A solar cell sheet grid wire vulcanization treatment process

A technology for solar cell and vulcanization treatment, which is applied in the field of solar cell processing technology, can solve problems such as silver vulcanization and poor appearance of cell grid lines, and achieve the effects of low implementation cost, easy implementation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

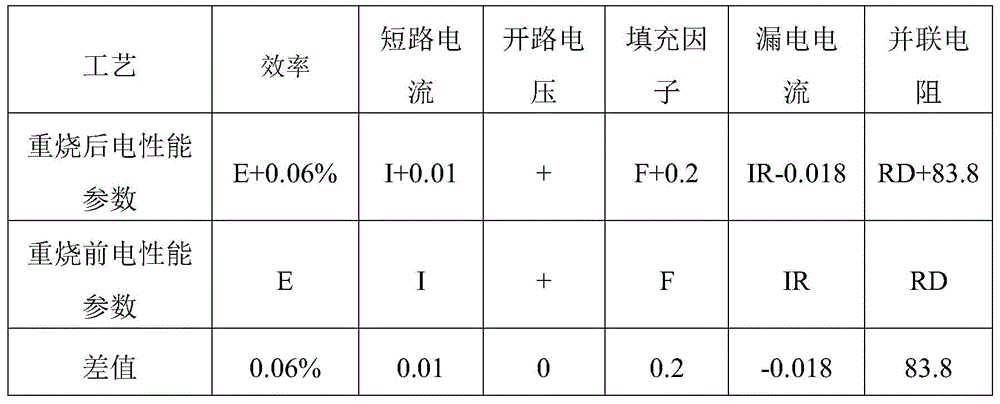

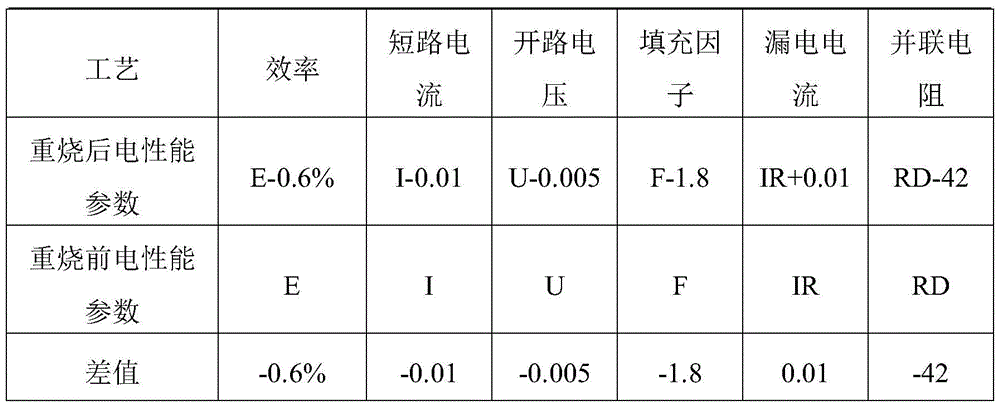

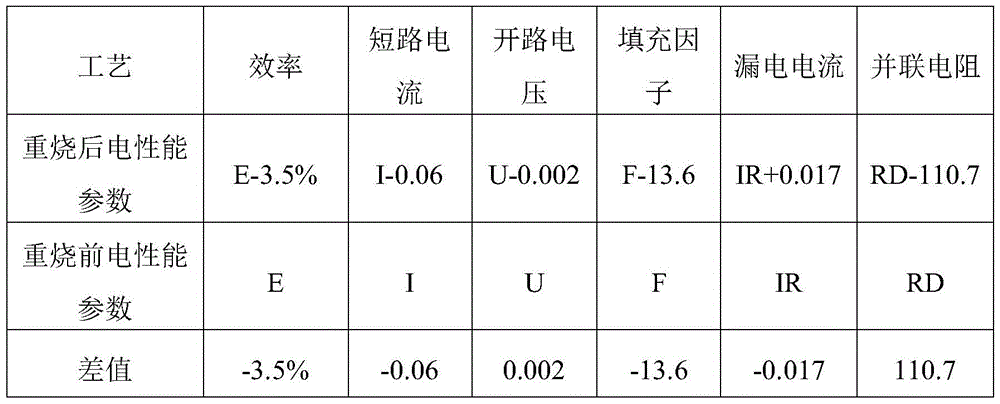

[0026] The invention discloses a solar cell sheet grid line vulcanization process, which is to heat the solar cell sheet with vulcanized grid line at 350±10°C for at least 80 seconds and then cool it. After heating the solar cells with sulfided grid lines, the silver sulfide can be completely decomposed, so as to achieve the purpose of removing sulfide and avoiding poor appearance, and will not affect the conversion efficiency of the cells.

[0027] In this embodiment, the sintering furnace on the solar cell production line is used to heat the solar cells whose grid lines are vulcanized. The sintering furnace is produced by Despatch, and the conveyor belt of the sintering furnace runs at a speed of 250 in / min.

[0028] The heating temperature is obtained through the following specific steps:

[0029] ⑴Take the sorted out solar cells with vulcanized grid lines;

[0030] ⑵Heat one of the solar cells at 250°C for at least 80 seconds;

[0031] ① If the silver sulfide on the grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com