Display module structure and installing method thereof

一种显示模组、安装方法的技术,应用在非线性光学、仪器、光学等方向,能够解决不利整机成本控制、生产成本高等问题,达到利于整机成本控制、适配性强、尺寸灵活的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

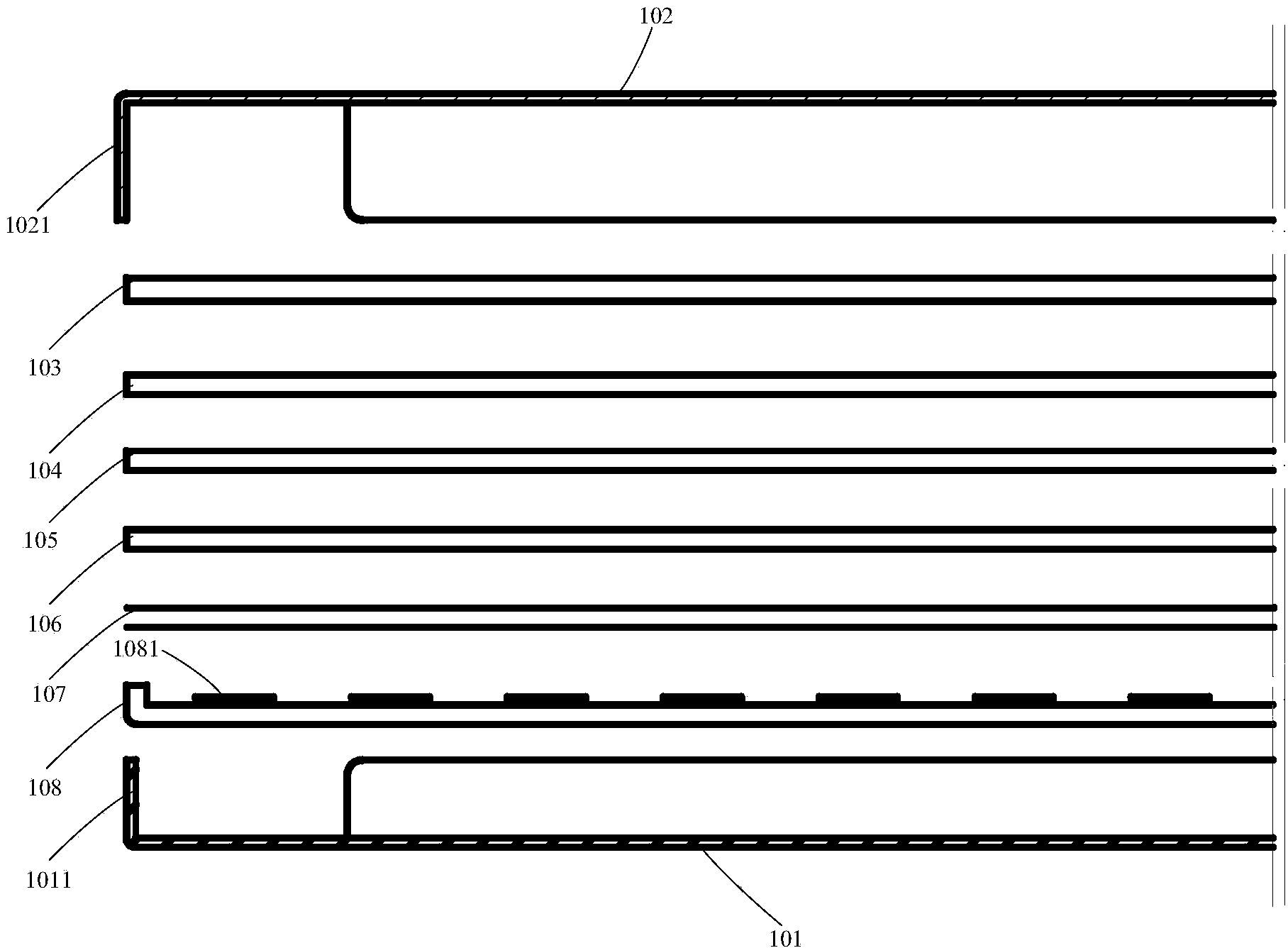

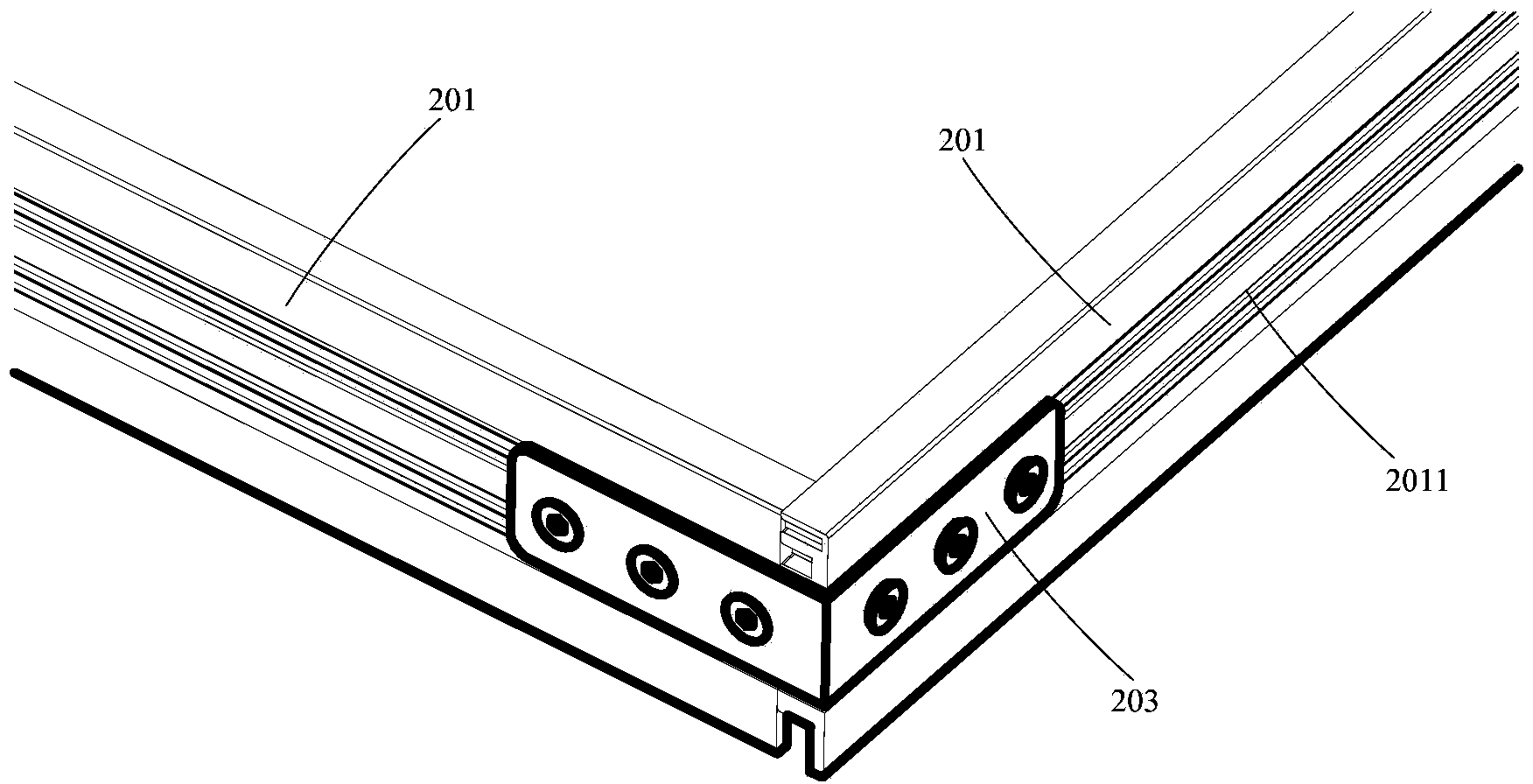

[0051] For the convenience of description, such as Figure 14 As shown, the detailed description is defined as follows: the four sides B surrounded by the installation frame are the inner side, the side C opposite to the inner side is the outer side, and the end face D connected between the installation frame and the liquid crystal panel (open cell) is the installation frame. The first end, the end face E where the installation frame is connected to the light panel is the second end of the installation frame.

