Patents

Literature

33results about How to "Does not affect conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

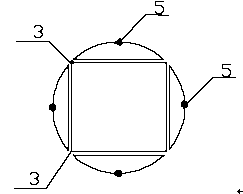

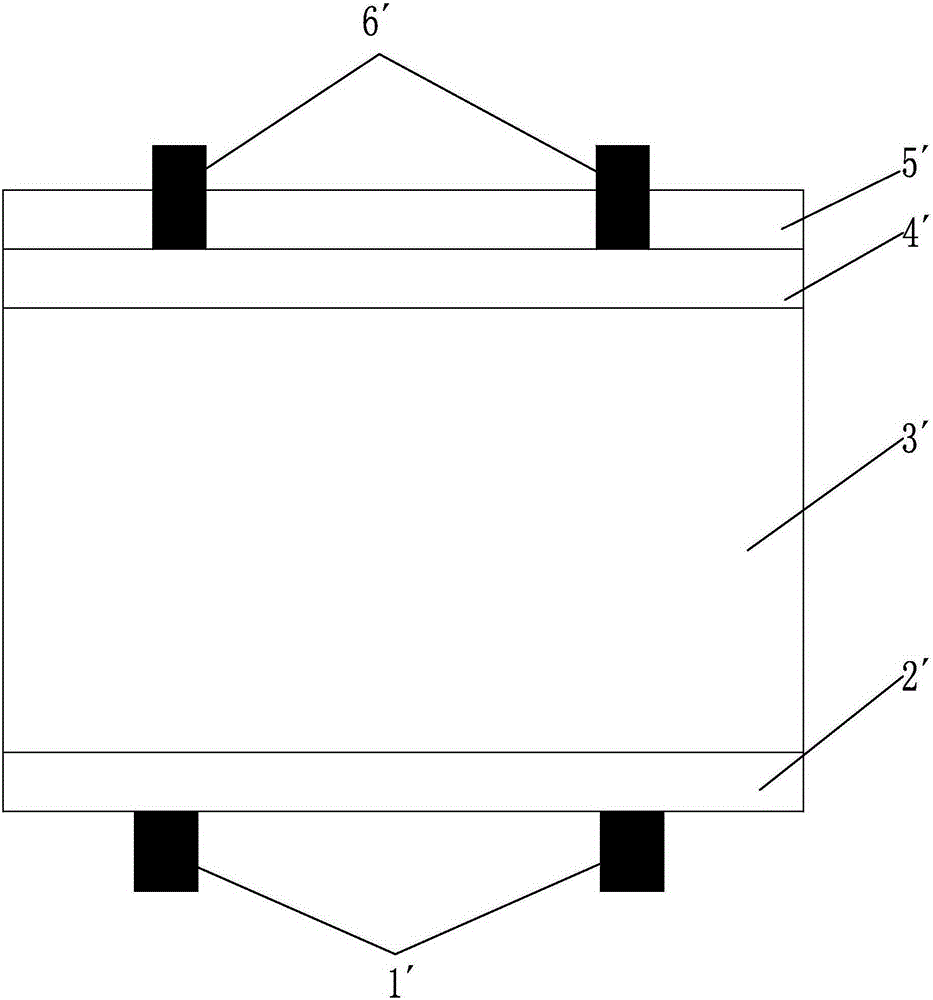

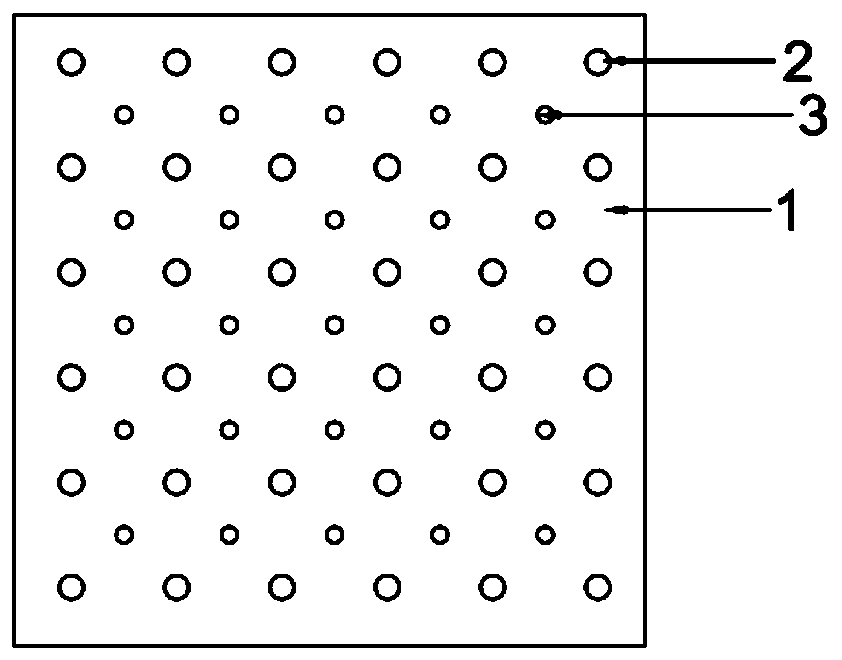

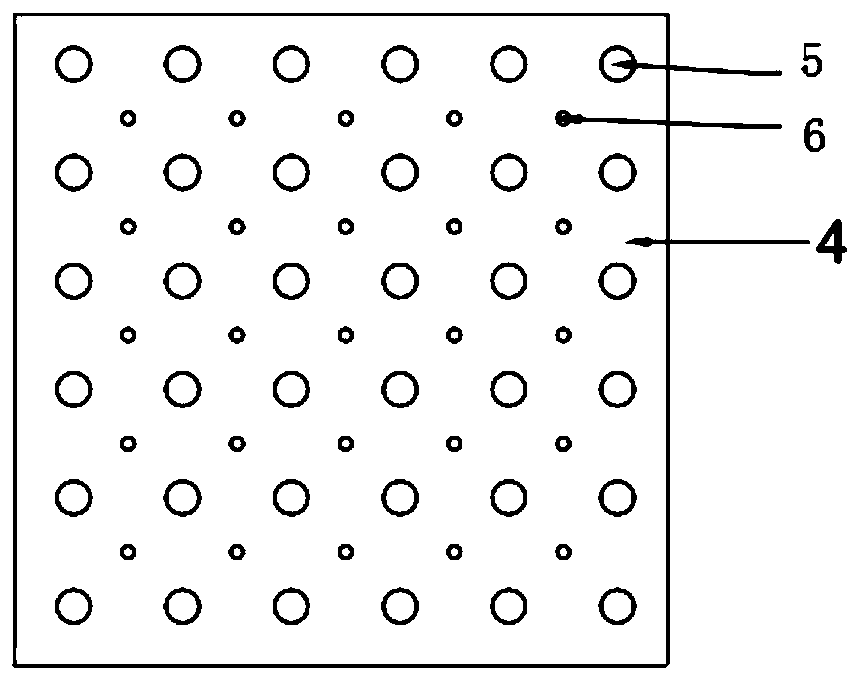

Solar cell, screen printing plate and solar cell module thereof

InactiveCN101826569AReduce stressReduce contact areaPhotovoltaic energy generationSemiconductor devicesScreen printingInterconnector

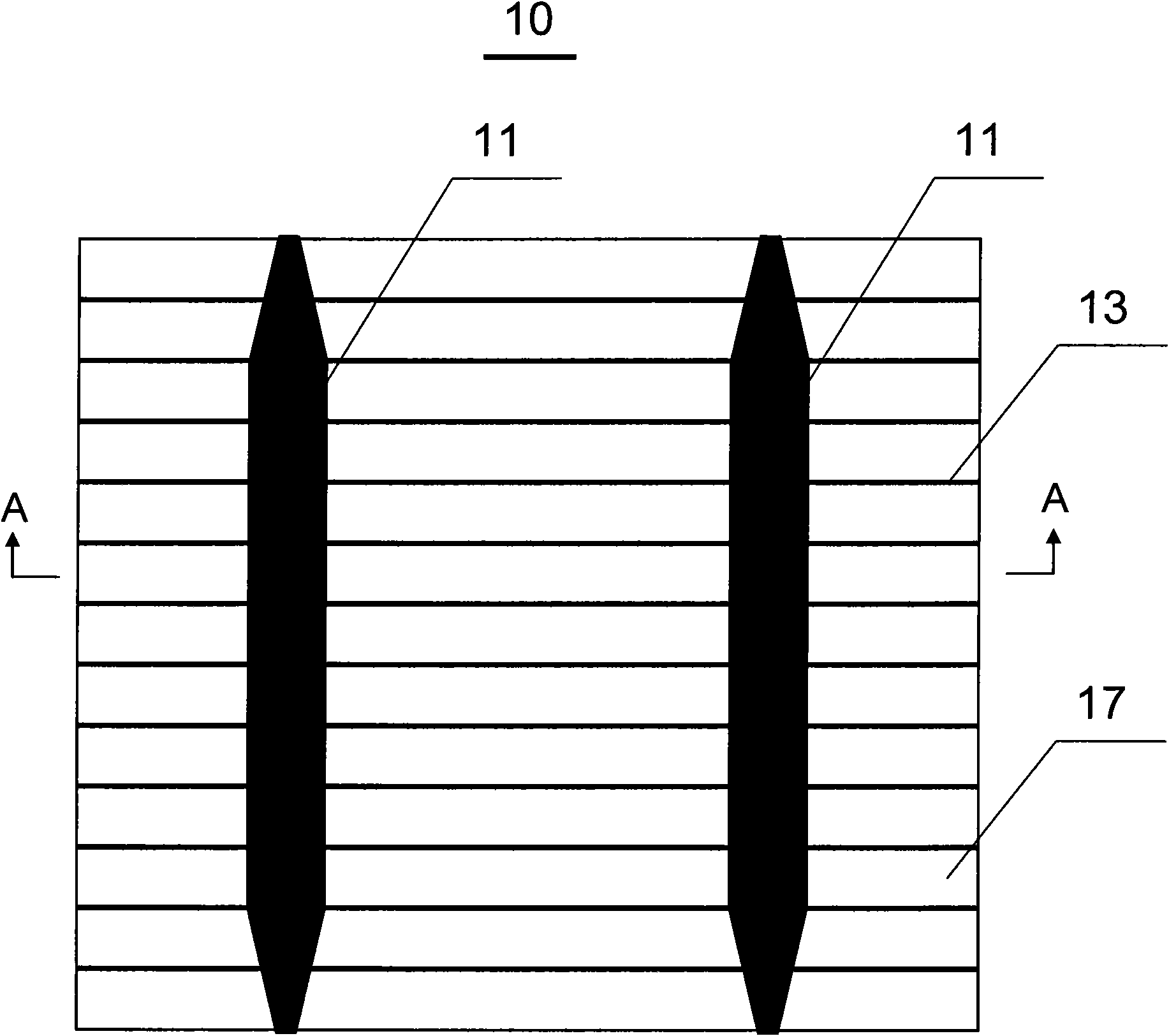

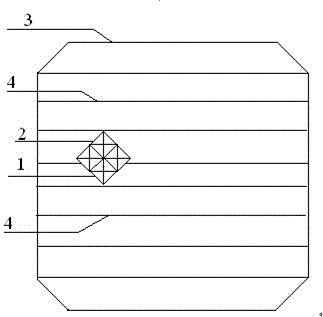

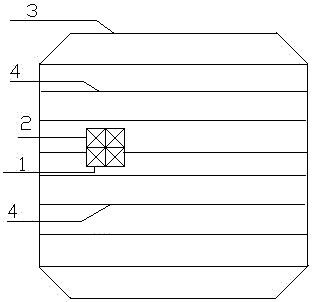

The invention discloses a solar cell, a screen printing plate and a solar cell module thereof, belonging to the technical field of photovoltaics. The solar cell of the invention comprises a cell substrate and an electrode, wherein the electrode is arranged on the substrate; the electrode comprises a main grid line; the construction of the line area of the main grid line is in a structure comprising at least one thin grid line to reduce the contact area between the main grid line and the substrate; the screen pringting plate provided by the invention is used for manufacturing the electrode of the solar cell of the invention by screen printing; and meshes for composing and forming the main grid line of the electrode are arranged on the screen printing plate. The solar cell module provided by the invention comprises a plurality of the solar cells provided by the invention. The solar cell and the solar cell module have low cost, and because the compound area between the metal electrode and the silicon in the cell structure is reduced, the conversion efficiency is improved, the output power of the module is increased, and in addition, the reliability after an interconnector is welded with a cell plate is good.

Owner:WUXI SUNTECH POWER CO LTD

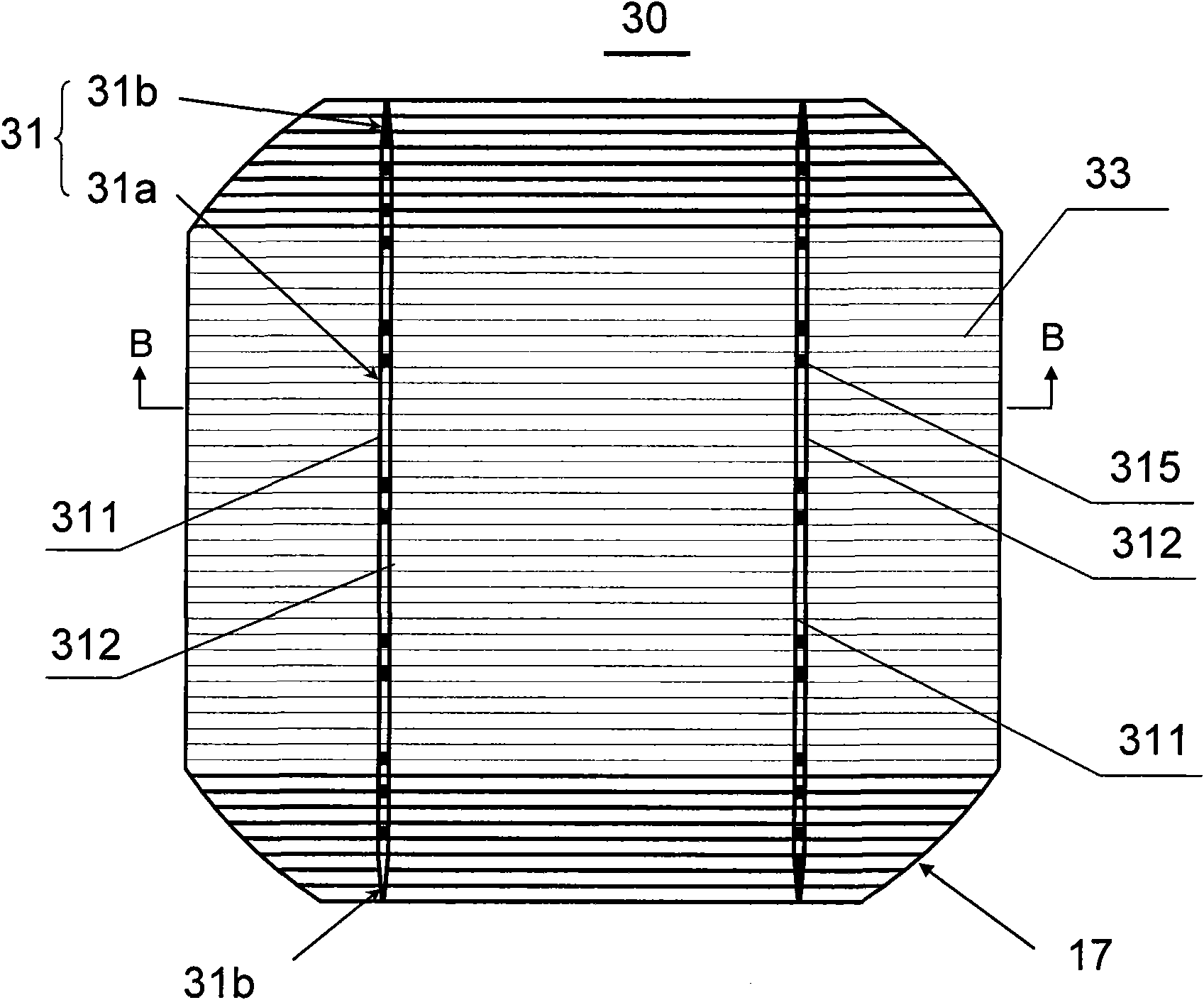

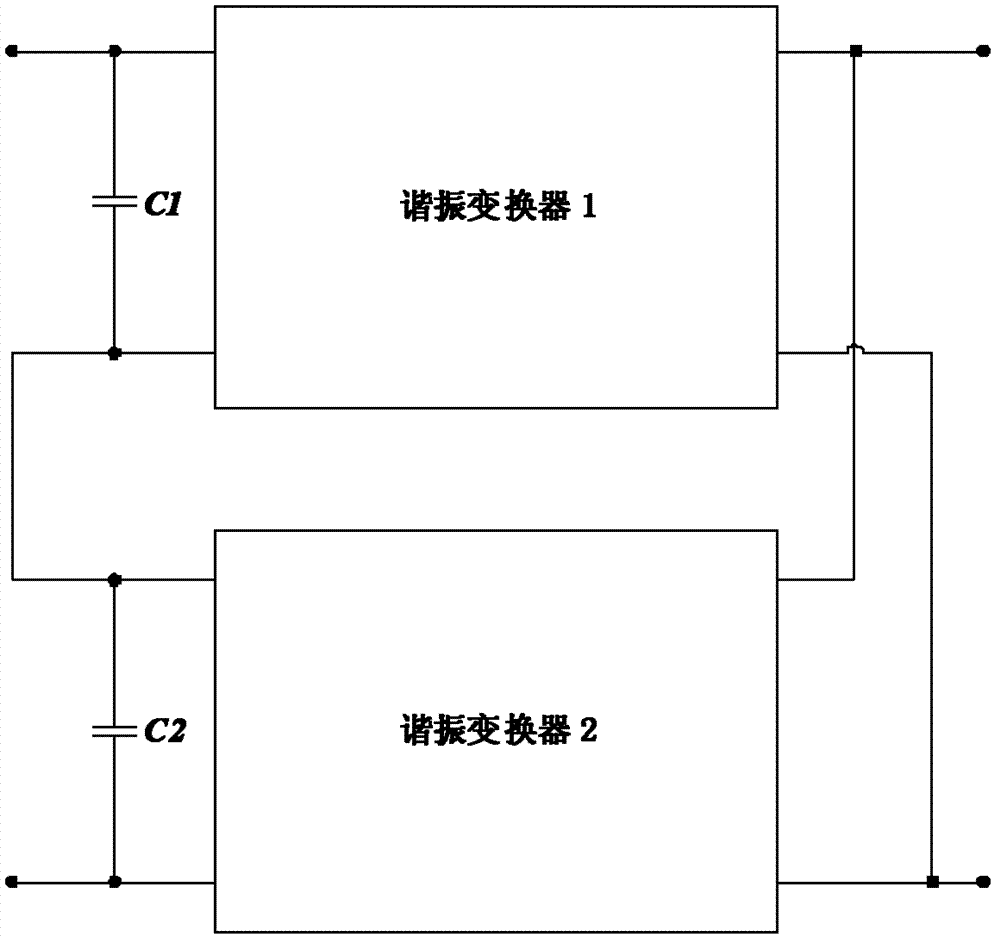

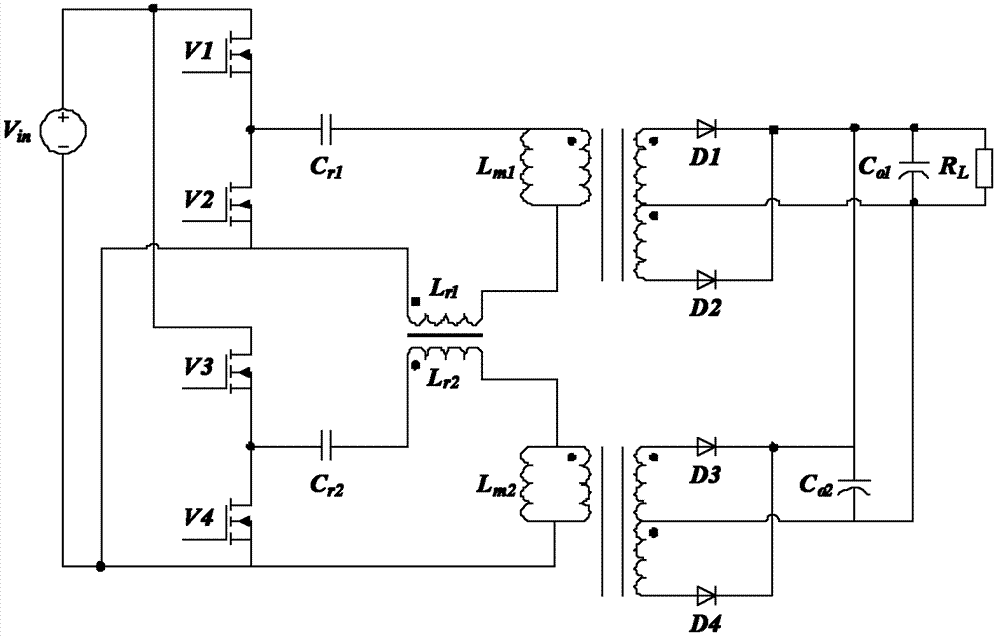

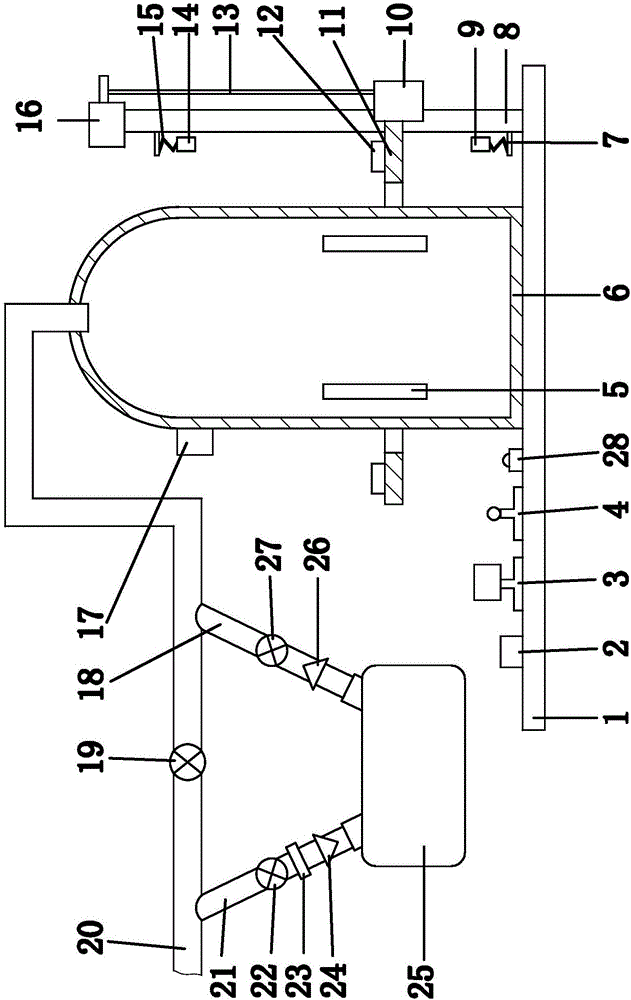

Multi-phase alternating resonant converter

InactiveCN102790533ARealize current sharingDoes not affect conversion efficiencyEfficient power electronics conversionDc-dc conversionEngineeringResonant converter

The invention discloses a multi-phase alternating resonant converter. The multi-phase alternating resonant converter comprises at least two unit resonant circuits, wherein each unit resonant circuit comprises an inverter circuit, a resonant circuit, a transformer and a rectifying circuit; the inverter circuit is used for generating square waves and is connected with input voltage; an input port of the resonant circuit is connected with the inverter circuit; an output port of the resonant circuit is connected with the primary side of the transformer in parallel; the secondary side of the transformer is connected with the rectifying circuit; the secondary side of the transformer in one unit resonant circuit is connected with the secondary side of the transformers of other unit resonant circuits in a star-shaped manner. The invention provides the multi-phase alternating resonant converter which is formed by connecting at least two unit resonant circuits in parallel, so that the flow equalization of the multi-phase power conversion unit is achieved, the output ripple current is reduced, and the conversion efficiency of the resonant conversion circuit system is improved.

