Steel structure fire disaster temperature field inverse presumption method based on displacement forms

A steel structure and temperature field technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as structural residual performance analysis deviations, and achieve high accuracy of calculation results and high iteration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

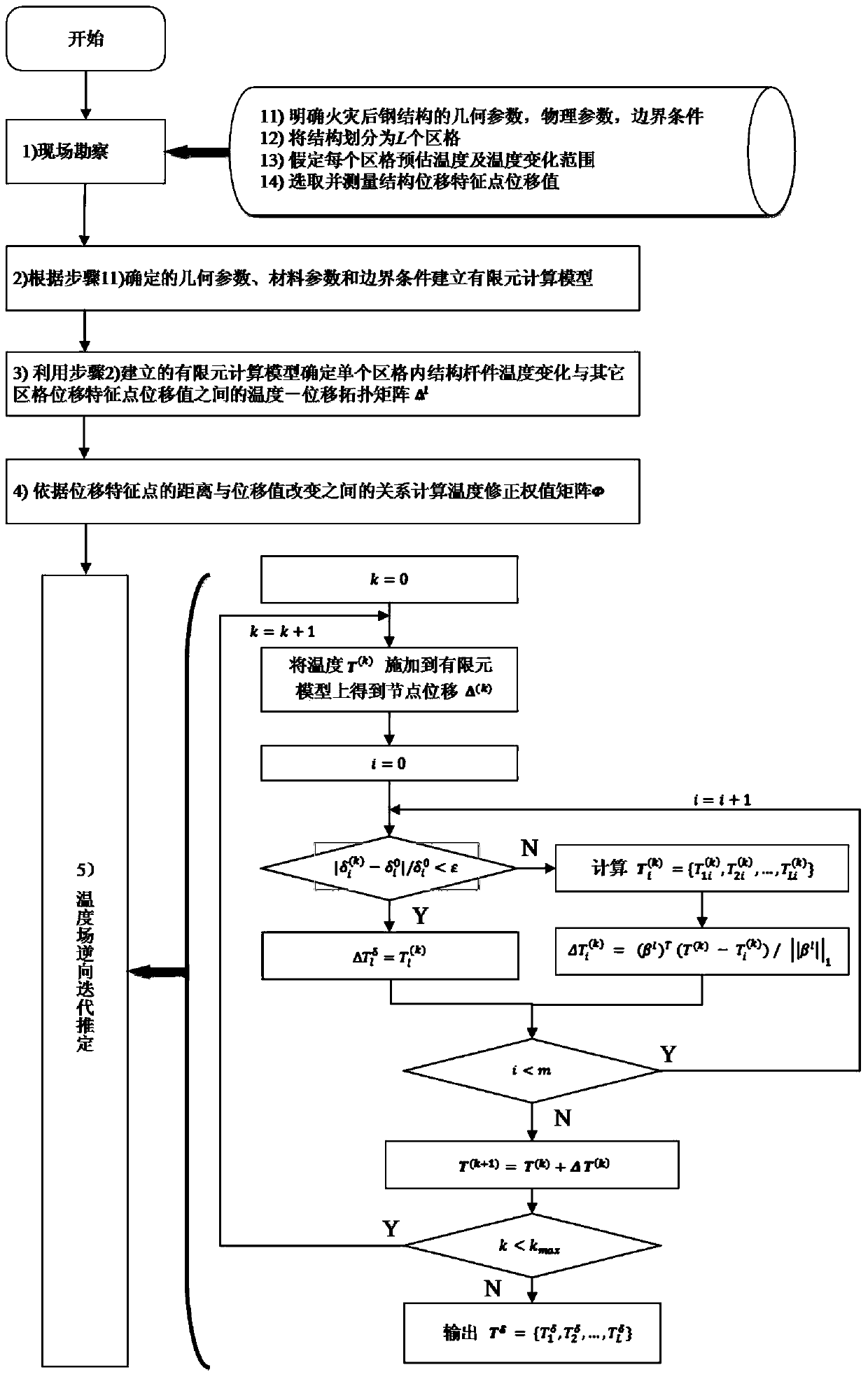

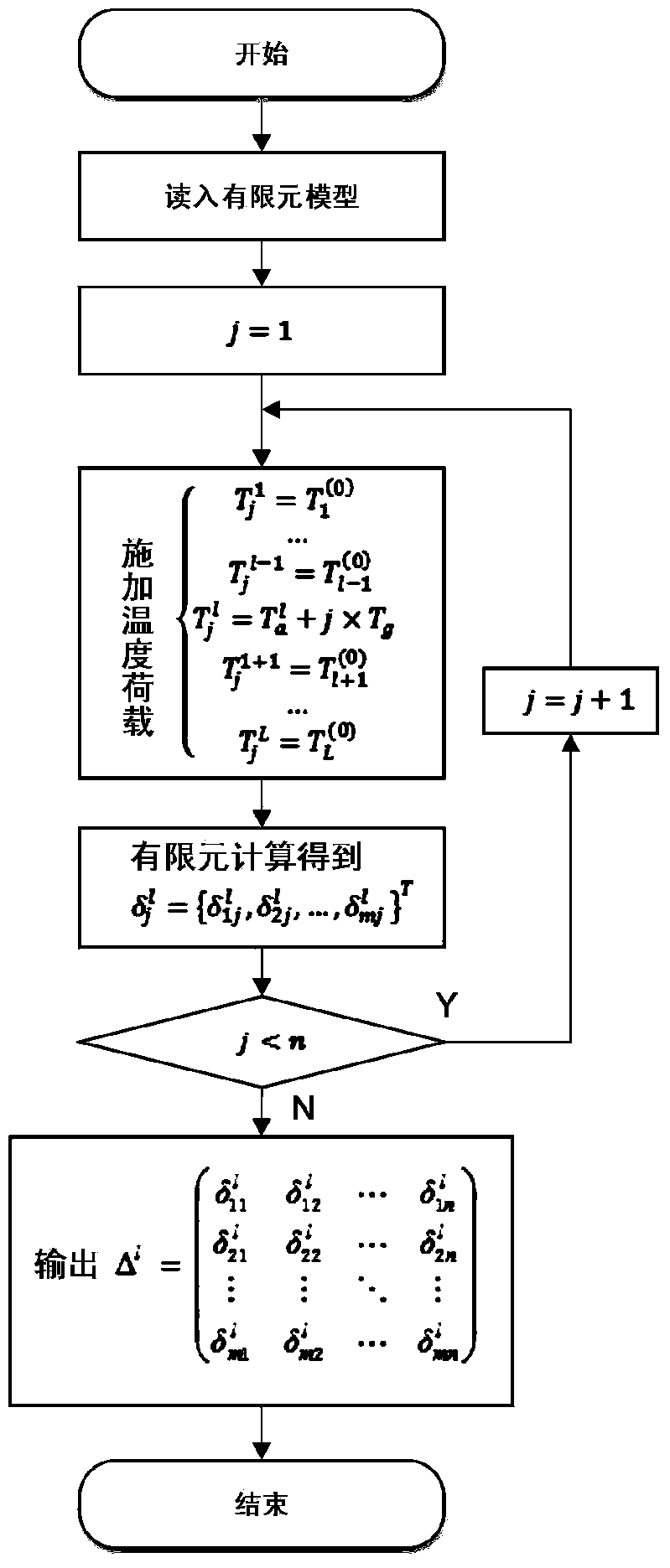

Method used

Image

Examples

Embodiment 1

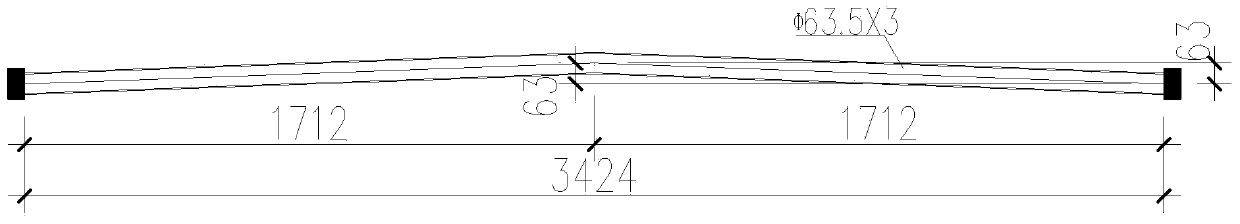

[0086] Such as image 3 It is the dimensional drawing of Williams double-bar steel structure, with a total length of 3424mm and a height of 63mm. The steel material is Q235B ordinary structural steel, and the section of the bar is fixed at both ends. Measure and record the temperature of the Williams double-rod steel structure in the fire test, and compare it with the results of the method of the present invention.

[0087] 1) Site survey

[0088] 11) According to the field survey, the geometric conditions of the Williams double-bar steel structure after the fire are 3424mm in total length, 63mm in height, and cross-section of the bar; the boundary conditions are fixed support conditions at both ends; the trace features include the paint color of the bar at both ends of the steel structure From sky blue to dark blue with condensation, the paint on the middle members is peeled off, and the steel exposed in the air is black. The remaining structural features include the mid-spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com