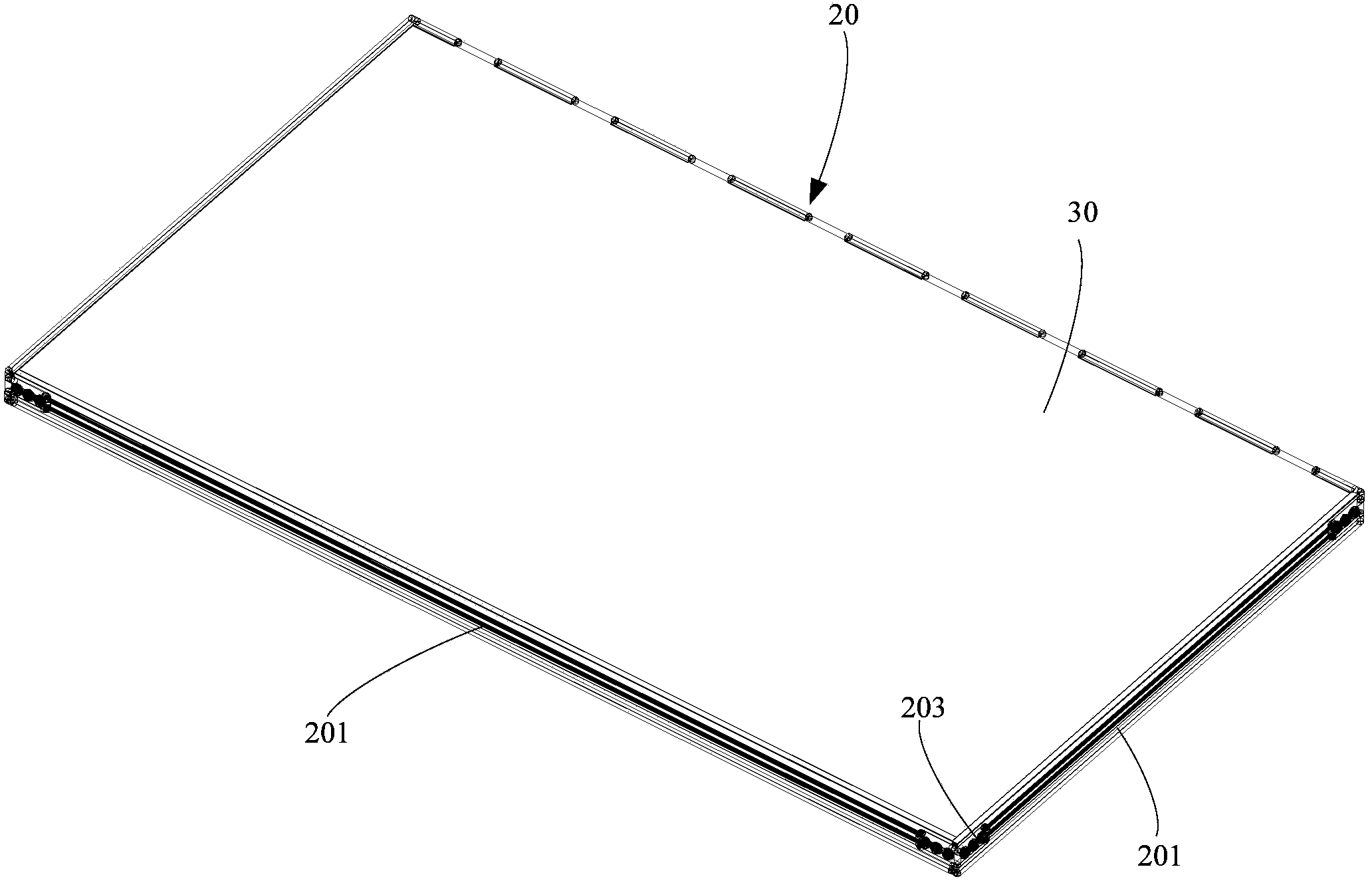

[0052] refer to figure 2 , shows a schematic diagram of the structure of the display module of the present invention. The display module structure of the present invention fixes a plurality of functional boards through the installation frame, and the installation frame is formed by enclosing and splicing a plurality of installation ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com