Suspended ceiling hanging and connecting structure

A technology for connecting structures and ceilings, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of difficult to re-adjust the position, reduce efficiency, complicated operation, etc., to improve the stability of the connection, reduce the cost, and enhance the strength. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

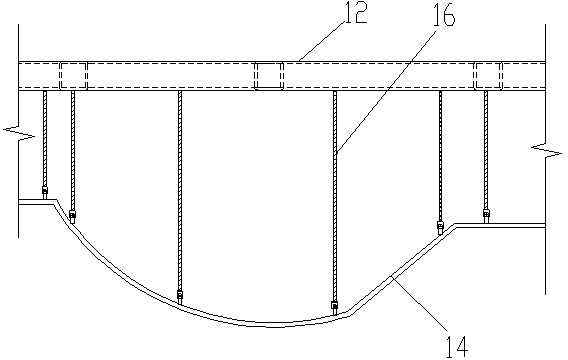

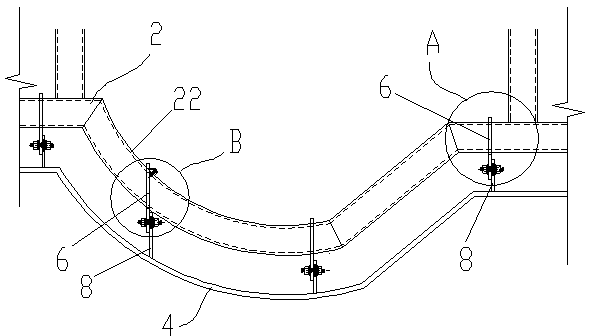

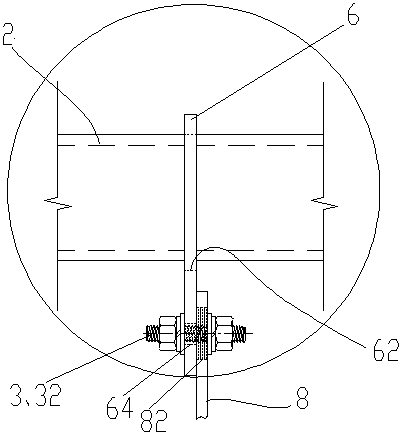

[0033] Such as Figure 2-8 As shown, a suspended ceiling hooking structure includes a fixed transversely extending keel 2 , a panel 4 arranged below the keel 2 , and multiple sets of hooking components arranged transversely to connect the keel 2 and the panel 4 . The hitch assembly includes a hitch piece 6 and a connecting piece 8 connected up and down, and the hitch piece 6 is movably sleeved on the keel 2 .

[0034] Specifically, the hanging piece 6 and the connecting piece 8 are sheet-shaped extending along the height direction respectively, and the bottom of the hanging piece 6 is connected with the top of the connecting piece 8 . Wherein, the upper part of the hooking part 6 is provided with a hooking hole 62 , and is movably sleeved on the keel 2 through the hooking hole 62 ; the lower part of the connecting part 8 is fixedly connected with the panel 4 . The hooking hole 62 is an integral punching structure with better connection performance, and the inner shape of the ...

Embodiment 2

[0038] Such as Figure 2-3 , Shown in 5-9, a hanging structure of a suspended ceiling, differs from Embodiment 1 in that: the keel 2 is a round tube keel, and the cross-sectional shape is circular, so the articulated hole 62 is also a circle matching it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com