Straw treatment method and application thereof

A treatment method and technology of straw, applied in the direction of waste fuel, fermentation, etc., can solve the problem of low utilization rate of straw resources, achieve good economic value, good pretreatment effect, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

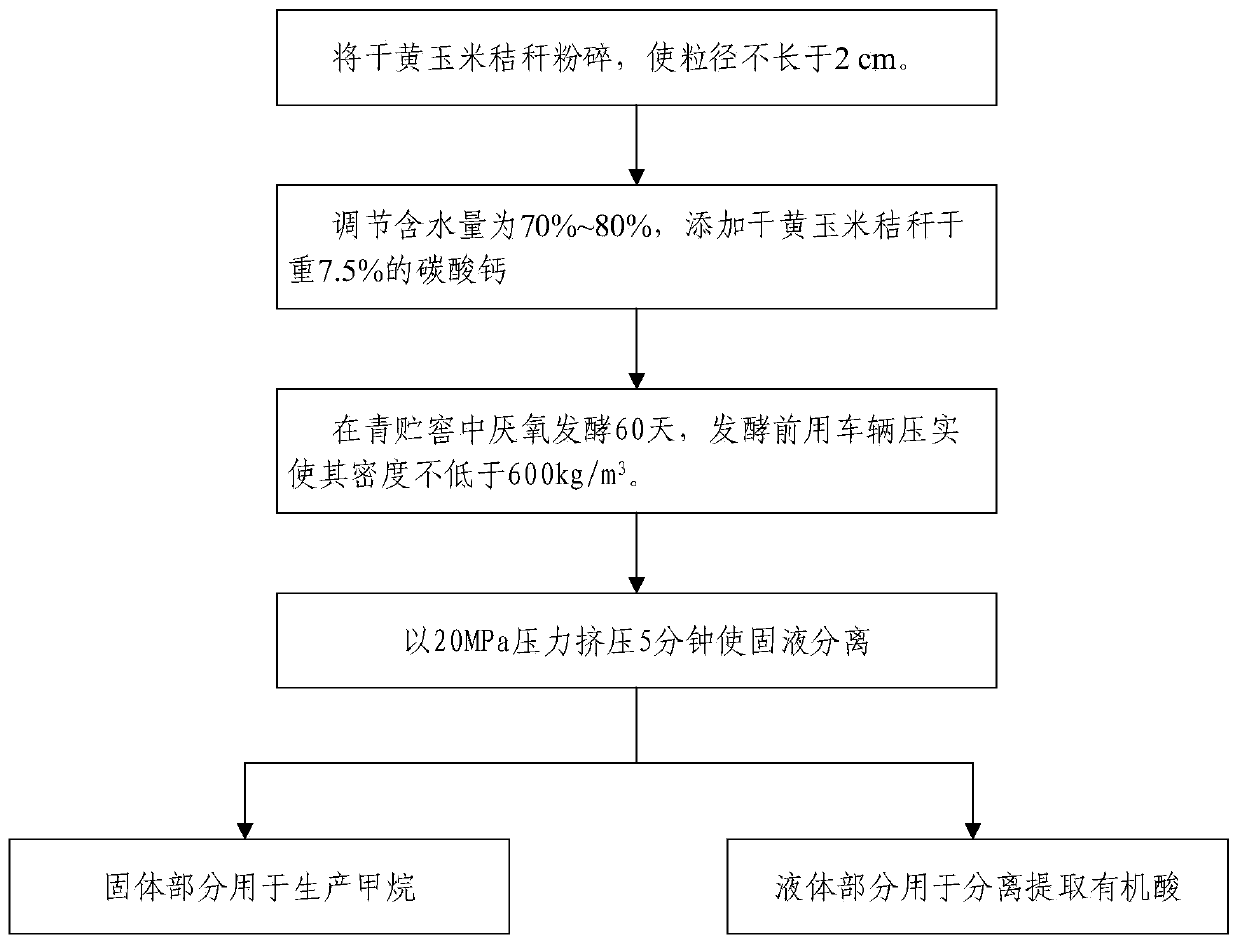

[0033] The invention provides a method for treating stalks. The dry yellow corn stalks used come from the Shangzhuang Experimental Station of China Agricultural University, such as figure 1 As shown, the fermentation process specifically includes the following steps:

[0034] 1. Wet storage control stage

[0035] (1) Grinding dry yellow corn stalks so that the particle size is not longer than 2 cm is used as raw material.

[0036] (2) Adjust the moisture content of the raw material to 70% to 80%, and add calcium carbonate with a dry basis weight of 7.5%.

[0037] (3) Fill raw materials into airtight equipment such as silage pits, compact by vehicles to make the compaction density not less than 600kg / m3, seal with plastic film after compaction, place heavy objects on the outside of the plastic film for suppression, and maintain a closed anaerobic environment environment.

