Titanium alloy skin laser cutting method based on flexible supporting device

A flexible support and laser cutting technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that affect the cutting accuracy of parts, the parts and fixtures cannot be tightly fitted, and occupy a large inventory area, so as to reduce scrap rate and repair rate, reduce the labor intensity of workers, and reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

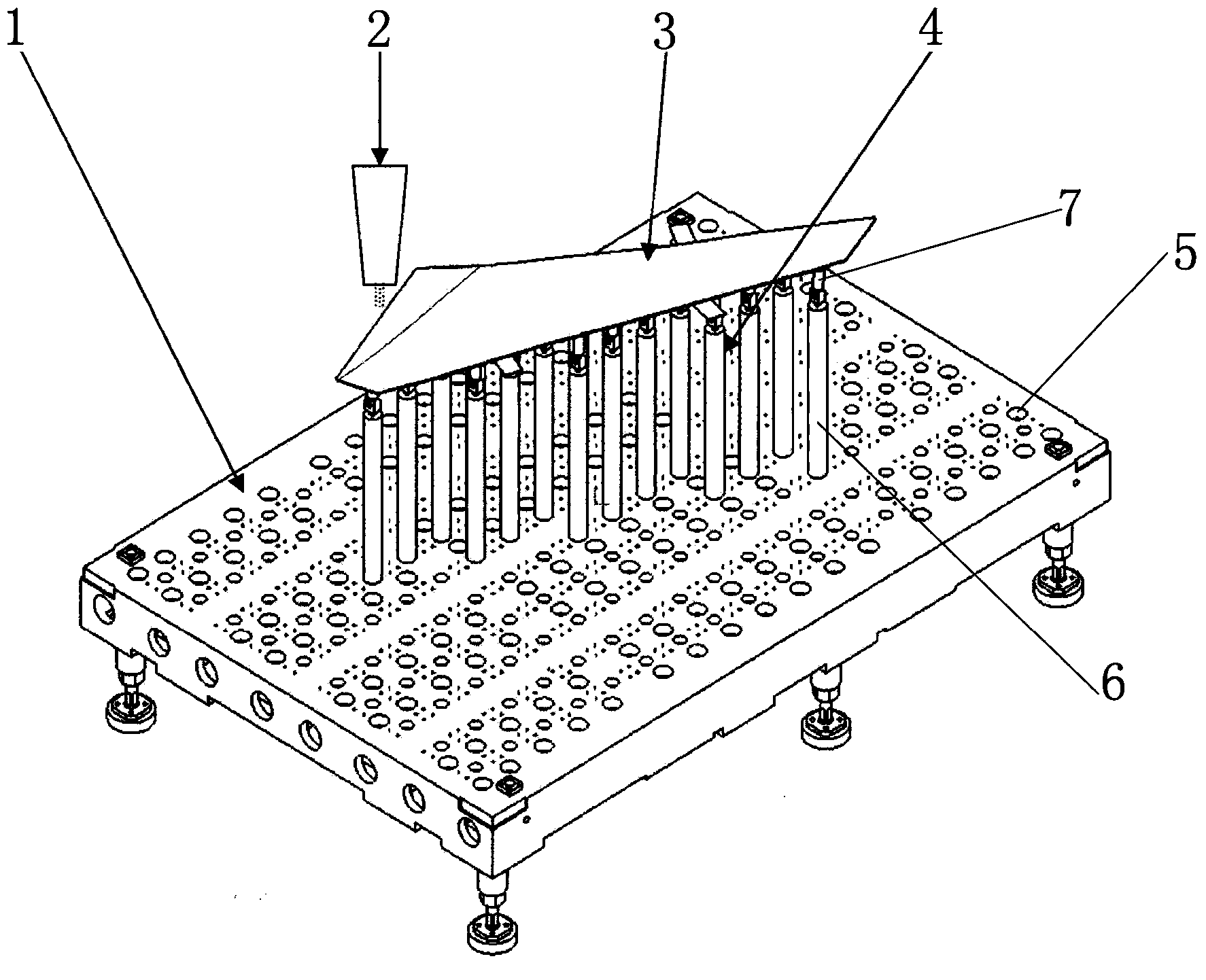

[0019] Such as figure 1 Shown is a schematic diagram of the flexible supporting device and the laser cutting of the titanium alloy skin. The flexible supporting device includes a platform 1 , holes 5 evenly distributed on the platform 1 , positioning rods 4 and supporting rods 6 placed in the holes 5 .

[0020] A kind of laser cutting method of titanium alloy skin based on flexible supporting device, comprises the steps:

[0021] 1) Design the digital model of the titanium alloy skin 3 according to the drawing requirements of the titanium alloy skin 3, design three lugs on the digital model of the titanium alloy skin 3, the three lugs respectively have a positioning hole, and three positioning holes The projection of the hole center on the XY plane is an integer multiple of 100mm in the X and Y directions, and the process digital model of the titanium alloy skin 3 is generated;

[0022] 2) Based on the process digital model, manufacture a titanium alloy skin 3 with three lugs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com