The static contact assembly of the valve hall and the connection fittings between the tubular busbar and the static contact

A tube-shaped busbar and connecting hardware technology, which is applied in the direction of contact electrical connection, contact shell/screen, etc., can solve problems such as unfavorable anti-corona ball assembly, reducing the anti-corona ball anti-corona effect, and increasing the structural complexity of the connecting hardware. , to achieve the effect of reducing the complexity of the structure, good anti-halation effect, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

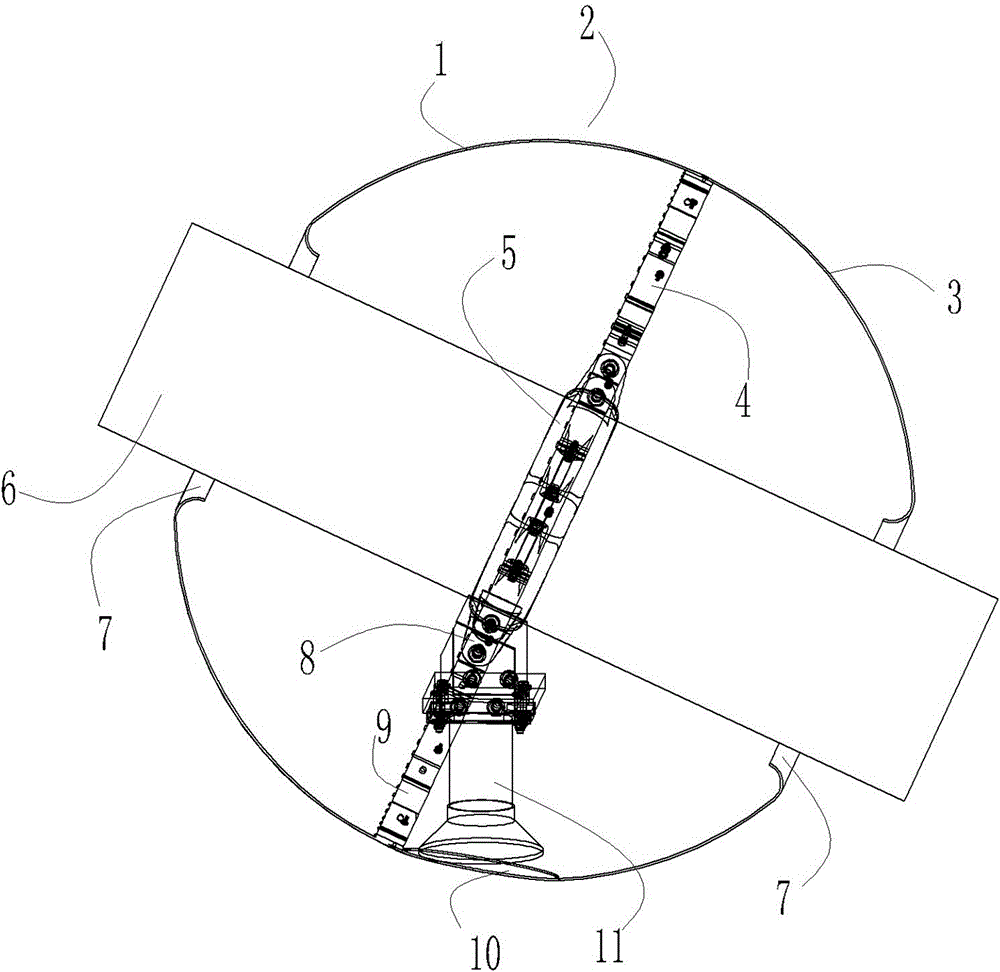

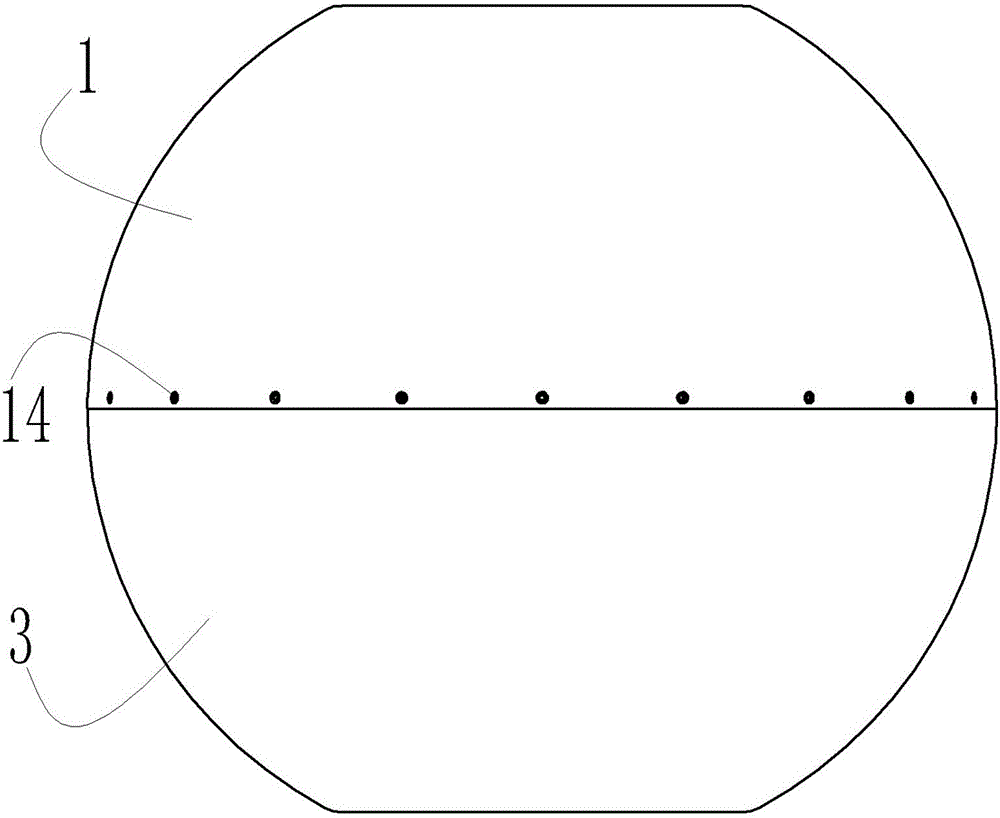

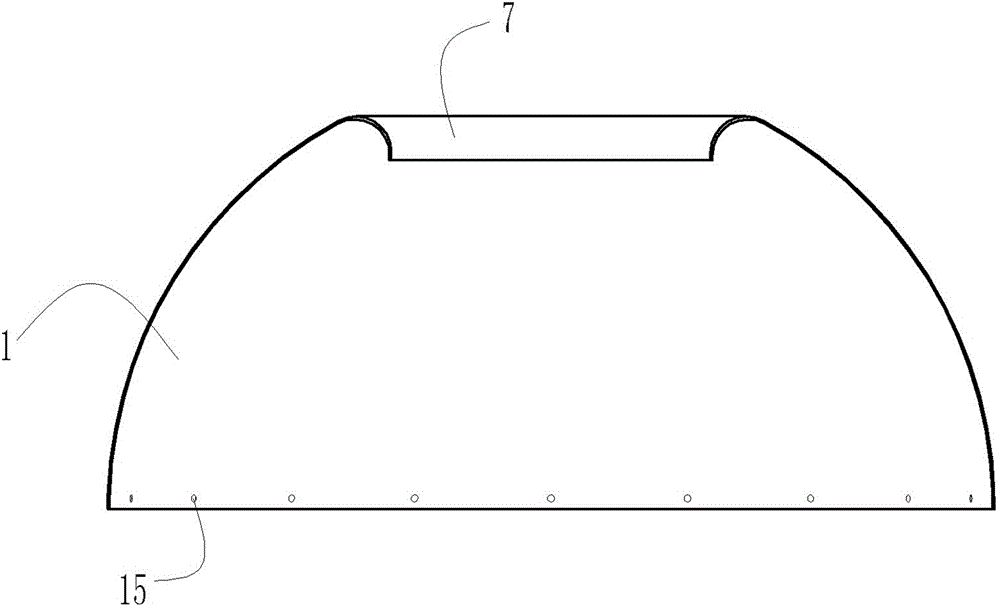

[0029] The embodiment of the static contact assembly of the valve hall is as follows: Figure 1~12Shown: includes static contact 1, tubular busbar 6 and connecting fittings connecting static contact 1 and tubular busbar 6, connecting fittings include shielding ball 2 with a spherical shell, on the opposite side of the spherical shell A pair of busbar perforations 7 are provided, and the openings of the busbar perforations are turned inward along the inside of the shielding ball. The spherical shell is formed by butting the upper hemisphere 1 and the lower hemisphere 3. Both the upper and lower hemispheres are made of metal materials, preferably aluminum The surfaces of the upper and lower hemispheres are polished. Two of the pair of busbar perforations are respectively arranged on the upper and lower hemispheres. The tubular busbar 6 runs through the busbar throughholes 7 . The connecting ring plate 9 extending circumferentially along the docking interface is provided at the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com