[0038] 2. Raw material reprocessing stage

[0039] (1) The raw materials stored for 60 days are taken ...

experiment example 1

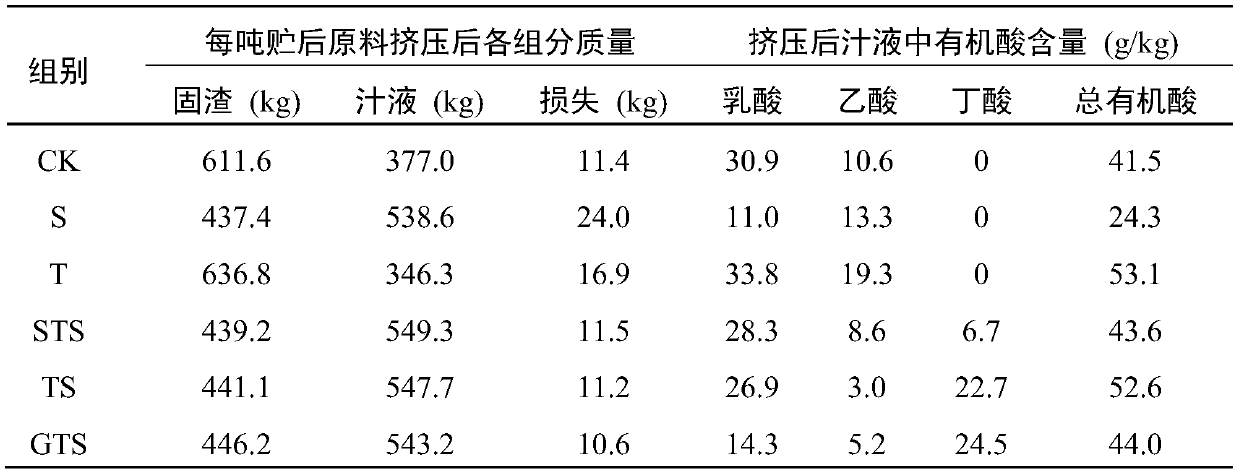

[0043] This experimental example detects the economic benefit of the straw fermentation method of embodiment 1, specifically as follows:

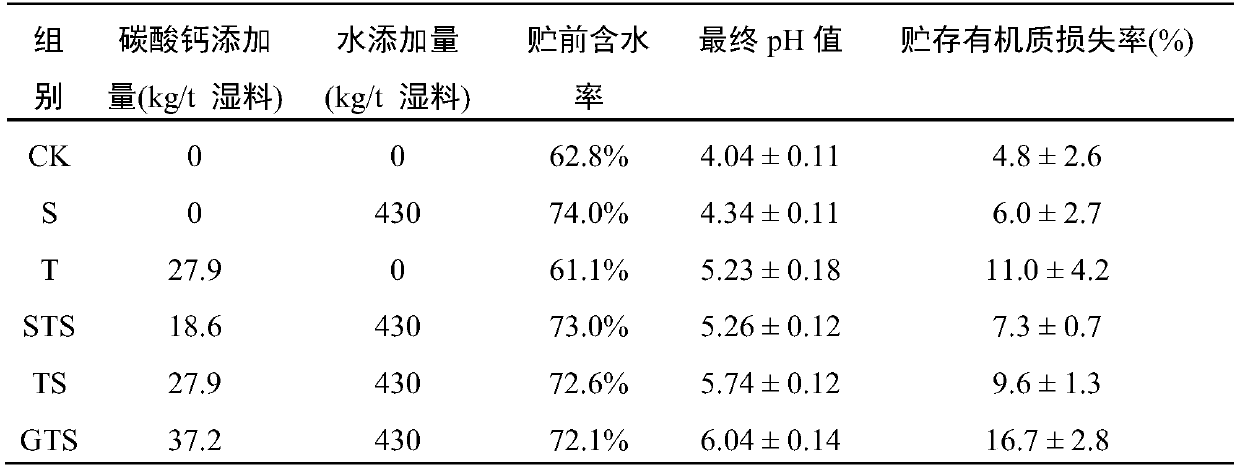

[0044] The present invention sets respectively the following treatment groups:

[0045] Experimental group (TS): the straw fermentation method of embodiment 1;

[0046] Control group (CK): Compared with the experimental group, calcium carbonate is not added and moisture is not adjusted;

[0047] Moisture adjustment group (S): Compared with the experimental group, only the water content is adjusted, and calcium carbonate is not added;

[0048]Calcium carbonate addition group (T): Compared with the experimental group, the water content was not adjusted, and an equal amount of calcium carbonate was added;

[0049] A small amount of calcium carbonate added group (STS): compared with the experimental group to add an equal amount of moisture, and add calcium carbonate less than the experimental group's added amount (the added amount is 5% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com