Preparation method of coating slurry and preparation method of coating type cu molecular sieve scr catalyst

A technology of SCR catalyst and molecular sieve, which is applied in the field of diesel engine exhaust purification catalyst, can solve the problems of low adhesion, low temperature window, toxicity, etc., and achieve the effect of good coating strength, simple process and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

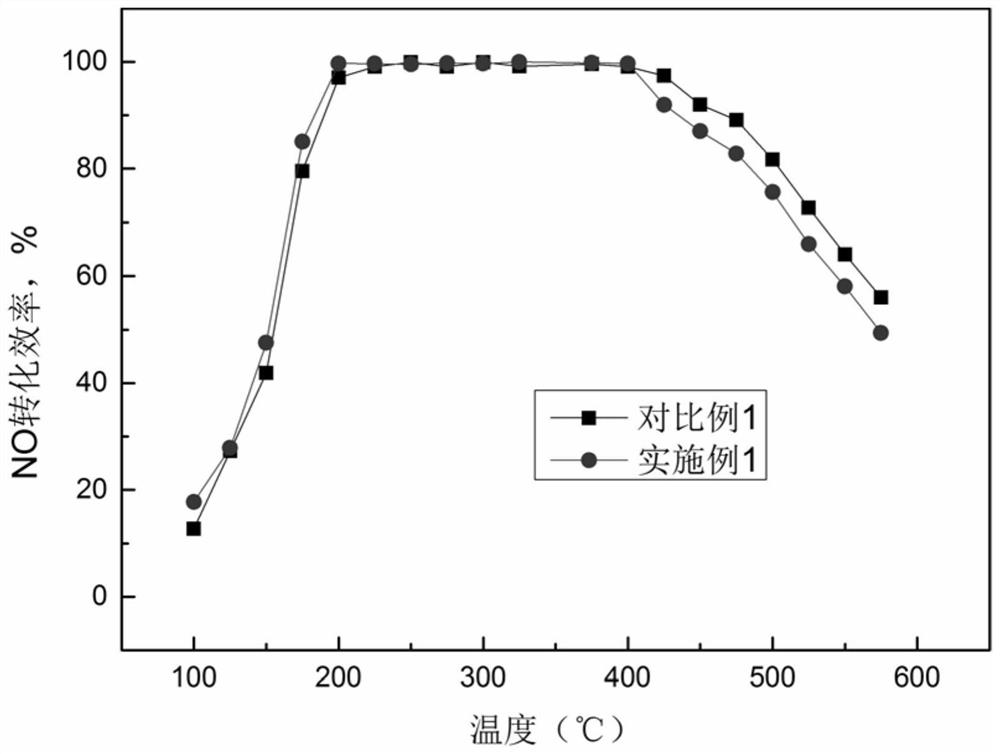

Embodiment 1

[0055] Dissolve 0.77g of copper nitrate in 20g of deionized water, stir and dissolve fully to form a blue transparent solution, then add 6.8g of SAPO-34 powder and 4.82g of acidic silica sol in sequence, the pH is 4, stir for 6h to form a stable slurry. Cut the cordierite honeycomb ceramics into a cross-section of 12mm*12mm~15mm*15mm, and a length of 18~25mm, weigh them, and then immerse them in the slurry under ultrasonic conditions for 5 minutes, take them out and purge the pores, dry them at 120°C for 4 hours, take them out Then immerse in the slurry, repeat 3 times, and finally put it into a muffle furnace for calcination at 550°C for 5 hours to obtain the desired coated catalyst and weigh it. The prepared coated catalyst was ultrasonically treated for 30 minutes, then dried in a drying oven at 120°C for 4 hours, then calcined in a muffle furnace at 550°C for 5 hours, and weighed. The results are shown in Table 1.

