Installation method of rear door glass of passenger car

An installation method and technology for rear doors, applied in the installation of window glass, sealing devices, vehicle parts, etc., can solve the problems of increasing costs in the research and development stage, lack of clear assembly methods, and time-consuming, and reduce the time for layout and verification. , The effect of increasing installation space and reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

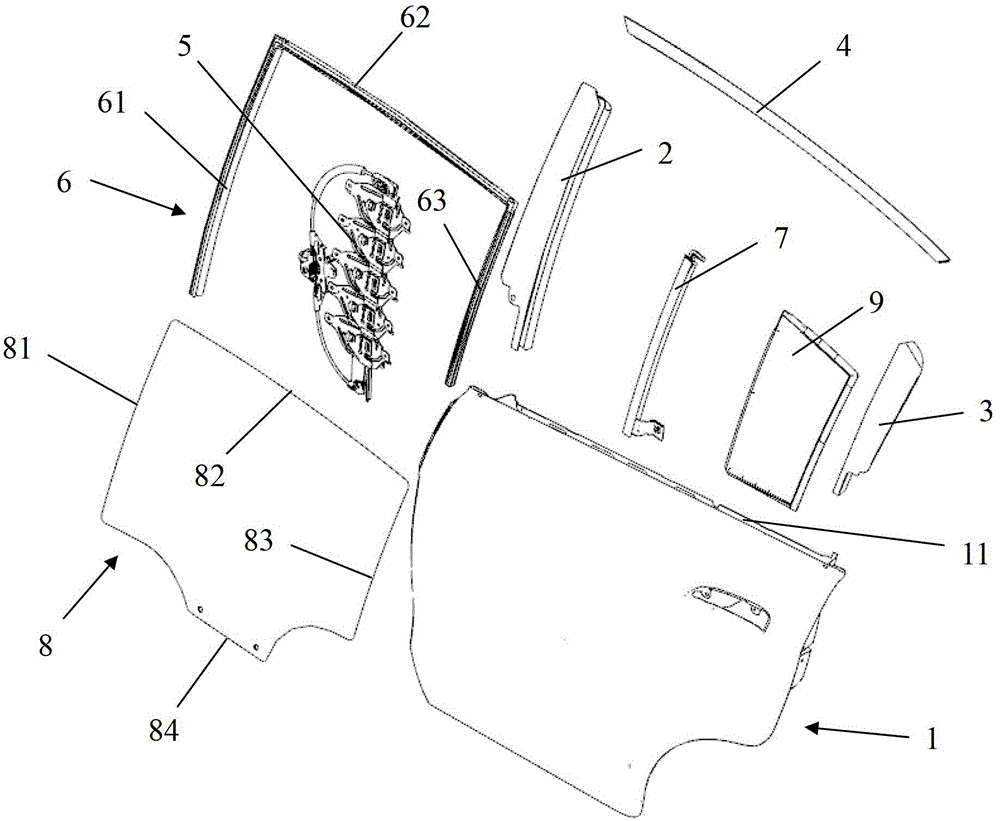

[0055] In an embodiment of the present invention, a method for installing rear door glass of a passenger car includes the following steps:

