Pore filling slurry and its preparation method and use

A hole-filling and slurry technology, applied in coatings, electrical components, circuits, etc., can solve problems such as contamination, normal sheet pollution, and adverse effects of normal sheets, and achieve good hole filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

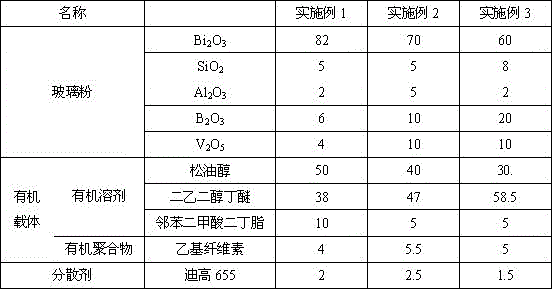

[0025] The present invention will be further described in conjunction with specific examples below, but it should be pointed out that the pore repairing slurry of the present invention and its preparation method and use are not limited to such specific components or proportions. Those skilled in the art can obviously understand that the following explanations can be directly applied to other similar components or proportions not specified herein even without any adjustment or modification.

[0026] The pore-filling slurry used in the solar silicon pinhole sheet of the present invention consists of 75-85% of special glass powder and 10-25% of organic carrier. The particle size of the glass powder is 0.1-2.5 μm, the composition of the glass powder (weight percent): Bi 2 o 3 75%~85%, SiO 2 2~10%, Al 2 o 3 1~5%, B 2 o 3 5~20%, other additives 2~8%. The organic carrier is composed of an organic solvent, an organic polymer and a dispersant, wherein the organic solvent is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com