wire for vehicle

A wire and vehicle technology, applied in the field of wire bodies, can solve problems such as short service life, damage, and inability to reduce friction, and achieve the effects of reducing frictional resistance, preventing moisture, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

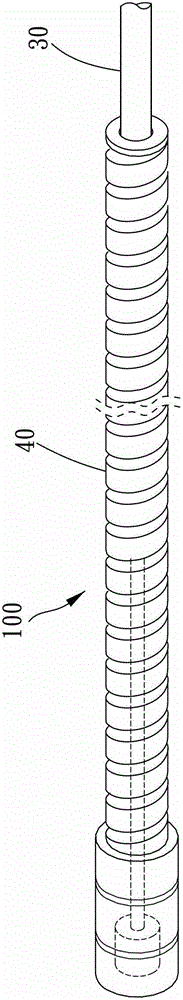

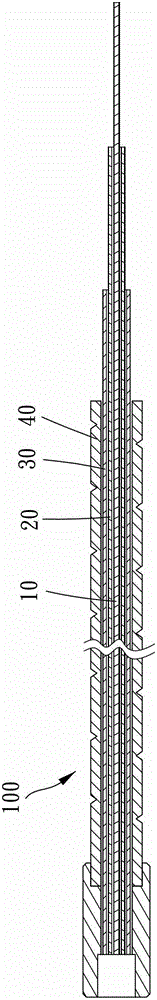

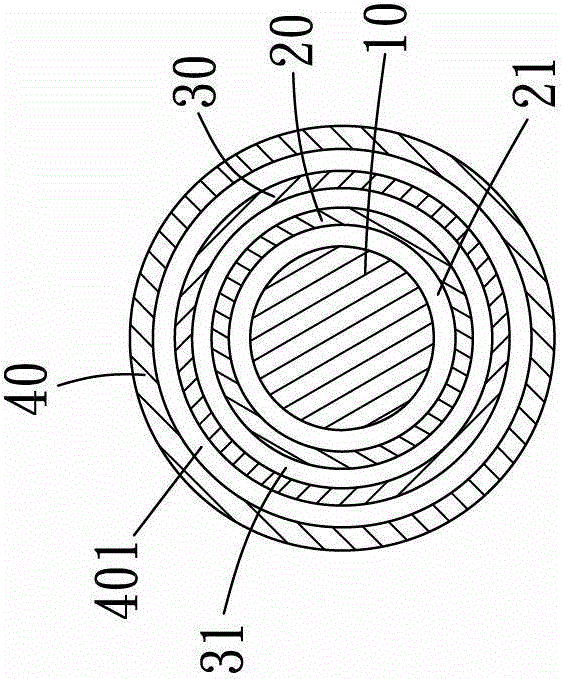

[0034] Please refer to Figure 1 to Figure 3 , which shows a preferred embodiment of the present invention, the vehicle wire 100 of the present invention includes a central line body 10 , a first sleeve body 20 , a second sleeve body 30 and an outer sleeve body 40 .

[0035] The central wire body 10 can be twisted by a plurality of wires and has a twisted peripheral surface, or can be a single wire with a relatively smooth peripheral surface.

[0036] The first sleeve 20 is sheathed on the centerline body 10 and can axially slide relative to the centerline body 10 . It should be noted that there is preferably a first gap 21 between the inner peripheral surface of the first sleeve body 20 and the outer peripheral surface of the central line body 10, but the first sleeve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com