Gas permeability characteristic parameter test device and method for measuring gas permeability characteristic parameters of micro-nano porous material by utilizing same

A characteristic parameter and gas permeation technology, applied in suspension and porous material analysis, measurement device, permeability/surface area analysis, etc., can solve problems such as difficult measurement, small permeation flow rate, and limitation of gas permeation characteristic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

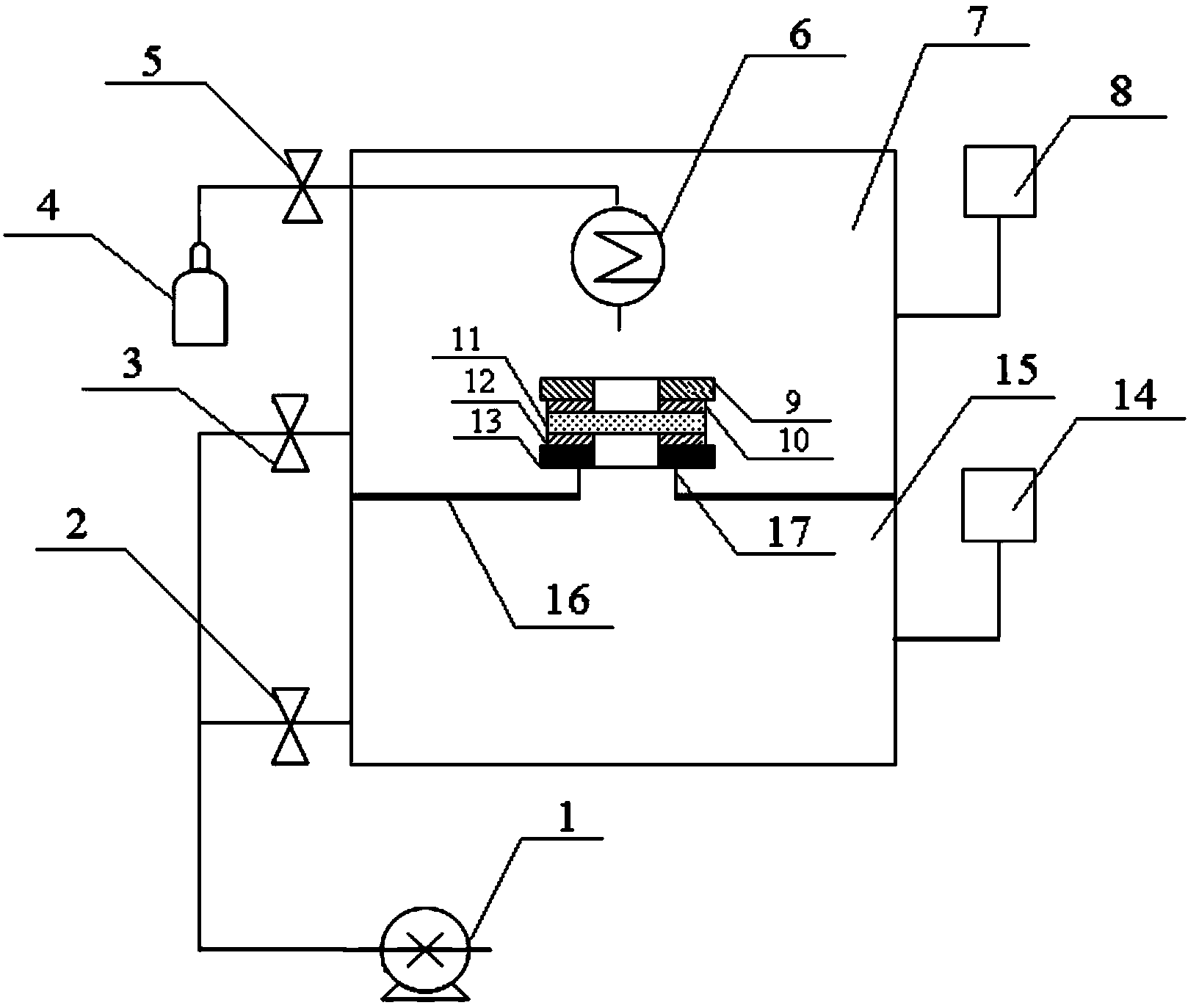

[0038] Specific Embodiment 1: This embodiment is a gas permeability characteristic parameter testing device including a vacuum pump 1, a first valve 2, a second valve 3, a gas source 4, a third valve 5, a heater 6, and a first experimental cylinder 7 , a first pressure sensor 8, a cover plate 9, a first high temperature sealing gasket 10, a second high temperature sealing gasket 12, a sample platform 13, a second pressure sensor 14, a second experimental cylinder 15, a partition 16 and a tube 17;

[0039] Described vacuum pump 1 communicates with the second experiment cylinder body 15 through the first valve 2; Vacuum pump 1 communicates with the first experiment cylinder body 7 through the second valve 3; The first experiment cylinder body 7 and the second experiment cylinder body 15 are provided with Partition 16, partition 16 separates the first experimental cylinder 7 from the second experimental cylinder 15, the middle of the partition 16 is provided with a first circular ...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment differs from Embodiment 1 in that: the diameter of the first circular hole is 100 mm to 300 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the diameter of the third circular hole is 30 mm to 100 mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com