Clothing production method based on seamless mapping of 3D to 2D clothing patterns

A production method and clothing technology, which are applied in the fields of 2D image generation, image data processing, special data processing applications, etc., can solve the problems of not taking into account the three-dimensional feature information of clothing, time-consuming and expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The method for seamlessly mapping the overall clothing pattern based on three-dimensional to two-dimensional clothing according to the present invention will be described in detail below in conjunction with the accompanying drawings.

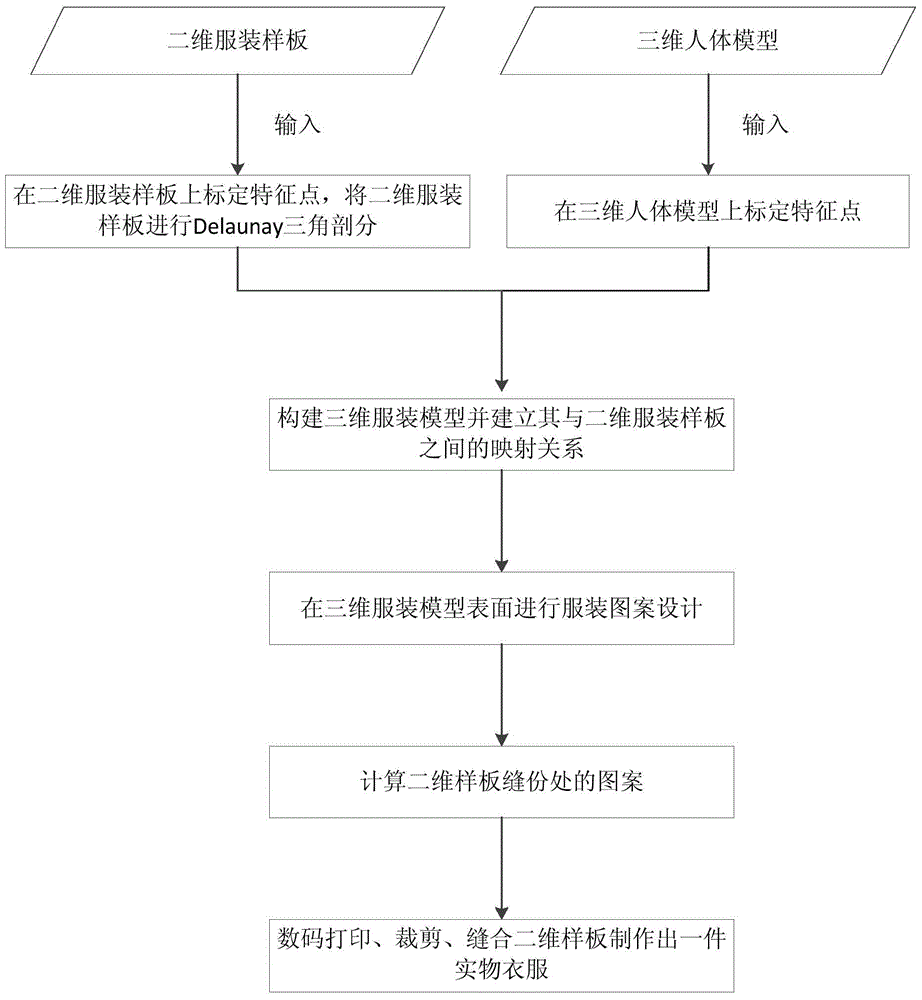

[0071] Such as figure 1 As shown, the method of the current embodiment of the present invention includes constructing a three-dimensional clothing model and establishing a mapping relationship between it and a two-dimensional template, performing clothing pattern design on the surface of the three-dimensional clothing model, calculating the pattern at the seam allowance of the two-dimensional template, and digitally printing , cutting, and sewing two-dimensional templates to produce a physical garment in four steps. details as follows:

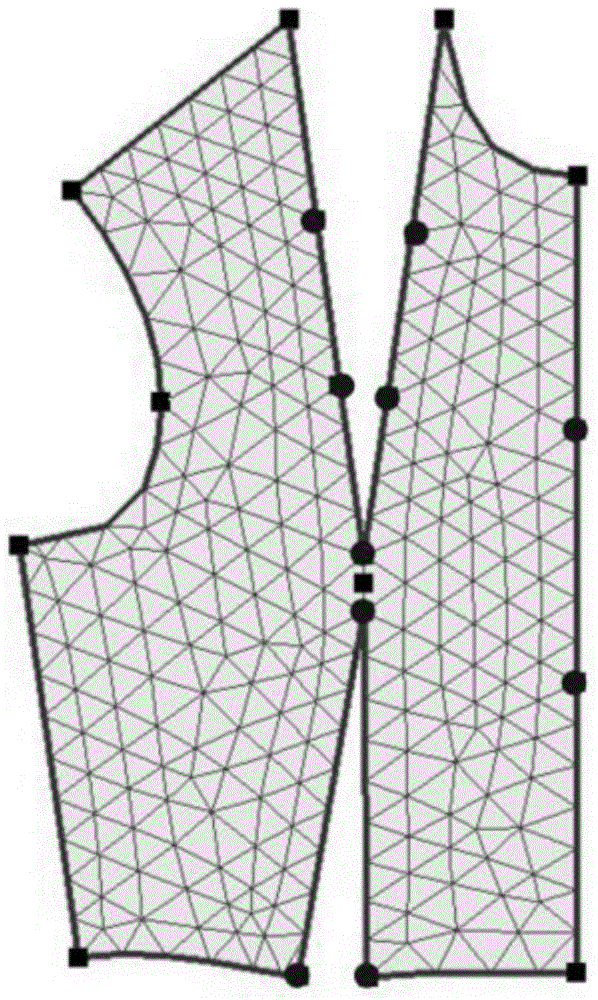

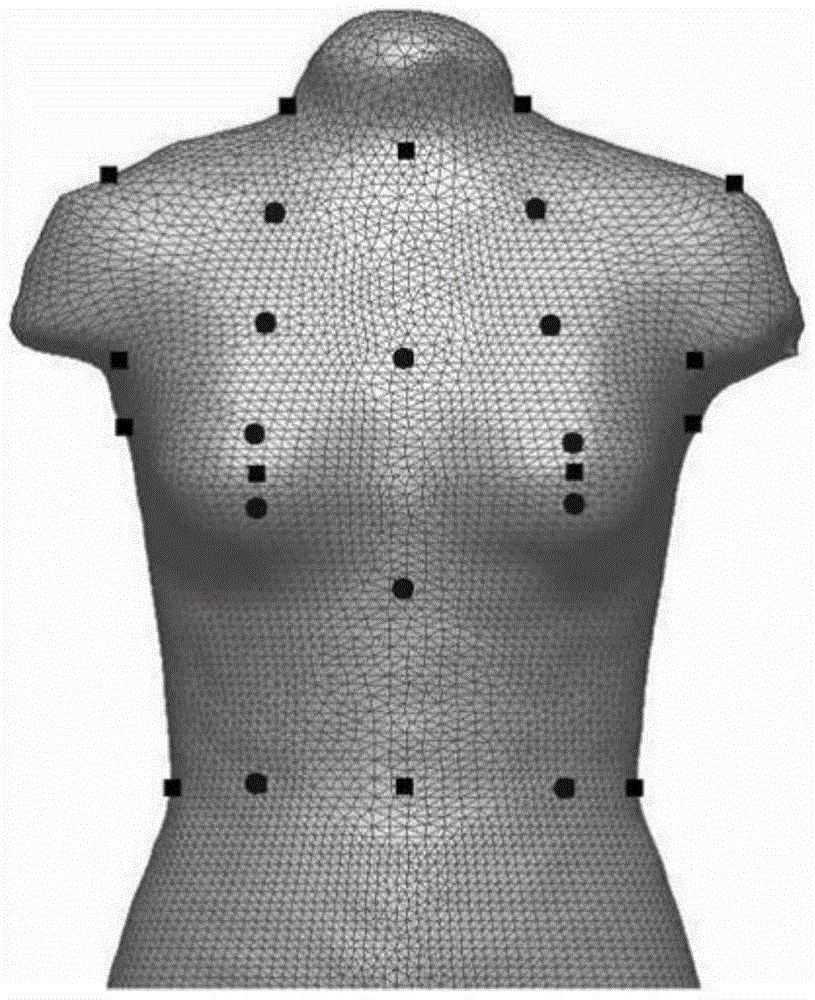

[0072] Step 1: Map the 2D template mesh model to the 3D human body model, and deform the grid in the 2D template mesh model to obtain the mapping relationship between the 3D clothing model and the 2D tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com