Owner:ZTE CORP

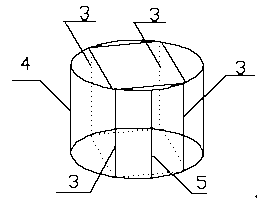

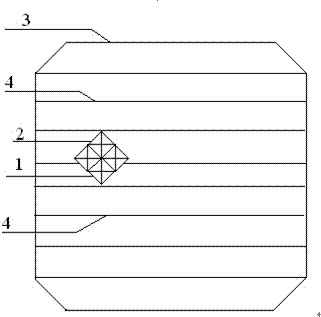

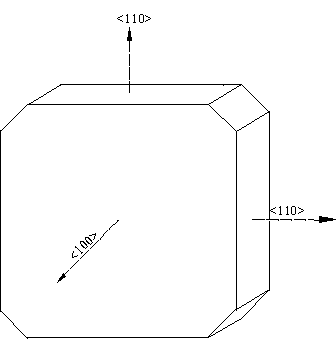

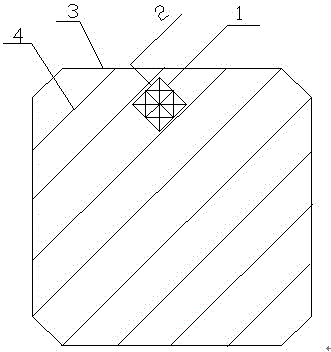

Squaring process and application of monocrystal silicon round bar for solar cells

ActiveCN103862584AShorten the transmission distanceImprove collection efficiencyFine working devicesCrystal orientationEngineering

The invention discloses a squaring process of a monocrystal silicon round bar for solar cells. The squaring process comprises the steps that the circumferential radian between a ridge line of the silicon bar and a ridge line of an adjacent crystal support is adjusted to be 2pi / 9-5pi / 18, and then the monocrystal silicon round bar is squared. The invention further provides a production process of a monocrystal silicon solar cell. The production process comprises the steps of preparation of monocrystal silicon cutting pieces, surface texturing and printing of electrode grid lines. The monocrystal silicon cutting pieces are quasi square silicon slices formed by wire-electrode cutting of cutting pieces by a monocrystal silicon square bar, and the monocrystal silicon square bar is obtained by the monocrystal silicon round bar through the squaring process, and the printed electrode grid lines are parallel to or perpendicular to the edges of the quasi square silicon slices. According to the squaring process of the monocrystal silicon round bar, four monocrystal silicon square bars with the lateral crystal orientations being <110> + / -5 degrees can be obtained, then four monocrystal silicon cutting pieces with the edge crystal orientations being <110> + / - 5 degrees are obtained, the bottom edge of a texturing face pyramid structure formed by conventional texturing of the monocrystal silicon slices can be used for transmitting photoproduction electrons, and route extending of the photoproduction electrons can not happen on the bottom edge of the pyramid structure.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

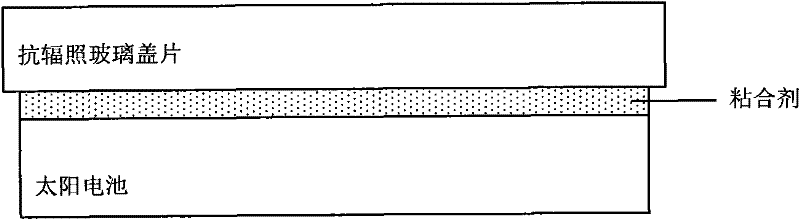

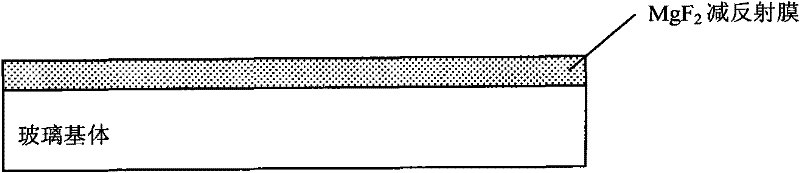

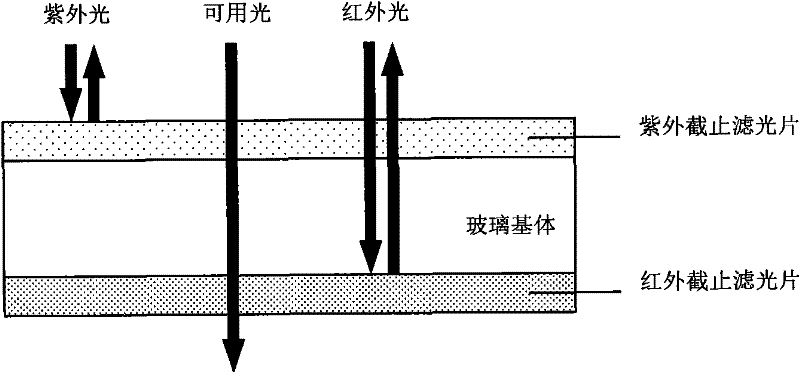

Band-pass filter of spatial silicon solar cell

InactiveCN102650709AIncreased on-orbit output powerAvoid deformationLayered productsPhotovoltaic energy generationBand-pass filterWorking temperature

The invention relates to a spatial power supply and discloses a band-pass filter of a spatial silicon solar cell, which comprises a layer of ceria-doped anti-radiation glass matrix; and an ultraviolet light interception filter is prepared on the upper surface of the glass matrix, and an infrared ray interception filter is prepared on the lower surface of the glass matrix. According to the band-pass filter of the spatial silicon solar cell, the problems of the prior art that an existing silicon solar cell intensely absorbs the infrared ray, so that the working temperature is high and the output power is greatly reduced are solved, and the beneficial effects of reducing the on-the-track working temperature of the silicon solar cell and improving the on-the-track output power are achieved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

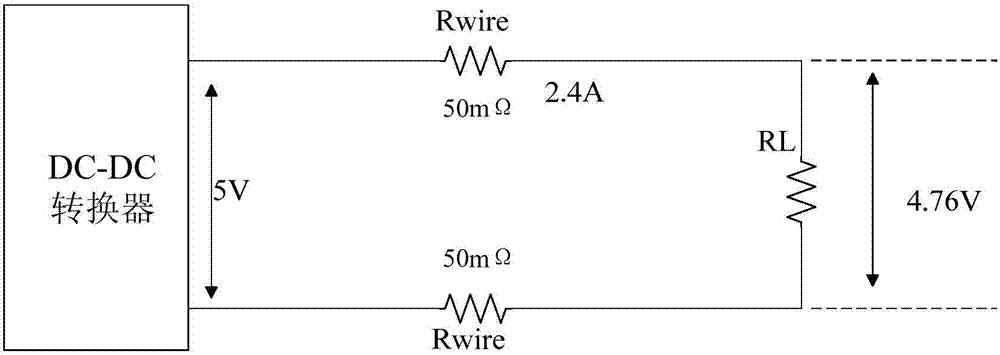

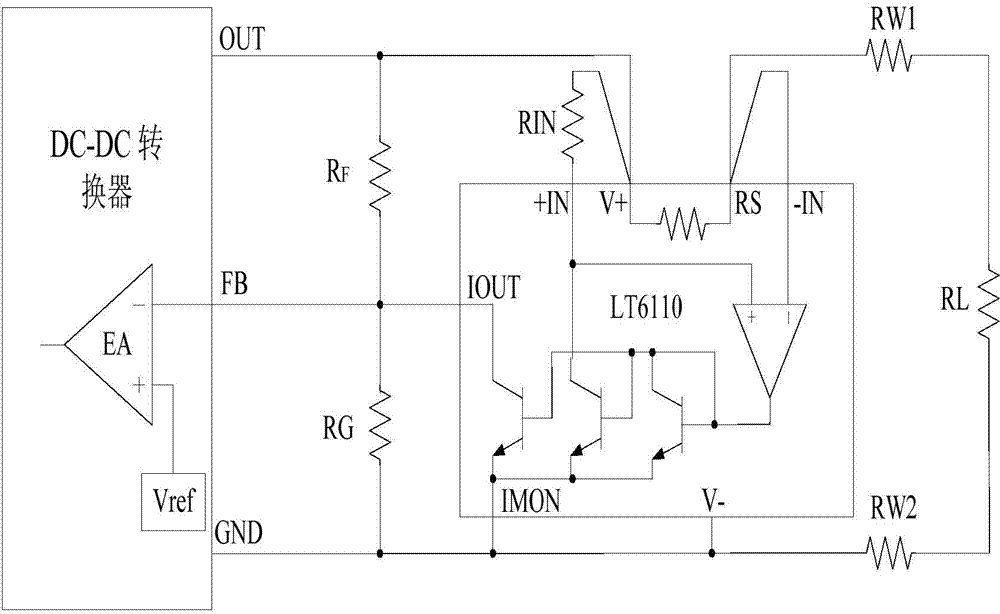

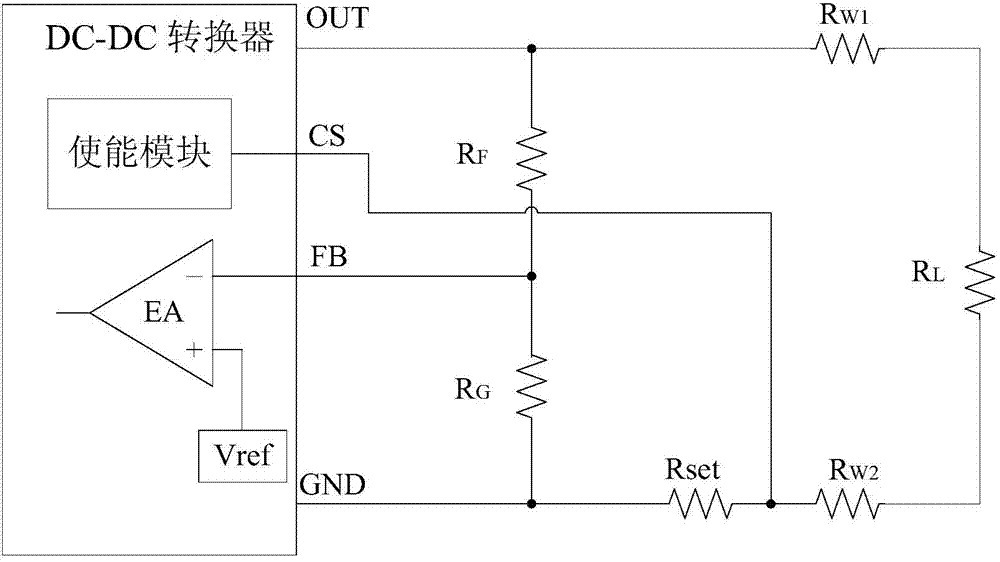

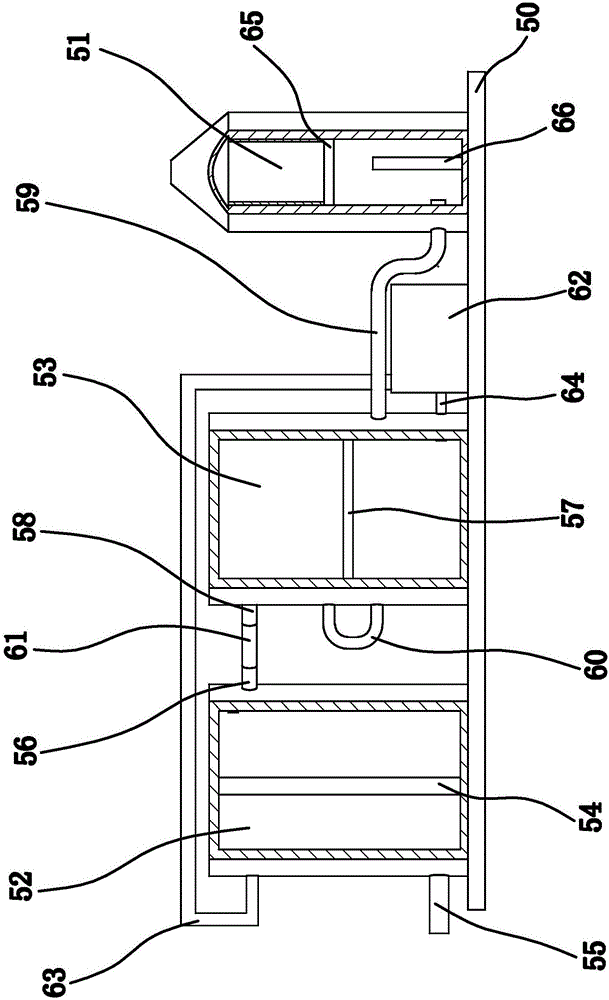

Adaptive line loss compensation circuit for DC-DC (direct current) converter

InactiveCN104333221AAdaptive compensation is easyDoes not affect conversion efficiencyDc-dc conversionElectric variable regulationElectrical resistance and conductanceCMOS

The invention discloses an adaptive line loss compensation circuit for a DC-DC (direct current) converter. The adaptive line loss compensation circuit comprises an operational amplifier, an NMOS (N-channel metal oxide semiconductor) tube, a low-side current sampling resistor and a compensation resistor, one end of the low-side current sampling resistor and one end of the compensation resistor are jointly grounded, the other end of the low-side current sampling resistor is connected with a CS end, the other end of the compensation resistor is connected with a Vcom end, an in-phase input end of the operational amplifier is connected with the CS end, an inverted input end of the operational amplifier is connected with the Vcom end, an output end of the operational amplifier is connected with a grid electrode of the NMOS tube, a source electrode of the NMOS tube is connected with the Vcom end, and a drain electrode of the NMOS tube is connected with an FB end of the DC-DC converter. The adaptive line loss compensation circuit has the advantages that the conversion efficiency of the DC-DC converter cannot be affected, the adaptive line loss compensation circuit is high in precision and easy to implement, and a full CMOS (complementary metal oxide semiconductor) process can be adopted. The adaptive line loss compensation circuit can be widely applied to the field of integrated circuits.

Owner:SUN YAT SEN UNIV

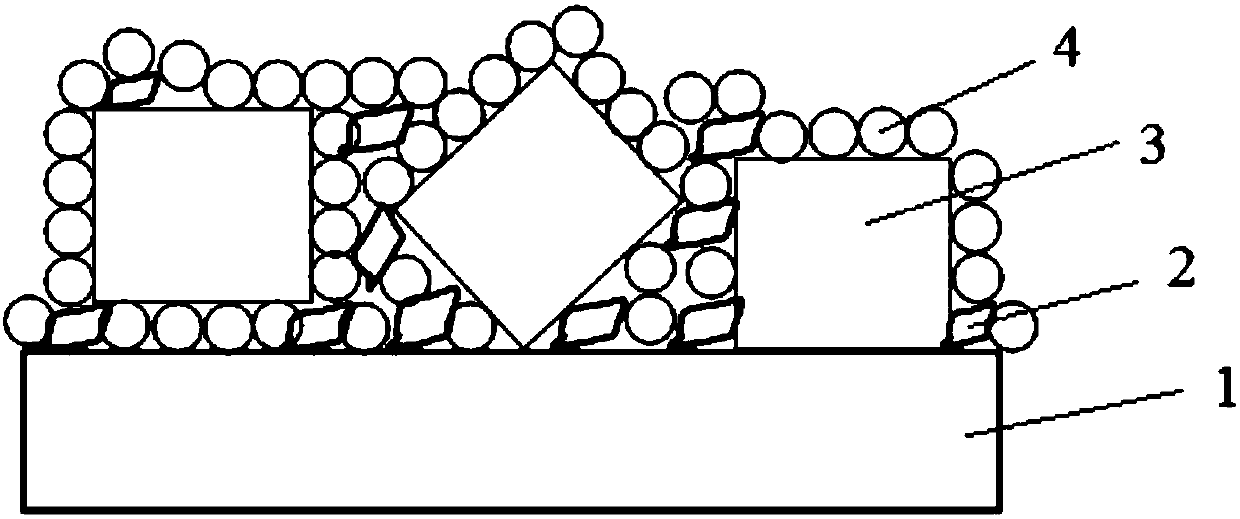

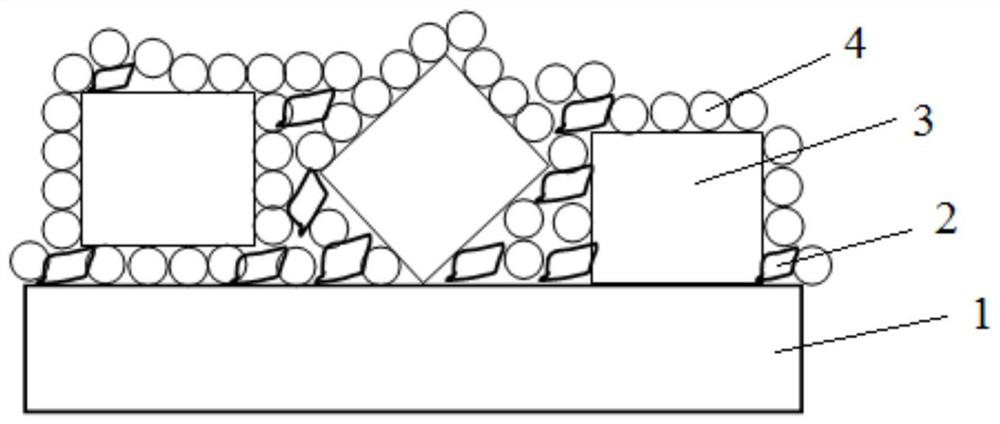

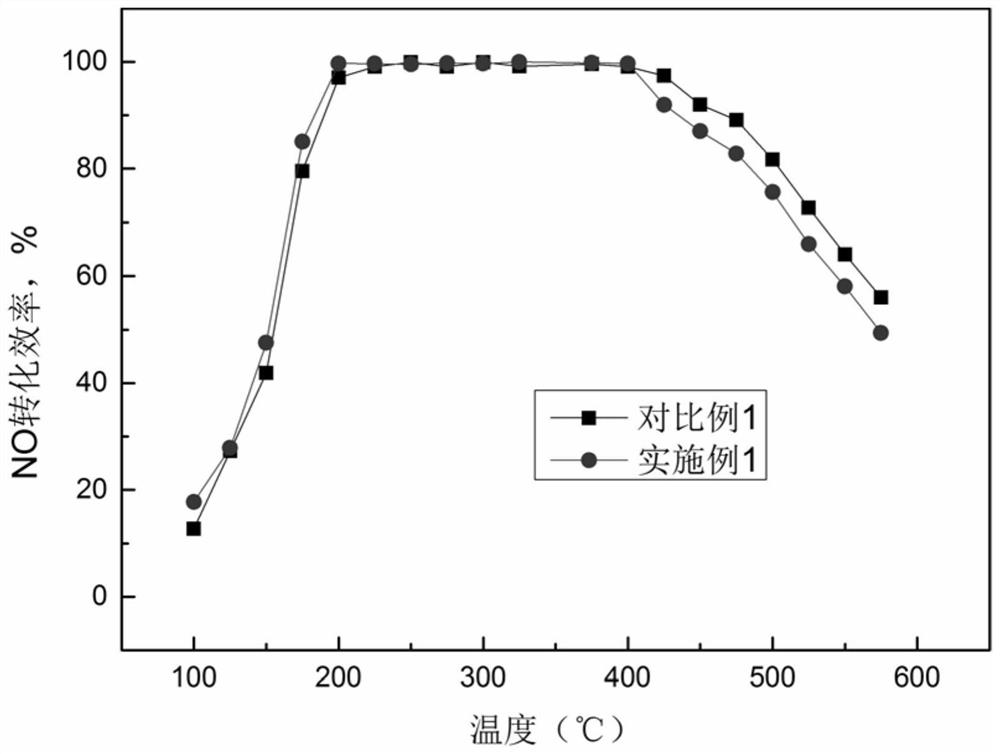

Preparation method of coating slurry, and preparation method of coated Cu molecular sieve SCR catalyst

ActiveCN107824217AShorten the timeReduce production processMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention provides a preparation method of a coating slurry, and a preparation method of a coated Cu molecular sieve SCR catalyst. A Cu precursor is directly added into the slurry, the active component Cu is simultaneously loaded on the surfaces of a molecular sieve and a binder, and the surface of the catalyst still has the active component after shedding. The time taken by the loading of theCu to the molecular sieve and the preparation technology of the catalyst are greatly reduced, and the preparation process is simplified; and the preparation technology is reduced, the energy consumption is greatly reduced, no dispersant is added, and the prepared catalyst has good coating strength and good NH3-SCR performance, and still has the active component after shedding.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

