Foam pipe rheological test system and application thereof

A testing system and foam tube technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problem of not considering the influence of tube diameter, etc., and achieve the effect of improving pressure resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

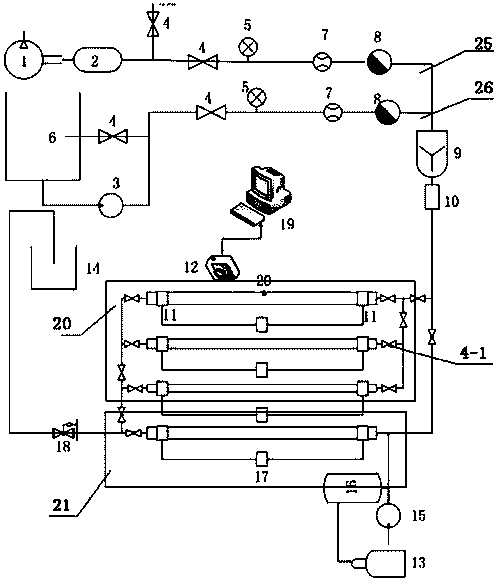

[0041] A foam tube rheological test system, the system includes a foam generator, a foam fluid test group pipe 20 and a foam sand-carrying fluid test pipe 21 respectively connected to the foam generator, in the foam fluid test group pipe 20 and The liquid outlet end of the foamy sand-carrying fluid test tube 21 is connected with a sedimentation tank 14; the liquid inlet of the foamy sand-carrying fluid test tube 21 is connected with a sand adding device; A plurality of foam fluid test tubes, a valve 4-1 is arranged on the pipeline connecting multiple foam fluid test tubes, and a single branch connection of a single foam fluid test tube is realized by opening and closing the valves 4-1 at different positions of the above pipelines into the foam generator, multiple foam fluid test tubes connected in parallel to the foam generator or multiple foam fluid test tubes connected in series to the foam generator.

[0042] Described foam generator comprises gas pipeline 25 and foam gener...

Embodiment 2

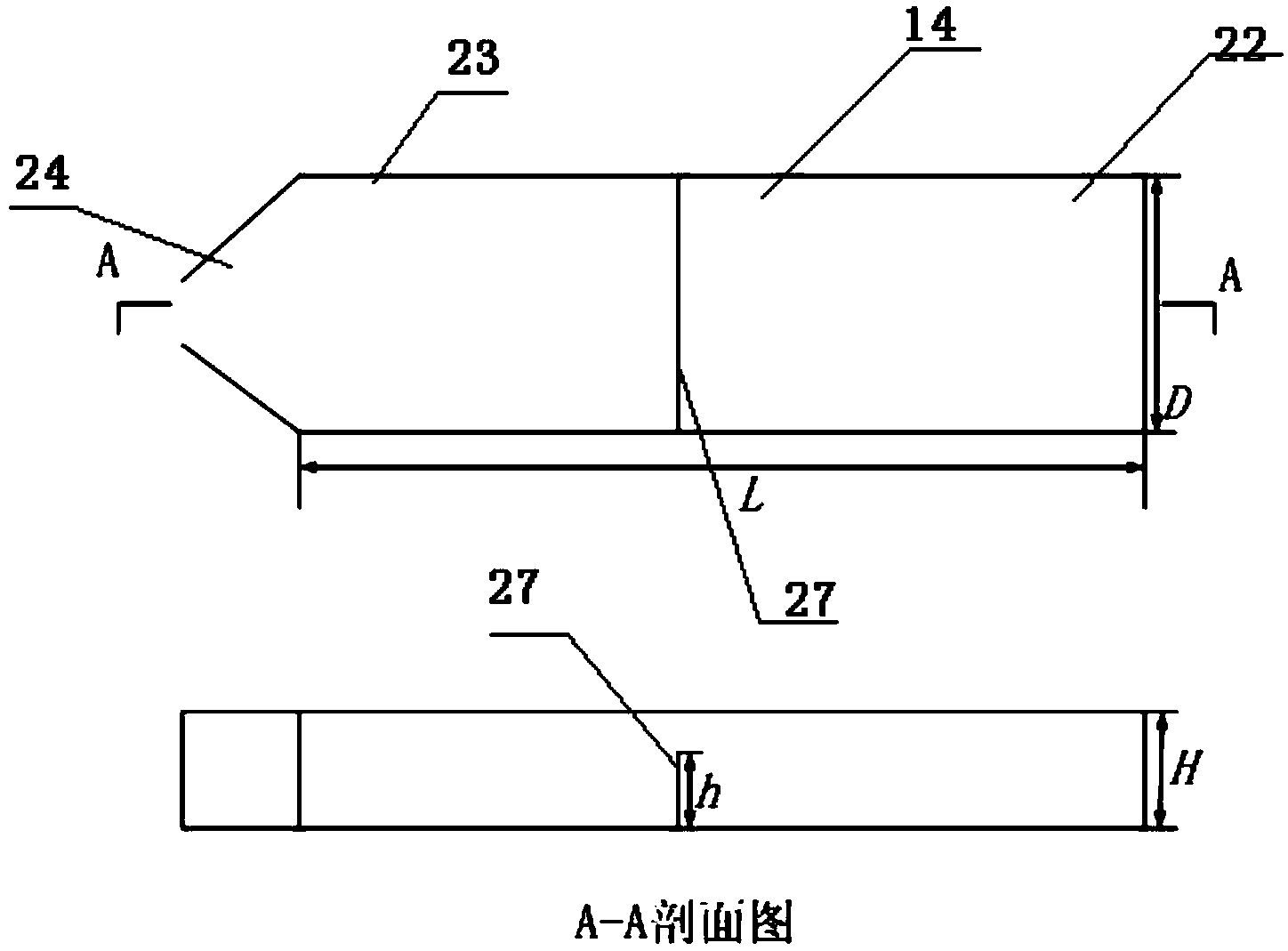

[0049] A foam tube rheological test system as described in Example 1, the difference is that the settling tank 14 is provided with two-stage settling tanks sequentially from the flow direction of the waste liquid, namely the primary settling tank 22 and the secondary settling tank 23 , the drain port 24 of the secondary sedimentation tank 23 is trapezoidal.

Embodiment 3

[0051] A kind of foam tube rheological test system as described in embodiment 1, its difference is that, the height of described boundary plate 27 is 2 / 3 of the height of sedimentation tank 14, and the width of sedimentation tank 14 is 2 / 3 of the foam fluid test group tube outlet. The diameter of the liquid port and the liquid outlet of the foam-carrying fluid test tube is 8-12 times, and the length of the sedimentation tank is 2-8 times its width. The bottoms of the primary sedimentation tank and the secondary sedimentation tank are provided with folded structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com