Inclined-plate inclined-tube sedimentation tank

A technology of inclined tube sedimentation tank and sedimentation tank, applied in the direction of sedimentation tank, etc., can solve the problems of treatment efficiency, effluent quality decline, reliability reduction, etc., and achieve the effects of good water quality treatment effect, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

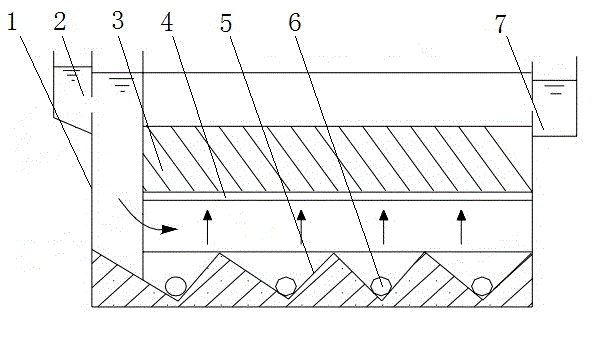

[0008] like figure 1 As shown, the present invention comprises a sedimentation tank 1, a water distribution tank 2 and a water collection tank 7 are provided above the sedimentation tank 1, a sludge bucket 5 is provided below the sedimentation tank 1, and a sludge bucket 5 is provided on the sludge bucket 5. The perforated mud discharge pipe 6, the sedimentation tank 1 is located above the sludge hopper 5 and is provided with a slanted plate slanted pipe body 3, and in order to prevent short circuit of water flow, a spoiler 4 is provided at the bottom of the slanted plate slanted pipe body 3.

[0009] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com