Polycrystalline solar cell surface silicon nitride antireflection film preparation method

ActiveCN105845748AHigh refractive indexDoes not affect conversion efficiencyFinal product manufacturePhotovoltaic energy generationGraphiteCrystalline silicon

The invention provides a polycrystalline solar cell surface silicon nitride antireflection film preparation method, which solves the technical problems that an existing solar cell is simple in structure, is easy to have continuous attenuation and is poor in product stability. The polycrystalline solar cell surface silicon nitride antireflection film preparation method comprises the following steps: a) carrying out cleaning, texturing, diffusion and etching on a crystalline silicon wafer; b) enabling the crystalline silicon wafer obtained after the step a) to pass through an ozone generation device to generate a 1-2 mm SiO2 oxidation film on the surface of the silicon wafer; c) cleaning a graphite boat through a cleaning device, placing the crystalline silicon wafer obtained after the step b) on the graphite boat, and placing the graphite boat loaded with the wafer to a tubular PECVD for pre-deposition and cleaning; d) carrying out tubular PECVD deposition on the crystalline silicon wafer obtained in the step c); and e) carrying out tubular PECVD deposition again on the crystalline silicon wafer obtained in the step d). The method has the advantages of stable and reliable product.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

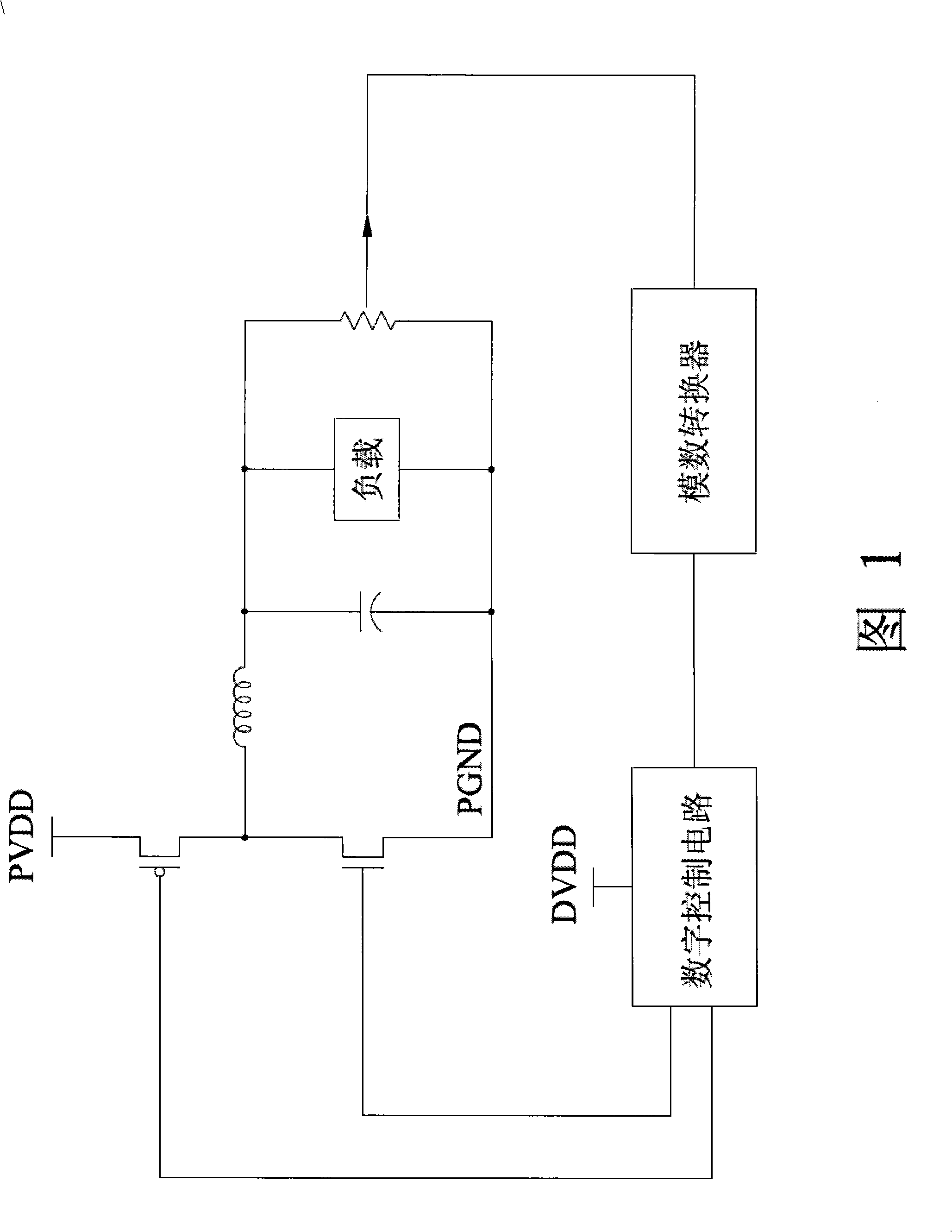

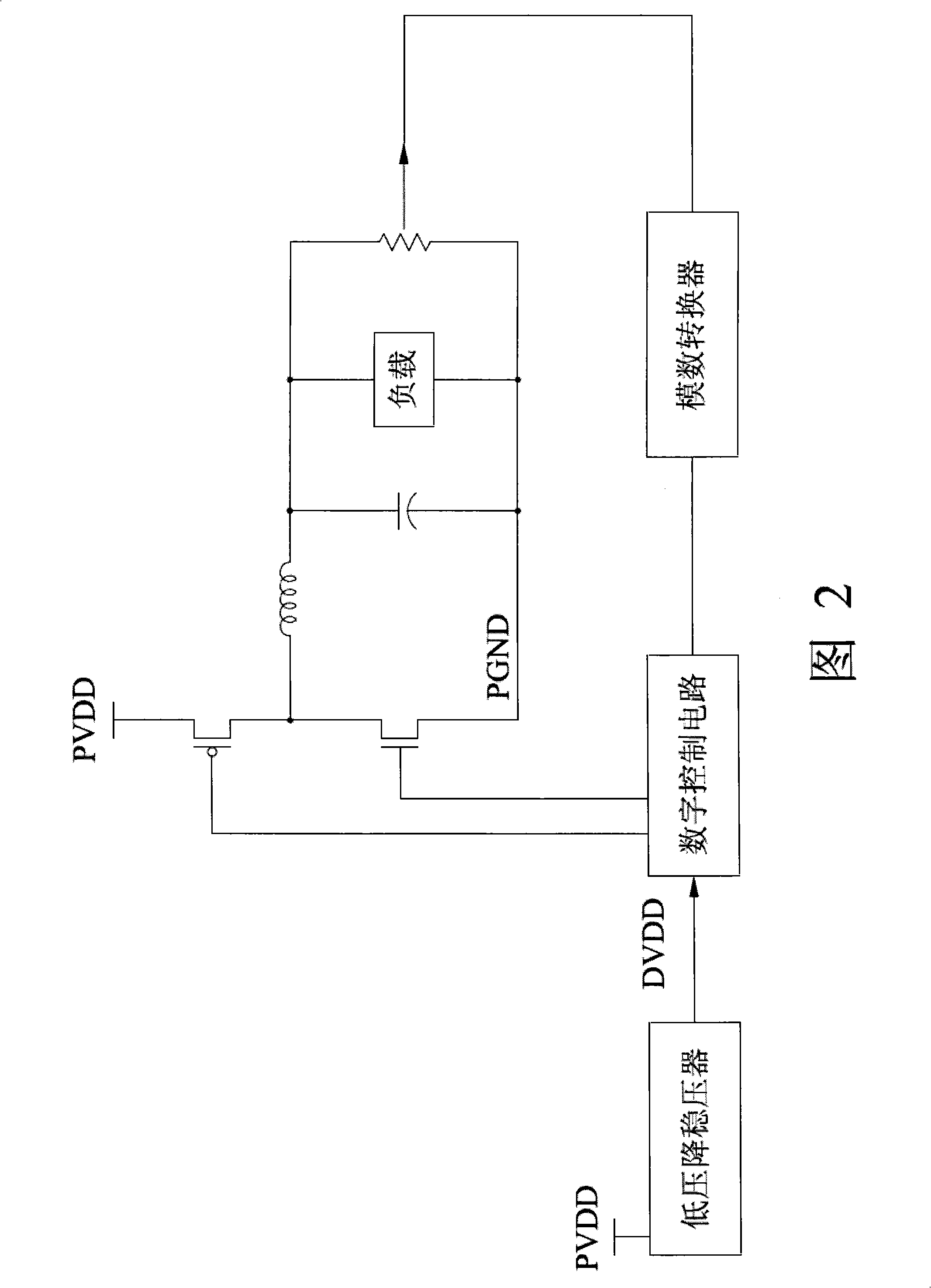

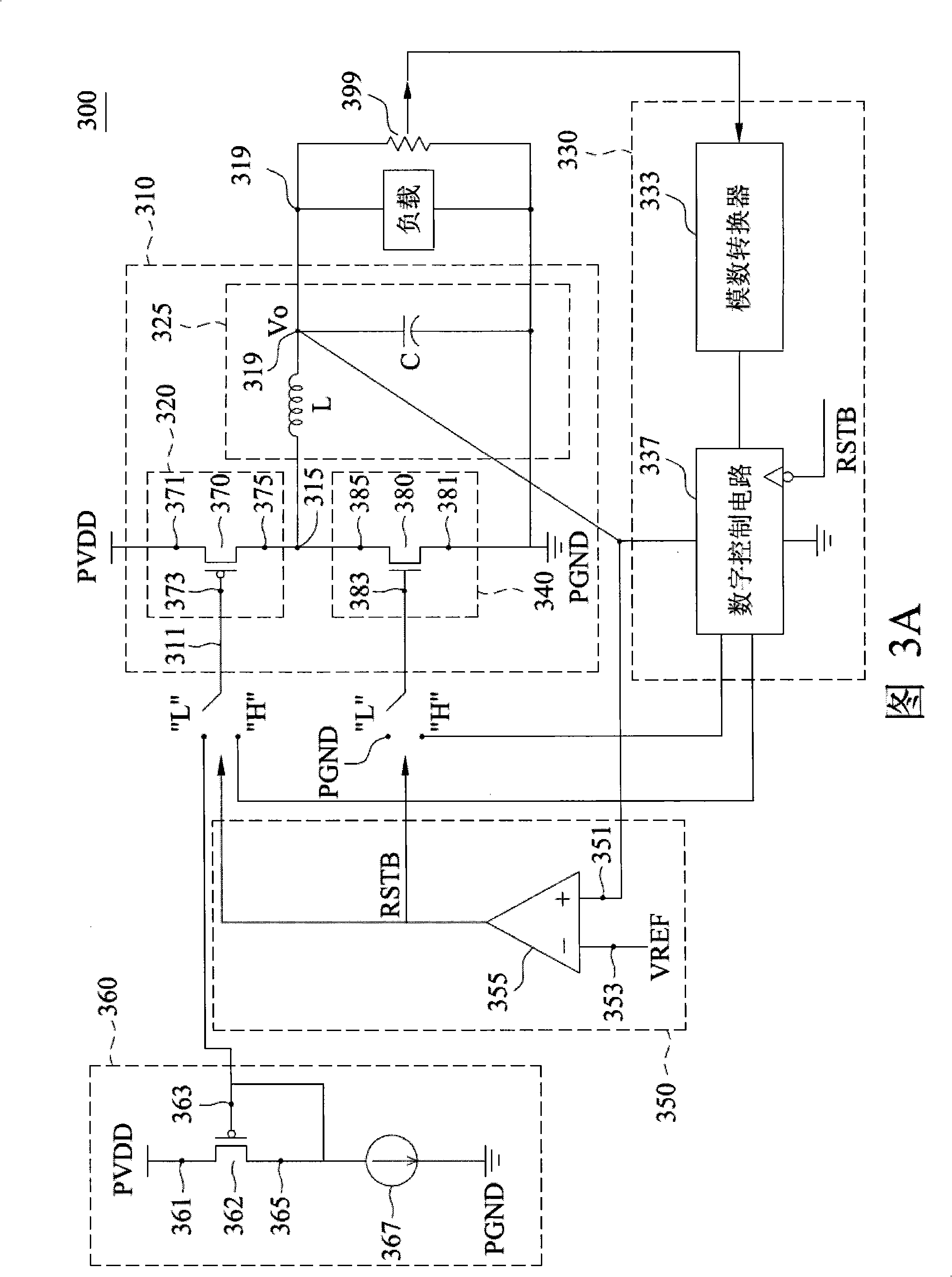

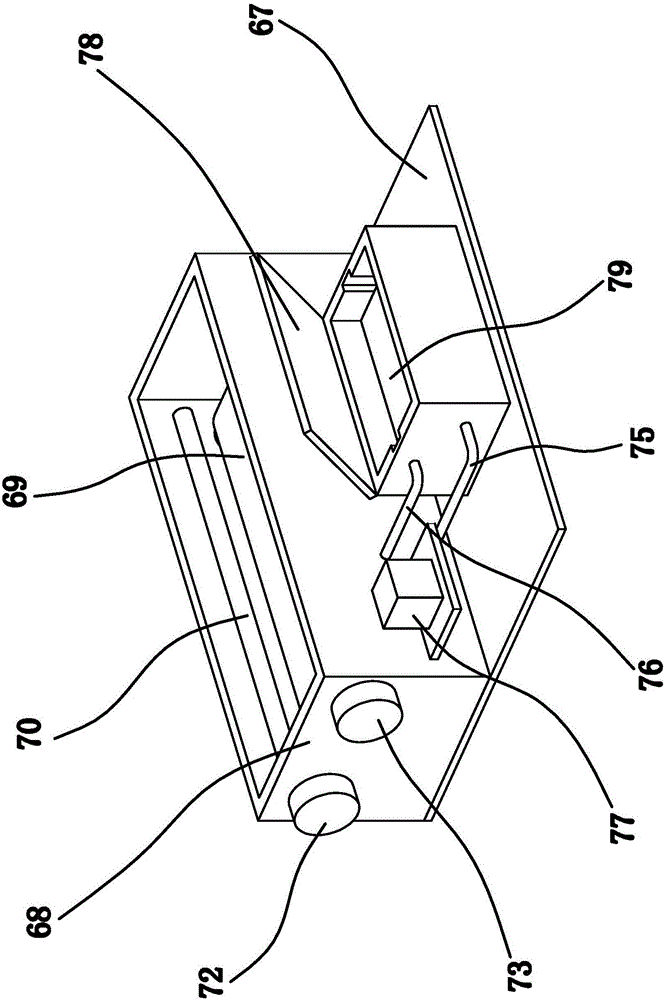

DC-DC converter

ActiveCN101404448ADoes not increase the areaDoes not affect conversion efficiencyEfficient power electronics conversionApparatus without intermediate ac conversionDc dc converterLow-pass filter

The present invention provides a DC-DC converter providing a DC output voltage at an output node. The DC-DC converter comprises an output stage, a digital controller, and a controller. The output stage comprises a pull-up circuit having a control terminal and coupled between a first fixed voltage and a internal node, a pull-down circuit coupled between the internal node and a second fixed voltage, and a low pass filter coupled between the internal node and the output node. The digital controller is powered by the DC output voltage and adjusts the DC output voltage by controlling the output stage. The controller controls a connection of a feedback path, comprising the digital controller, between the output node and the control terminal according to the DC output voltage.

