Method and clamp for clamping thin-walled cylinder-shaped workpieces

A thin-walled cylinder and workpiece technology, applied in the field of mechanical design, can solve problems such as workpiece clamping deformation, low production efficiency, and difficult to guarantee machining accuracy, and achieve the effect of preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

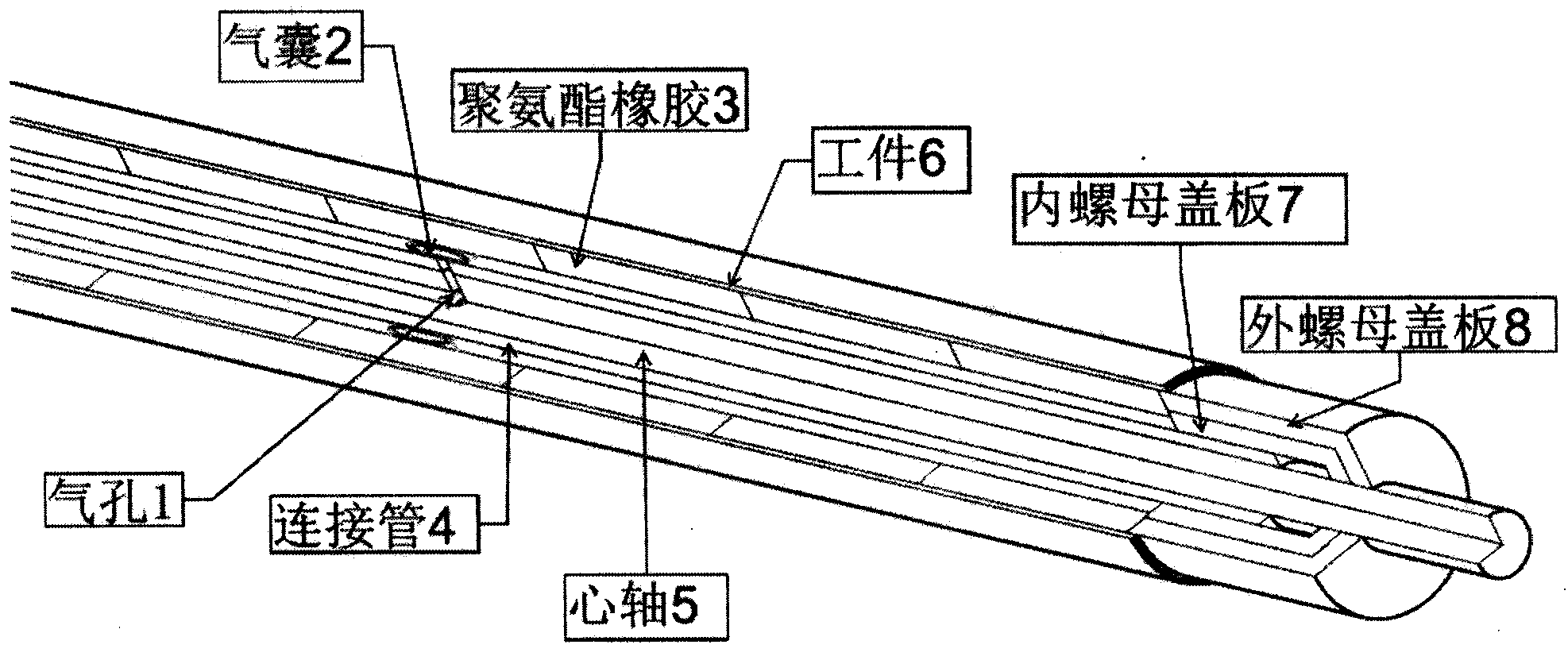

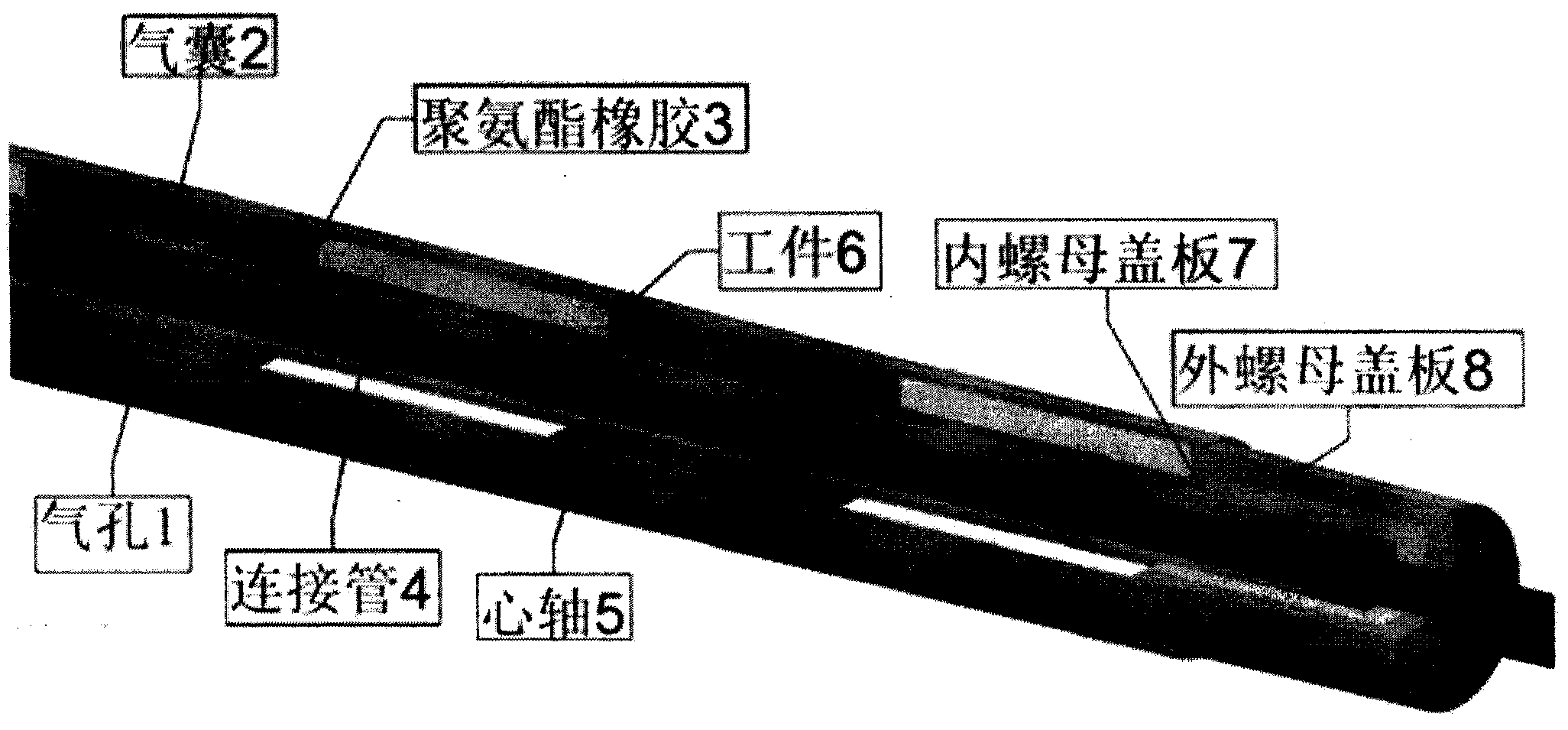

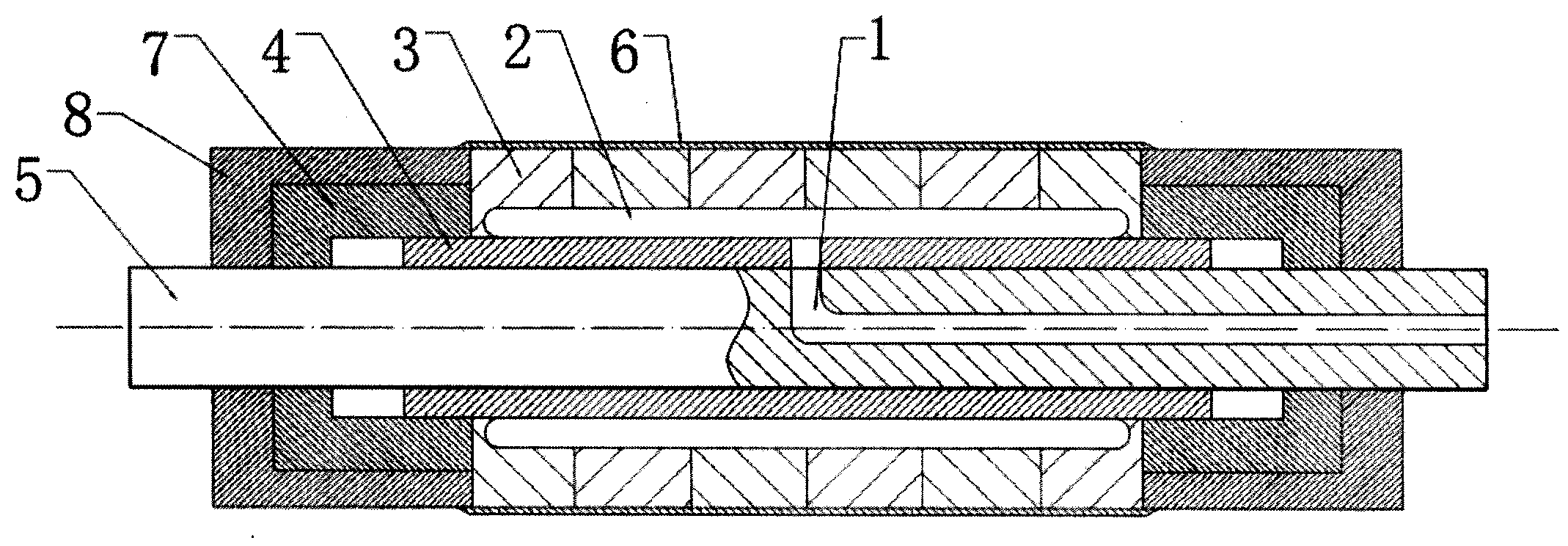

[0012] Tighten the inner nut cover plate 7 with a small force so that there is no gap between each section of the rubber sleeve, and then tighten the outer nut cover plate 8 with the same force. The outer diameter of the outer nut cover plate 8 is slightly smaller than the workpiece 6 inner diameter. At this time, the air bag 2 is inflated through the air hole 1 at the end of the mandrel 5, and the air bag 2 expands so that the polyurethane rubber 3 elastically deforms outward along the diameter of the mandrel, and is inflated to clamp the workpiece. The roughness of the contact part between the outer nut cover plate 8 and the rubber is relatively high. At this time, tighten the outer nut cover plate 8 with greater force to apply a pre-tightening force to the rubber sleeve to drive the outer ring of the rubber sleeve to rotate at a certain angle to prevent the workpiece from being processed. tremors. The screw thread of mandrel 5 left half is opposite to the screw thread of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com