Return-type material taking system and material stacking and taking method for bridge-type roller material taking machines of raw material storage yard

A reclaimer and stacker technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem that the stacking operation and the reclaiming operation cannot be carried out at the same time, increase the investment and maintenance costs and labor costs of equipment and infrastructure, and reduce the cost. Equipment use efficiency and other issues, to achieve the effect of realizing uninterrupted operation, reducing equipment and infrastructure investment, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the patent of the present invention will be described below in conjunction with the drawings.

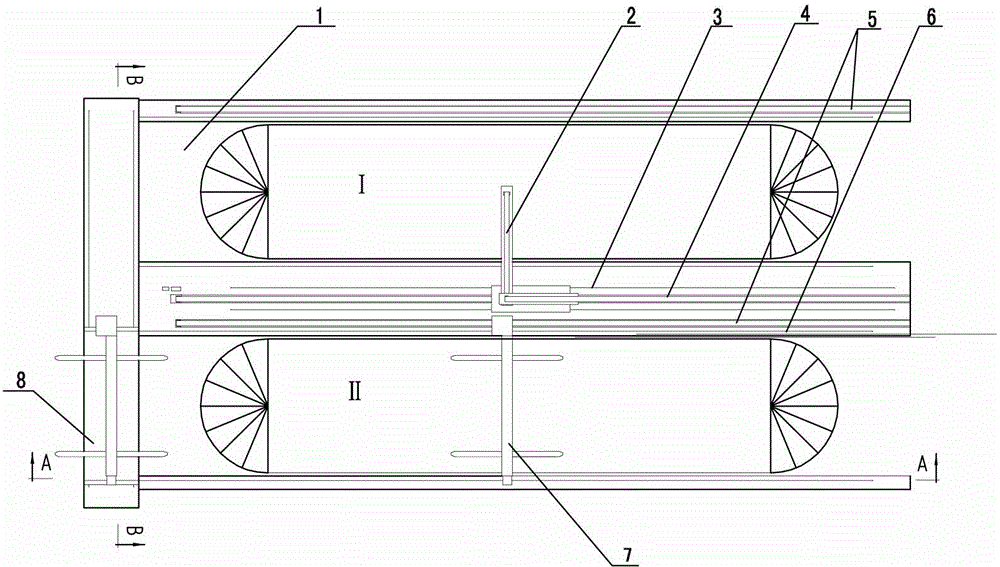

[0022] Such as Figure 1-3 As shown, the turn-back stacking and reclaiming system of the bridge-type drum reclaimer of the raw material storage yard of the present invention includes two or more strips arranged in parallel in the raw material storage yard 1, a rocker stacker 2 and a bridge The roller reclaimer 7 is characterized in that a rocker arm stacker track 3 is arranged between every two strips, that is, strip I and strip II, and the rocker stacker 2 is arranged on the strip Ⅰ and strip Ⅱ are in rolling connection with the rocker stacker track 3, and a stacking belt conveyor 4 is provided at the lower part of the rocker stacker 2;

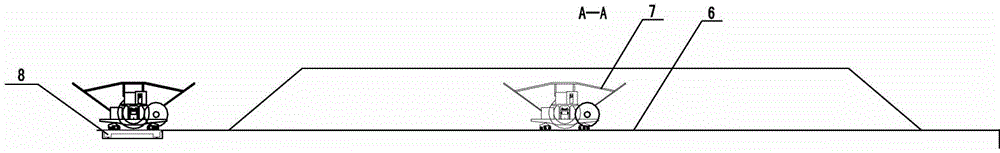

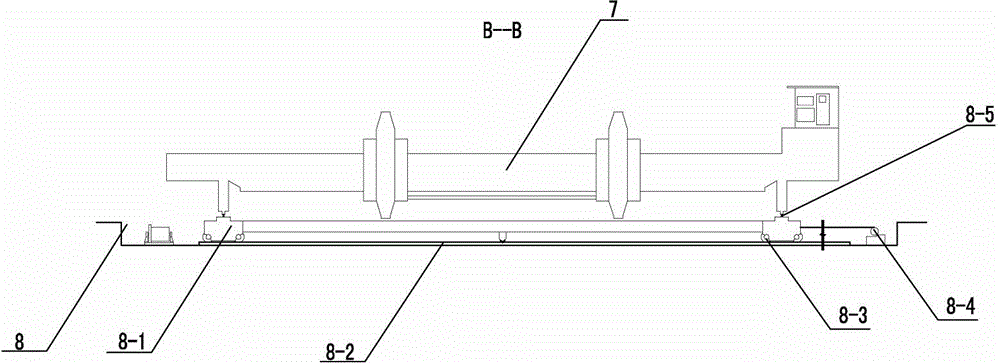

[0023] A bridge-type drum reclaimer track 6 is provided on both sides of each strip. The bridge-type drum reclaimer 7 is arranged across the strip and is connected in rolling connection with the bridge-type drum r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com