Rotary machine fault feature extraction method based on fractional order holographic principle

A technology for rotating machinery and fault characteristics, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc. It can solve problems such as high precision requirements, high difficulty, and complicated processes, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

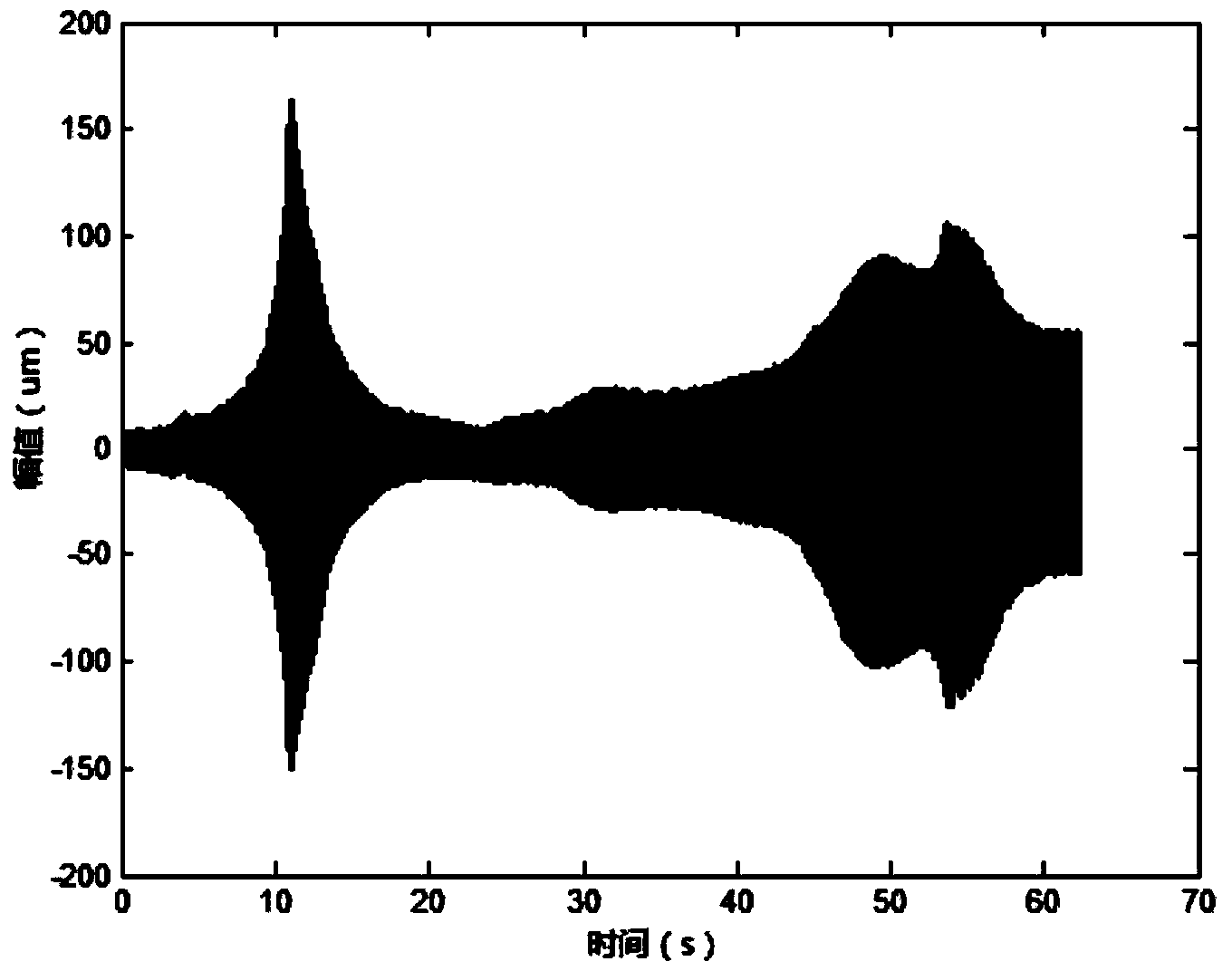

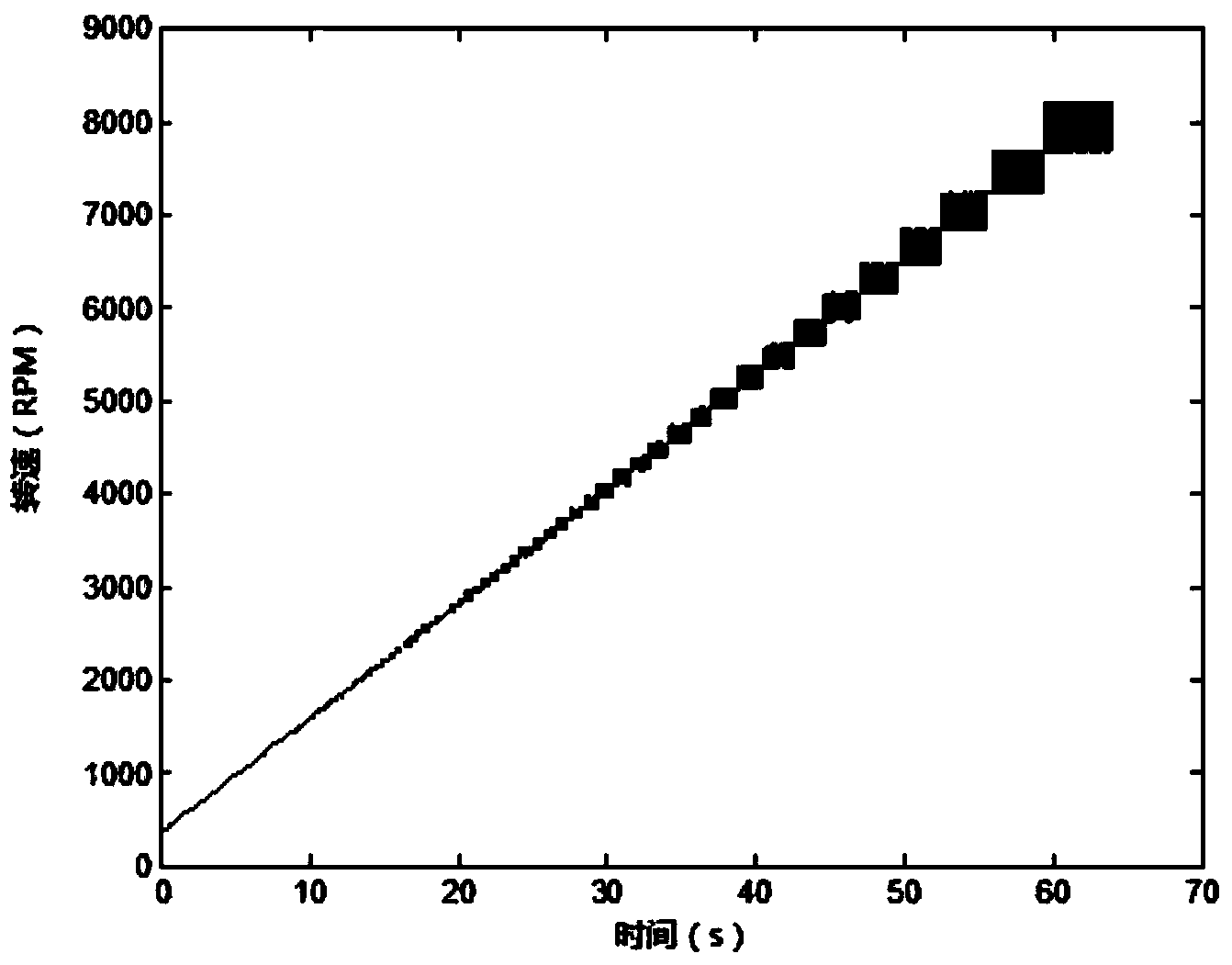

