New process of amino G acid ammonification production

A new process, amino technology, applied in the new process field of amino G acid ammoniation production, can solve the problems of low solubility of liquid ammonia, hydrolysis side reactions, low conversion rate, etc., and achieve the effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

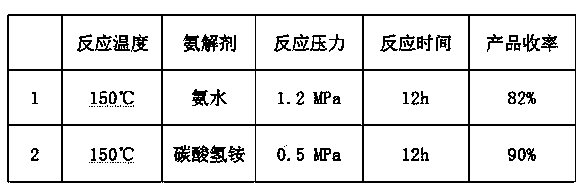

Examples

Embodiment 1

[0021] In a 5000L stainless steel ammoniation reaction kettle, add 1000L of water, 350 kg of ammonium bicarbonate, and 1600 kg of ammonium 6,8-naphthalene disulfonate (G salt), start stirring and open the jacket to freeze the water in the pot The internal temperature was lowered to 25° C., and the stirring was maintained for 15 minutes, and the stirring speed was controlled at 50 rpm. Open the jacket steam valve, slowly heat up to 60°C, at this time, the pressure in the reactor is 0.3Mpa, maintain the temperature and pressure for 2 hours, and control the stirring speed at 30 rpm. Within 60 minutes, continue to open the jacket steam valve to raise the temperature to 150° C., the pressure in the kettle is 0.5 Mpa, and maintain the temperature and pressure to react for 10 hours. After reacting for 10 hours, take a sample to analyze the ammonia content. If the content is more than 90%, it is qualified; if the ammonia content is less than 90%, it is unqualified. Continue to react u...

Embodiment 2

[0023] In a 5000L stainless steel ammoniation reaction kettle, add 1500L of water, 500 kg of ammonium bicarbonate, and 2000 kg of ammonium 6,8-naphthalene disulfonate (G salt), start stirring and open the jacket to freeze the water in the pot The internal temperature was lowered to below 25° C., and the stirring was maintained for 15 minutes, and the stirring speed was controlled at 60 rpm. Open the jacket steam valve, slowly heat up to 60°C, at this time, the pressure in the reactor is 0.3Mpa, maintain the temperature and pressure for 2 hours, and control the stirring speed at 30 rpm. Within 60 minutes, continue to open the jacket steam valve to raise the temperature to 150° C., the pressure in the kettle is 0.5 Mpa, and maintain the temperature and pressure to react for 10 hours. After reacting for 10 hours, take a sample to analyze the ammonia content. If the content is more than 90%, it is qualified; if the ammonia content is less than 90%, it is unqualified. Continue to r...

Embodiment 3

[0025] In the 5000L stainless steel ammoniation reaction kettle, add 800L of water, add 320 kg of ammonium bicarbonate, add 1300 kg of ammonium 6,8-naphthalene disulfonate (G salt), start stirring and open the jacket to freeze the water to cover the pot The internal temperature was lowered to below 25° C., and the stirring was maintained for 15 minutes, and the stirring speed was controlled at 60 rpm. Open the steam valve of the jacket, slowly heat up to 60°C, at this time, the pressure in the reactor is 0.3Mpa, maintain the temperature and pressure for 2 hours, and control the stirring speed at 30 rpm. Within 60 minutes, continue to open the jacket steam valve to raise the temperature to 150° C., the pressure in the kettle is 0.5 Mpa, and maintain the temperature and pressure to react for 10 hours. After reacting for 10 hours, take a sample to analyze the ammonia content. If the content is more than 90%, it is qualified; if the ammonia content is less than 90%, it is unqualif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com