Owner:MEDIATEK INC

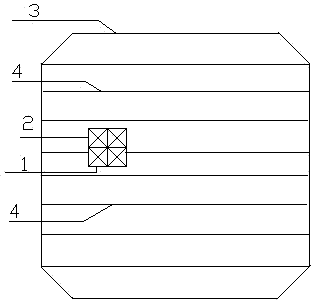

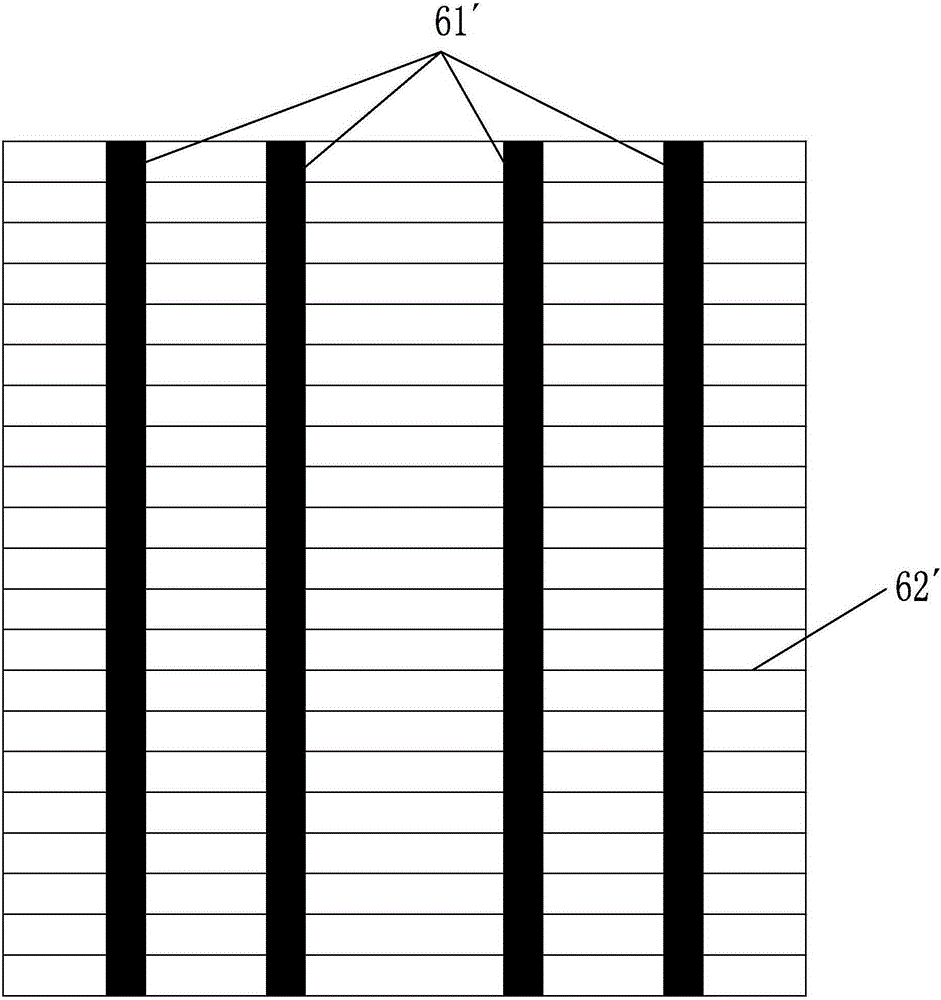

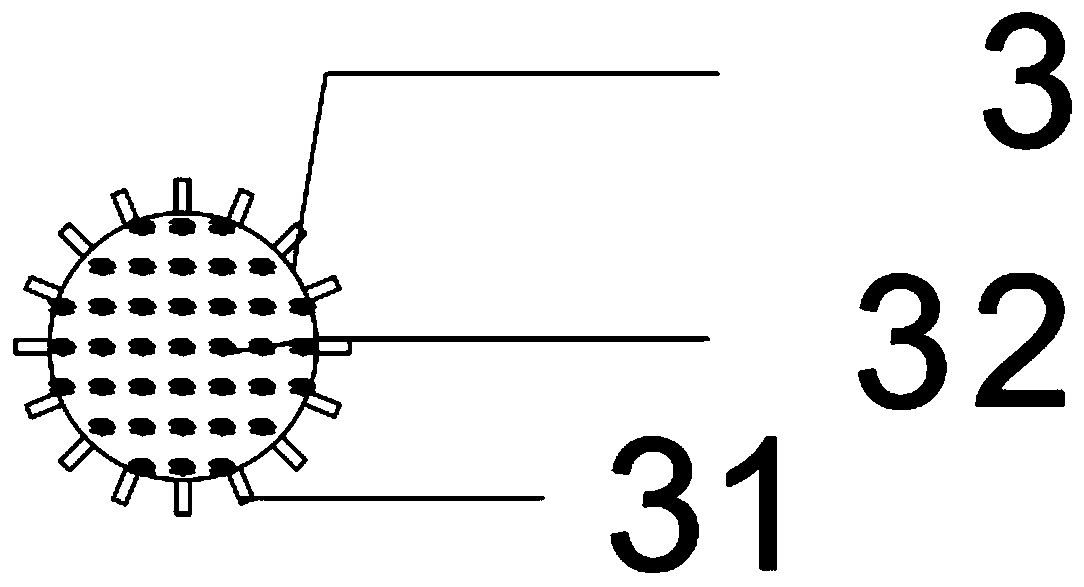

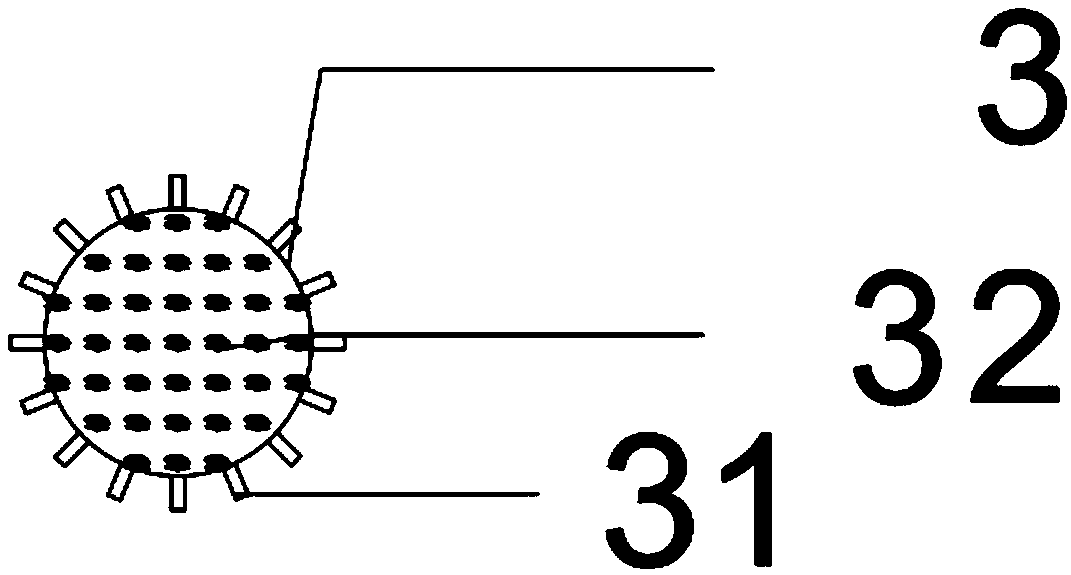

Single crystalline silicon solar cell

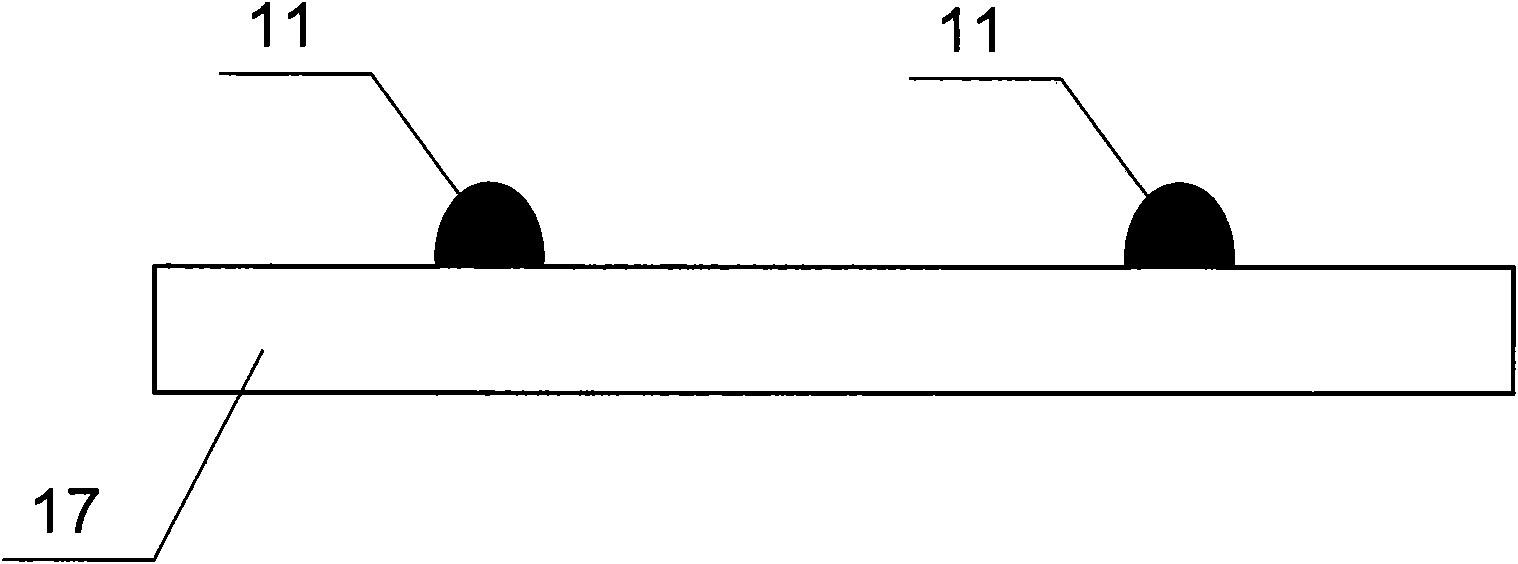

ActiveCN103928538AShorten the transmission distanceImprove collection efficiencyPhotovoltaic energy generationSemiconductor devicesCrystalline siliconSilicon chip

The invention discloses a single crystalline silicon solar cell. The single crystalline silicon solar cell comprises a silicon chip and electrode grid lines, wherein the silicon chip is provided with a pyramid-structure texturing surface, and the included angle between the tangent line of each portion of the electrode grid lines and one of the four edges on the bottom surface of a certain pyramid structure ranges from 0 degree to 10 degrees or from 80 degrees to 90 degrees. According to the single crystalline silicon solar cell, the bottom edges of the pyramid structure of the texturing surface of the silicon chip can be effectively used for transmitting photoproduction electrons, the transmission distance of the photoproduction electrons on the surface of the silicon chip is shortened, collection efficiency of the electrons is effectively improved, and then cell conversion efficiency is improved; the density of the grid lines can be reduced under the condition that the cell conversion efficiency is not affected, and then the cost is reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

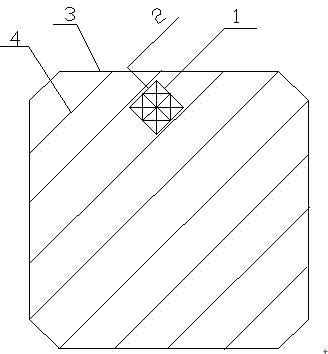

Monocrystalline silicon cutting piece and solar cell piece with the same

ActiveCN103872157AShorten the transmission distanceImprove collection efficiencyPhotovoltaic energy generationSemiconductor devicesCrystal orientationSolar cell

The invention discloses a monocrystalline silicon cutting piece used by a solar cell. The monocrystalline silicon cutting piece is a quasi-square silicon piece formed by cutting a monocrystalline silicon crystal bar. The surface crystal orientation is 100 + / - 3 degrees, and the four margin crystal orientations are 110 + / - 5 degrees. The invention further provides a monocrystalline silicon solar cell piece which comprises an electrode grid line and the monocrystalline silicon cutting piece. The monocrystalline silicon cutting piece forms a texturing face with a pyramid structure by texture making. The electrode grid line and the edge of the monocrystalline silicon cutting piece are in parallel or perpendicular. A pair of bottom sides of the texturing face pyramid structure formed after texture making of the monocrystalline silicon cutting piece is basically perpendicular to the edge of a silicon piece, the bottom sides are basically perpendicular to the normally-printed electrode grind line, the pair of bottom sides of the pyramid structure can be used for transmitting photoproduction electrons, path extension of the photoproduction electrons on the bottom sides of the pyramid structure can be avoided, compared with the prior art, the transmission distance of the photoproduction electrons on the surface of the silicon piece is shortened, electron collecting efficiency is effectively improved, and then cell converting efficiency is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

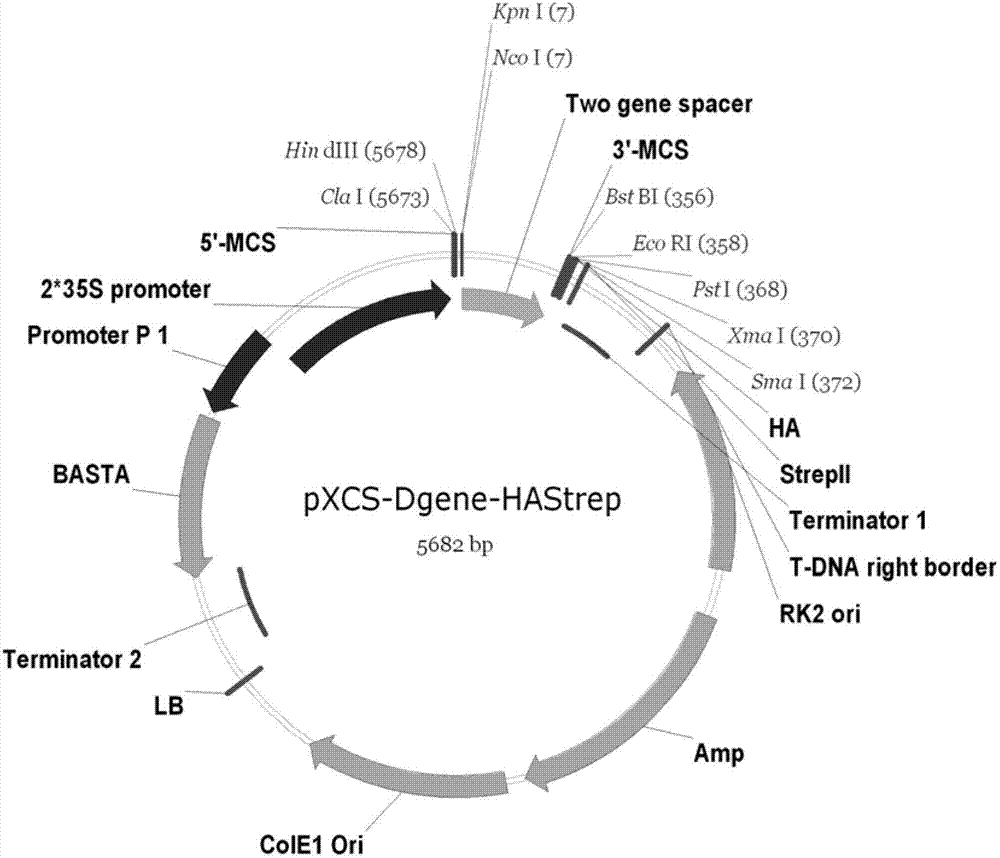

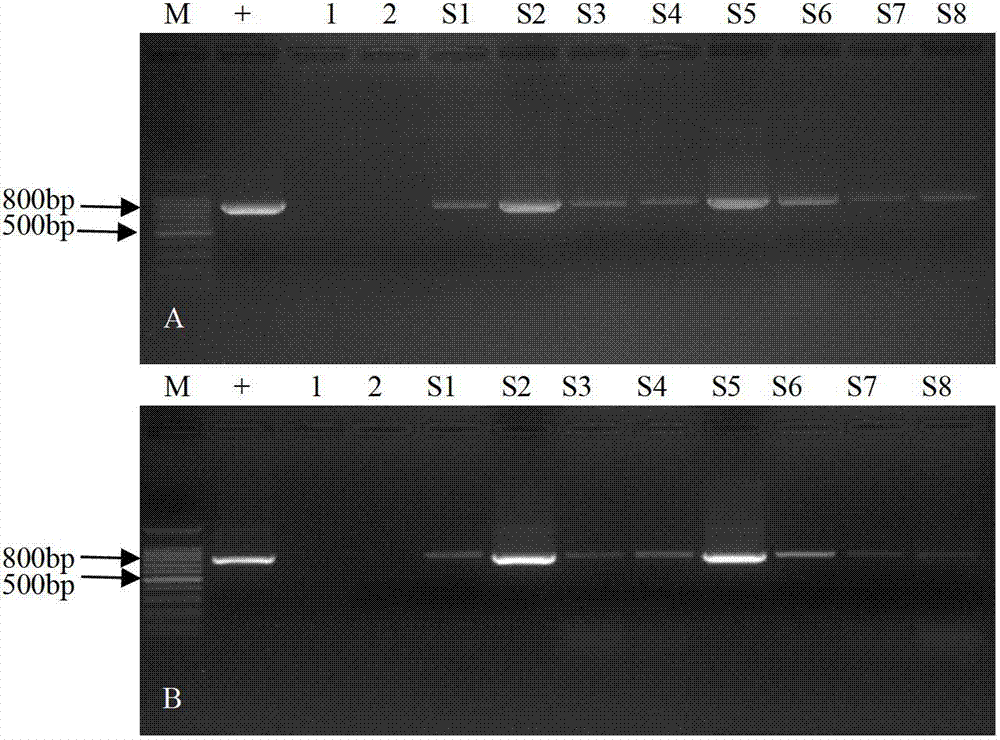

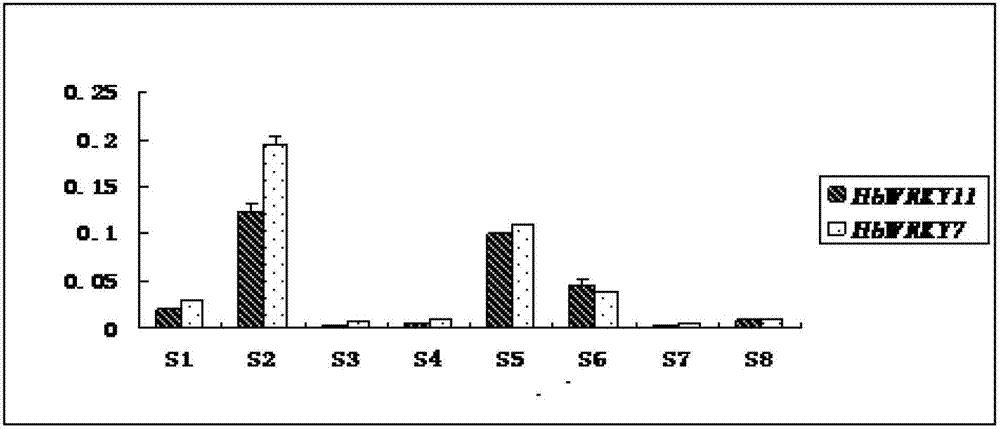

Construction method of plant dual-gene co-expression vector

InactiveCN103088055AAvoid troubleOvercoming disequilibriumVector-based foreign material introductionRestriction Enzyme Cut SiteGene coexpression

The invention relates to a construction method of a plant dual-gene co-expression vector. The construction method is characterized by comprising the following steps of: adding restriction enzyme cutting sites of Nco1 and EcoR I incision enzymes at two ends of a spacer sequence in a plasmid pGWB 605 (the registration number of which is AB543114 in GenBank) through PCR (Polymerase Chain Reaction) amplification, and then cloning the spacer sequence into a pXCS-HAStrep plasmid to construct the plant dual-gene co-expression vector pXCS-Dgene-HAStrep. The co-expression vector only has 5682Kb and can be loaded with two larger foreign genes which are independently expressed in an eukaryotic expression system. A bar gene is used as a screening marker gene in the co-expression vector. According to the construction method, the screening operation of a transgenic plant is simple, and the efficiency is high.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

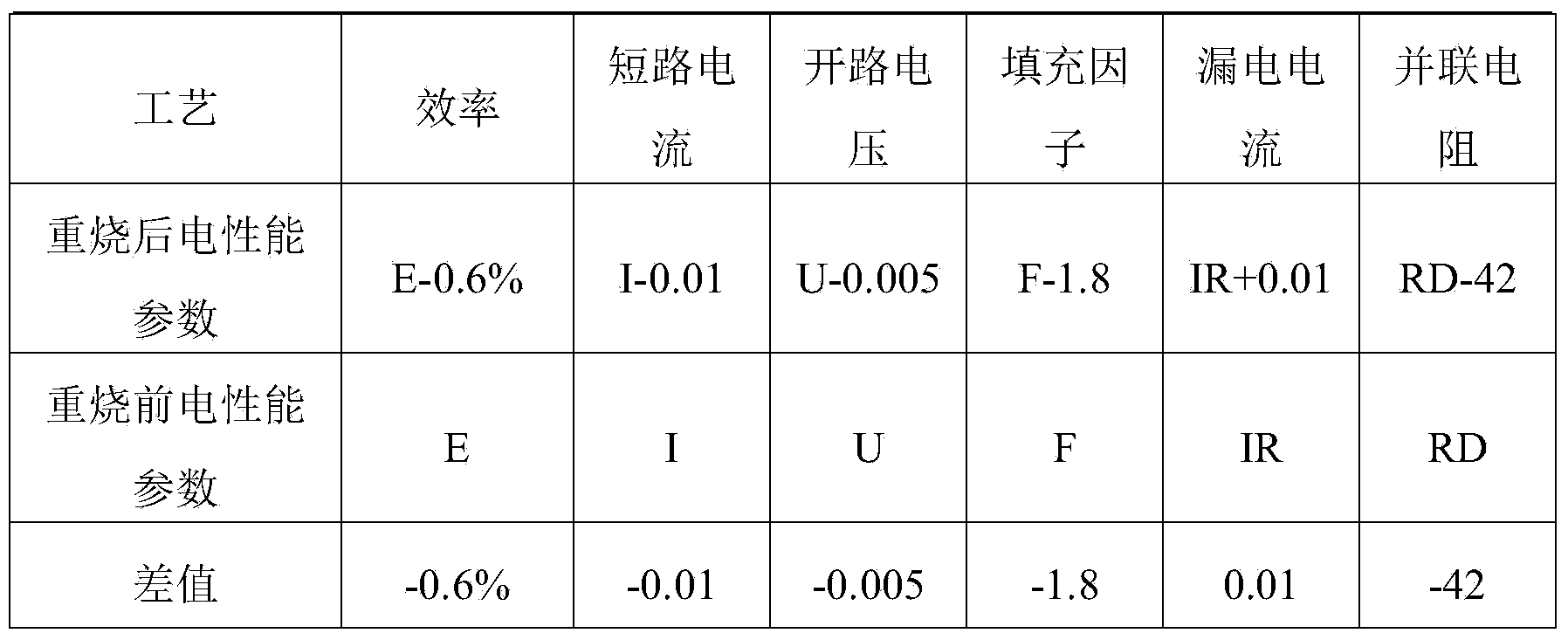

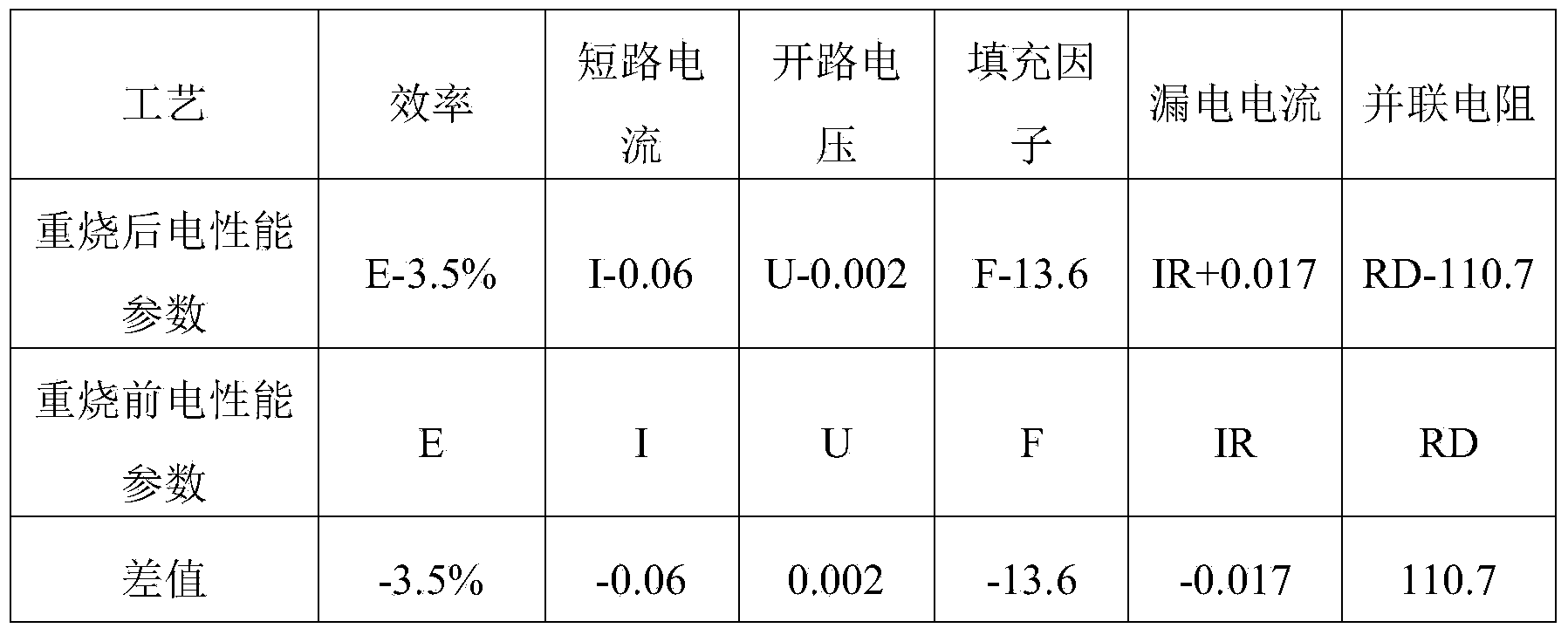

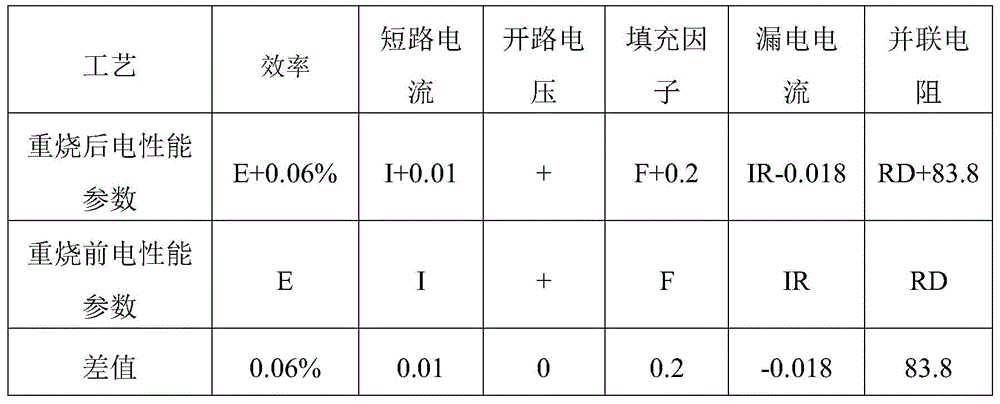

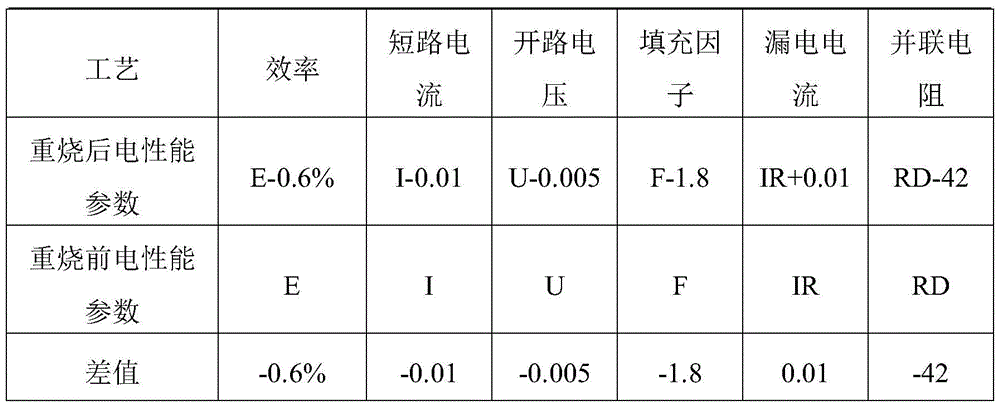

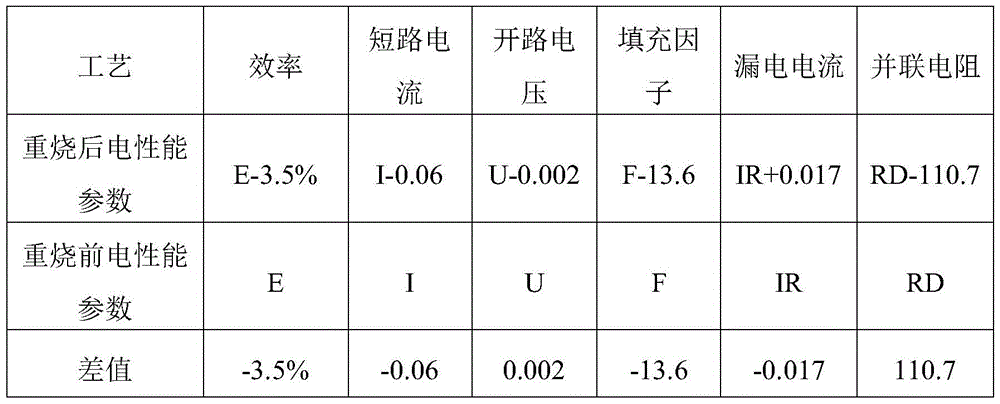

Sulfidizing process for gate lines of solar cell pieces

ActiveCN104037263ADoes not affect conversion efficiencyGood lookingFinal product manufacturePhotovoltaic energy generationProduction lineEngineering

The invention discloses a sulfidizing process for the gate lines of solar cell pieces. According to the sulfidizing process, heating treatment is carried out on the solar cell pieces with the sulfidized gate lines at a heating temperature of 350+ / -10 DEG C for at least 80 seconds, and then cooling to obtain products. The solar cell pieces with the sulfidized gate lines are heated by virtue of a sintering furnace on a solar cell piece production line, the running speed of the conveying belt of the sintering furnace is 250+ / -10in / min, the temperature of the drying area of the sintering furnace is 350+ / -10 DEG C, the temperature of the sintering area is 450+ / -10 DEG C, and the solar cell pieces are arranged on the conveying belt and sequentially pass through the drying area and the sintering area. According to the sulfidizing process disclosed by the invention, after the heating treatment is carried out on the solar cell pieces with the sulfidized gate lines, silver sulphide can be completely decomposed, thus achieving the purposes of achieving sulfidizing removal and avoiding poor appearance, and avoiding influence on the conversion efficiency of the cell pieces. The sulfidizing process disclosed by the invention is simple, low in implementation cost, and beneficial to wide popularization and application.