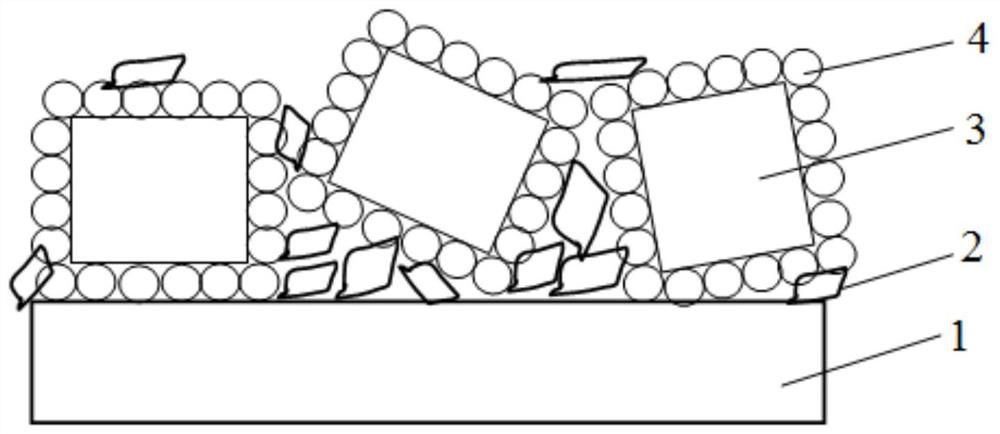

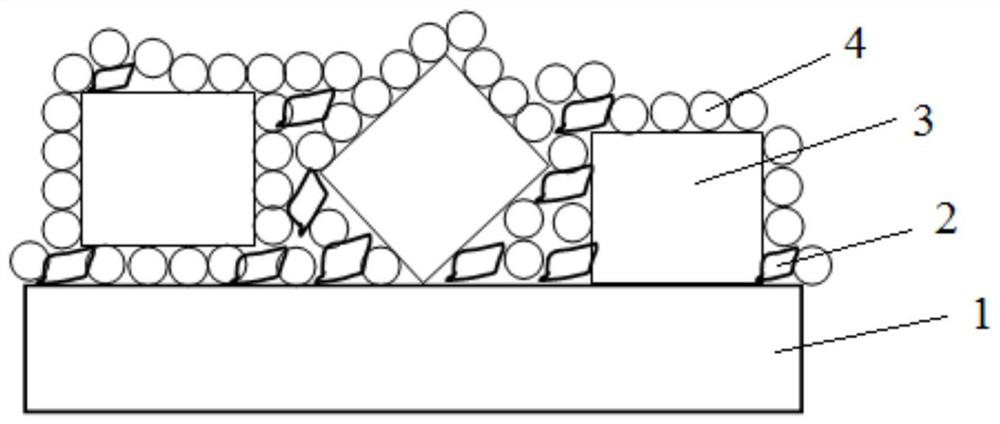

[0056] The schematic diagram of the prepared catalyst st...

Embodiment 2

[0058] Dissolve 0.77g of copper nitrate in 20g of deionized water, stir and dissolve fully to form a blue transparent solution, then add 6.2g of SAPO-34 powder and 7.65g of acidic silica sol in sequence, the pH is 4, stir for 6h to form a stable slurry. Cut the cordierite honeycomb ceramics into a cross-section of 12mm*12mm~15mm*15mm, and a length of 18~25mm, weigh them, and then immerse them in the slurry under ultrasonic conditions for 5 minutes, take them out and purge the pores, dry them at 120°C for 4 hours, take them out Then immerse in the slurry, repeat 3 times, and finally put it into a muffle furnace for calcination at 550°C for 5 hours to obtain the desired coated catalyst and weigh it. The prepared coated catalyst was ultrasonically treated for 30 minutes, then dried in a drying oven at 120°C for 4 hours, then calcined in a muffle furnace at 550°C for 5 hours, and weighed. The results are shown in Table 1.

Embodiment 3

[0060] Dissolve 0.77g of copper nitrate in 20g of deionized water, stir and dissolve fully to form a blue transparent solution, then add 7.9g of SAPO-34 powder and 1.98g of acidic silica sol in sequence, the pH is 4, stir for 6h to form a stable slurry. Cut the cordierite honeycomb ceramics into a cross-section of 12mm*12mm~15mm*15mm, and a length of 18~25mm, weigh them, and then immerse them in the slurry under ultrasonic conditions for 5 minutes, take them out and purge the pores, dry them at 120°C for 4 hours, take them out Then immerse in the slurry, repeat 3 times, and finally put it into a muffle furnace for calcination at 550°C for 5 hours to obtain the desired coated catalyst and weigh it. The prepared coated catalyst was ultrasonically treated for 30 minutes, then dried in a drying oven at 120°C for 4 hours, then calcined in a muffle furnace at 550°C for 5 hours, and weighed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com