Detection tool for lens of output jumper wire of laser device

A technology for detecting tooling and lasers, applied in the direction of optical testing flaws/defects, etc., can solve the problem of inability to directly and clearly observe the lens, etc., to achieve convenient and reliable detection, ensure cleaning work, and improve the effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

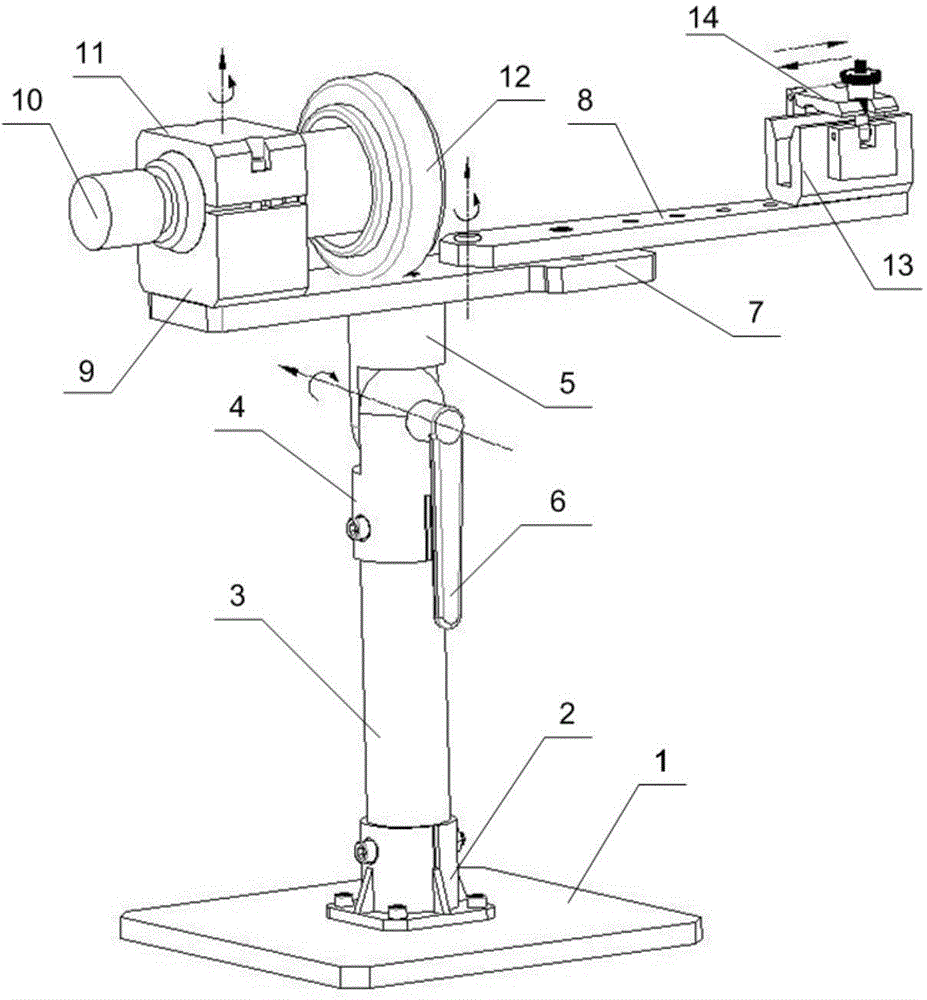

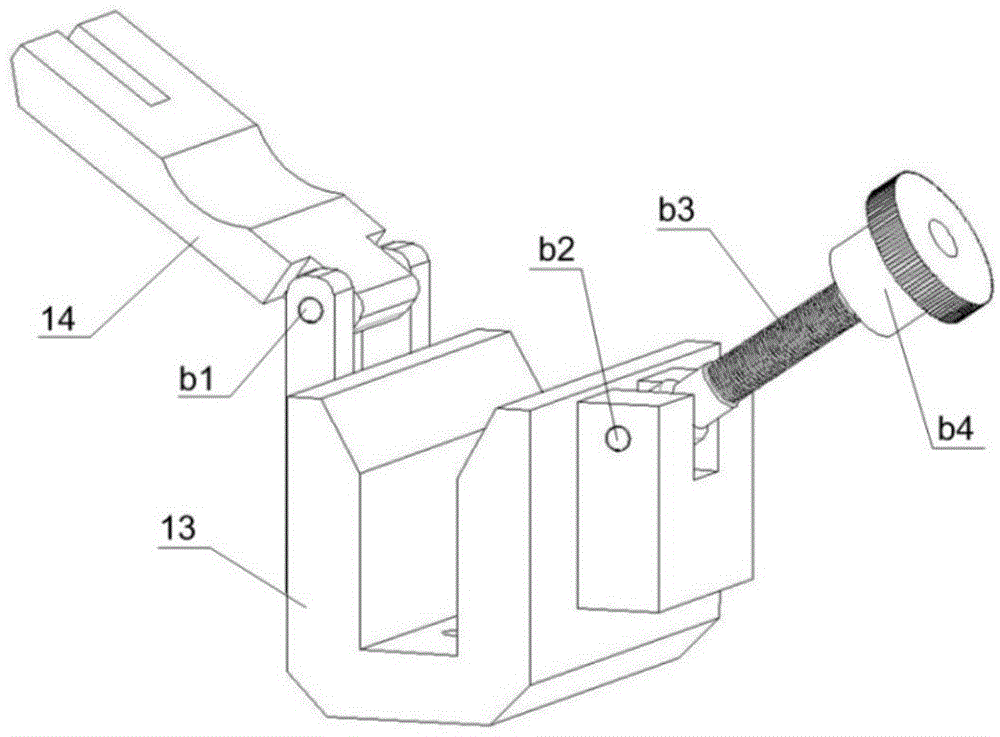

[0021] figure 1 A schematic diagram of this embodiment is shown. Referring to the figure, this embodiment consists of a rotatable bracket, a microscope group and a clamping seat, the microscope group and the clamping base are respectively installed on the rotatable bracket, and the rotatable bracket is used to support the microscope group and the clamping seat , the microscope group is used to enlarge the surface of the jumper lens for observation, and the clamping seat is used to clamp the output jumper of the laser to be tested.

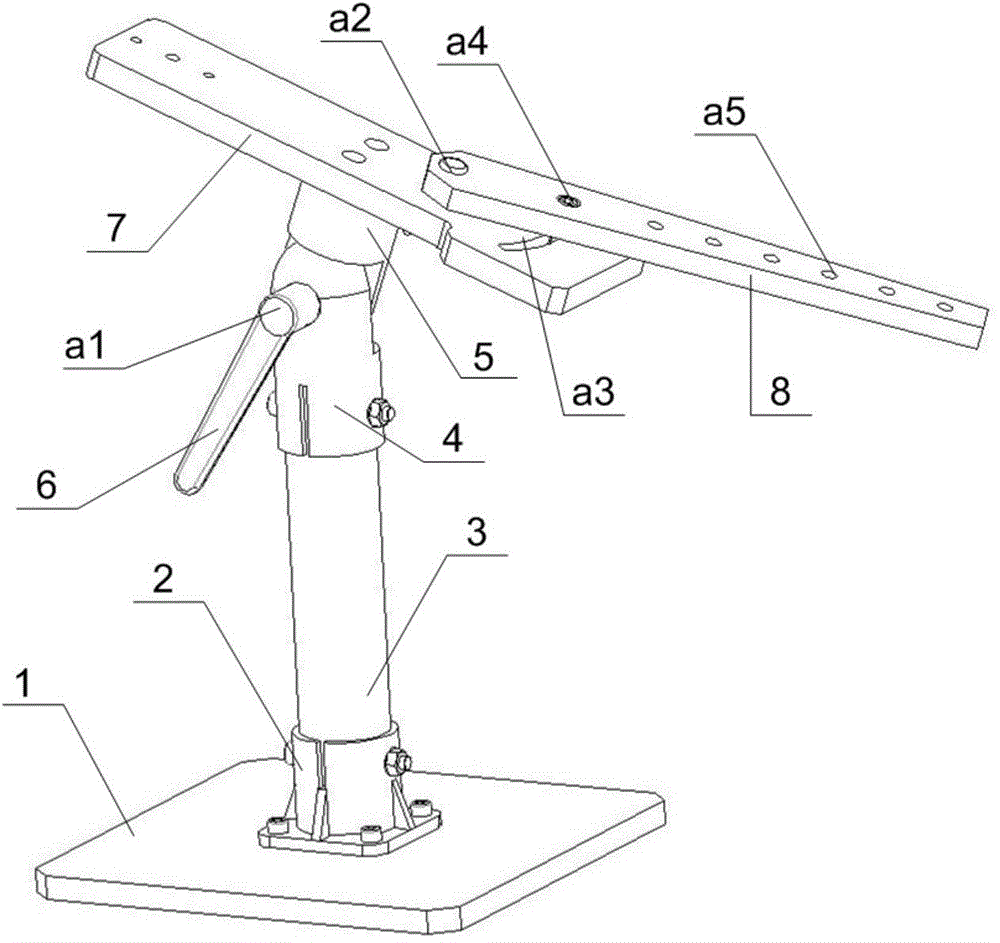

[0022] Such as figure 1 , figure 2 As shown, the rotatable bracket is composed of a bottom plate 1, a base 2, a pillar 3, a lower rotating column 4, an upper rotating column 5, a handle 6, a mounting plate 7 and a rotating plate 8; wherein the lower rotating column 4, the upper rotating column 5 It is connected with the handle 6 through the square neck screw a1; the rotation of the handle 6 can drive the rotation of the square neck screw a1, an...

Embodiment 2

[0026] The structure of the laser output jumper lens detection tool provided in this embodiment is the same as that in Embodiment 1. According to the difference between the height of the jumper to be detected and the observation environment, the angle between the upper rotating column 5 and the lower rotating column 4 can be adjusted through the handle 6, so as to observe the output jumper lens, such as Figure 4 shown.

Embodiment 3

[0028] The structure of the laser output jumper lens detection tool provided in this embodiment is the same as that in Embodiment 1. When it is necessary to detect the laser output jumper lens from different angles, the angle between the clamping seat and the microscope 10 can be adjusted by rotating the rotating plate 8 to obtain multi-angle observations, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com