Systems and methods for processing mixed solid waste

A technology of solid waste and waste, applied in the direction of solid waste removal, chemical instruments and methods, separating solids from solids with airflow, etc., can solve the problem of recyclable material waste flow disposal unrelieved, recycled Circulatory system inefficiency, energy consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] I. Introduction

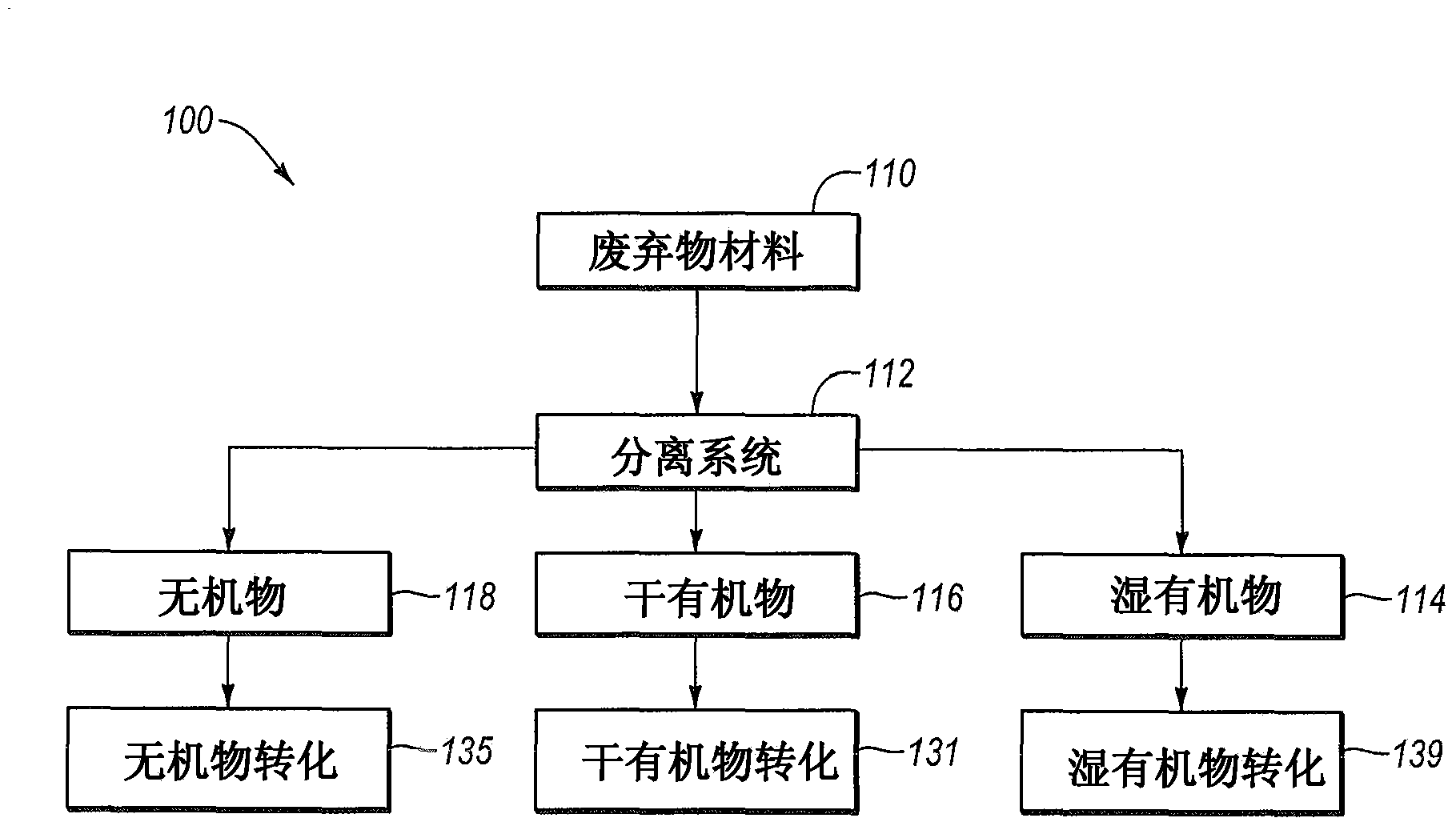

[0021] figure 1 is a schematic illustration of an integrated waste processing and recycling system 100 that produces renewable energy and / or products from mixed solid waste materials. System 100 includes a source 110 of a mixed solid waste stream. The mixed solid waste stream comprises at least 10% wet organic waste material and at least 10% dry organic and optionally inorganic waste material.

