Sucker rod rotating shock-absorbing anti-releasing device

An anti-dropping device and sucker rod technology, which is applied in drill pipes, drilling equipment, earthwork drilling, etc., can solve the problems of consuming a lot of manpower and material resources, complex force on sucker rod strings, affecting crude oil production, etc. Safe production, preventing fracture and tripping and falling well accidents, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

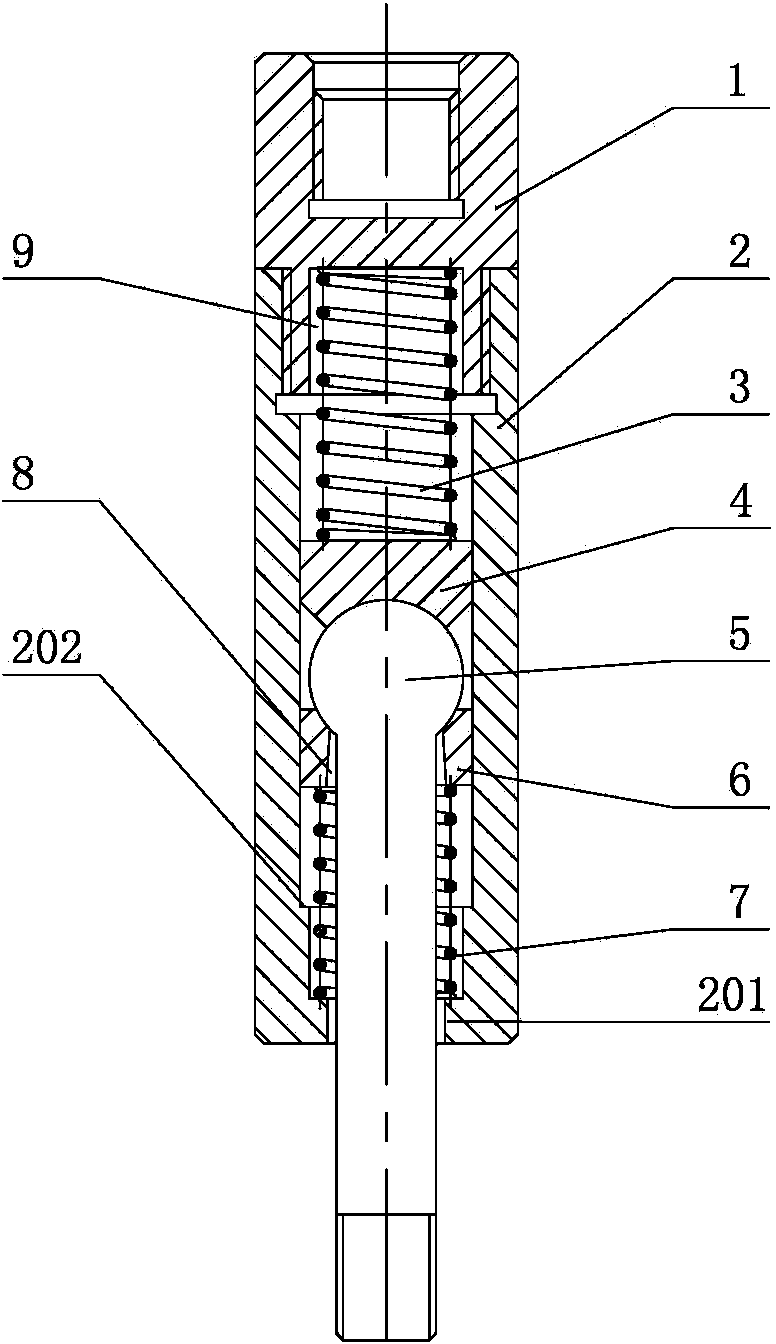

[0012] As shown in the figure, it is a sucker rod rotating shock-absorbing and anti-off device. Its body 2 is cylindrical. The center of the body 2 is provided with a through hole that penetrates the body 2 up and down. The lower ball seat 6 and the upper ball are arranged in the through hole. The seat 4, the upper ball seat 4 and the lower ball seat 6 are equipped with a ball screw 5, and the screw end of the ball screw 5 passes downward through the lower ball seat 6 and protrudes from the bottom of the through hole; the opening position of the upper end of the body 2 The upper joint 1 is connected with the internal thread, and the upper ball seat 4 and the lower ball seat 6 are slidably arranged in the through hole. A pre-compressed upper spring 3 is provided in the closed cavity between the upper end of the upper ball seat 4 and the upper joint 1. The cavity where the spring 3 is located can be a closed cavity; the lower opening of the through hole is provided with an inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com