Steel band rolling-up pressing arm

A technology of pressing arms and steel strips, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve problems such as the influence of unloading of steel strip winders, and achieve the effect of simple structure and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

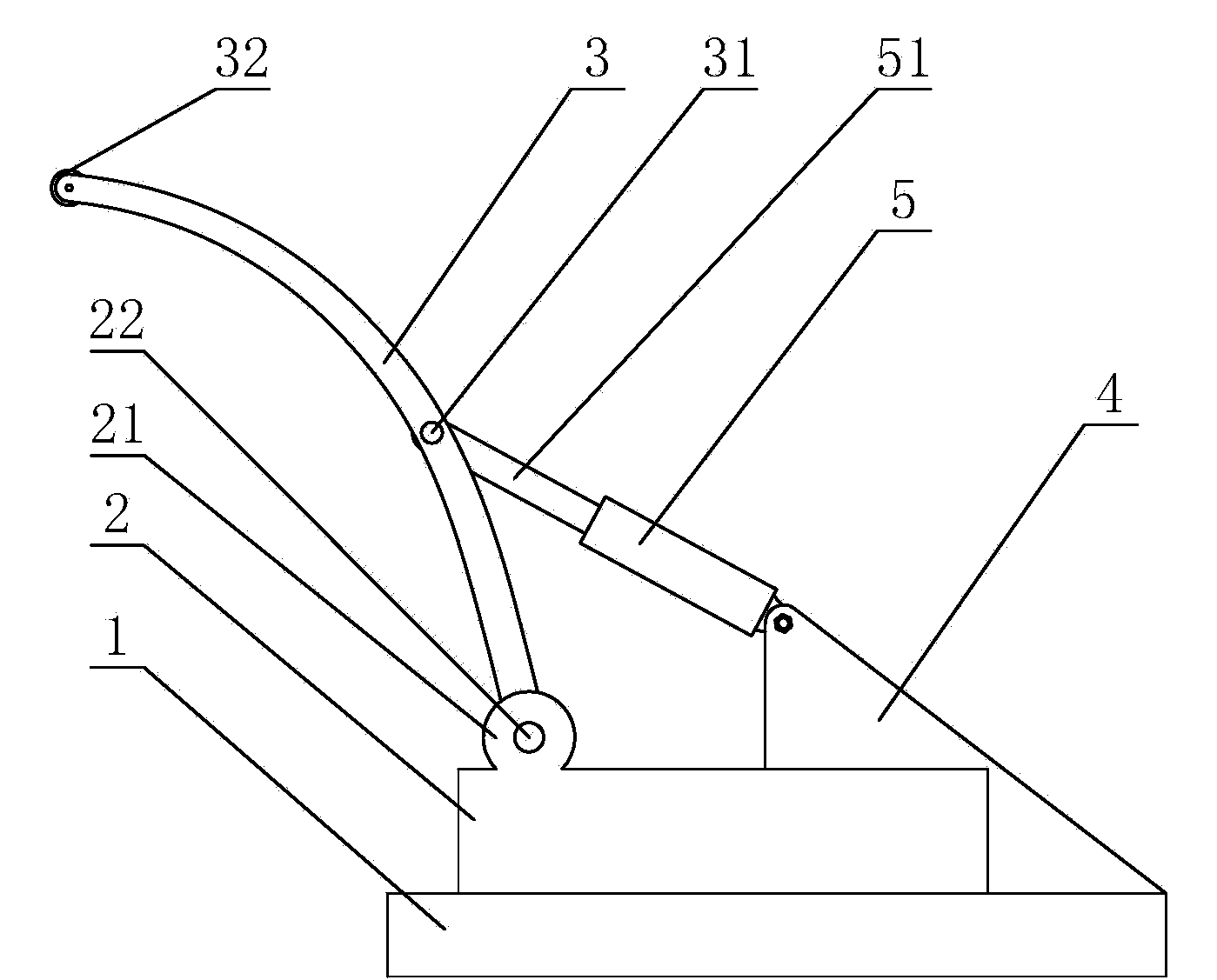

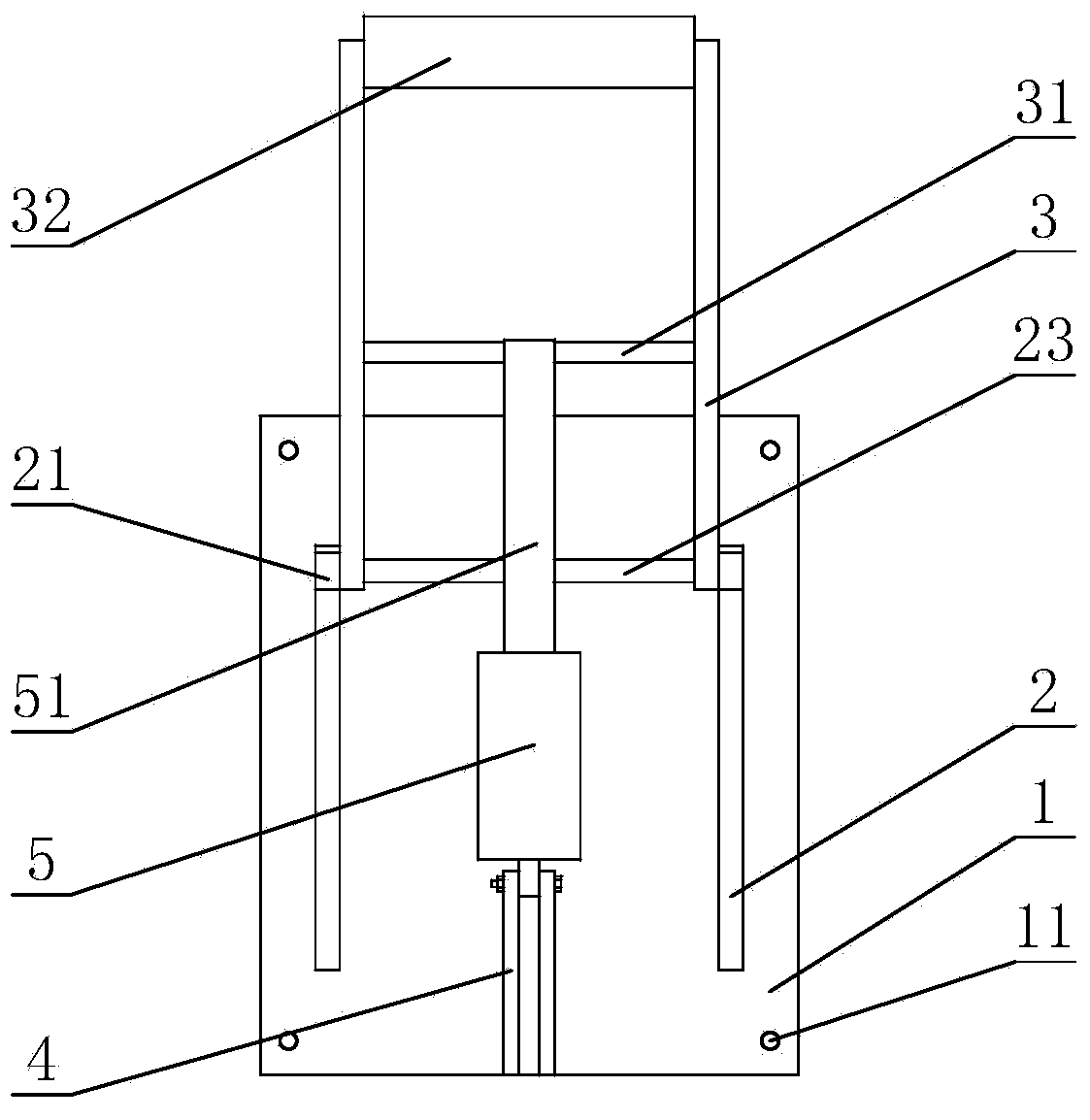

[0015] Such as Figure 1 to Figure 2 As shown, the steel strip winding pressing arm includes a base plate 11, a side plate 2, an arc pressing arm 3, a cylinder 4 and a pressing roller 32, and the base plate 1 is nailed into the four through holes 11 provided around the base plate 1. The screw is fixed on the ground on one side of the main shaft of the winding machine, and two side plates 2 are integrally fixed symmetrically on the left and right sides of the bottom plate 1, and the side plate 2 is provided with a pressing arm installation part 21, and the A mounting hole 22 is opened on the pressing arm mounting part 21, and a connecting rod 23 is fixed in the mounting hole 22. The lower end of the arc-shaped pressing arm 3 is rotatably connected to the connecting rod 23, and is connected to the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com