Owner:JA SOLAR

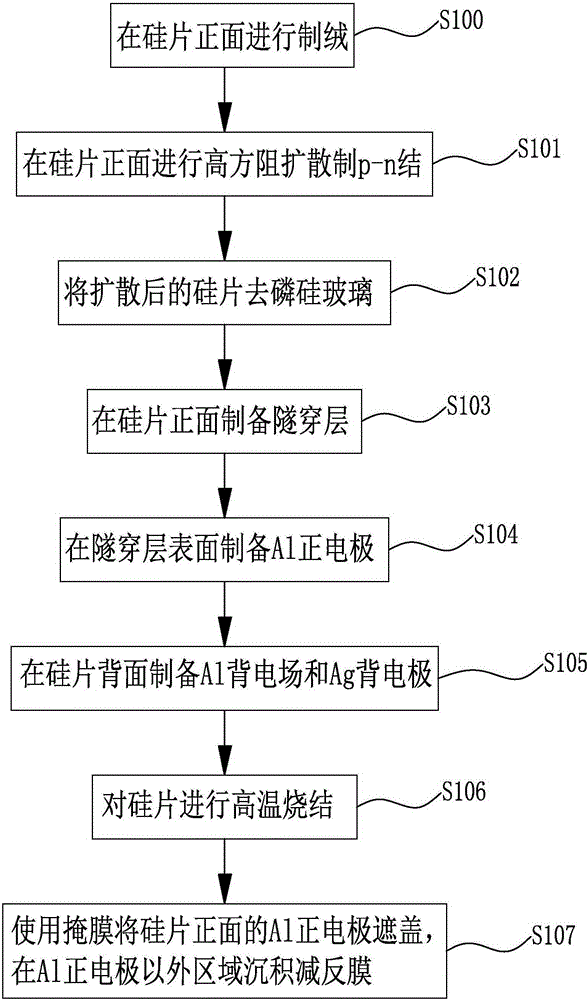

MIS crystalline silicon solar cell and manufacturing method therefor

InactiveCN105304759ALow manufacturing costImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationSheet resistanceElectric field

The invention discloses an MIS crystalline silicon solar cell and a manufacturing method therefor. The manufacturing method comprises the following steps of: a), texturing the front surface of a silicon wafer; b), performing high-sheet-resistance diffusion on the front surface of the silicon wafer to make a p-n junction; c) removing phosphorosilicate glass from the diffused silicon wafer; d) preparing a tunneling layer on the front surface of the silicon wafer; e) preparing an Al positive electrode on the surface of the tunneling layer; f) preparing an Al back electric field and an Ag back electrode on the back surface of the silicon wafer; g) performing high-temperature sintering on the silicon wafer; and h) depositing an antireflection film in a region outside the Al positive electrode. Compared with the prior art, the method has the following beneficial effects that: the Al positive electrode, the tunneling layer and an N+ layer form an MIS structure, and electrons collected by silicon in the N+ layer can completely penetrate through the insulated tunneling layer to be in contact with the Al positive electrode by an MIS tunneling effect, so that the electrons are exported; the Al positive electrode is not in direct contact with the N+ layer due to the isolation of the tunneling layer, so that the p-n junction is not formed again and the conversion efficiency of the cell is not influenced; and the manufacturing cost can be greatly reduced and the conversion efficiency can be improved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH

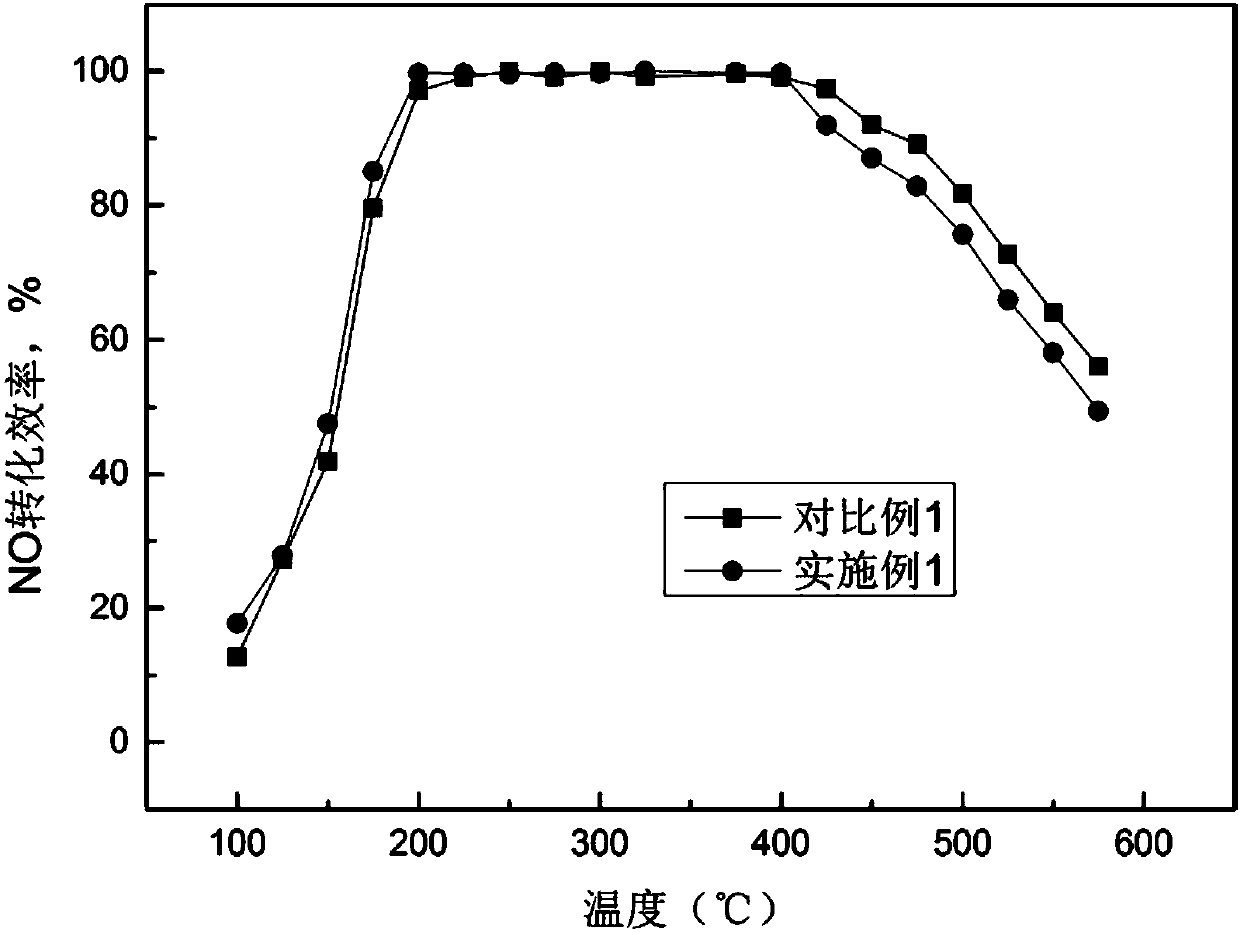

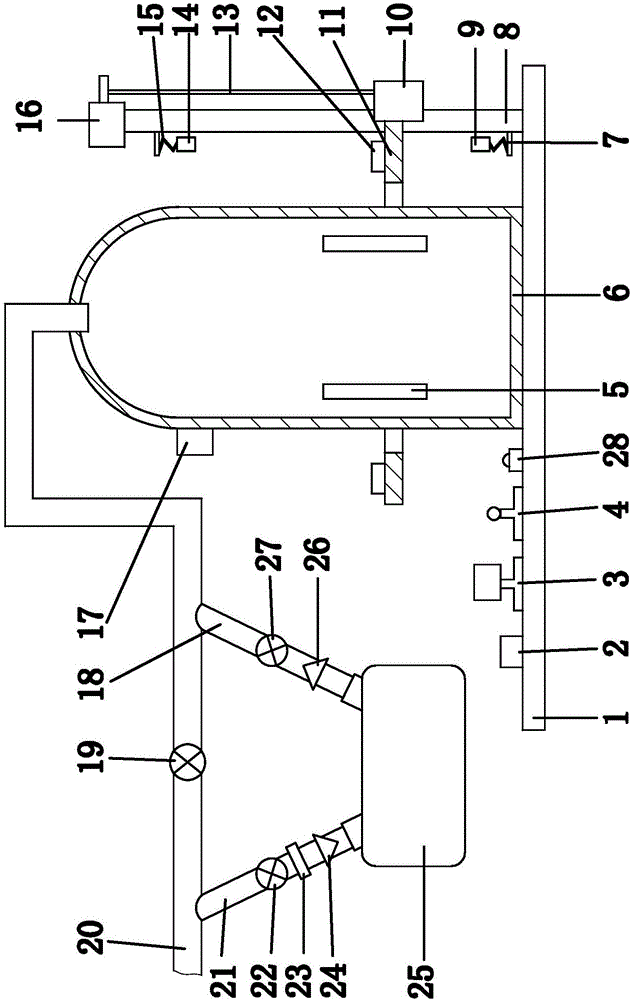

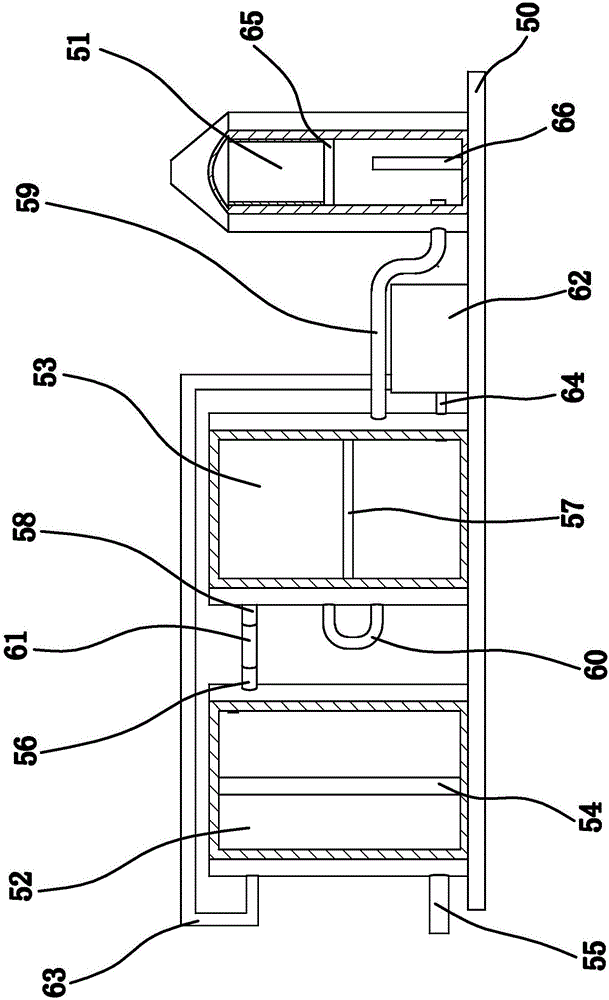

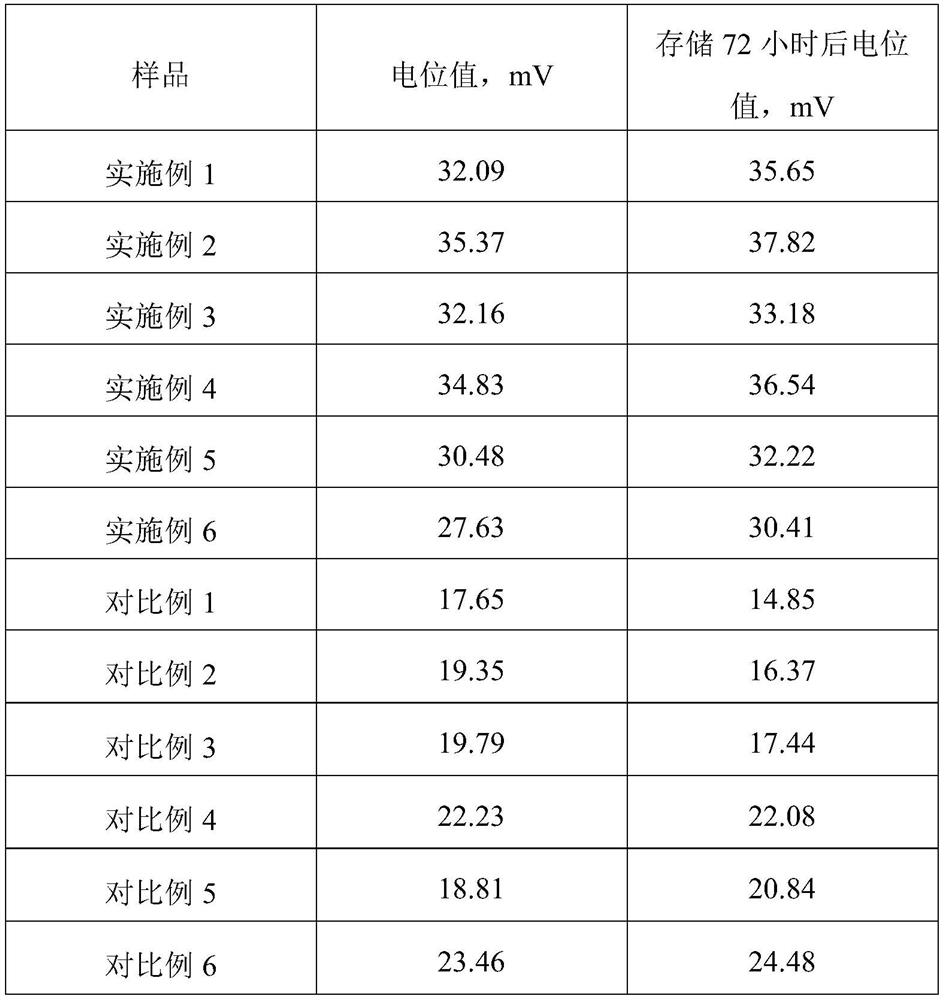

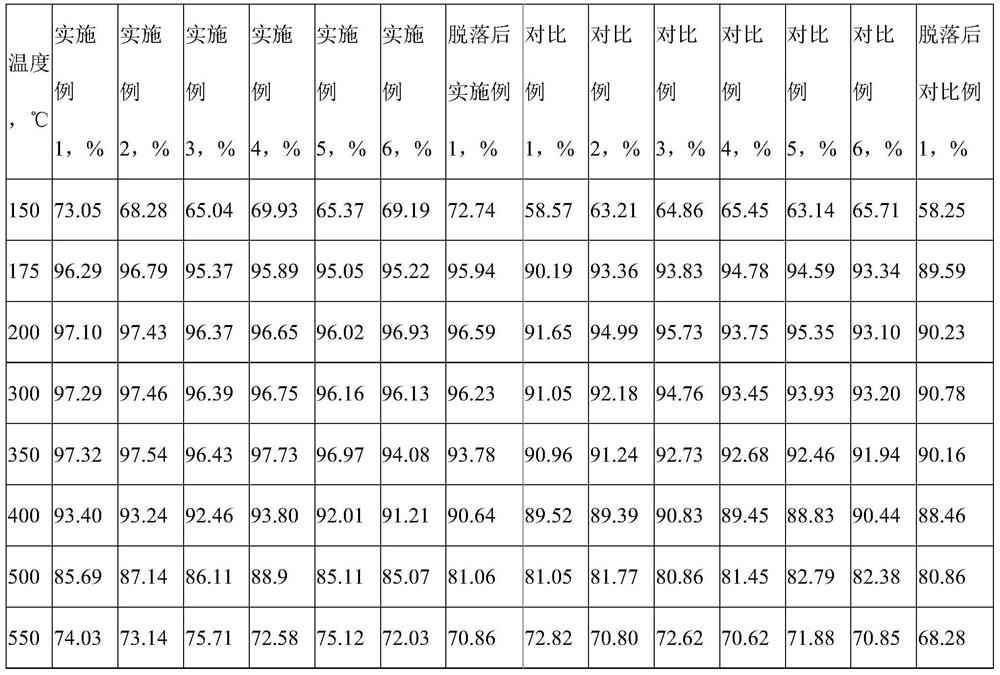

Preparation method of molecular sieve coating slurry for integral catalyst

ActiveCN112808302ASmall granularityStrong thixotropyMolecular sieve catalystsInternal combustion piston enginesMolecular sievePhysical chemistry

The invention provides a preparation method of a molecular sieve coating slurry for a monolithic catalyst, which comprises the following steps: mixing a molecular sieve with alumina sol dry powder, adding the mixture into water of which the pH value is adjusted in advance, carrying out ball milling dispersion, and aging the discharged slurry to form a stable and uniform mixed solution, namely the coating slurry. Compared with the traditional liquid sol, the Zeta potential value of the coating slurry obtained by the preparation method disclosed by the invention is obviously increased and can be increased from 17.65 mv to 35.37 mv, so that the problems that the molecular sieve slurry is unstable and easy to settle are thoroughly solved. The coating prepared by the method has good stability and good coating strength, wherein the one-time coating load rate can reach 36.45%, and the shedding rate can reach 2.87% or below. The coating slurry provided by the invention still does not settle after being kept for 6 months at most, so that the difficulty of a coating process is greatly reduced, and the slurry does not influence the conversion efficiency of NOx.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