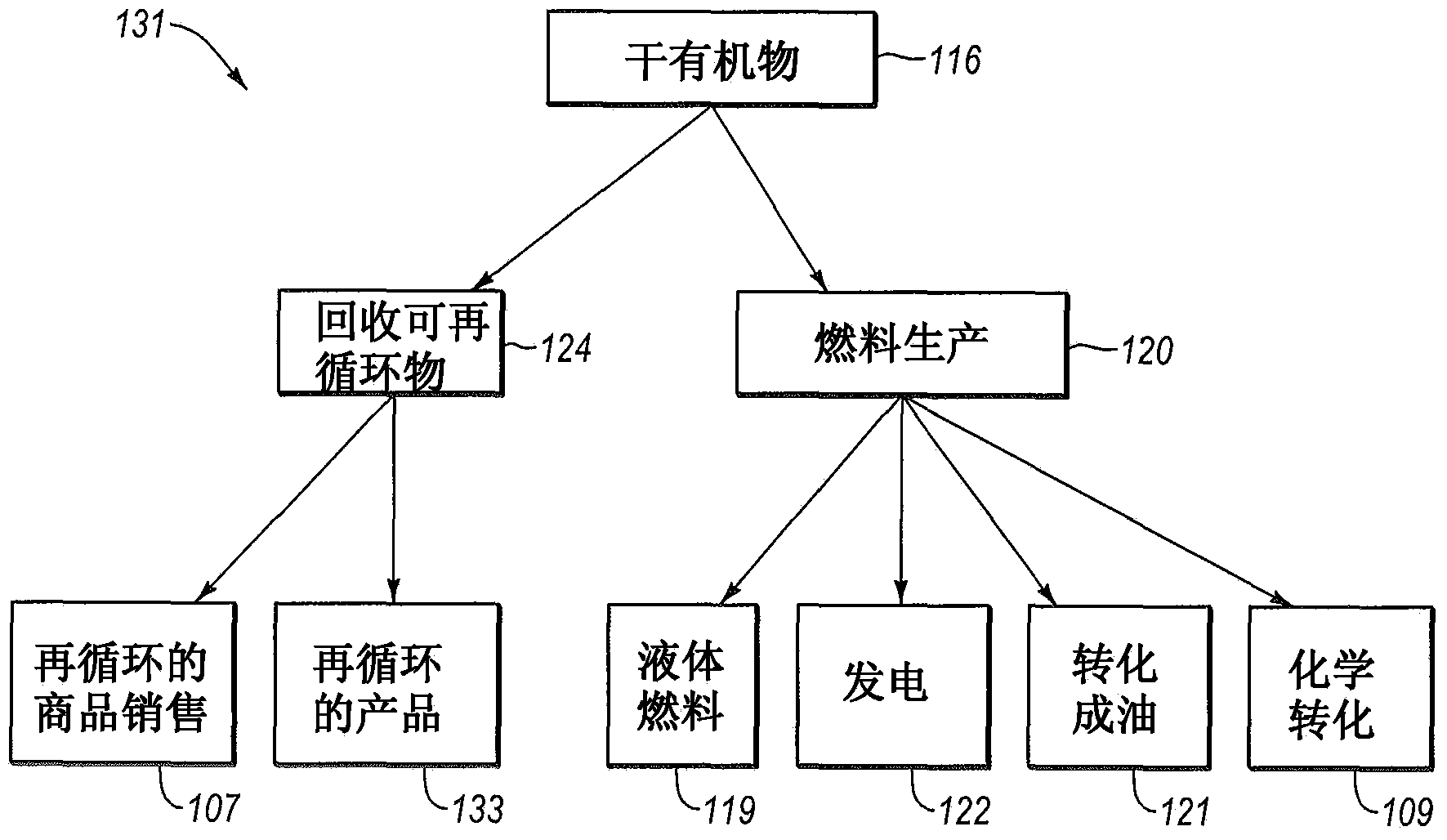

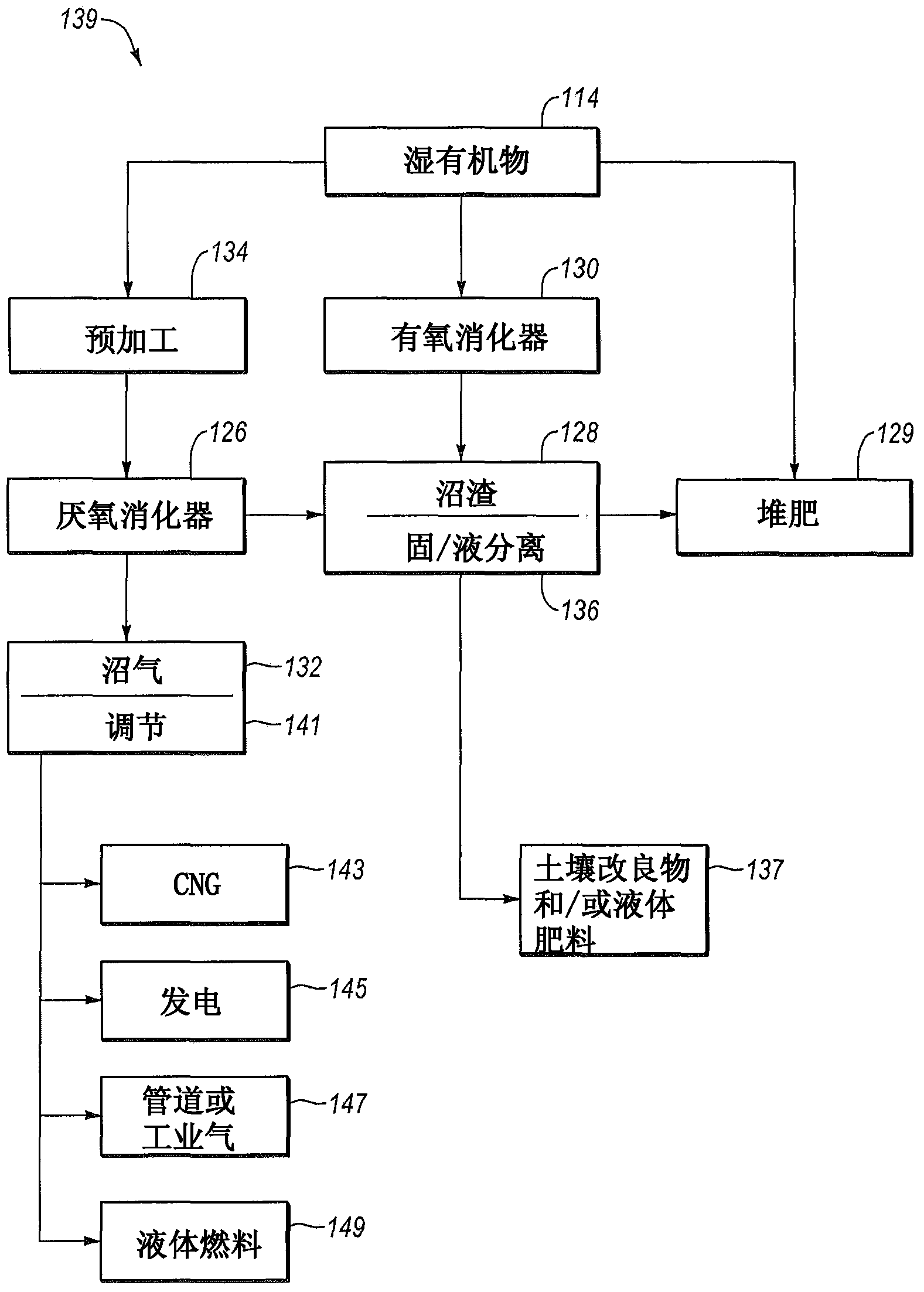

[0022] The mixed waste material 110 is mechanically sorted to produce wet organics 114 and dry organics 116 , and optionally inorganics 118 . The waste material is processed in the mechanical separation system 112 to produce a plurality of individually sorted waste fractions suitable for conversion into renewable energy and / or products. At least a portion of the dry organics and wet organics are independently processed using separate conversion processes 131 and 139, respectively. Optional inorganics 118 may be converted to renewable or recyclable products ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com