Slipping installation method of big flue of sintering machine and rail installation mechanism thereof

An installation method and large flue technology, applied in the direction of mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of high cost of machinery, low work efficiency, hidden safety hazards, etc., to save labor, facilitate implementation, avoid The effect of crooked pull and oblique hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

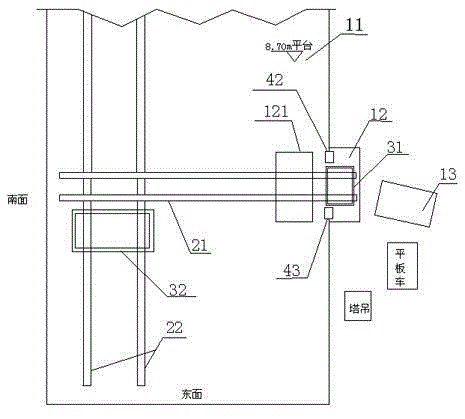

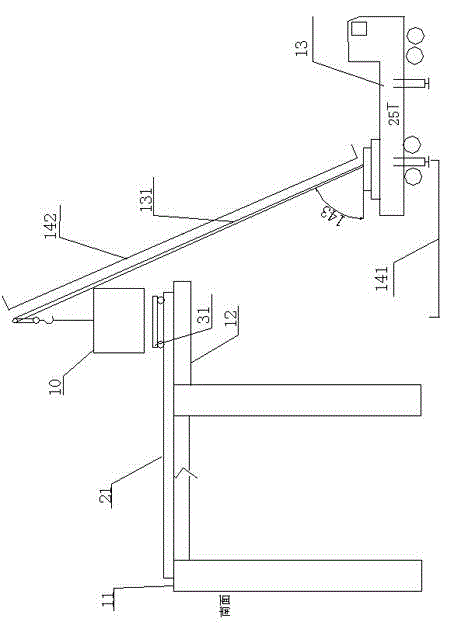

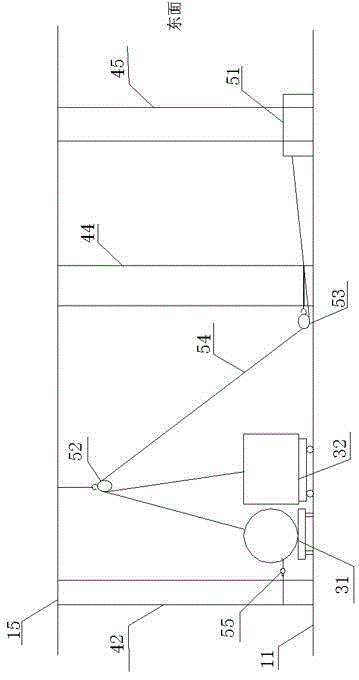

[0031] The specific steps of the sliding installation method for the large flue of the sintering machine described in the present invention are as follows: figure 1 , figure 2 , image 3 , Figure 4 shown in the following:

[0032]Including the following steps, the hoisting and transfer steps of the large flue, hoisting the large flue 10 to be installed to the horizontal transfer trolley 31 at the lifting platform 12 of the hoisting hole with a lifting device, and then transferring it to the horizontal transfer rail 21 by the horizontal transfer trolley 31 The transfer place with the longitudinal transfer track 22; use the hoist 51 and the wire rope 54 to cooperate with the first pulley 52 and the second pulley 53 to lift the large flue 10, and hoist the large flue 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com