Touch display panel and touch display device

A touch display panel and touch display device technology, applied in optics, instruments, electrical digital data processing, etc., can solve the problems of scratches on the color resist surface, affecting the size of the frame, prone to electrostatic discharge, etc., to increase the production quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

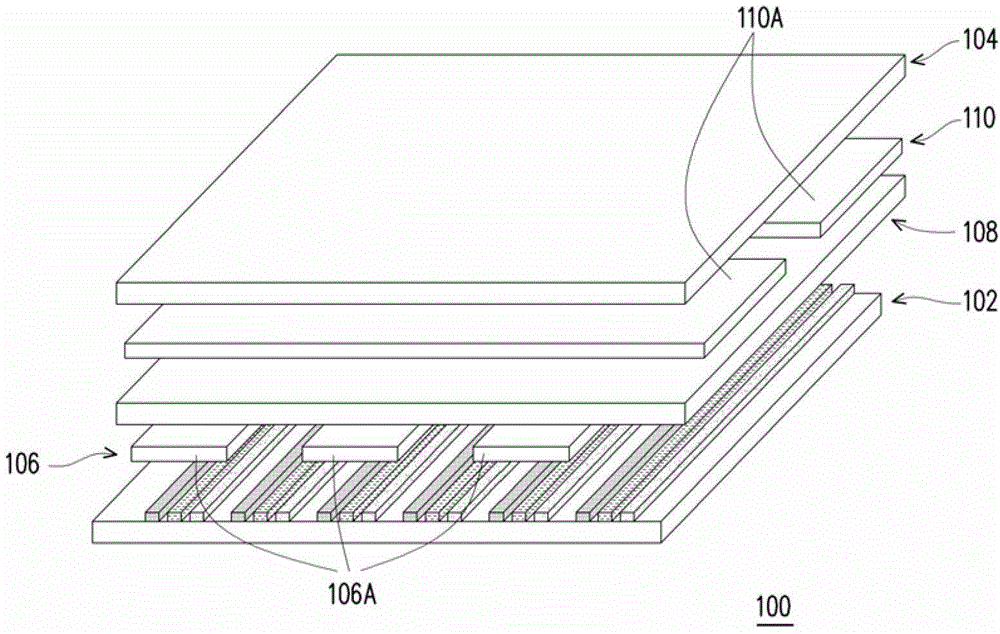

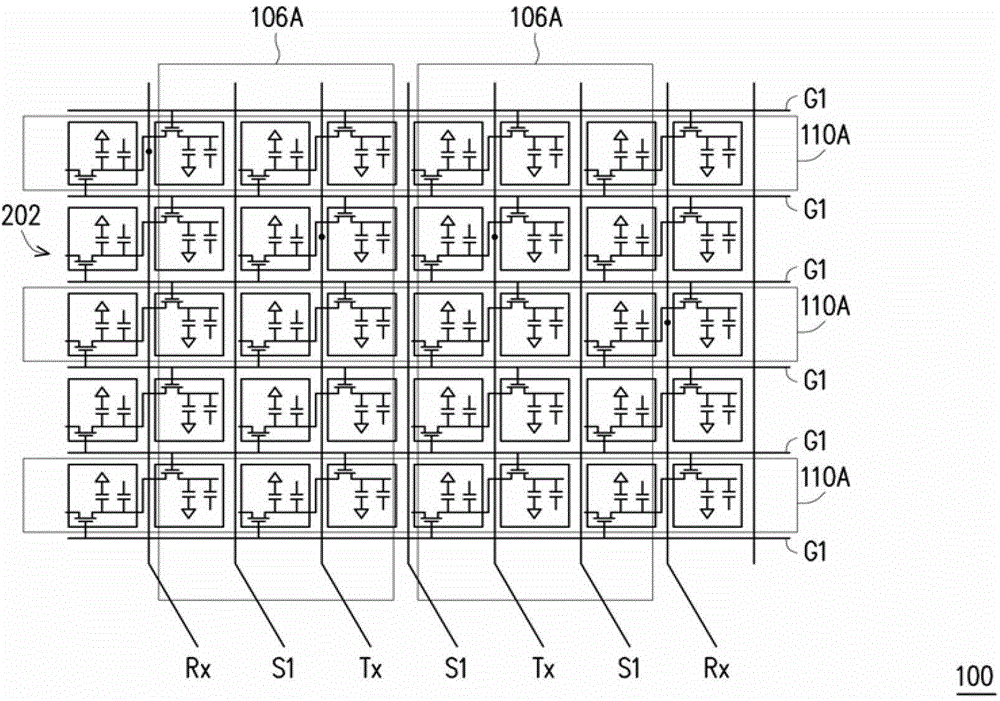

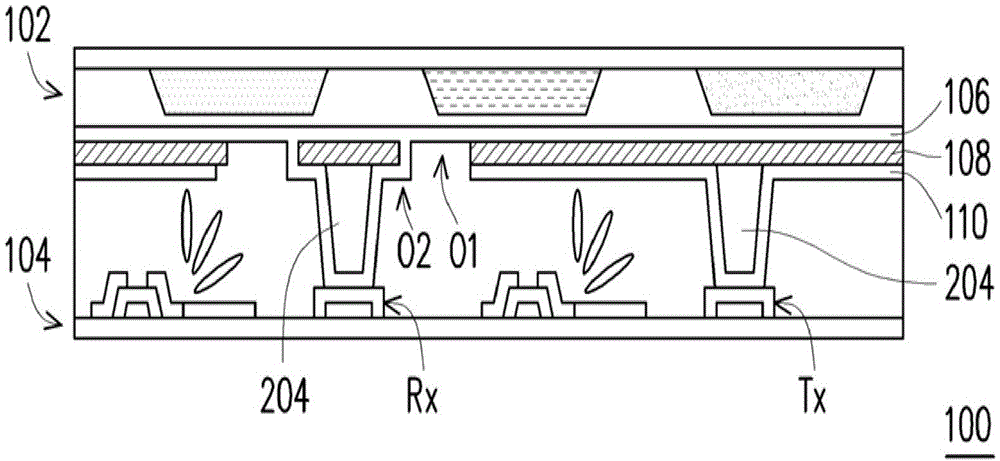

[0049] figure 1 It is a schematic diagram of a touch display panel according to an embodiment of the present invention, please refer to figure 1 . The touch display panel 100 includes a color filter substrate 102 , an active element array substrate 104 , a first transparent conductive layer 106 , an insulating layer 108 and a second transparent conductive layer 110 . Wherein the color filter substrate 102 has red, green and blue (RGB) color resists, and the first transparent conductive layer 106 and the second transparent conductive layer 110 can be, for example, indium tin oxide layers. The first transparent conductive layer 106 , the insulating layer 108 and the second transparent conductive layer 110 are located between the color filter substrate 102 and the active element array substrate 104 , and are disposed on the same side as the RGB color resist. The first transparent conductive layer 106 is disposed on the color filter substrate 102. In this embodiment, the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com