A X-ray Light Field Imaging and Calibration Method Based on Pinhole Array

A pinhole array and light field imaging technology, which is applied in the fields of radiological diagnostic equipment, medical science, and diagnosis, can solve the problems of missing depth information of X-ray images, overlapping images of different depths, and difficulty in distinguishing them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An X-ray light field imaging and calibration method based on a pinhole array, comprising the following steps:

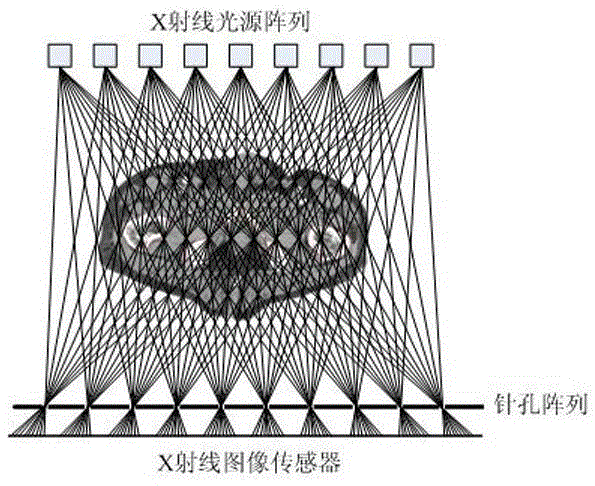

[0047] Step 1: Establish an X-ray light field imaging model based on a pinhole array, the schematic diagram of the imaging plane structure is as follows figure 1 As shown, it includes an X-ray light source array, a pinhole array and an X-ray image sensor. The X-ray image sensor adopts a digital image sensor that can directly image X-rays. The X-ray image sensor array is a group of digital image sensors that can be directly imaged by X-rays. In this embodiment, what the image sensor adopts is a CCD or CMOS chip.

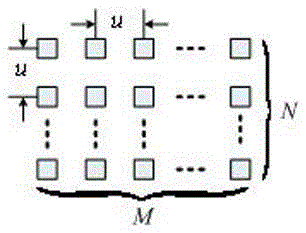

[0048] The X-ray light source array is a two-dimensional planar array of M×N orthogonal arrangements composed of multiple X-ray light sources, such as figure 2 shown. The size of the X-ray light source array determines the angular resolution of the X-ray light field imaging.

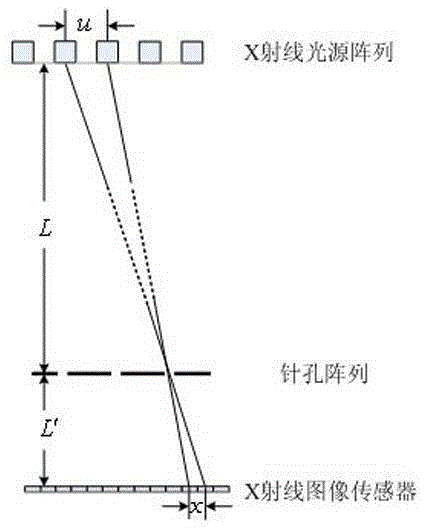

[0049] according to image 3 In the X-ray pinhole imaging geometry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com