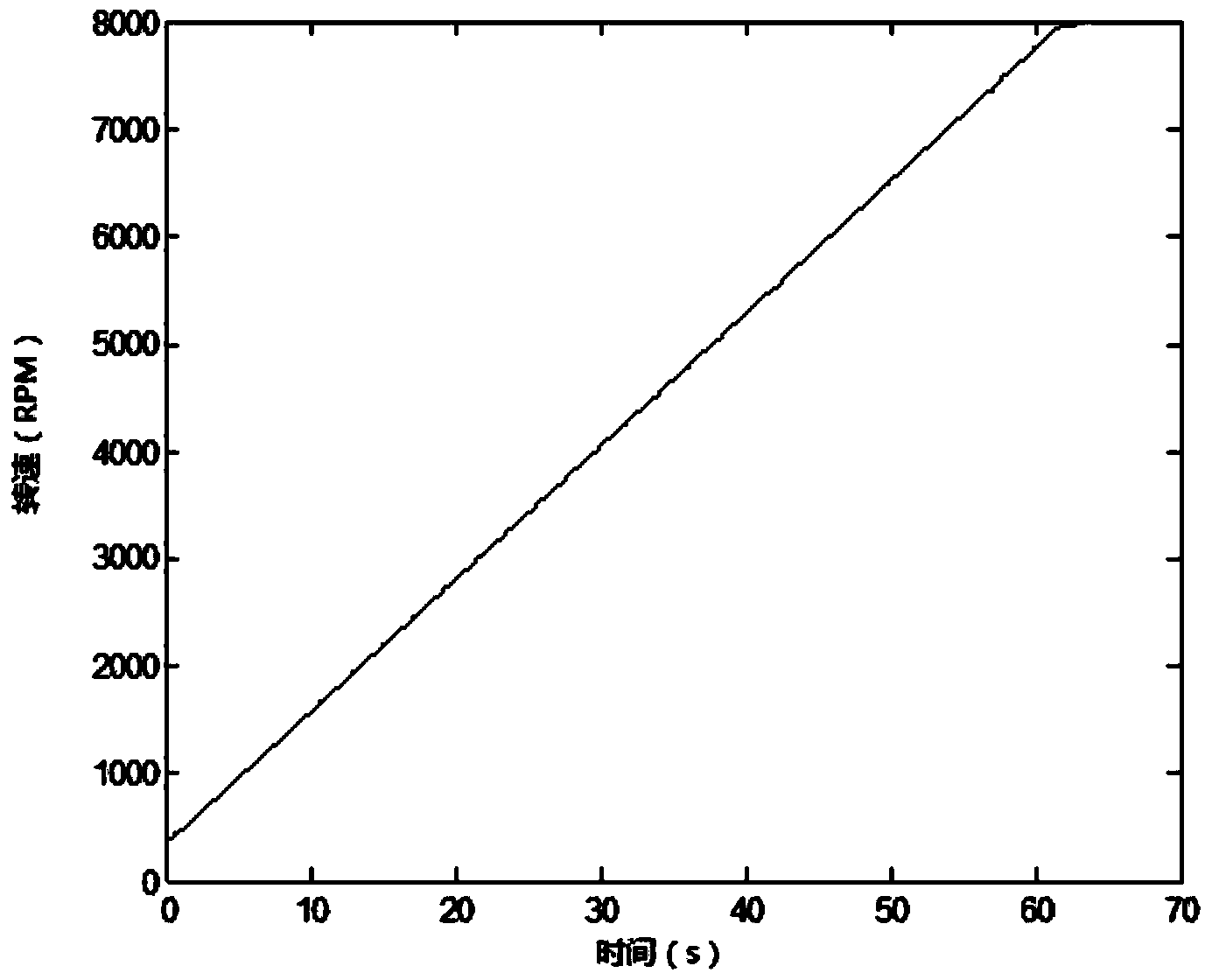

[0038] The present invention firstly calculates the average rotational speed per revolution through the key phase signal, and then calculates the rotational speed value corresponding to each sampling point (sampling moment) of the vibration signal through linear interpolation within each revolution. Use the calculated rotational speed signal sequence to perform fractional-order Fourier transform on the vibration signals of each vibration channel, and extract the 1st to 3rd-order frequency multiplier components. Through the Hilbert transformation of each order frequency multiplier component, the corresponding rotational speed of each component can be obtained. According to the amplitude and phase of the car, the holographic waterfall diagram during the starting process is drawn according to the principle of holographic spectrum. Through the holographic w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com