MIS crystalline silicon solar cell and manufacturing method therefor

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of complex process, Cu oxidation, and lower conversion efficiency of solar cells, and achieve the effect of improving conversion efficiency and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

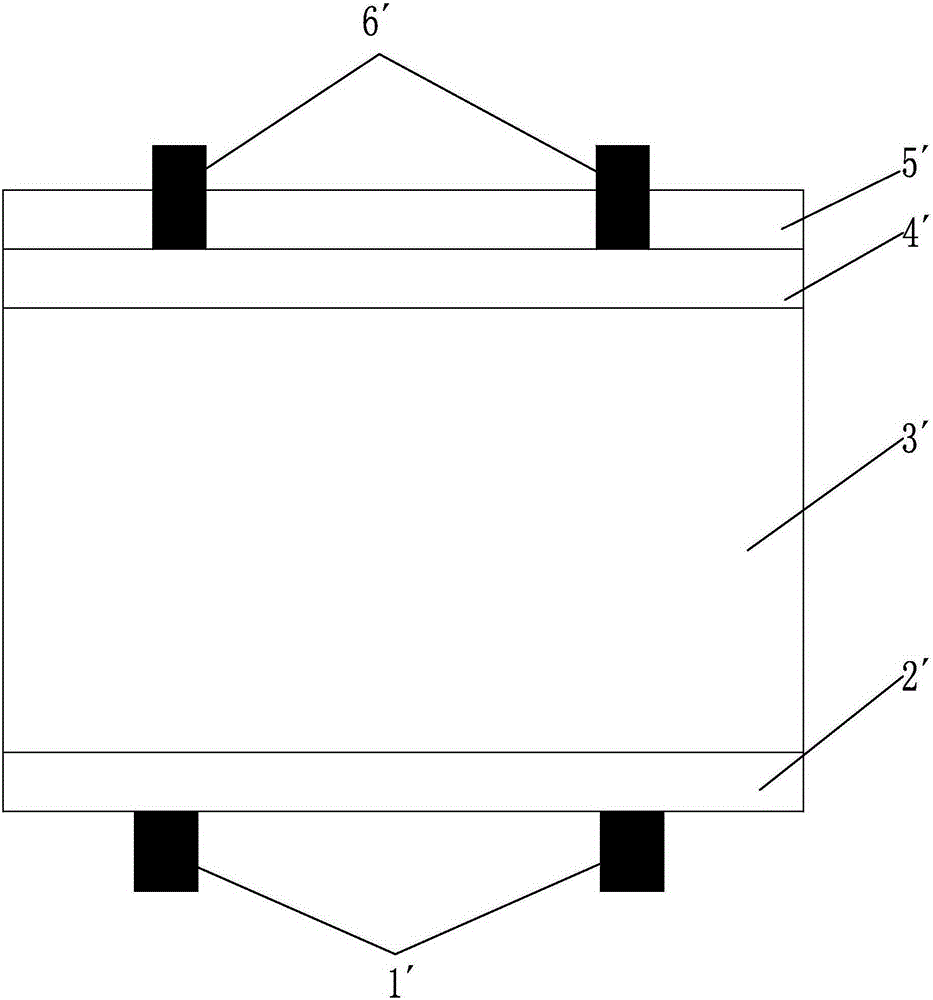

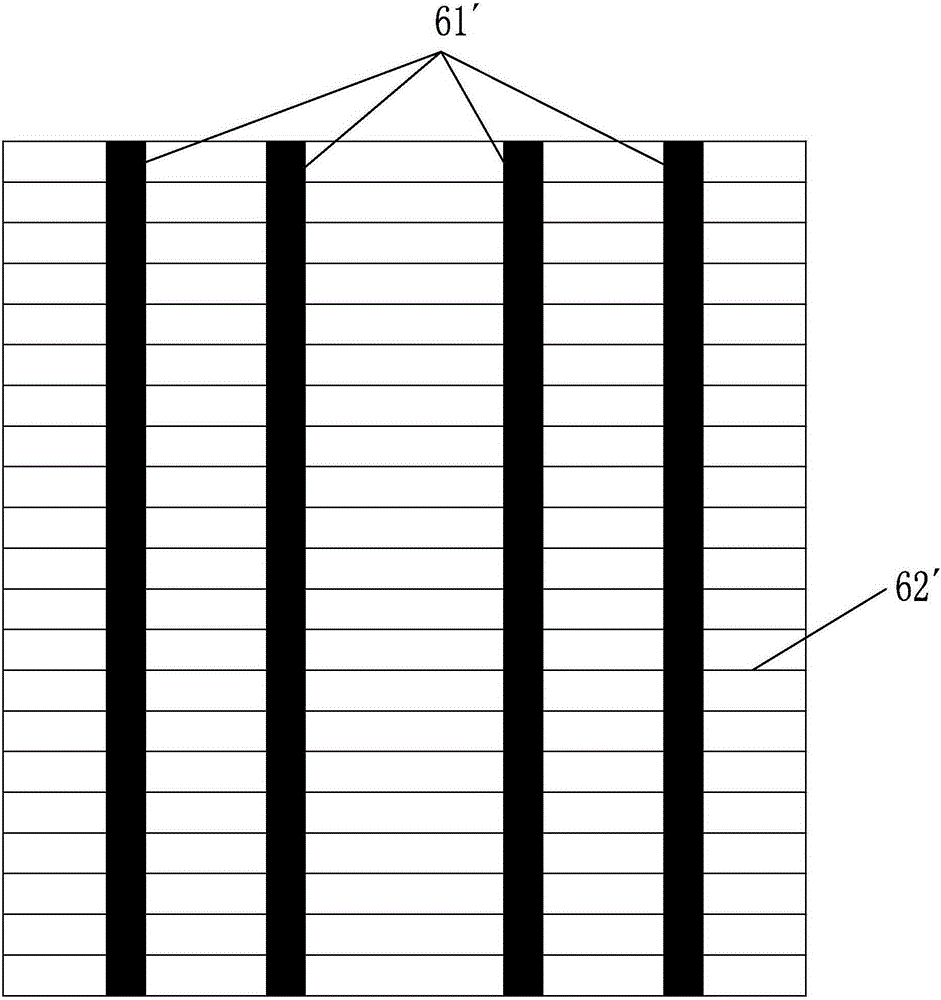

[0029] Such as figure 1 , figure 2 Shown: The structure of the crystalline silicon solar cell in the prior art is Ag back electrode 1′, Al back electric field 2′, P-type silicon 3′, N+ layer 4′, anti-reflection film 5′ and Ag positive electrode from bottom to top. 6', the Ag positive electrode of the solar cell is composed of Ag main grid lines 61' and Ag sub-grid lines 62', the Ag main grid lines 61' and Ag sub-grid lines 62' are perpendicular, and the Ag main grid lines 61' are parallel to each other and uniform distribution, the Ag sub-gate lines 62' are parallel to each other and evenly distributed.

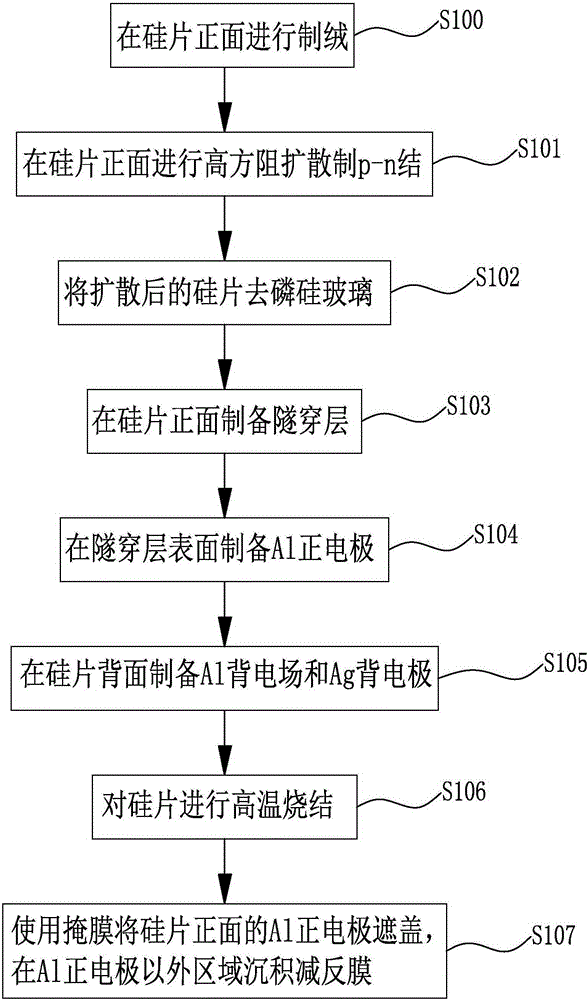

[0030] image 3 It is a preparation flowchart of a kind of MIS crystalline silicon solar cell of the present invention, comprises the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com