Double-clamping flat-pushing non-gravity-type electro-hydraulic vehicle retarder

A double-clamp flat-push, non-gravity technology, applied in track brakes, railway car body parts, transportation and packaging, etc., can solve problems affecting normal marshalling operations, large changes in braking force, and unstable braking friction , to achieve the effect of low service life, low working pressure and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

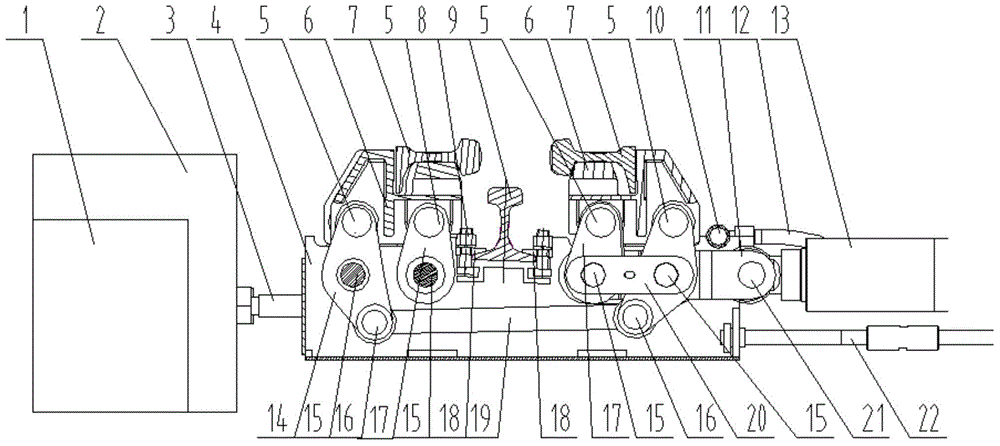

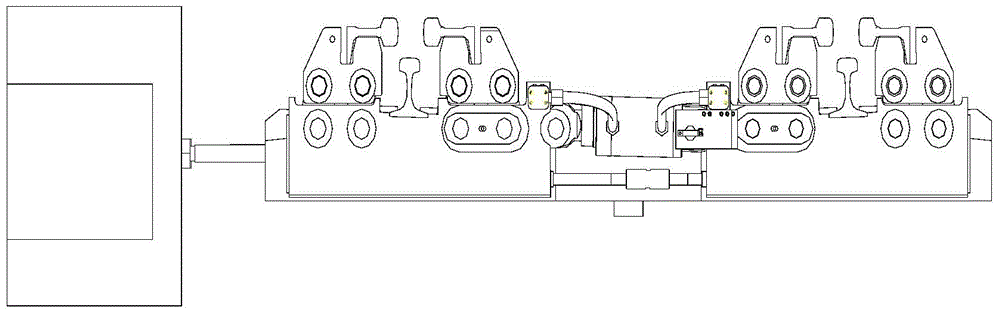

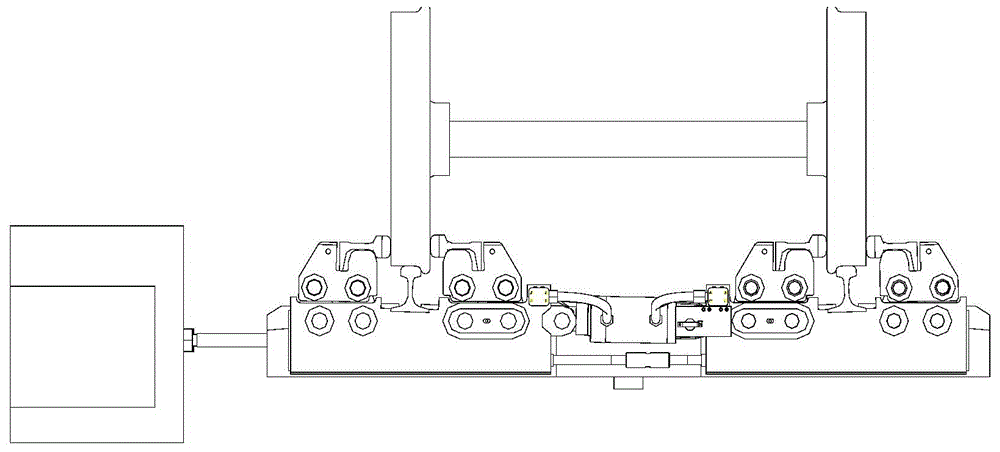

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1~4 As shown, a double-clamp flat-push non-gravity electro-hydraulic vehicle speed reducer includes a speed reducer installed on the basic rail 9 and a brake splint 7, and the speed reducer is a double-clip flat-push brake mechanism, including two complete For the same brake mechanism unit, a double-rod cylinder 13 is arranged between the two brake mechanism units, and is symmetrical about the double-rod cylinder 13 . The brake pads 7 are respectively in contact with the side surfaces of the wheels to achieve the purpose of braking. The oil cylinder 13 is connected with the hydraulic station 2 and the electric control box 1 . The hydraulic station 2 is connected with the oil cylinder 13 through the oil pipe, and the oil pipe includes the main rubber hose 3, the oil distribution pipe 10, and the rubber hose 12 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com