A rapid construction staircase formwork

A formwork and staircase technology, which is applied in the field of rapid construction staircase formwork, can solve the problems of low reuse rate, difficult construction operation, and low precision, and achieve the effects of high work efficiency, simple structure, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

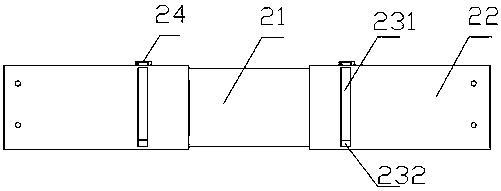

[0019] Such as image 3 , 4 , 5 and 6, a rapid construction staircase formwork, including outer formwork 4,

[0020] Also includes,

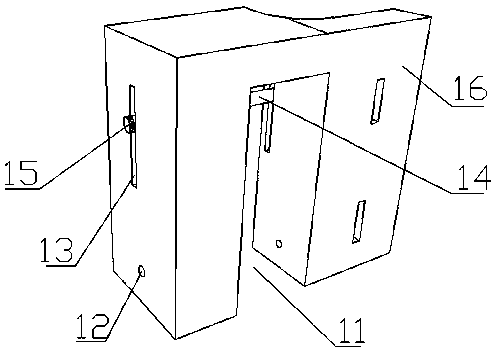

[0021] The outer locator 1 is a rectangular block. The middle part is vertically provided with an outer template card slot 11 for fixing the outer locator on the outer template 4. The lower part of the card slot walls on both sides is provided with card holes 12 symmetrically. The upper part of the slot wall is provided with a vertical chute 13 correspondingly, and it also includes a limit slide bar 14 mounted on the two chutes. There are knobs 15 on both sides of the limit slide bar. The limit slide bar 14 is adjusted by the knob 15 to slide. The position on the groove 13 is integrally connected to the side of the outer locator with a kicking template fixing block 16 provided with a rectangular fixing hole. It also includes a two-way threaded tensioner 17, which is composed of a two-way threaded sleeve and two fixing hooks. One end of the hook is m...

Embodiment 2

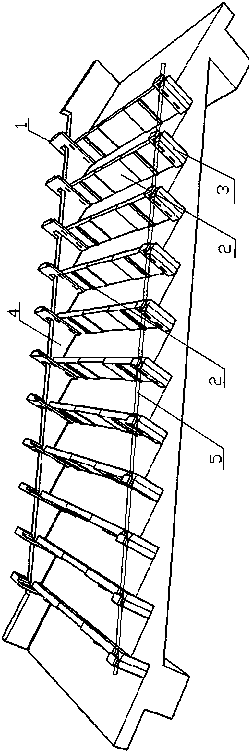

[0027] Such as figure 1 , 2 As shown, when the stairs are constructed on one side of the wall, the outer formwork is required on the outside, and the outer formwork is not needed on the side against the wall. A long connecting rod 5 is often fixed on the wall. The two ends of the long connecting rod are connected with the starting surface and the end The kick surface is connected and fixed. The inner locator of the present invention is used to fix on the long connecting rod 5.

[0028] The inner locator is a rectangular block. The upper part is provided with a slot 31 transversely, and the lower part is provided with a rectangular fixing hole 32 for fixing the kicking template. The upper side wall of the slot 31 is provided with two positioning rods 33, one long and one short. The lower side wall is a convex arc surface 34 for fixing the long connecting rod.

[0029] The positioning rod cooperates with the convex arc surface to fix the obliquely installed long connecting rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com