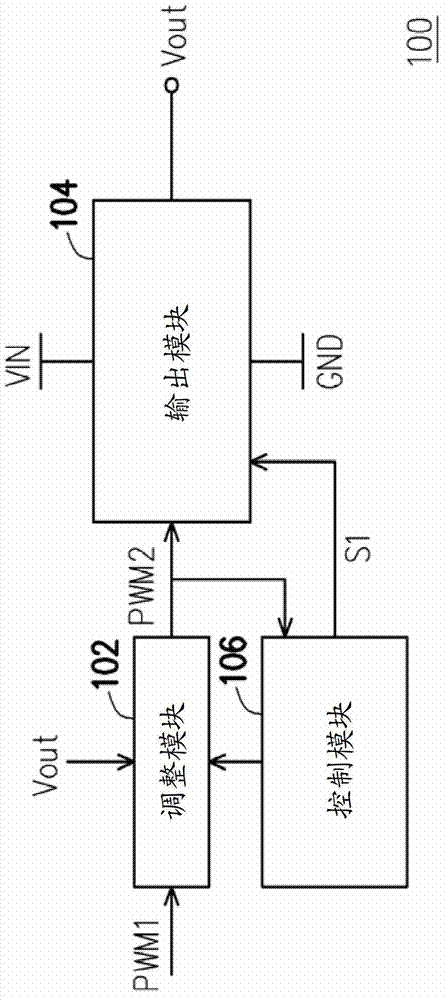

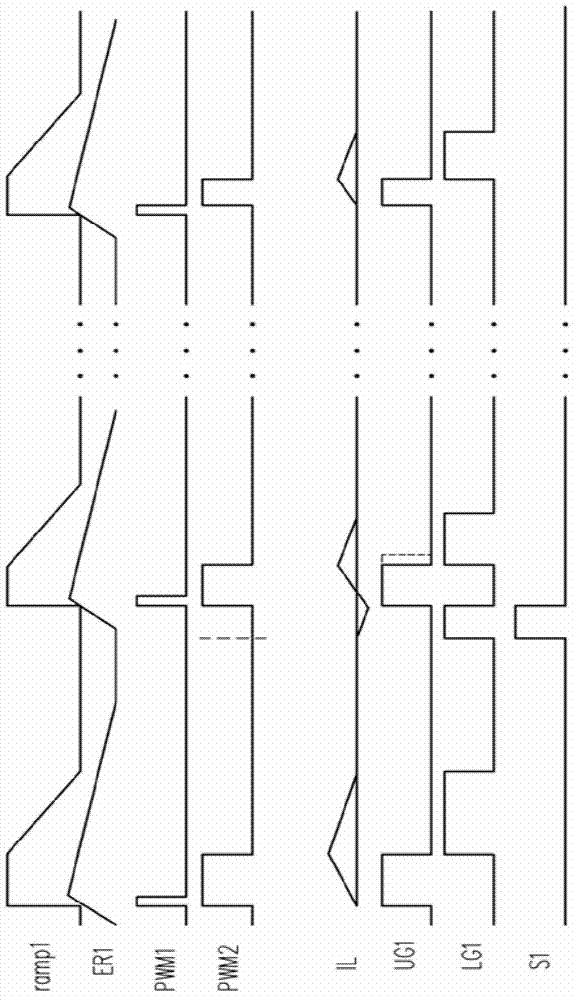

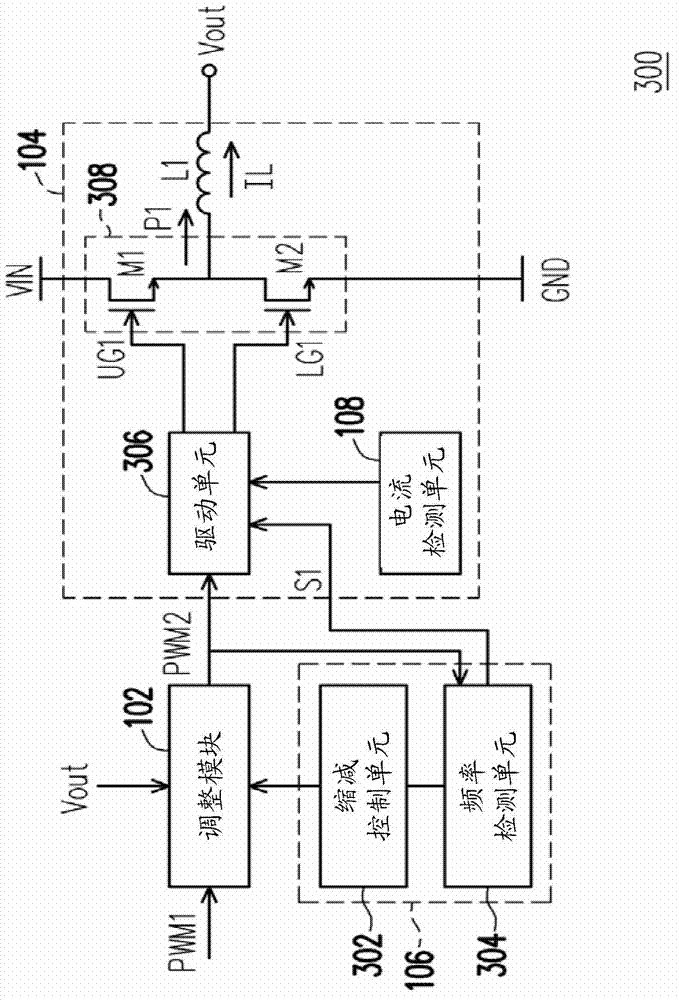

Dc-dc converter and voltage conversion method thereof

ActiveCN102904443AHigh frequencyDoes not affect conversion efficiencyEfficient power electronics conversionDc-dc conversionDc dc converterPwm signals

The invention provides a DC-DC converter and a voltage conversion method thereof. When a load of the DC-DC converter is too light, the DC-DC converter can raise a frequency of its PWM signal, and reduce a pulse width of the PWM signal, so as to avoid the frequency of the PWM signal falling into a frequency range that can heard by human's ear and maintain high conversion efficiency of the DC-DC converter.

Owner:UPI SEMICON CORP

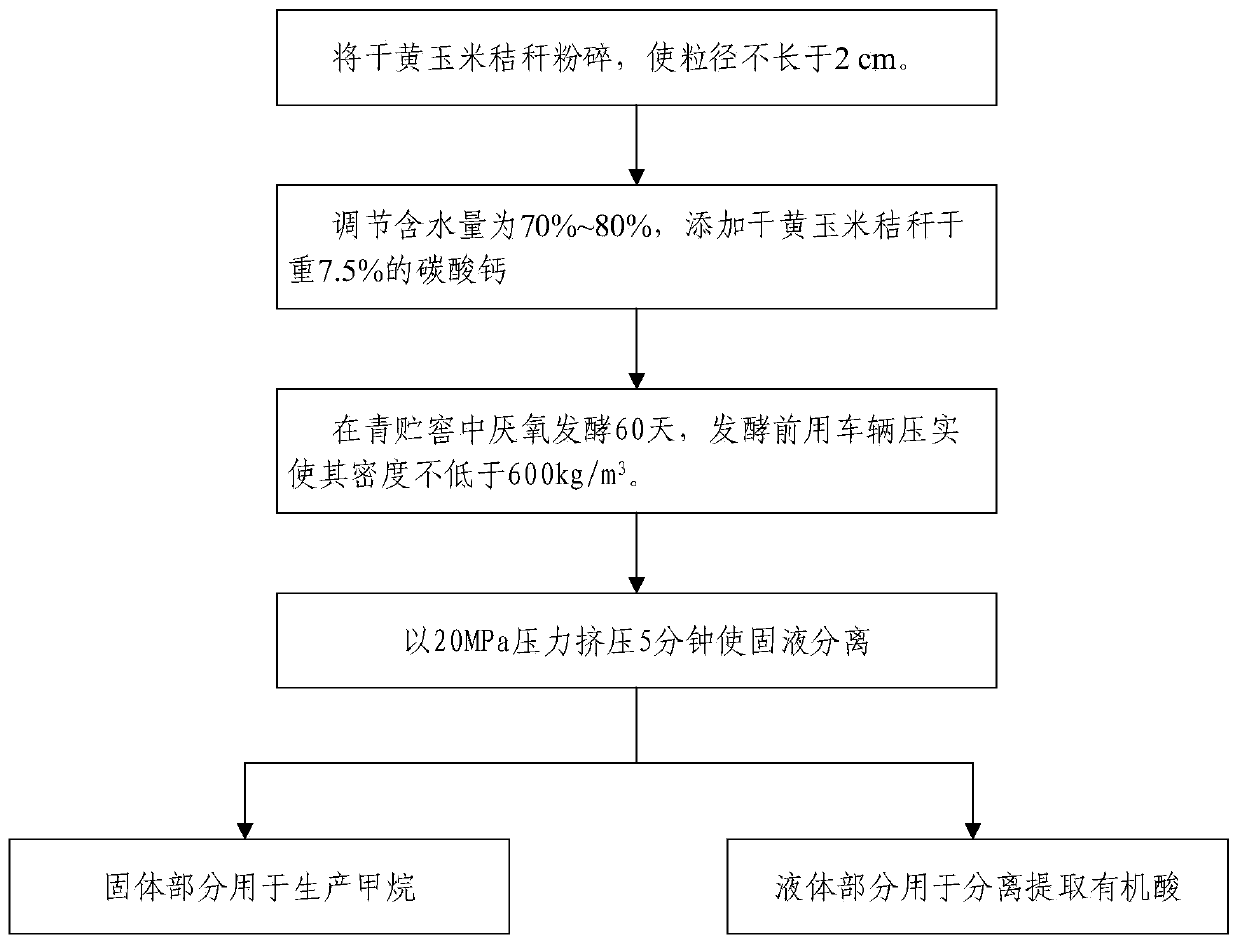

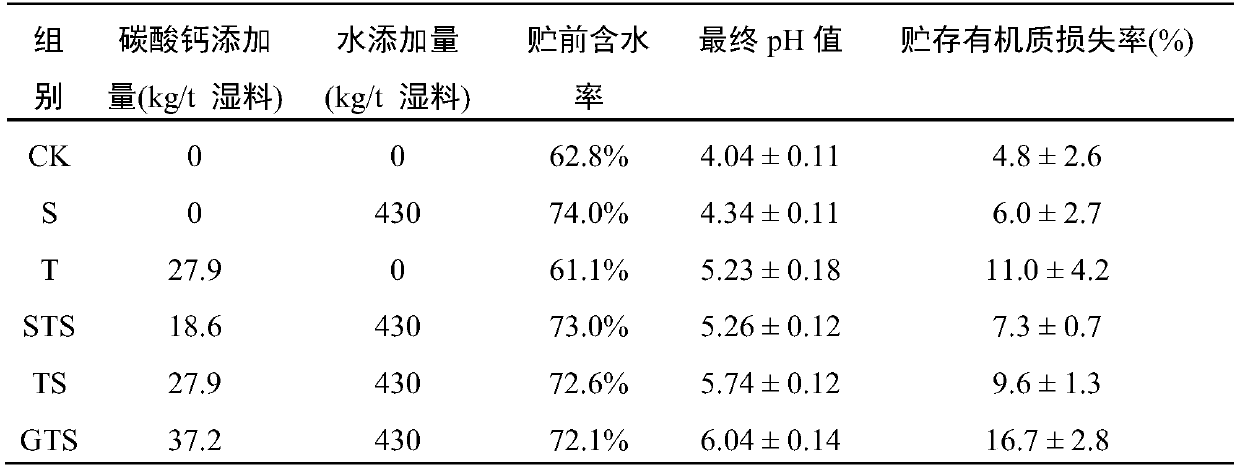

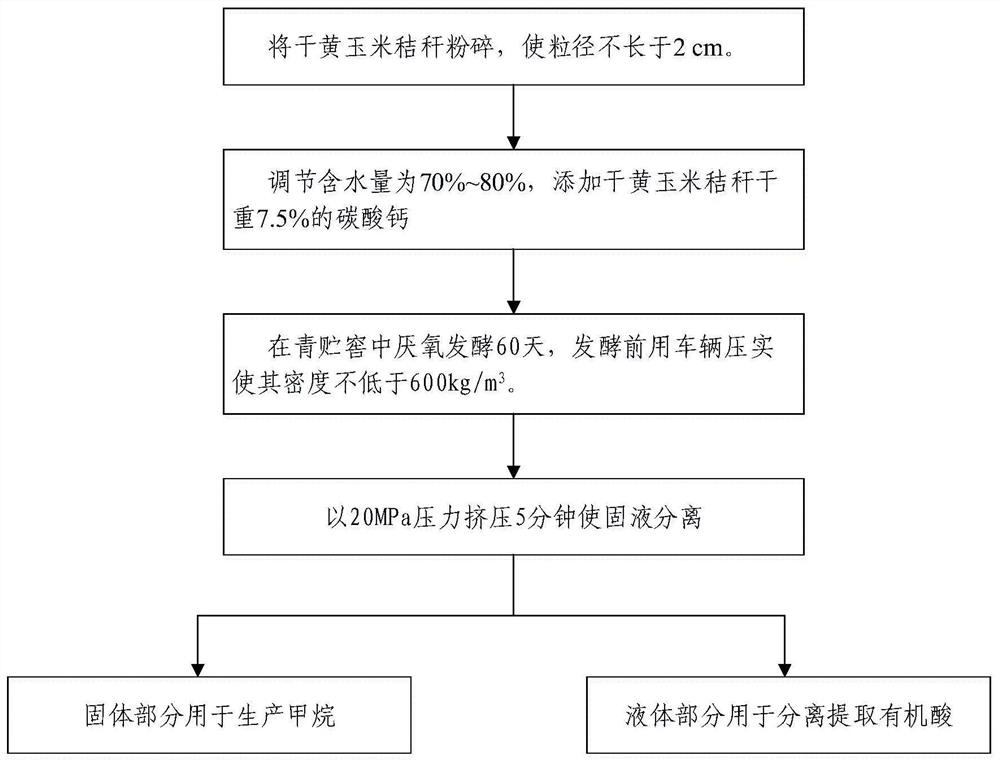

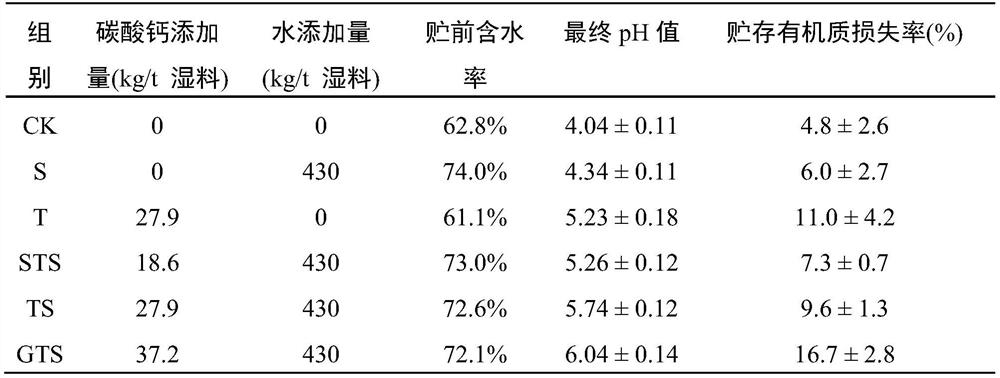

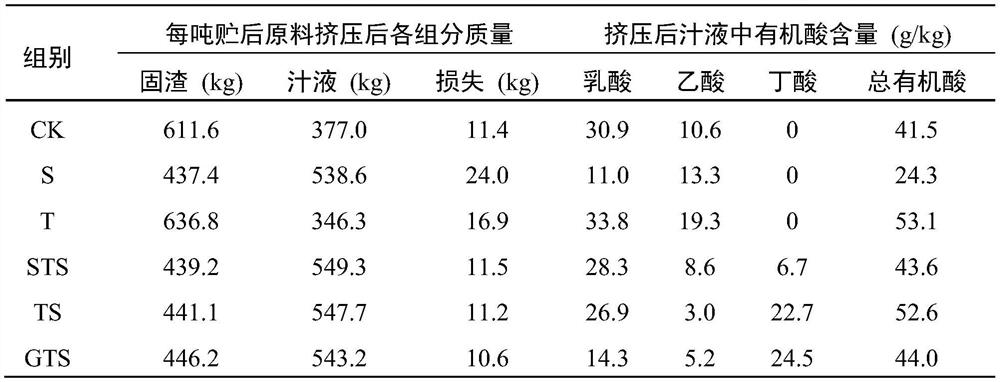

Straw treatment method and application thereof

ActiveCN110643638APlay a pre-decomposition effectImprove conversion efficiencyWaste based fuelFermentationOrganic acidEconomic benefits

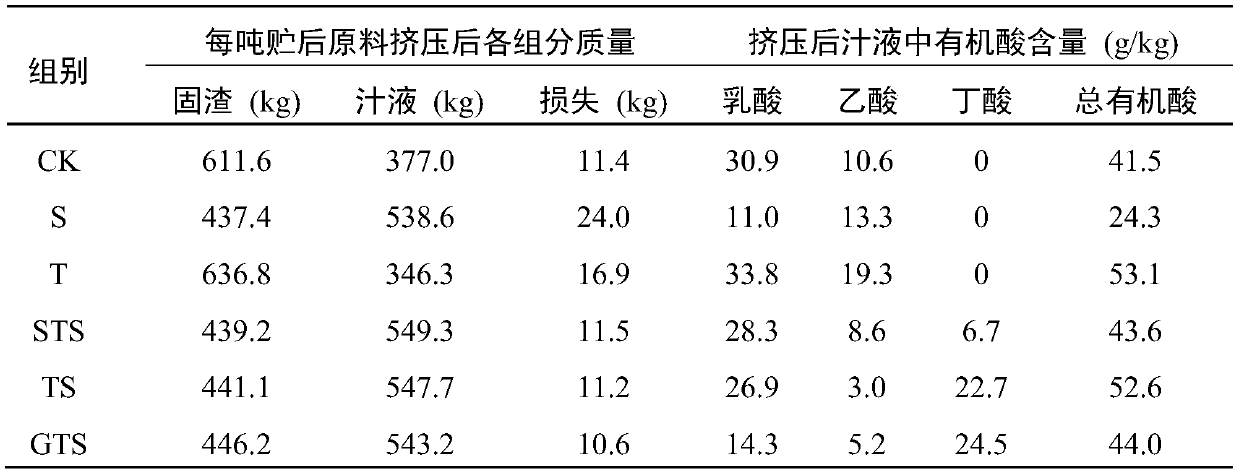

The invention relates to a straw treatment method and application thereof. The method comprises a wet storage regulation stage. The wet storage regulation stage comprises the following steps: adjusting the moisture content of straw to 70-80%, performing fermentation under an anaerobic condition, and maintaining the pH value at 5.2-6.0 in the fermentation process. By regulating the water content and the pH value in the wet storage process, the straw treatment method provided by the invention extracts out a liquid part after anaerobic fermentation, can extract various organic acids such as lactic acid and butyric acid to increase economic benefits, can produce 53 kg of lactic acid and 45 kg of butyric acid from each ton of corn straw without influencing the methane conversion efficiency of asolid part, and can greatly improve the economic benefits of the process and promote the development of the straw biogas engineering industry.

Owner:CHINA AGRI UNIV

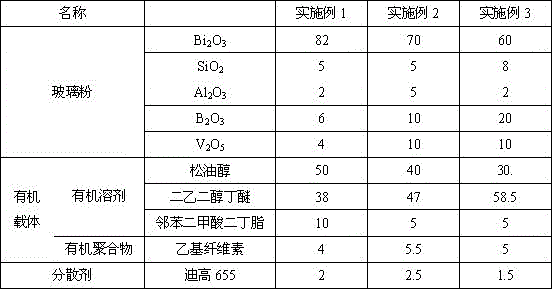

Hole patching slurry, preparation method and applications thereof

ActiveCN104212247AEfficient use ofDoes not affect conversion efficiencyCoatingsSemiconductor devicesSlurryCell sheet

The invention relates to a hole patching slurry, a preparation method and applications thereof. The hole patching slurry is composed of the following components in percentage by weight: 75 to 85% of tailor-made glass powder, and 10 to 25% of organic carrier, wherein the glass powder is composed of the following raw materials in percentage by weight: 75% to 85% of Bi2O3, 2 to 10% of SiO2, 1 to 5% of Al2O3, 5 to 20% of B2O3, and 2 to 8% of other additives. After the front gate electrode is printed, the hole patching slurry is filled into the pin holes of a cell sheet by tailor-made equipment. The hole patching slurry can be used to patch holes in a solar pin hole sheet so as to effective utilize the cell sheets with pin holes.

Owner:安徽尚夏光能有限公司

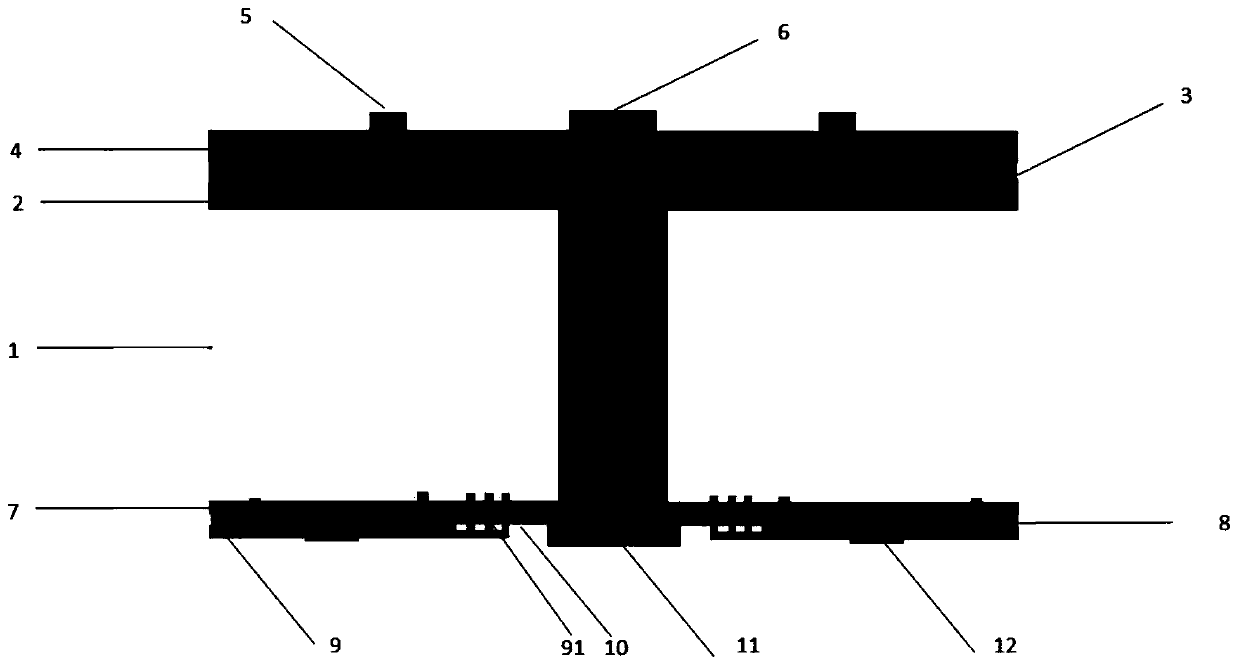

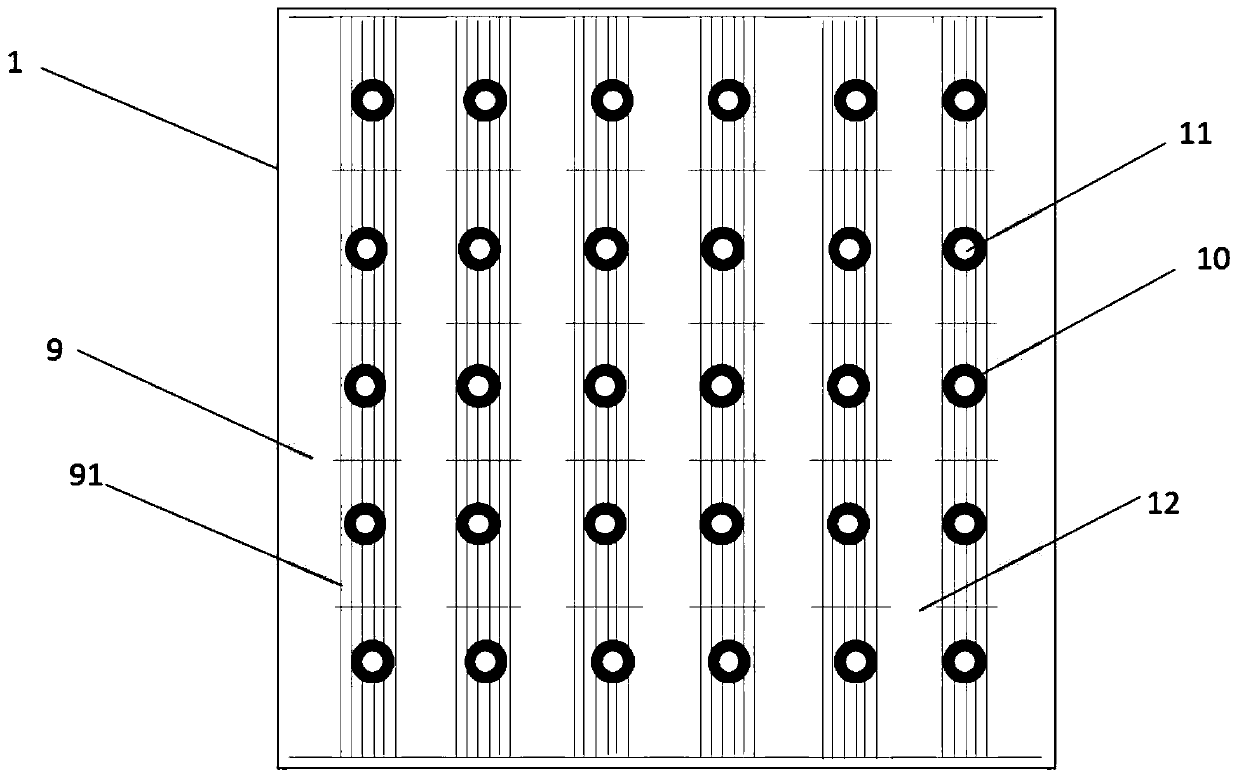

Back electric field structure of MWT solar cell and manufacturing method of back electric field structure

