A carrier and its screw lifting device

A technology of screw lift and screw lift, applied in the field of carrier and screw lift device, can solve the problems of increased maintenance cost, low space utilization rate, heavy load of load-bearing structure, etc. The effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0036] The structure and working principle of the carrier of the present invention will be described in detail below by taking the application of the carrier of the present invention in an automated three-dimensional warehouse, specifically, being installed on a stacker in an automated three-dimensional warehouse as an example. However, it can be understood that the carrier of the present invention can also be applied to other equipment, and these are not limitations of the present invention.

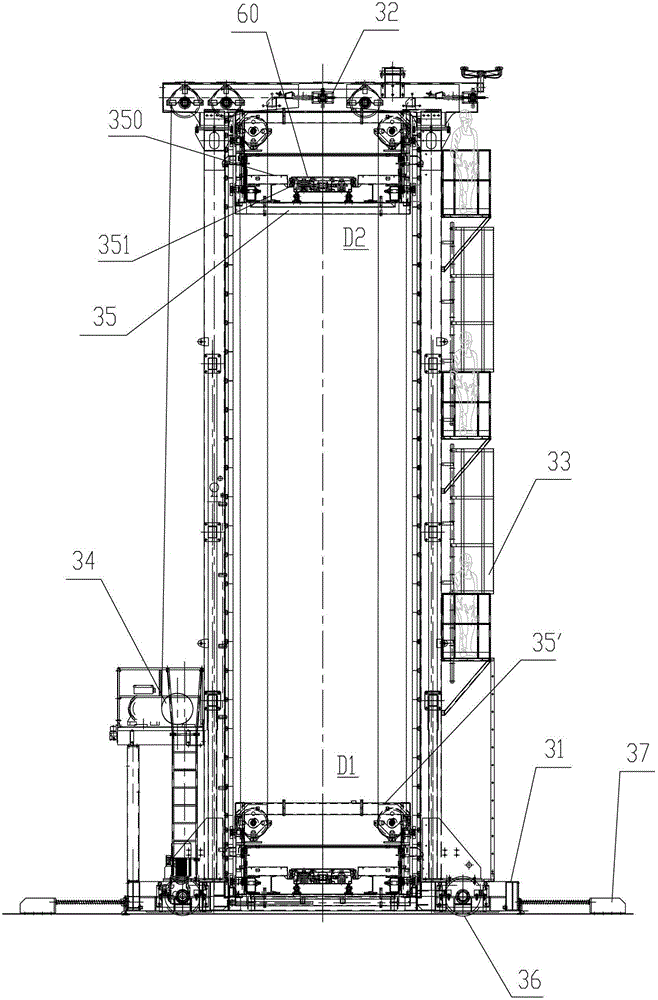

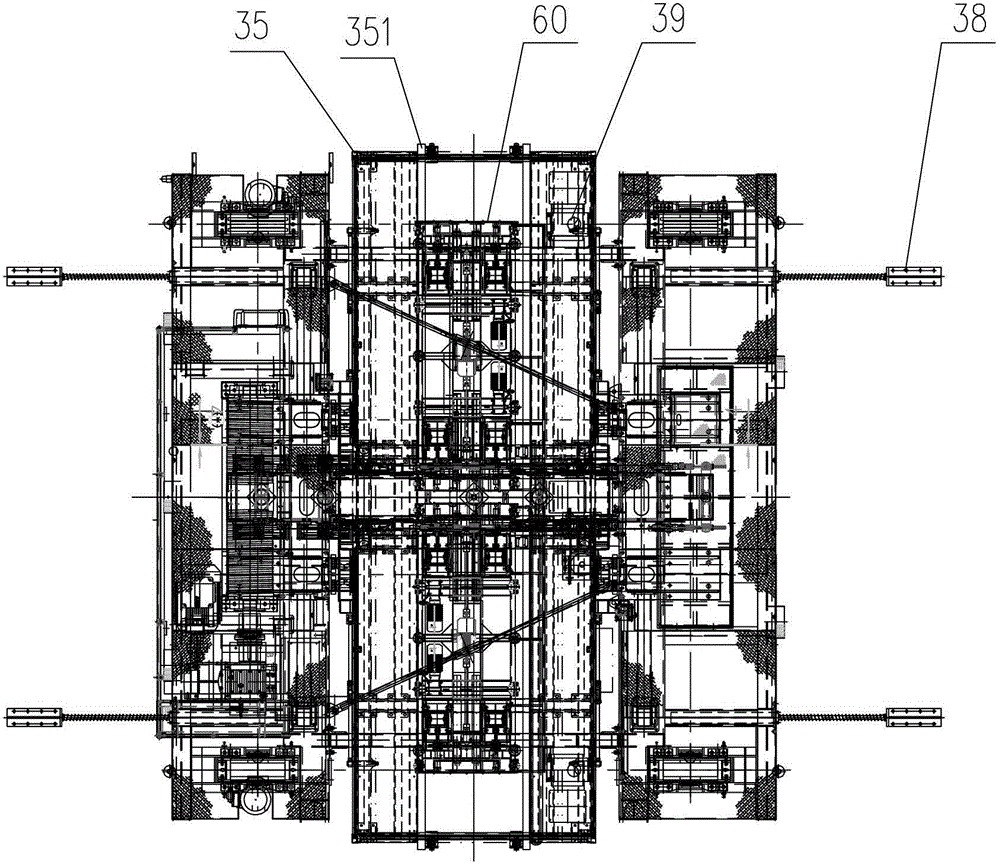

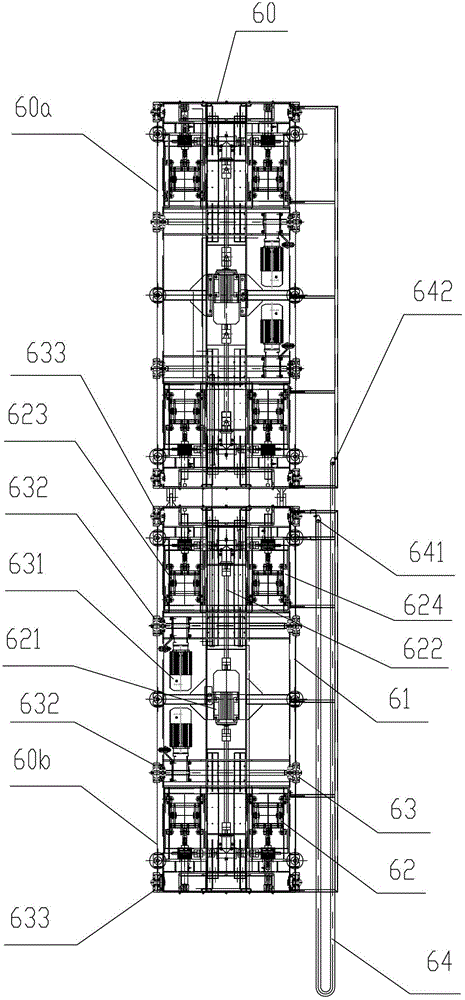

[0037] Such as Figure 1 ~ Figure 2 As shown, the structure of the stacker 30 is similar to the structure of the prior art, and can include structures such as an underframe 31, a gantry frame 32, a ladder assembly 33, a lifting mechanism 34, and a loading platform 35, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com