Tow-position six-way reversing valve for pressure-adjusting type suspended load sampler

A suspended mass sampler, two-position six-way technology, applied in the direction of sampling devices, etc., can solve the problems of easy breakage of gear teeth, long pressure adjustment time, complex structure, etc., and achieve adjustable sealing pressure, extended working life, Simple effect of drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

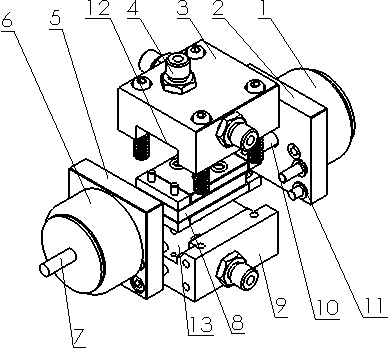

[0033] see figure 1 , Figure 4 , the two-position six-way reversing valve for the pressure-regulating suspended mass sampler consists of electromagnets 1 and 6 mounted on the end covers 2 and 5, a valve cover 3, a valve body 9, positioning blocks 25, 26 and 27, 28 and Ceramic spool 8 composition.

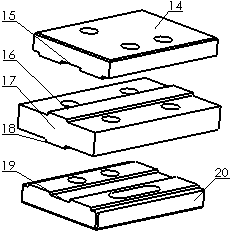

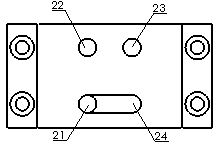

[0034] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the ceramic valve core 8 is made up of the upper static plate 14, the moving plate 17, and the lower static plate 20. There are water holes 21 and vent holes 22, 23 on the upper static piece 14, and there is a blind groove 24 communicating with the water hole 21 on the contact surface of the upper static piece 14 relative to the moving piece 17; Water holes 33, 36 and air holes 34 have blind grooves 35 communicating with air holes 34 on the contact surface of the lower static plate 20 relative to the moving plate 17; water holes 29, 32 and air holes are arranged on the moving plate 17. 30, 31. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com