Test system and test method for underwater explosion impact equivalent loading experiment

A technology of loading experiments and underwater explosions, applied in the field of impact dynamics, can solve the problems of high requirements for experimental hardware facilities, high experimental costs, and low experimental efficiency, and achieve improved safety, high repeatability, and low experimental costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Bullet 2 adopts aluminum cylindrical bullets, the speeds are respectively 10m / s, 20m / s, 30m / s, 40m / s and 50m / s; the lengths are respectively 5cm, 4cm, 3cm, 2cm, 1cm. 2 In this way, 5 tests were performed according to 10m / s, 20m / s, 30m / s, 40m / s, and 50m / s, and 25 tests were performed.

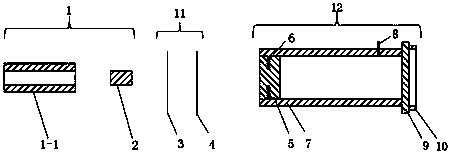

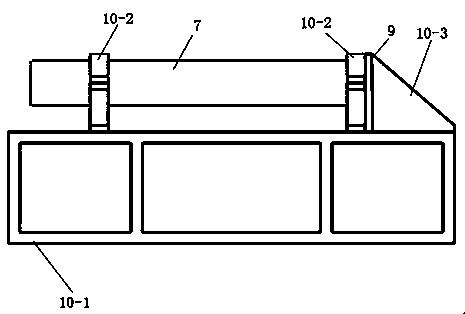

[0055] Described bullet velocity measuring system 11 is made up of two sets of time recorders 3 that are arranged in parallel, time recorder 3 includes two sheets of conductive paper and a dual-channel time on-off recorder, the conductive layers of the two conductive papers do not touch, and the two conductive papers Connect with the dual-channel time on-off recorder respectively. The conductive paper of the two sets of time recorder 3 is arranged in parallel at an interval of 50 cm. The conductive paper of the time recorder 3 is set on the flight path of the bullet 2. When the bullet 2 passes through the first set of time When the conductive paper on the recorder 3 is in contact with the...

Embodiment 2

[0059] The bullet 2 is made of aluminum foam, and the speed is 10m / s, 20m / s, 30m / s, 40m / s, and 50m / s respectively; the length is 5cm, 4cm, 3cm, 2cm, 1cm, and each length In this way, 5 tests were performed at 10 m / s, 20 m / s, 30 m / s, 40 m / s, and 50 m / s, and 25 tests were performed.

[0060] Described bullet velocity measuring system 11 is made up of two sets of time recorders 3 that are arranged in parallel, time recorder 3 includes two sheets of conductive paper and a dual-channel time on-off recorder, the conductive layers of the two conductive papers do not touch, and the two conductive papers Connect with the dual-channel time on-off recorder respectively. The conductive paper of the two sets of time recorder 3 is arranged in parallel at an interval of 78cm. The conductive paper of the time recorder is set on the flight path of the bullet. When the bullet passes through the first set of time recorder 3 When the conductive paper on the conductive paper, the conductive layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sampling frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com