Server cabinet

A technology for server cabinets and cabinets, applied in the field of server cabinets, can solve problems such as poor cooling performance of cabinets, overheating of servers, and reduced heat dissipation of cabinets, so as to reduce the space occupied, speed up the heat dissipation process, and improve dustproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

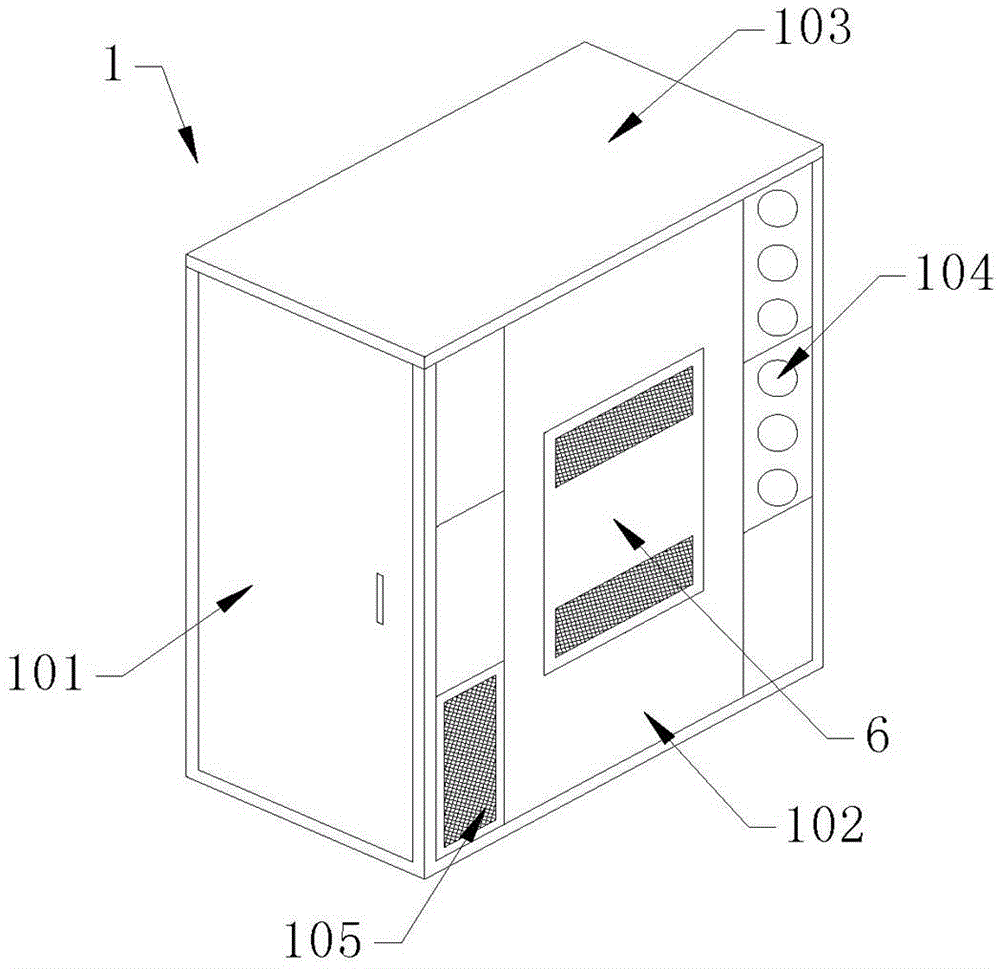

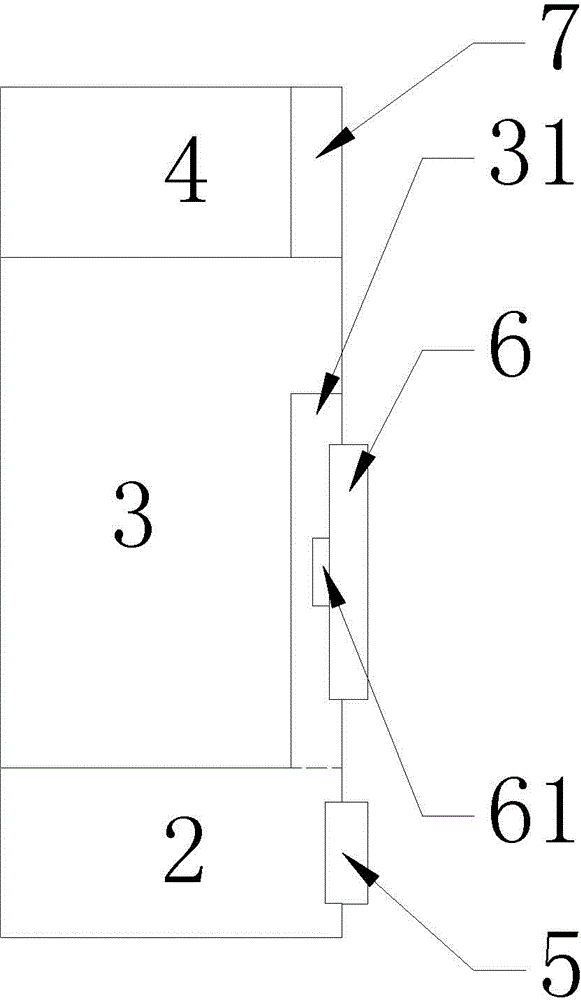

[0041] see figure 1 , a server cabinet, including a cabinet body 1, and the cabinet body 1 includes a front cabinet door 101, a left cabinet body panel, a right cabinet body panel 102, a rear cabinet door, a top cabinet body panel 103 and a bottom cabinet body panel; see figure 2 , the interior of the cabinet body 1 is provided with an air supply chamber 2, an equipment compartment 3 and a return air chamber 4 in sequence along the direction from the front cabinet door 101 to the rear cabinet door. The equipment compartment is provided with a refrigeration chamber 31, which is connected to the supply chamber. The air chamber 2 is connected (indicated by the dotted line in the figure); at least one air inlet is provided on the left cabinet body plate and / or the right cabinet body plate 102 corresponding to the air supply chamber 2, and a filter device 5 is installed on each air inlet; The left cabinet body plate and / or the right cabinet body plate 102 corresponding to the ...

Embodiment 2

