Back electric field structure of MWT solar cell and manufacturing method of back electric field structure

A technology for a solar cell and a manufacturing method, applied in the field of solar cells, can solve problems such as reducing area, and achieve the effect of reducing area, reducing consumption, safe and efficient continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

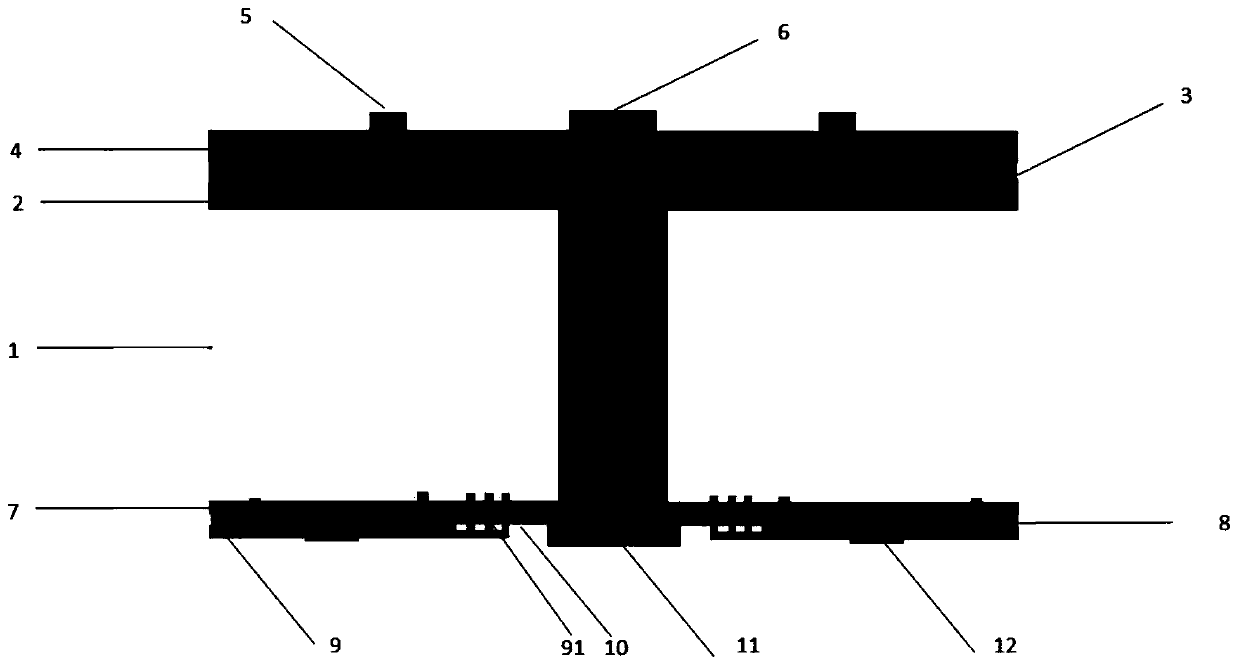

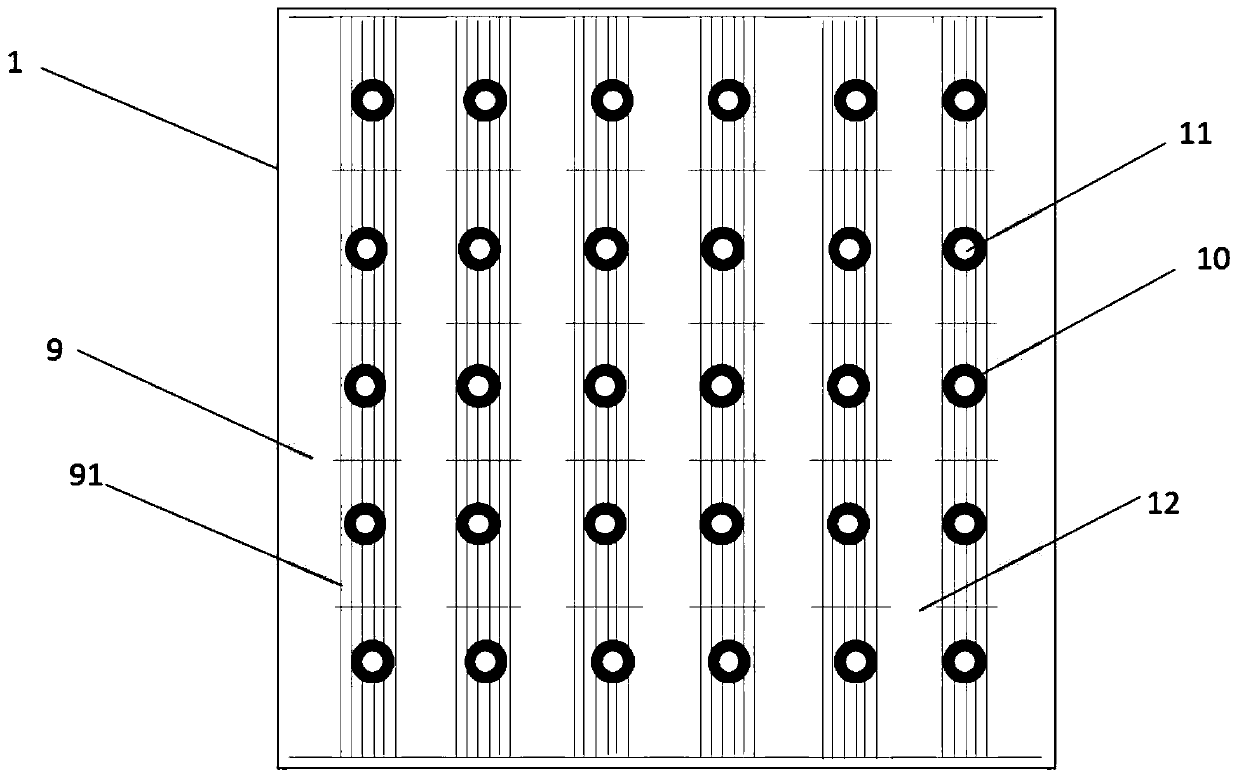

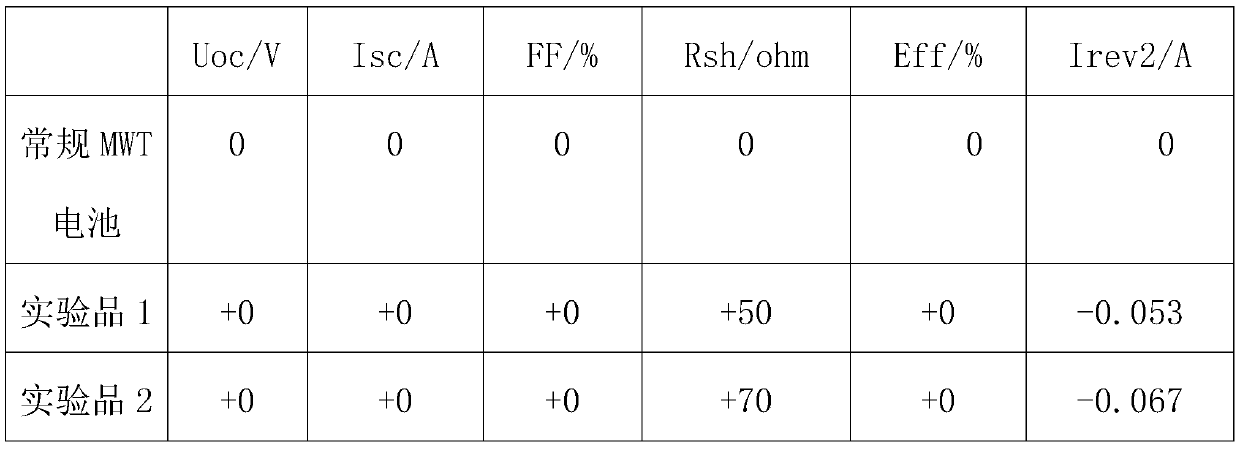

[0031] Embodiment: a kind of MWT solar cell back field structure of this embodiment, such as figure 1 and figure 2As shown, it includes a front silicon nitride film 4, a silicon dioxide film 3, a PN junction 2, a silicon wafer 1, an aluminum oxide film 7 and a back silicon nitride film 8 stacked sequentially from top to bottom. The positive electrode silver grid line 5 and the front side of the through-hole electrode 6 are provided, the back side is provided with an all-aluminum back field 9, the back side of the through-hole electrode 11 and evenly distributed back electrodes 12, and the all-aluminum back field 9 is provided with an aluminum grid line back field 91 , a through-hole isolation groove 10 is provided between the aluminum gate line back field 91 and the back through-hole electrode 11 . The part of the back field outside the isolation groove 10 in the through-hole electrode area on the back of the battery is designed from the all-aluminum back field 9 to the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com