Press-fit cavity power divider

A power divider and press-fit technology, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of difficult control of processing accuracy, deterioration of overall performance indicators, and deterioration of product performance indicators, so as to enhance the environment. The effect of adaptability, shortening the processing period and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: Combined figure 1 — Figure 5 , the press-fit cavity power divider of this embodiment includes:

[0027] The microwave conductive rod 4 , the signal transmission cavity 3 , and the insulating medium 2 are coaxially arranged in the inner hole of the outer conductor 3 .

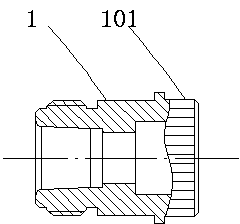

[0028] The signal transmission cavity 3 has an outer square and an inner circle, which is an integral structure through die-casting, and coincides with the central axis of the microwave conductive rod 4, and is press-fitted and connected through the press-fitted rule 101 of the outer conductor 1;

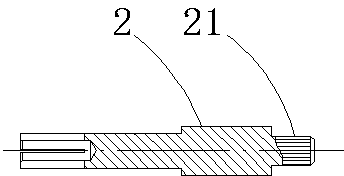

[0029] One end of the microwave conductive rod 4 is provided with an input press-fit hole 41 of a coaxial structure, and the other end is provided with an output press-fit hole 42 of a vertical structure. shape, the microwave conductive rod 4 is press-fitted and connected through the press-fitted rule 21 of the inner conductor 2;

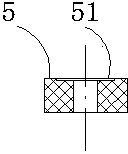

[0030] One side of the insulating medium 5 is provided with an imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com