Method for reducing hidden cracking of back electrode region of MWT (Metal Wrap Technology) battery

A backside electrode and battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of rising fragmentation rate at the component end, and achieve the effect of reducing fragmentation rate, reducing coverage area, and reducing hidden cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for reducing the hidden cracks in the electrode area on the back of the MWT battery comprises the following steps:

[0028] (1) Silicon wafer: use solar-grade P-type single crystal or polycrystalline silicon wafer as the substrate;

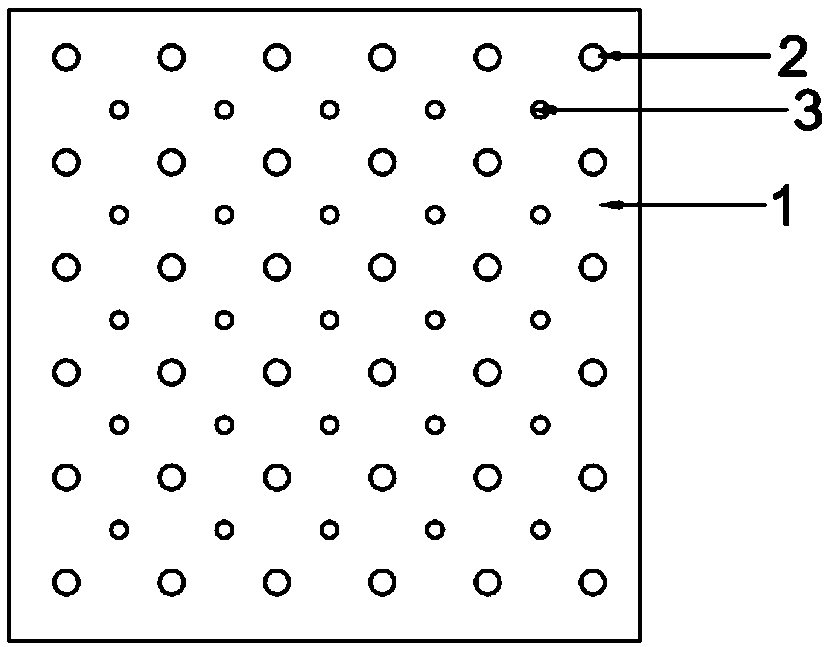

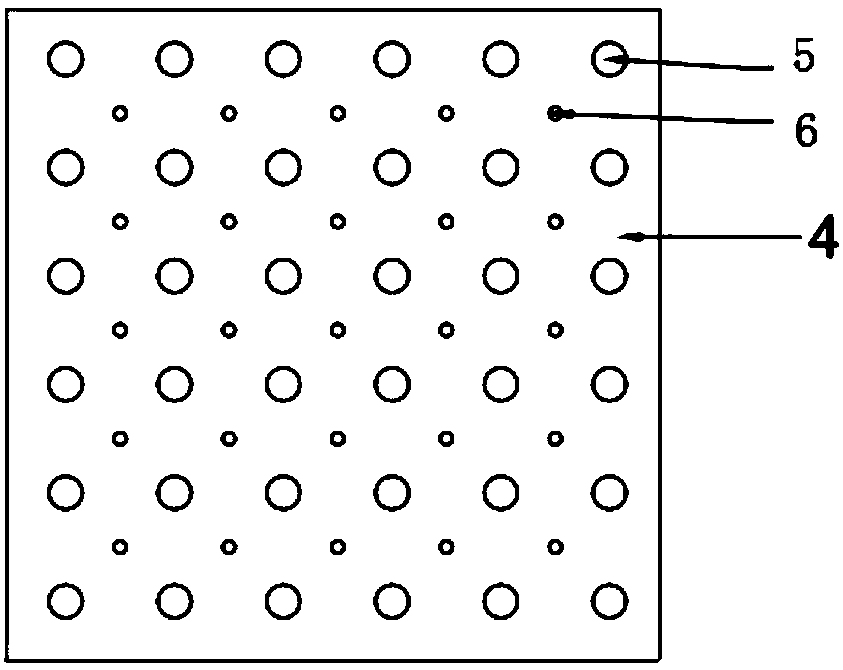

[0029] (2) Laser drilling: laser drilling on silicon wafers, the holes are an N×N array, and the shape of the holes is a circle center, square or cone, etc.; a better choice, the diameter of the laser drilling is 100-400μm ;

[0030] (3) Texturing: use conventional chemical cleaning and texturing methods to make texturing to form a light trap surface;

[0031] (4) Diffusion: use POCl3 diffusion source on the suede surface for high-temperature single-sided diffusion to form a PN junction;

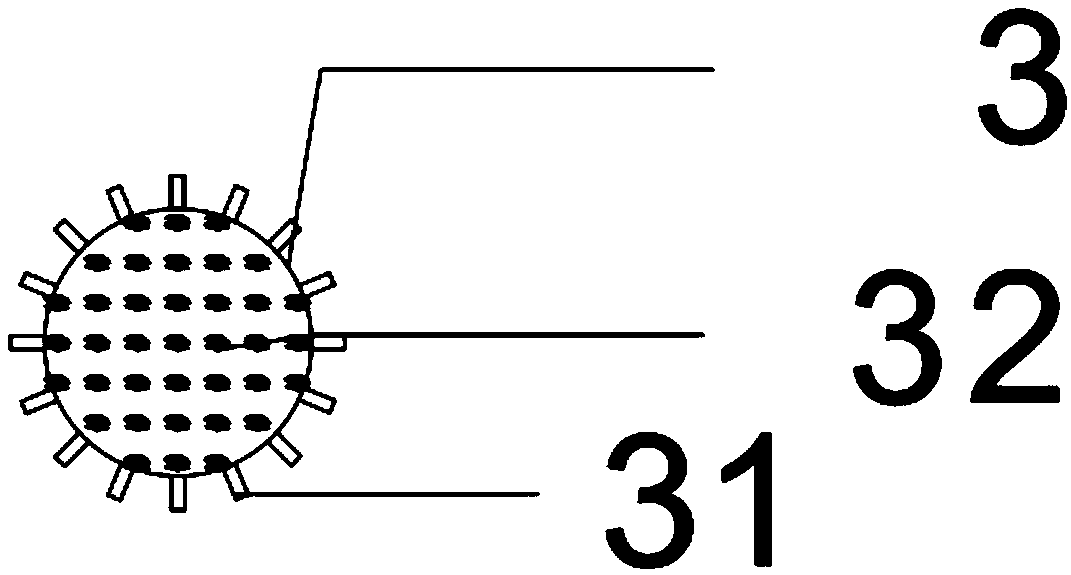

[0032] (5) Mask: On the back surface of the silicon wafer (with the punched hole as the center), prepare a diameter of 1-10mm (for example, a diameter of 1, 2, 4, 8, 10mm), and a thickness of 1-50μm (for example, a thickness of 25μm) A circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com