Fabricated building automatic flow production line and production process thereof

A building automation and assembly technology, applied in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of low efficiency and poor quality of keel manufacturing, and achieve the effects of labor saving, high speed and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

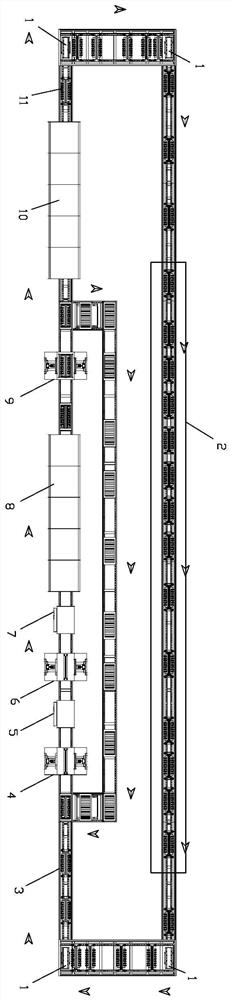

[0020] Example 1, as figure 1 As shown, the prefabricated building automation production line includes mobile formwork turning equipment 1, keel upper die area 2, mobile formwork 3, primary grouting equipment 4, primary quality inspection equipment 5, secondary grouting equipment 6, secondary quality Inspection equipment 7 , constant temperature hardening control equipment 8 , mold opening control equipment 9 , constant temperature atomization maintenance control equipment 10 , finished product hoisting area 11 .

[0021] Further, the keel upper mold area 2, primary grouting equipment 4, primary quality inspection equipment 5, secondary grouting equipment 6, secondary quality inspection equipment 7, constant temperature hardening control equipment 8, mold opening control equipment 9, constant temperature The atomization maintenance control device 10 and the finished product hoisting area 11 are communicated in turn through the mobile formwork 3 and the mobile formwork turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com