Polar axis calibration mechanism of equatorial telescope and calibration method thereof

A technology of calibration mechanism and equatorial mount, which is applied in astronomy and measurement fields, can solve the problems of complex steps, increase user inconvenience, and cumbersome, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

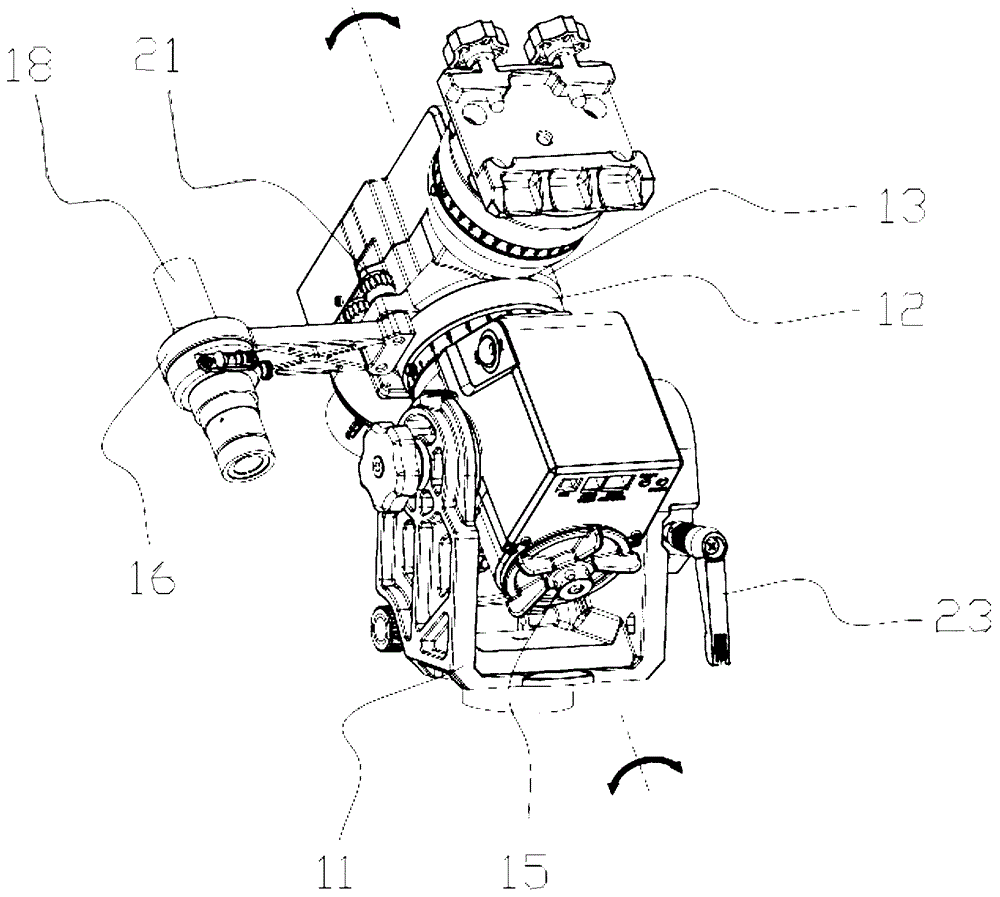

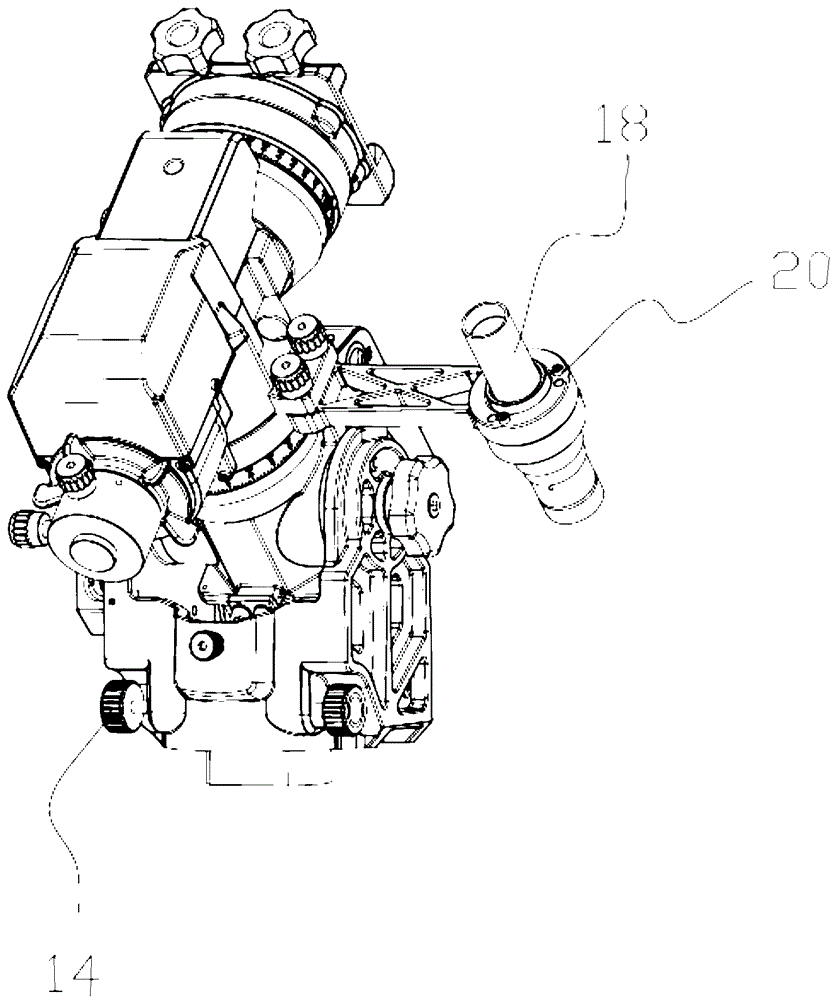

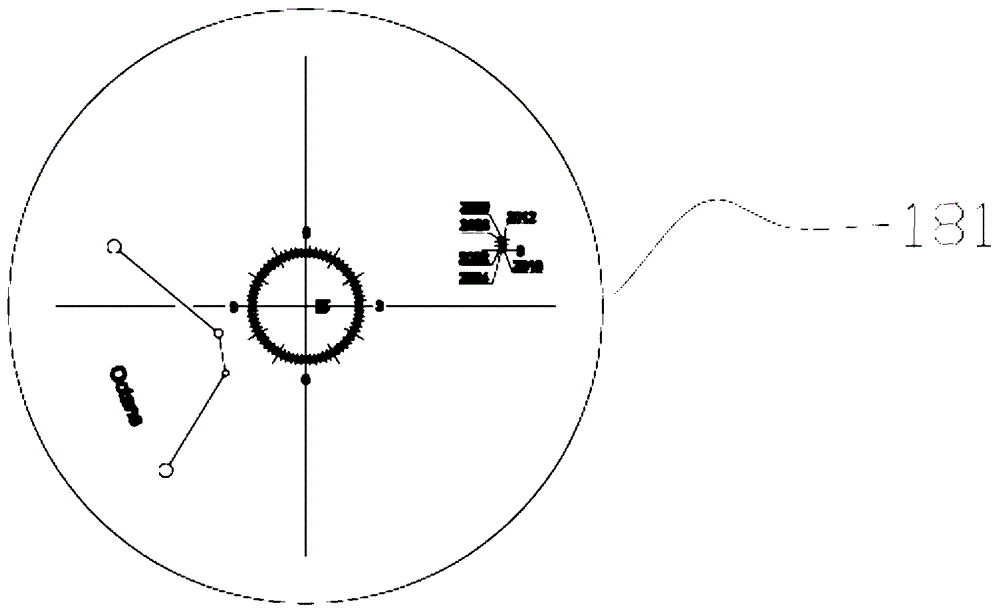

[0035] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

[0036] see Figure 1-4 As shown, a polar axis calibration mechanism of an equatorial mount, the equatorial mount includes a base 11, an hour angle assembly 12 mounted on the base 11, a declination assembly 13 fixedly connected to the end face of the hour angle assembly 12, and an hour angle assembly 12 The connected latitude adjustment mechanism, the horizontal azimuth handwheel 14 located at the lower end of the base 11 and the hour angle locking handwheel 15 located at the end of the hour angle assembly 12, the latitude adjustment mechanism is used to adjust the pitch angle of the equatorial mount, so that the time The angle assembly 12 rotates around the base 11, the horizontal azimuth handwheel 14 is used to adjust the horizontal angle of the equatorial mount, and the hour angle locking handwheel 15 is used to lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com