PendingCN111211179AReduce consumptionReduce areaPhotovoltaic energy generationSemiconductor devicesPhysicsLaser drilling

The invention discloses a back electric field structure of an MWT solar cell. The back electric field structure comprises a front silicon nitride film, a silicon dioxide film, a PN junction, a siliconwafer, an aluminum oxide film and a back silicon nitride film which are all sequentially stacked from top to bottom; the front surface of the silicon wafer is provided with positive electrode silvergrid lines and a through hole electrode front surface; the back surface of the silicon wafer is provided with an all-aluminum back surface field, a through hole electrode back surface and uniformly-distributed back electrodes; the all-aluminum back surface field is provided with aluminum grid line back surface fields; through hole isolation grooves are arranged between the aluminum grid line backsurface fields and a back surface through hole electrode. The invention discloses a manufacturing method of the back electric field of the MWT solar cell. The manufacturing method comprises the following steps of: laser drilling; texturing; diffusion; mask printing; etching; annealing; film coating ; back surface laser grooving; screen printing; and sintering. The design mode of combining the all-aluminum back surface field and the aluminum grid lines is realized on the back surface of the MWT cell in ingeniously; the consumption of Al metal slurry is reduced while conversion efficiency not influenced; the influence of Al metal powder residues on the through hole electrode is greatly avoided; and the safe, efficient and continuous operation of the MWT solar cell is ensured.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

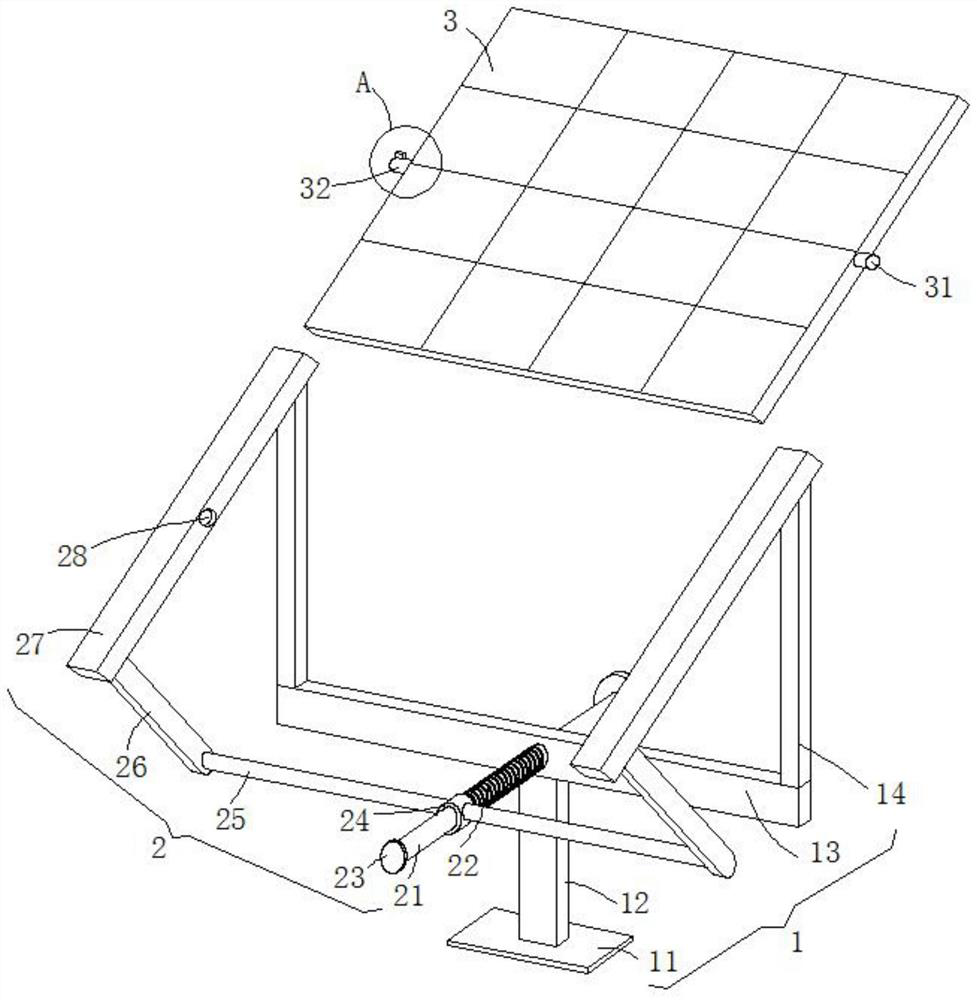

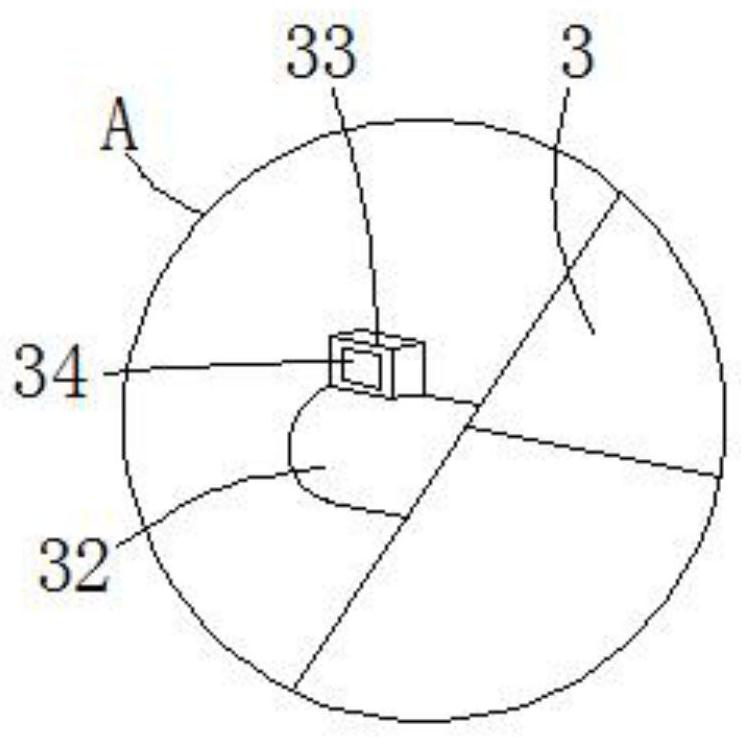

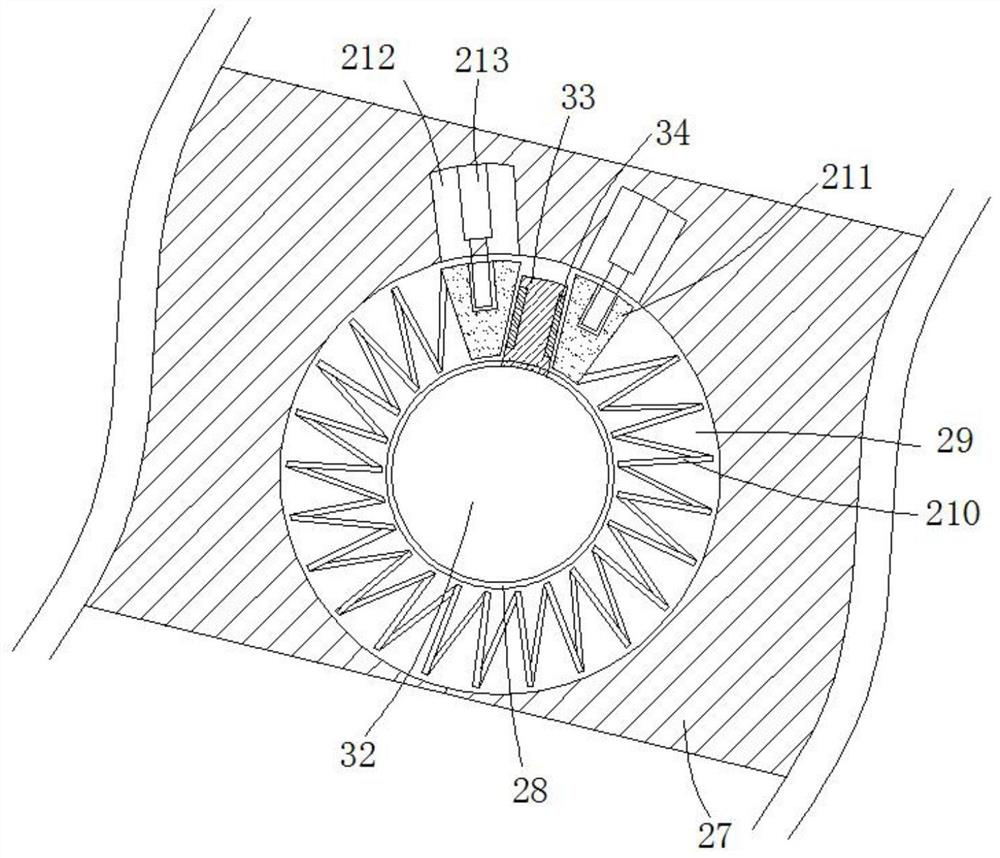

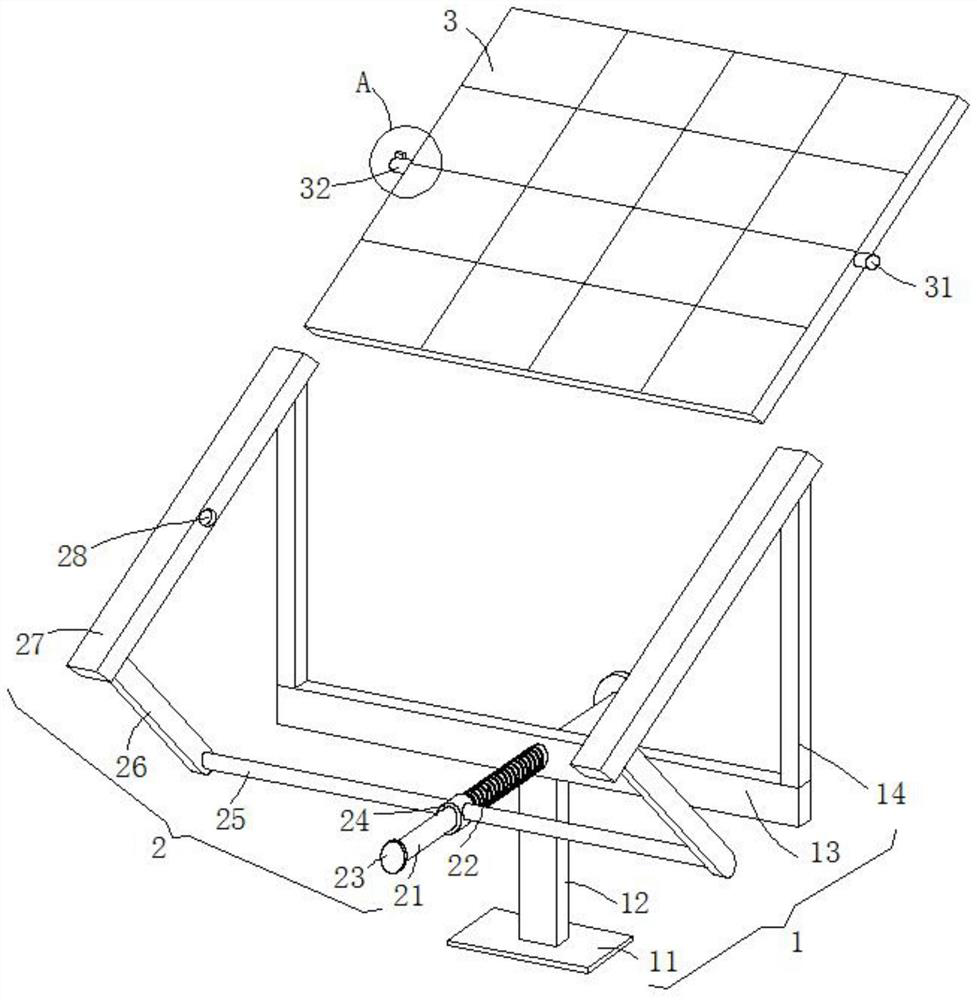

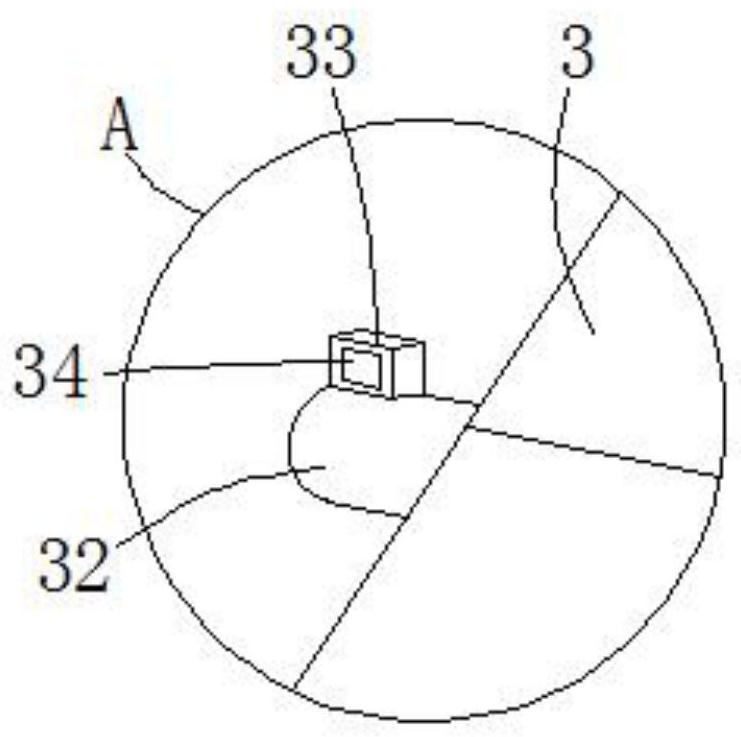

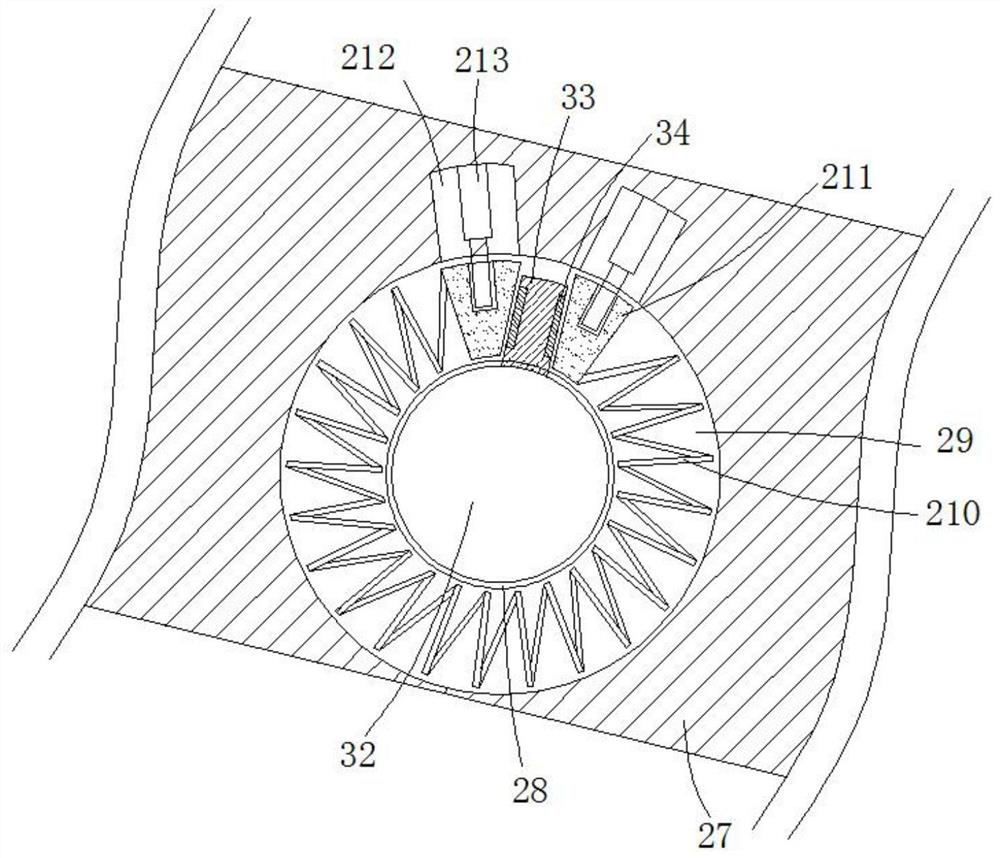

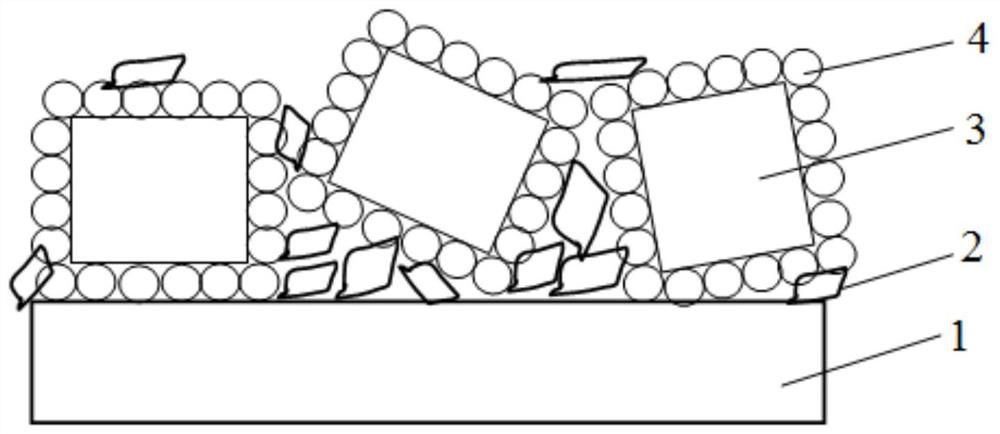

Height-adjustable new-energy photovoltaic bracket and supporting and mounting method thereof

ActiveCN112260624AImprove power generation efficiencyChange support heightPhotovoltaic supportsSolar heating energyNew energyStructural engineering

The invention discloses a height-adjustable new-energy photovoltaic bracket and a supporting and mounting method thereof. The height-adjustable new-energy photovoltaic bracket comprises a supporting mechanism, an adjusting mechanism and a photovoltaic panel, wherein the supporting mechanism comprises a base, a supporting column, a horizontal beam and two stand columns; the adjusting mechanism comprises a threaded adjusting rod, a threaded sleeve, two extension rods, two hinge plates and two supporting cross beams; and the photovoltaic panel is located between the two supporting cross beams, afirst inserting column and a second inserting column are fixedly arranged at the center positions of the left end face and the right end face of the photovoltaic panel correspondingly, and the photovoltaic panel is rotatably inserted into the middle sections of the opposite side walls of the two supporting cross beams through the first inserting column and the second inserting column correspondingly. When the photovoltaic panel is installed, the supporting angle of the photovoltaic panel can be adjusted by adjusting the height of the bottom of the front end of the photovoltaic panel, so the photovoltaic panel obtains maximum power generation efficiency, birds can be prevented from nesting or excreting excrement on the photovoltaic panel, and daily receiving of solar illumination of the photovoltaic panel for electric energy conversion operation is not affected.