[0047] In order to better manage the cooling airflow, this embodiment further optimizes Embodiment 1.

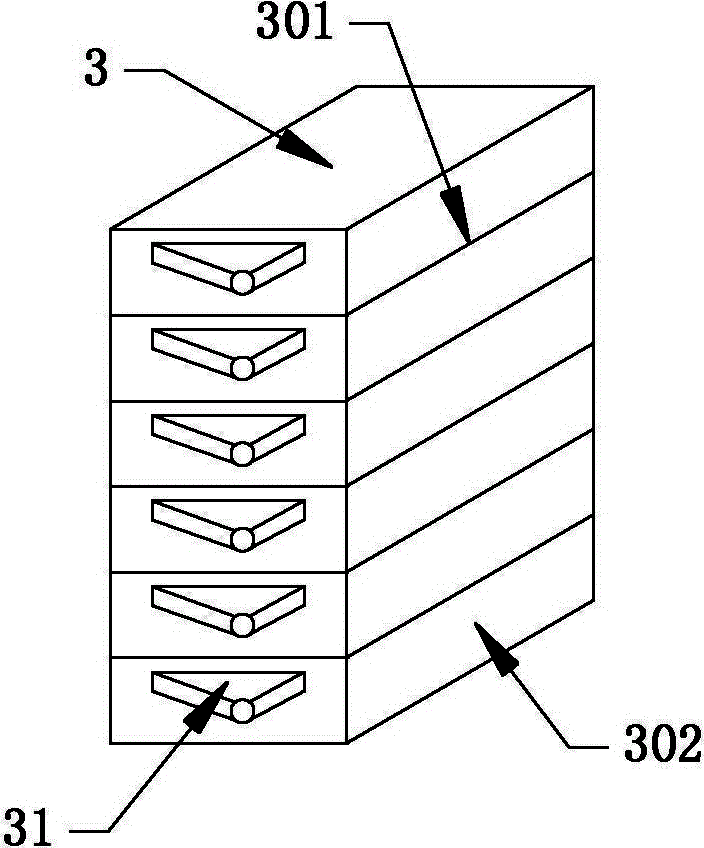

[0048] see image 3 , the equipment compartment 3 is divided into several thermal management sections 302 by partitions 301, and the present embodiment is divided into 6 thermal management sections as an example for illustration; the partitions 301 can be selected from high-density plastic plates and metal insulation partitions 1. One of the high-strength plexiglass plates. When used in occasions with high confidentiality, metal insulation partitions can be used to improve the ability to resist damage. When it is necessary to observe the internal conditions in real time, high-strength plexiglass can be used ; Each thermal management section 302 is provided with an airflow control device 31 at a position in contact with the air supply chamber 2, see Figure 4 , the airflow control device 31 includes a baffle plate 311 and an electromagnetic control valve 312; a temperatu...

Embodiment 3

[0053] As a preferred solution of Embodiment 1, wind pressure gauges are respectively arranged on both sides of the filter device 5 to monitor the change of the air volume at the air inlet. When the detected data changes significantly, it indicates that the filtering effect of the filter device has declined. , It is necessary to replace and clean the filter device in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com