Prefabricated steel-concrete combined beam-column frame structure system

A hybrid combined beam and frame structure technology, applied in building structure, construction, etc., can solve the problems of difficult anti-corrosion and fire prevention treatment technology, complex node connection structure, slow construction speed, etc., to save external formwork materials and improve labor conditions for workers , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

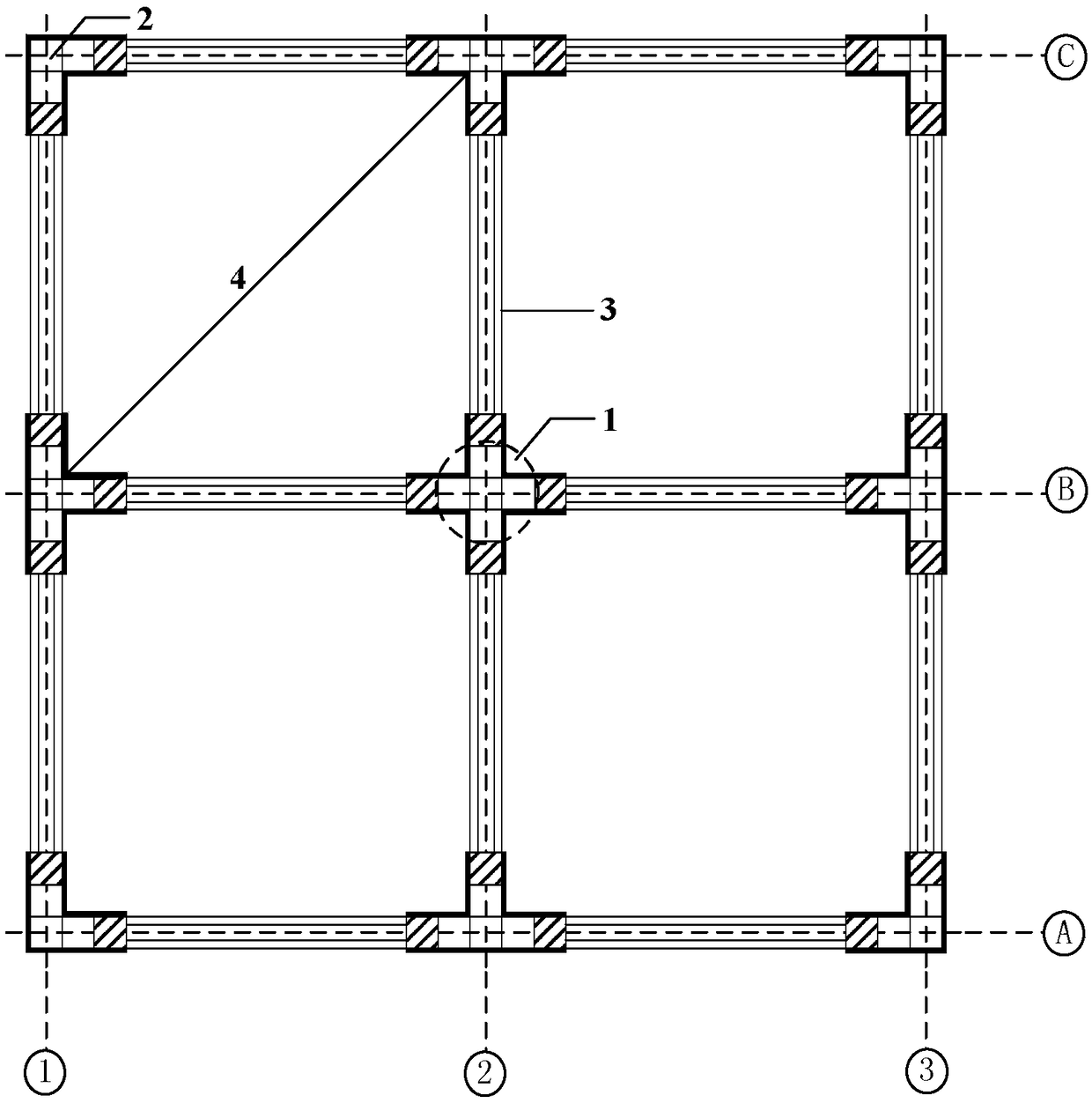

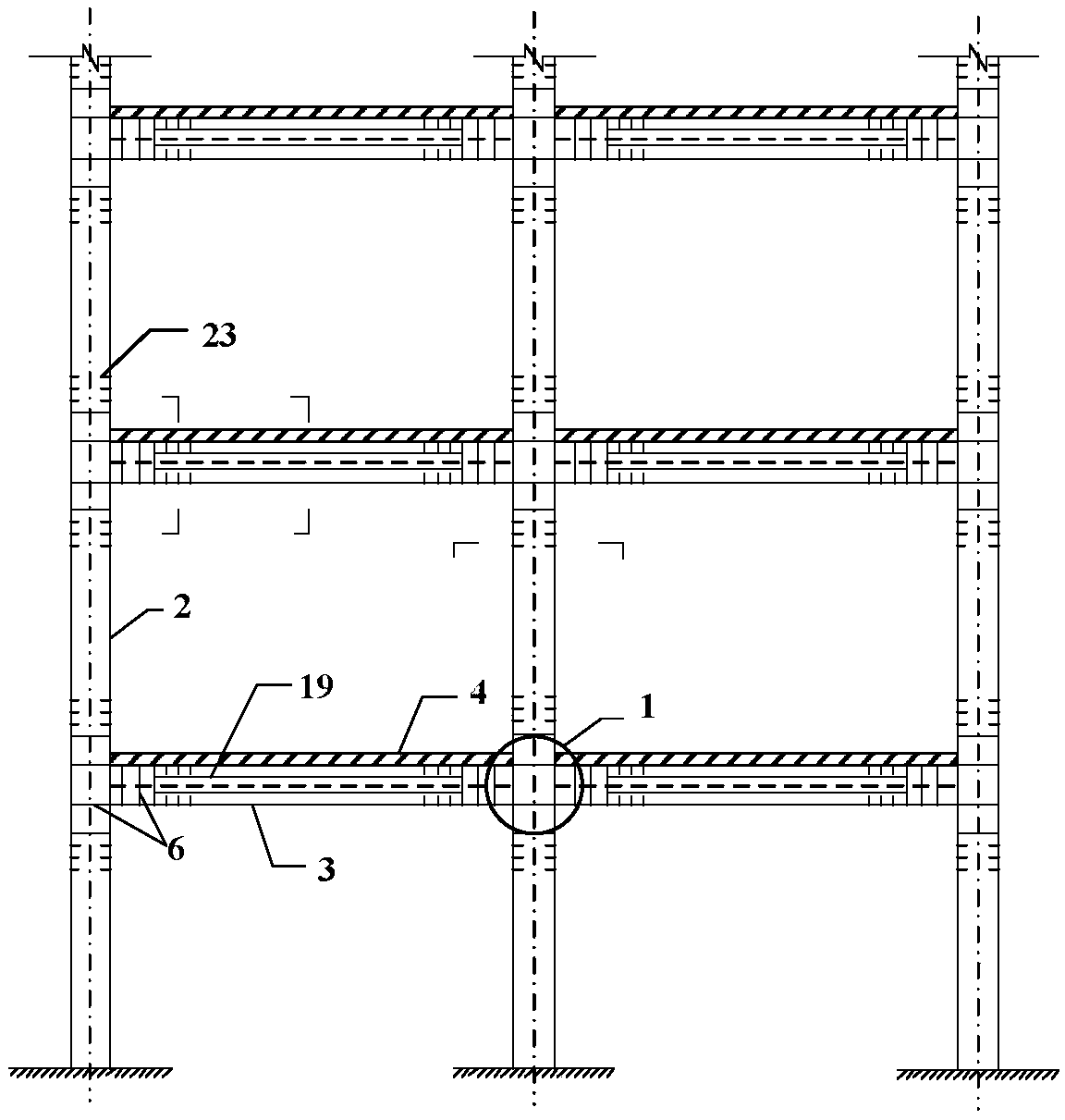

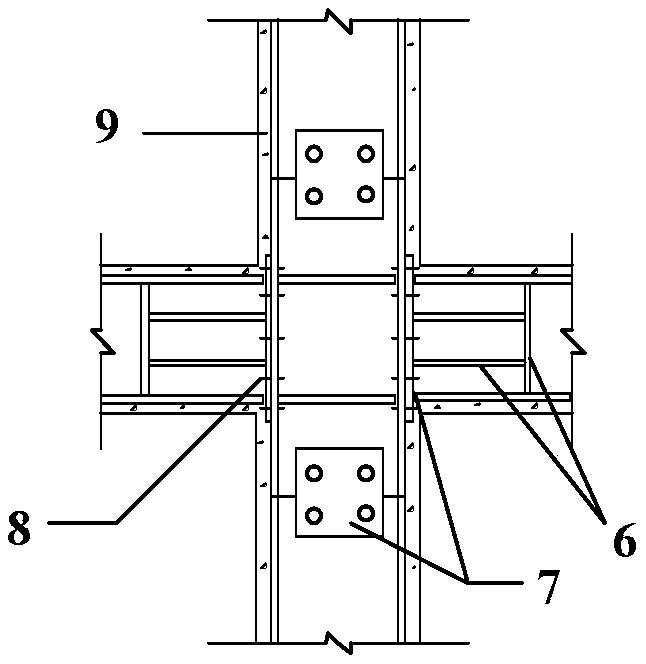

[0038] Prefabricated steel-concrete combined beam-column frame structure system, the plan view and elevation view of the frame system are as follows Figure 1~2 As shown, the frame system is composed of steel nodes 1, steel-concrete combined columns 2, steel-concrete combined beams 3, and laminated plates 4; the steel nodes are as follows image 3 As shown, the stiffener 6 is welded in the middle of the section steel 5 to increase the stiffness of the joint, the connecting plate 7 is connected with the web end of the section steel 5 through the bolt 8, and at the same time, welding is used at the joint to further strengthen the connection performance between them, and at the steel node 1. Concrete protection layer 9 is poured outside; the cross-section of the steel-concrete combined column 2 is square such as Figure 4As shown, the concrete column 10 is equipped with steel bars 13. The specific size and reinforcement ratio of the concrete column 10 are calculated according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com