Owner:安徽铭达智能科技有限公司

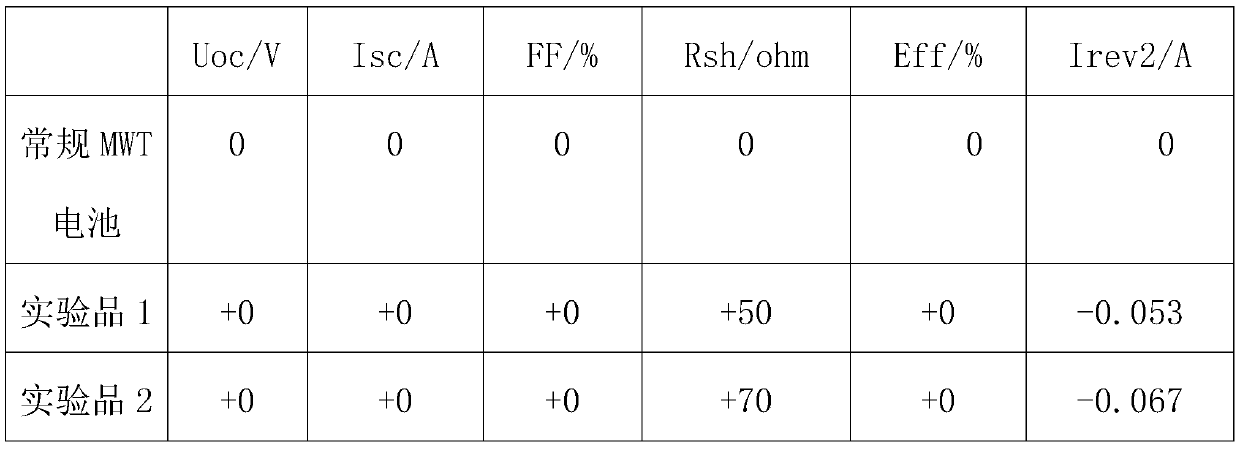

A method for reducing cracks in the back electrode region of MWT batteries

ActiveCN108630767BDoes not affect conversion efficiencyDoes not affect reliabilityPhotovoltaic energy generationSemiconductor devicesAntenna designMetallurgy

The invention discloses a method for reducing hidden cracking of a back electrode region of a MWT (Metal Wrap Technology) battery. In the preparation process of a positive electrode region of a back electrode of the MWT battery, hollow-out and antenna designs are adopted for the positive electrode region; the hollow-out design is that a plurality of non-printing regions are arranged in a middle region of a positive pole printing region, and the antenna design is that a plurality of printing regions are arranged in an edge region of the positive pole printing region; in the preparation processof an aluminium back field, a hollow-out design is adopted for a region of the aluminium back field, which is overlapped with the positive electrode region; and the hollow-out design of the aluminiumback field is that a plurality of non-printing regions are arranged in the overlap region of the aluminium back field and the positive electrode region. The hollow-out design of the positive electroderegion can effectively reduce an overall height of the positive electrode region under the condition of ensuring that a welding area of a component is unchanged, and the antenna design can reduce a coverage area of the overlap region under the condition of effectively ensuring current transmission of the positive electrode region and the aluminium back field. The hollow-out design of the overlapregion of the aluminium back field can reduce a height of the overlap region under the condition of ensuring that an area of the overlap region of the aluminium back field and the positive electrode region is unchanged.

Owner:JIANGSU SUNPORT POWER CORP LTD

A kind of straw treatment method and its application

ActiveCN110643638BIncrease added valueDoes not affect methane conversion efficiencyWaste based fuelFermentationBiotechnologyOrganic acid

Owner:CHINA AGRI UNIV

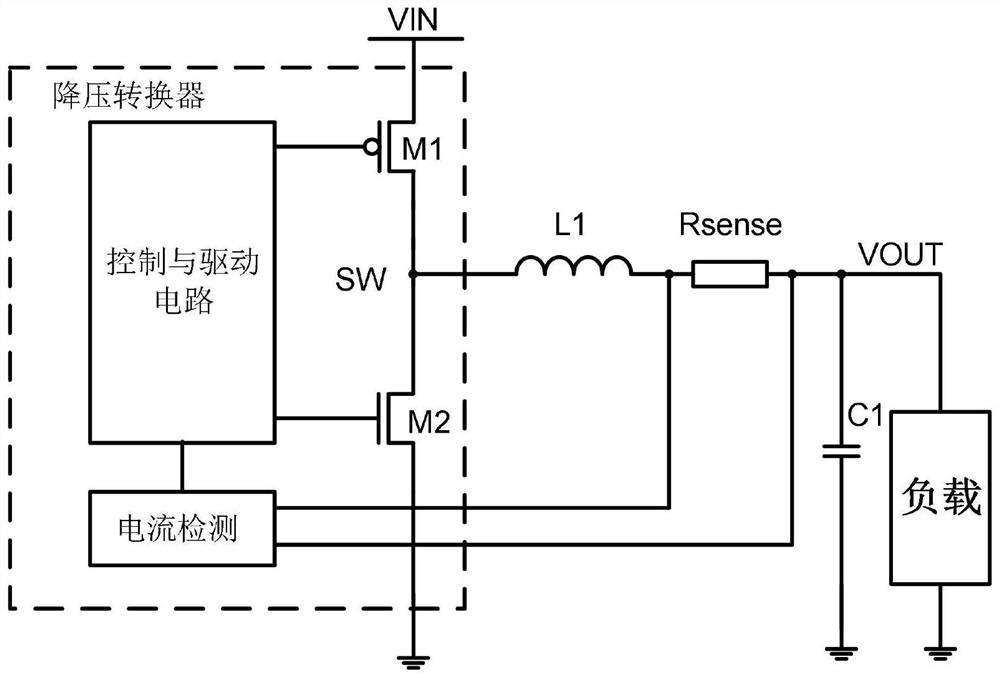

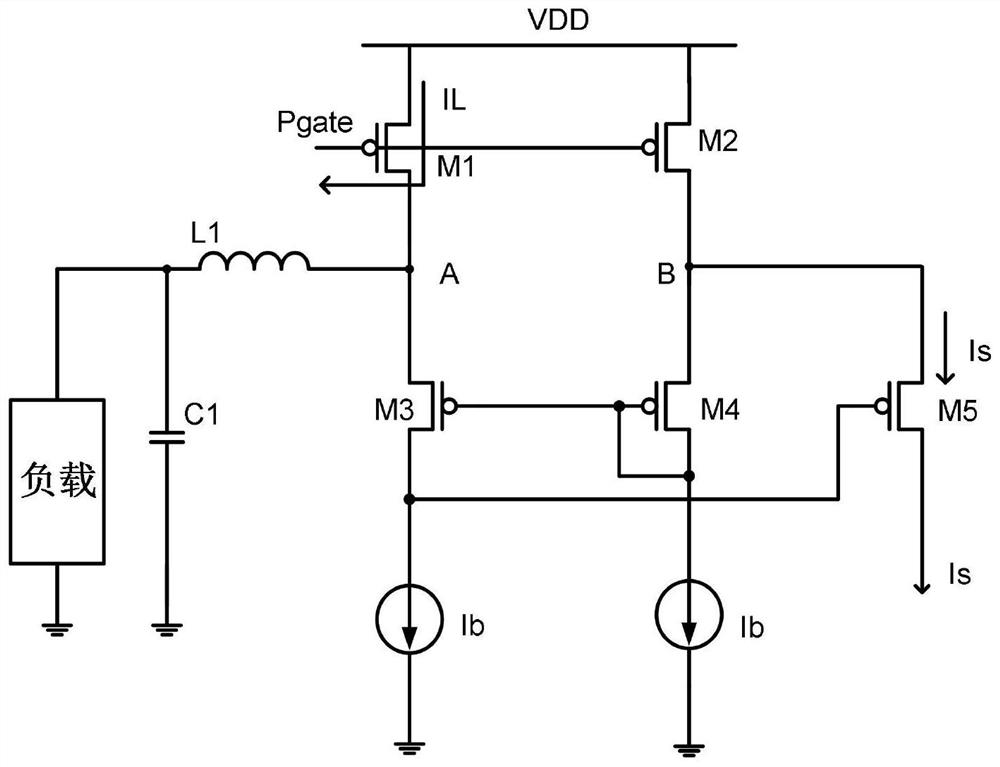

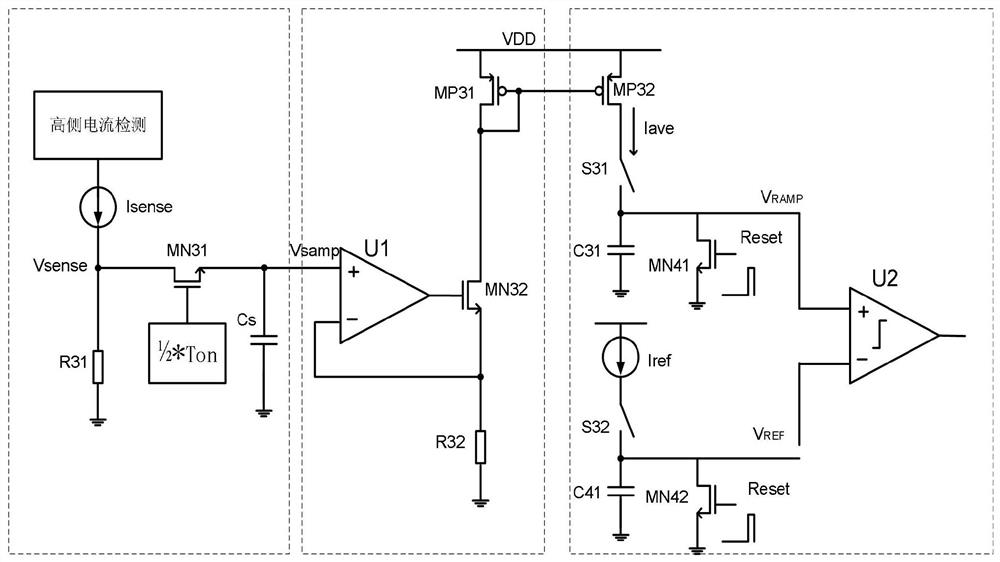

An average current detection circuit applied to dc-dc converter

ActiveCN111313697BDoes not affect conversion efficiencyImprove conversion efficiencyDc-dc conversionCurrent measurements onlyConvertersAverage current

Owner:SHANGHAI CHIPANALOG MICROELECTRONICS LTD

Monocrystalline silicon solar cells

ActiveCN103928538BShorten the transmission distanceImprove collection efficiencyPhotovoltaic energy generationSemiconductor devicesCrystalline siliconSilicon chip

The invention discloses a single crystalline silicon solar cell. The single crystalline silicon solar cell comprises a silicon chip and electrode grid lines, wherein the silicon chip is provided with a pyramid-structure texturing surface, and the included angle between the tangent line of each portion of the electrode grid lines and one of the four edges on the bottom surface of a certain pyramid structure ranges from 0 degree to 10 degrees or from 80 degrees to 90 degrees. According to the single crystalline silicon solar cell, the bottom edges of the pyramid structure of the texturing surface of the silicon chip can be effectively used for transmitting photoproduction electrons, the transmission distance of the photoproduction electrons on the surface of the silicon chip is shortened, collection efficiency of the electrons is effectively improved, and then cell conversion efficiency is improved; the density of the grid lines can be reduced under the condition that the cell conversion efficiency is not affected, and then the cost is reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

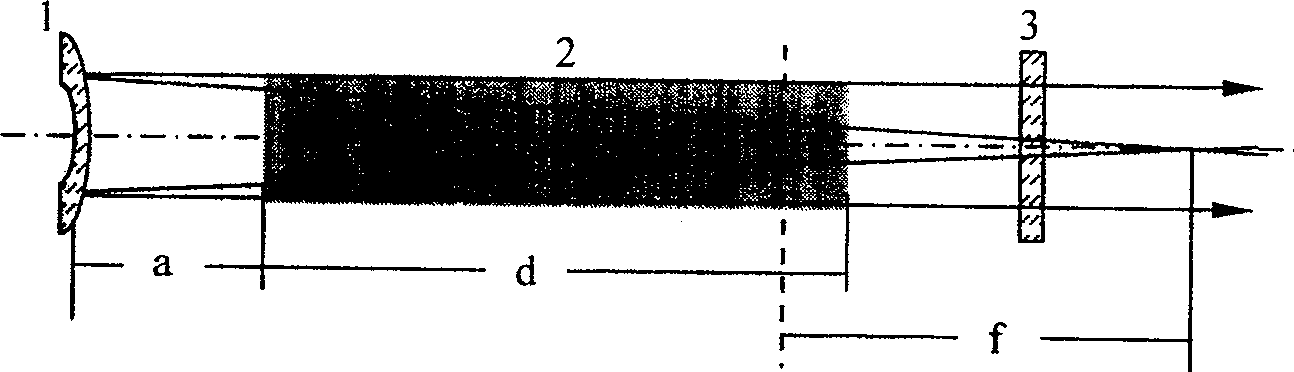

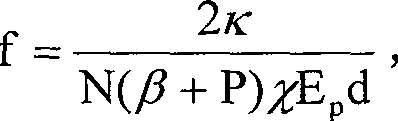

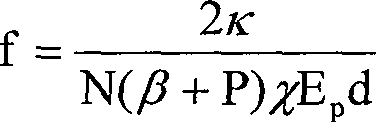

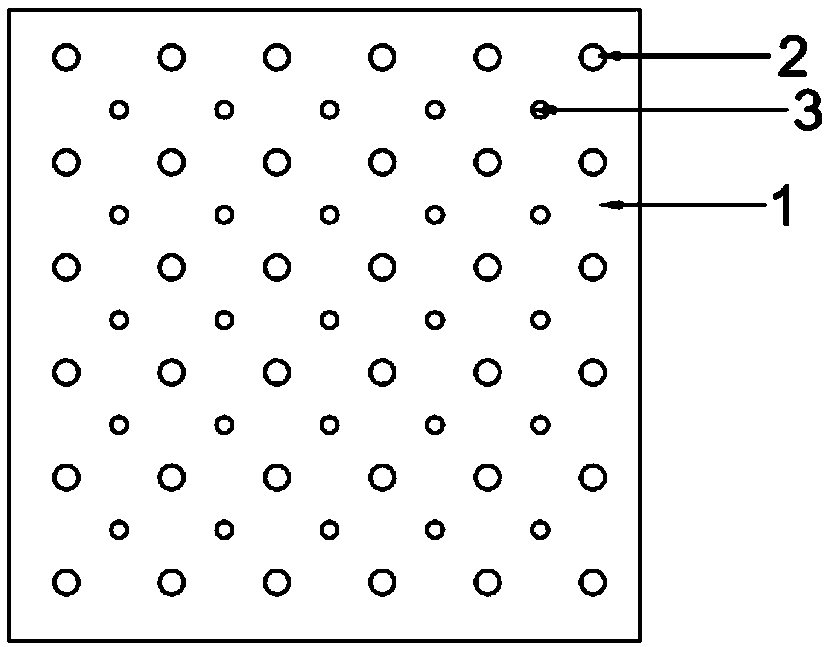

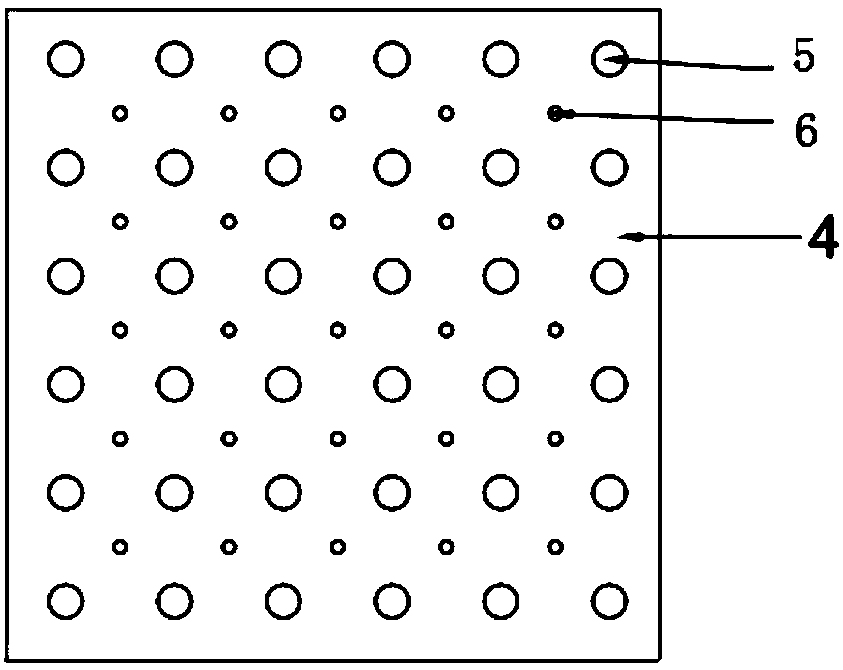

A compensation method for laser bar thermal lens effect

InactiveCN100468888CIncrease lossDoes not affect conversion efficiencyOptical resonator shape and constructionMotor driveOptical axis

The disclosed thermal-lensing compensation method for laser rod comprises: setting the holophote with a step-motor driving movable mechanism in optical resonator of laser as raised convex mirror toward the laser rod; controlling the step motor by a computer to make the distance from mirror to rod as a = f - R / 2 - d / 2n. Wherein, R for curvature radius of the mirror, d for rod length, n for refractive index of rod, and f for lens focus. This invention simplifies system structure, affects no energy conversion efficiency, and applies computer to control laser frequency N and pumping energy density Ep for complete automatic compensation.

Owner:NINGBO UNIV

Method for reducing hidden cracking of back electrode region of MWT (Metal Wrap Technology) battery

ActiveCN108630767ALower the altitudeReduce coverage areaPhotovoltaic energy generationSemiconductor devicesAntenna designMetal

The invention discloses a method for reducing hidden cracking of a back electrode region of a MWT (Metal Wrap Technology) battery. In the preparation process of a positive electrode region of a back electrode of the MWT battery, hollow-out and antenna designs are adopted for the positive electrode region; the hollow-out design is that a plurality of non-printing regions are arranged in a middle region of a positive pole printing region, and the antenna design is that a plurality of printing regions are arranged in an edge region of the positive pole printing region; in the preparation processof an aluminium back field, a hollow-out design is adopted for a region of the aluminium back field, which is overlapped with the positive electrode region; and the hollow-out design of the aluminiumback field is that a plurality of non-printing regions are arranged in the overlap region of the aluminium back field and the positive electrode region. The hollow-out design of the positive electroderegion can effectively reduce an overall height of the positive electrode region under the condition of ensuring that a welding area of a component is unchanged, and the antenna design can reduce a coverage area of the overlap region under the condition of effectively ensuring current transmission of the positive electrode region and the aluminium back field. The hollow-out design of the overlapregion of the aluminium back field can reduce a height of the overlap region under the condition of ensuring that an area of the overlap region of the aluminium back field and the positive electrode region is unchanged.

Owner:JIANGSU SUNPORT POWER CORP LTD

Fabrication method of silicon nitride antireflection film on surface of polycrystalline solar cell

ActiveCN105845748BHigh refractive indexDoes not affect conversion efficiencyFinal product manufacturePhotovoltaic energy generationUltrasound attenuationGraphite

The invention provides a polycrystalline solar cell surface silicon nitride antireflection film preparation method, which solves the technical problems that an existing solar cell is simple in structure, is easy to have continuous attenuation and is poor in product stability. The polycrystalline solar cell surface silicon nitride antireflection film preparation method comprises the following steps: a) carrying out cleaning, texturing, diffusion and etching on a crystalline silicon wafer; b) enabling the crystalline silicon wafer obtained after the step a) to pass through an ozone generation device to generate a 1-2 mm SiO2 oxidation film on the surface of the silicon wafer; c) cleaning a graphite boat through a cleaning device, placing the crystalline silicon wafer obtained after the step b) on the graphite boat, and placing the graphite boat loaded with the wafer to a tubular PECVD for pre-deposition and cleaning; d) carrying out tubular PECVD deposition on the crystalline silicon wafer obtained in the step c); and e) carrying out tubular PECVD deposition again on the crystalline silicon wafer obtained in the step d). The method has the advantages of stable and reliable product.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

Pore filling slurry and its preparation method and use

ActiveCN104212247BEfficient use ofDoes not affect conversion efficiencyCoatingsSemiconductor devicesFritSlurry

The invention relates to a pore-filling slurry and its preparation method and application. The pore-filling slurry consists of 75-85% of special glass powder and 10-25% of an organic carrier. The composition (percentage by weight) of described glass powder: Bi 2 o 3 75%~85%, SiO 2 2~10%, Al 2 o 3 1~5%, B 2 o 3 5~20%, other additives 2~8%. Using the hole-filling paste of the present invention, after printing the front grid electrode, use special equipment to point the hole-filling paste into the pinholes of the battery sheet, which can be used for hole-filling of solar silicon pinhole sheets, and the batteries with pinholes Tablets are used effectively.

Owner:安徽尚夏光能有限公司

A solar cell sheet grid wire vulcanization treatment process

ActiveCN104037263BDoes not affect conversion efficiencyGood lookingFinal product manufacturePhotovoltaic energy generationProduction lineVulcanization

Owner:JA SOLAR

A height-adjustable new energy photovoltaic support and support installation method

ActiveCN112260624BImprove power generation efficiencyPrevent nestingPhotovoltaic supportsSolar heating energySolar lightNew energy

The invention discloses a height-adjustable new energy photovoltaic bracket and a support installation method, including a support mechanism, an adjustment mechanism and a photovoltaic panel. The support mechanism includes a base, a support column, a horizontal beam and two upright columns. The adjustment The mechanism includes a threaded adjustment rod, a threaded sleeve, two extension rods, two hinged plates and two supporting beams, the photovoltaic panel is located between the two supporting beams, and the center positions of the left and right ends of the photovoltaic panel are fixed respectively There are a first plug-in column and a second plug-in column, and the photovoltaic panel is respectively connected to the middle section of the opposite side wall of the two support beams through the first plug-in column and the second plug-in column. When the photovoltaic panel is installed, the height of the bottom of the front end of the photovoltaic panel can be adjusted to meet the adjustment of the supporting angle of the photovoltaic panel, so that the photovoltaic panel can obtain the maximum power generation efficiency and can prevent birds from building nests or excreting feces on the photovoltaic panel , does not affect the photovoltaic panel's daily acceptance of sunlight for electrical energy conversion operations.

Owner:安徽铭达智能科技有限公司

Preparation method of coating slurry and preparation method of coating type cu molecular sieve scr catalyst

ActiveCN107824217BShorten the timeReduce production processMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention provides a method for preparing a coating slurry and a method for preparing a coating-type Cu molecular sieve SCR catalyst. The Cu precursor is directly added to the slurry, and the active component Cu is simultaneously loaded on the surface of the molecular sieve and the binder. There are still active components on the surface of the catalyst after the catalyst has fallen off; this method greatly reduces the time and preparation process for Cu to be loaded on the molecular sieve, and simplifies the preparation process; the present invention reduces the preparation process, greatly reduces energy consumption, and does not need to be added Dispersant, the prepared catalyst has good coating strength and good NH3‑SCR performance, and active components remain after the catalyst falls off.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com