method includes the steps of 1), establishing three-dimensional models of the tracking-type photovoltaic devices; 2), establishing rotation transformation models; 3), determining composite rotation transformation models of photovoltaic panels; 4), selecting shadow calculation key points; 5), calculating shadow coordinates of the key points; 6), drawing annual shadow position track lines of the key points and calculating configuration spaces among neighboring photovoltaic devices; 7), acquiring array configuration results of the photovoltaic devices. Complexity in shadow calculation of the tracking-type photovoltaic devices is taken into consideration, shadow transformation matrix models under shining of the sun are structured, the annual shadow position track lines of the key points of the tracking-type photovoltaic devices are calculated and drawn, the minimum configuration spaces among the neighboring photovoltaic devices without shading of shadows are acquired, land occupation area and consumption of building materials for construction of a photovoltaic power station are reduced, and installed capacity and generating efficiency of the photovoltaic power station can be improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Condensation collecting device

InactiveCN108975971AReduce loadReduce energy consumptionClimate change adaptationSewage/sludge fertilisersWater vaporSludge

The invention relates to a condensation collecting device for collecting water vapor generated during turning and aeration of materials such as sludge, and discloses a method and equipment for removing moisture from solid waste for better fermentation and recovering the moisture. The device structurally comprises a metal condensate plate, a suction hole and a condensation collecting mechanism. According to the device, water removal equipment required in the process of sludge turning is combined with a fermentation chamber structure, so that the device is suitable for the aeration and turning process of the sludge aerobic composting process, and is capable of removing moisture in the exhaust gas generated by the sludge and recycling the moisture to achieve the effects of saving time and saving energy.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com