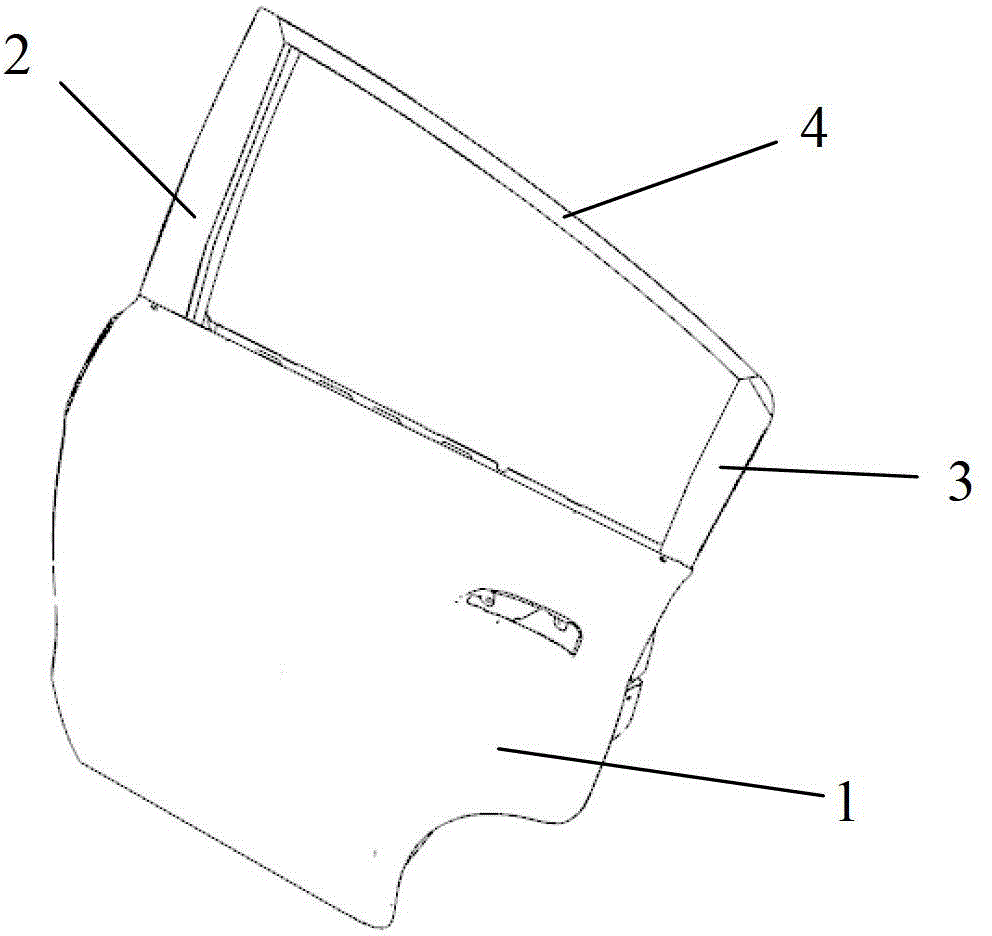

[0056] S101: Such as figure 2 As shown, the front guide groove 2 and the rear guide groove 3 are welded along the longitudinal direction on the upper frame 11 of the rear door 1, and the upper guide groove is welded between the top ends of the front guide groove 2 and the rear guide groove 3 4.

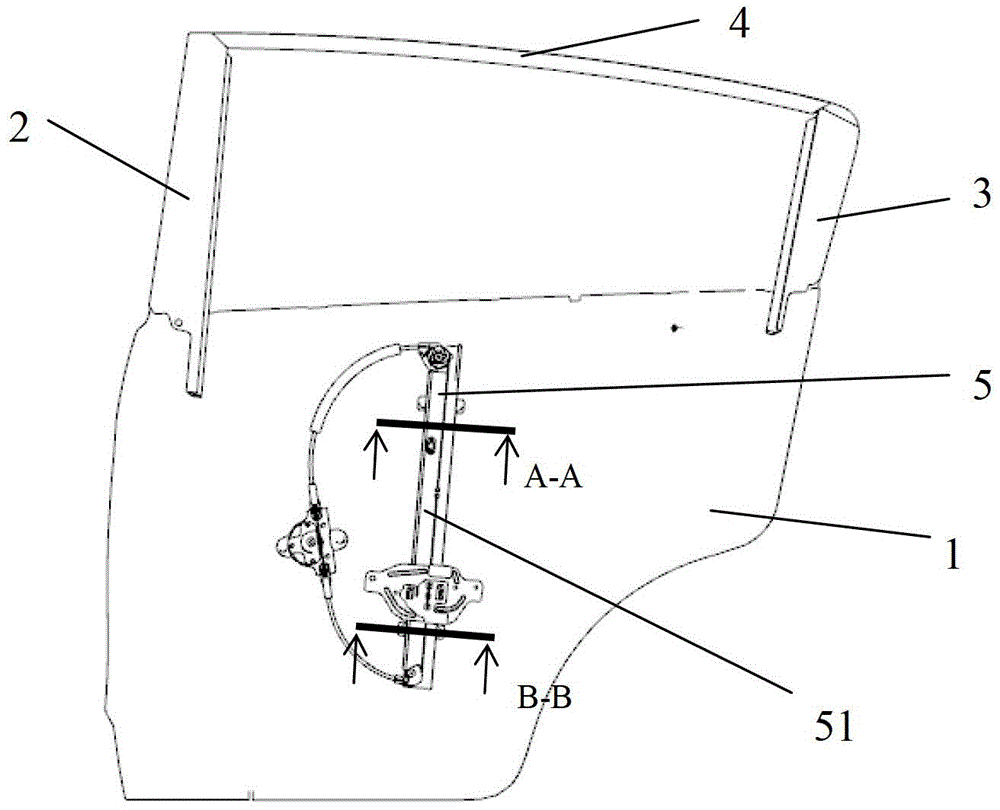

[0057] S102: Such as Figure 3A As shown, install the lifting system 5 to the back of the rear door 1, Figure 3A For perspective painting, Figure 4A , Figure 5A , Figure 6A , Figure 7A It is also perspective painting.

[0058] Preferably, as Figure 3B-3C As shown, the rear door 1 includes a door outer panel 12 and a door inner panel 13, and the lifting system 5 is installed on the door inner panel 13 in the space between the door outer panel 12 and the door inner panel 13.

[0059] Preferably, as Figure 3A-3C As shown, the upper and lower ends of...

Embodiment 2

[0068] In another embodiment of the present invention, a method for installing rear door glass of a passenger car includes the following steps:

[0069] S201: Weld the front guide groove along the longitudinal direction at the front end of the upper frame of the rear door, and weld the arc-shaped upper guide groove between the top end of the front guide groove and the rear end of the upper frame;

[0070] S202: Install the lifting system on the back of the rear door;

[0071] S203: Insert the front edge of the sealing strip into the front guide groove, insert the top edge of the sealing strip into part of the upper guide groove, and reserve the rear edge of the sealing strip for the middle guide groove;

[0072] S204: Install the lower edge of the rear door glass to the lifting system, slide the front edge of the rear door glass into the front edge of the sealing strip, and the upper edge of the rear door glass can be embedded in the top edge of the sealing strip. The rear edge is emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com