Millstone crusher

A crusher and disc-type technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems of complex crushing process, small crushing ratio, and increased crushing time, and achieve simple crushing process, high grinding force, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

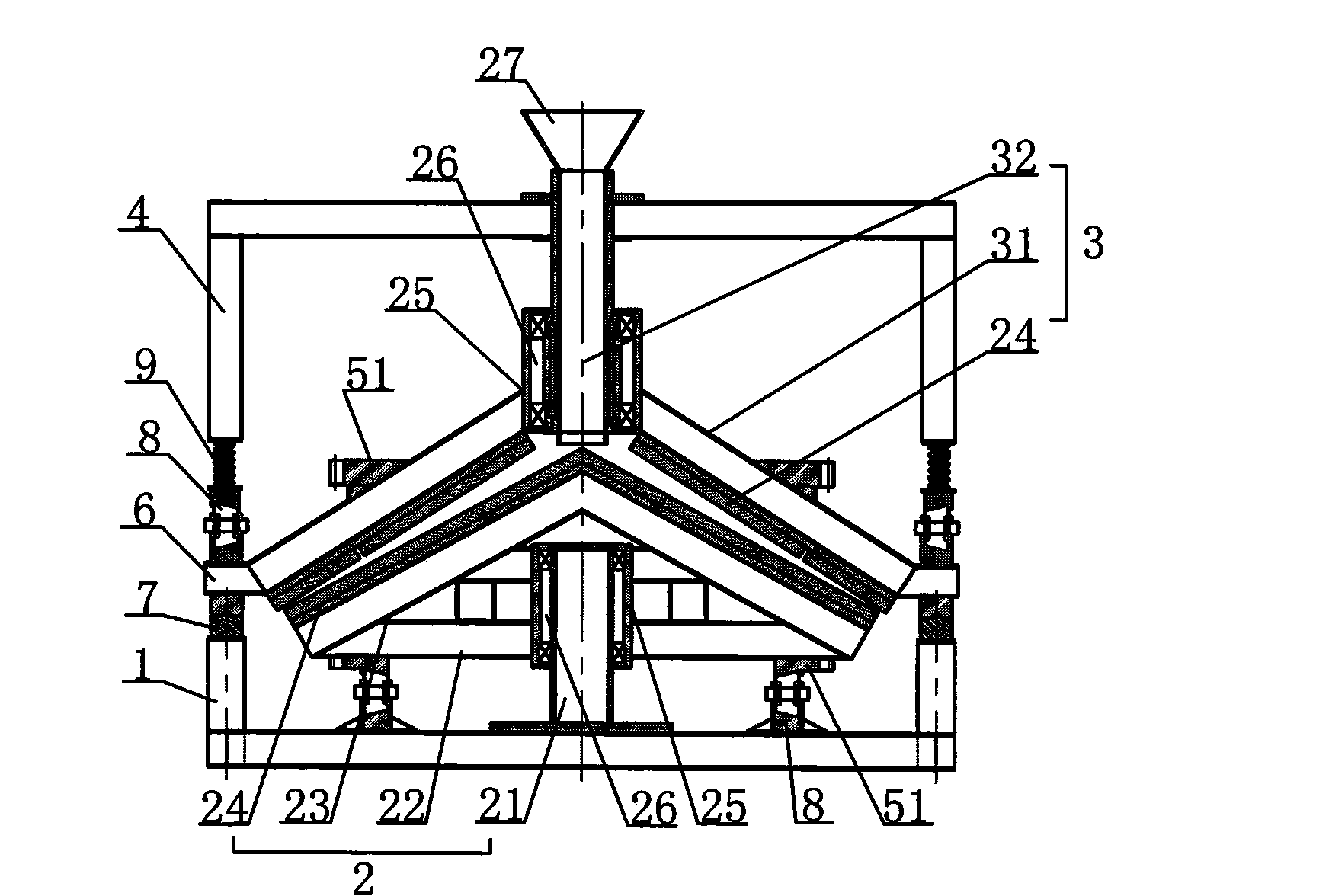

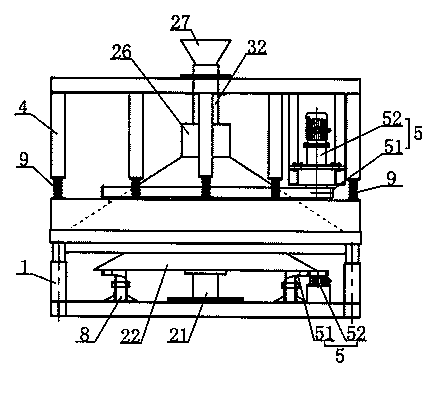

[0021] like figure 1 and figure 2 As shown, the structure schematic diagram of the millstone crusher of the present invention, it comprises lower bracket 1, lower millstone crushing device 2, upper millstone crushing device 3, upper bracket 4 and driving device 5, and lower millstone crushing device 2 is installed on the lower support 1, The upper millstone crushing device 3 is installed on the upper bracket 4 and suspended above the lower millstone crushing device 2, and the drive device 5 drives the lower millstone crushing device 2 and the upper millstone crushing device 3 to rotate in reverse respectively; the lower millstone 2 includes a mandrel 21 , the tray 22, the lower cone cover 23 and the crushing wall 24, the mandrel 21 is fixed on the lower bracket 1, the center of the tray 22 is provided with a through hole 25, the through hole 25 is fixed with a bearing 26, and the tray 22 is set on the mandrel through the bearing 26 21, the lower cone cover 23 is fixed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com