Flexible torque control system capable of eliminating stick-slip vibration of drill column and control method

A technology of torque control and stick-slip vibration, which is applied in the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of drilling engineering impact, achieve the effect of eliminating stick-slip vibration and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

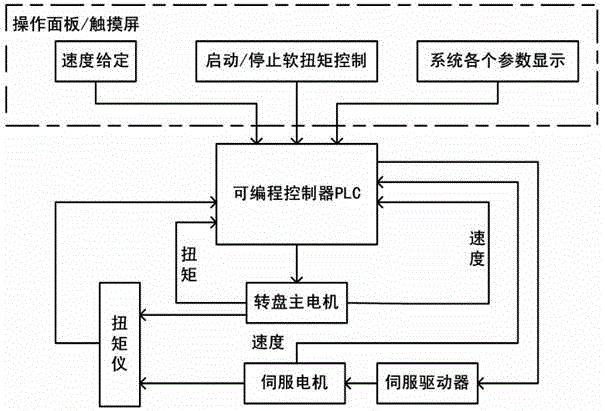

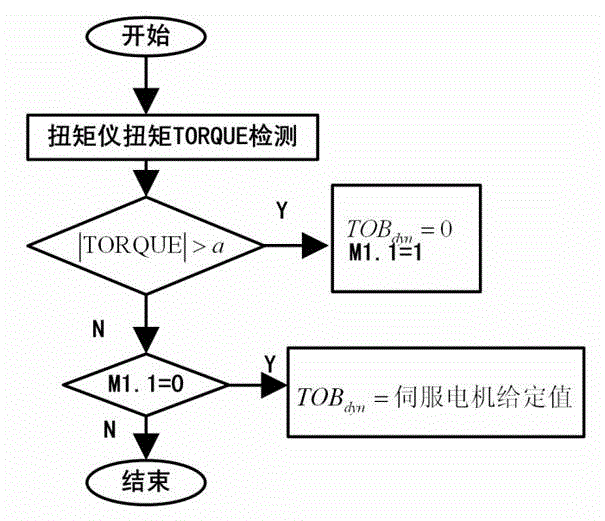

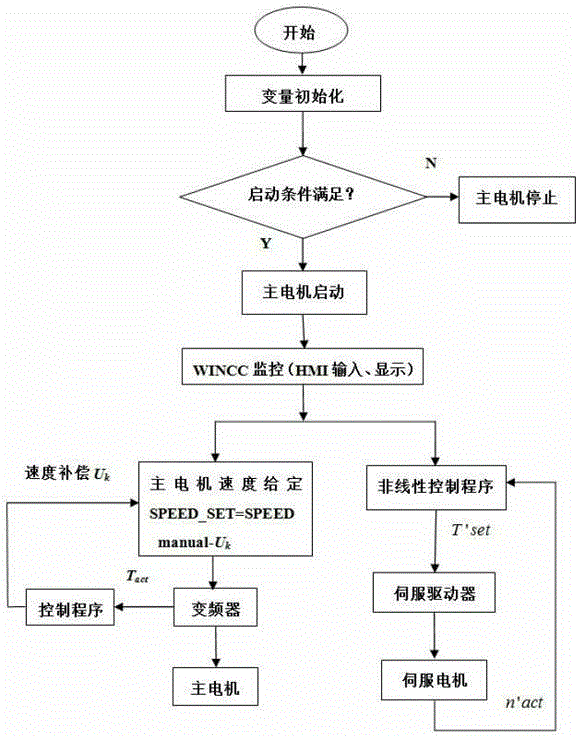

[0040] see Figure 1 to Figure 10 , a flexible torque control system that can eliminate the stick-slip vibration of the drill string, such as figure 1 As shown, it includes a touch screen or an operation panel with a display screen, a programmable logic controller PLC, a main motor with an encoder, a high-speed counter, a torque meter, a servo motor and a servo driver;

[0041] The touch screen or the operation panel is directly connected with the programmable controller PLC, and is used for displaying the given speed and rotational torque of the main motor, setting the given value of the main motor speed and displaying system parameters;

[0042] The programmable controller PLC collects the actual torque value of the main motor and compares the difference between the torque value of the main motor and the actual torque value of the servo motor monitored by the torque meter, and compares the deviation after comparison to the entire drill string system. Corresponding deviatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com