Connector structure used in highly integrated flip-chip cob light sources

A highly integrated, connector technology, used in connections, electrical components, conductive connections, etc., can solve the problems of shortening the service life of highly integrated flip-chip COB light sources, consuming a lot of time and labor costs, and reducing production efficiency. Conductive insulation separation effect, convenient disassembly and assembly, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

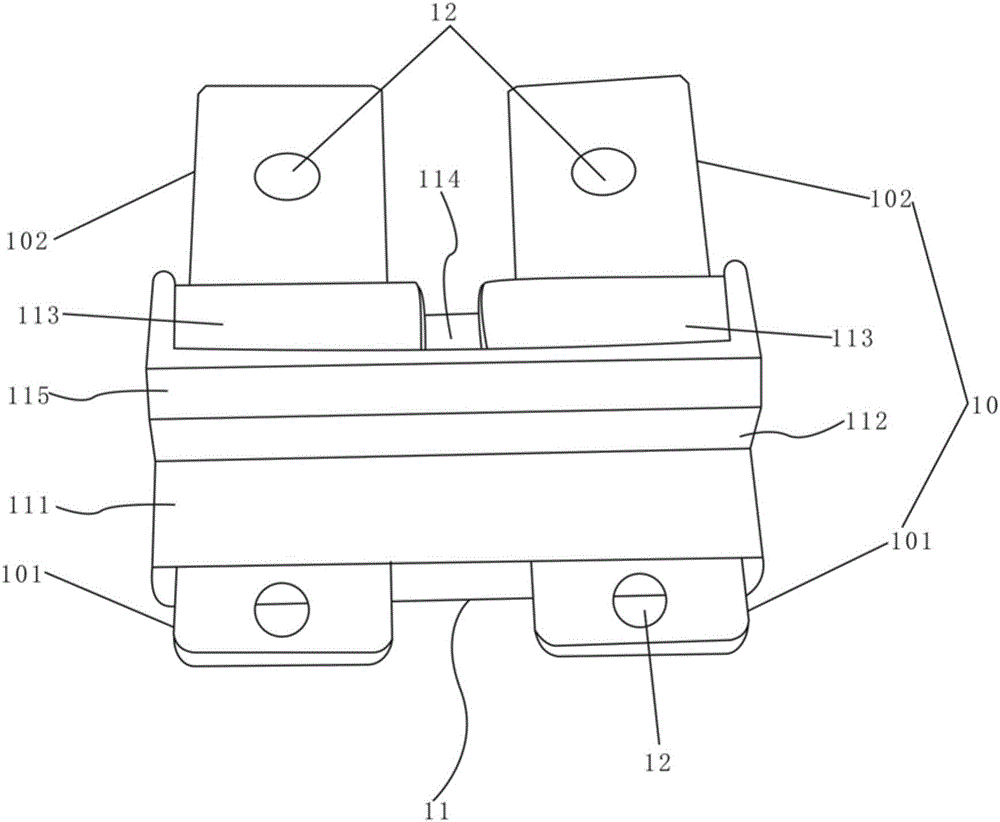

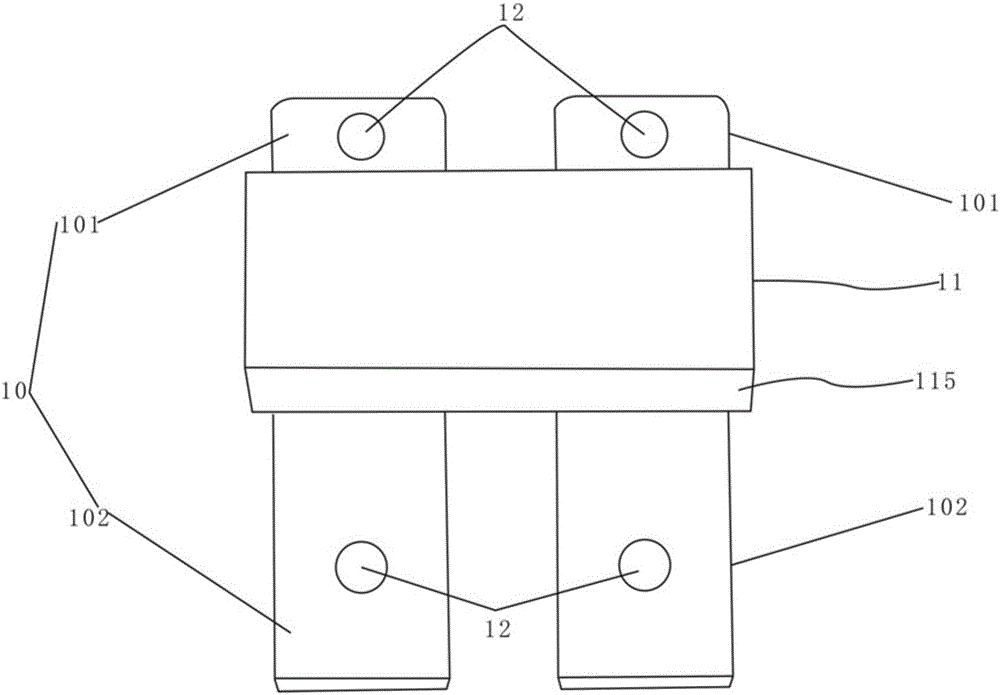

[0021] see Figure 1-2 , the connector structure used in the highly integrated flip-chip COB light source of the present invention includes two metal contact inserts 10 and an insulator 11, the two metal contact inserts 10 are respectively positive metal contact inserts and negative metal contact inserts The middle parts of the two metal contact inserts 10 are injected into the insulator 11, the front ends of the two metal contact inserts 10 form a welding portion 101 that is closely abutted with the heat dissipation substrate, and the rear ends of the two metal contact inserts 10 are formed The plug portion 102 electrically connected to the external power supply; the insulator 11 is provided with a horizontal insulating contact surface 111 and a vertical insulating contact surface 112 that are perpendicular to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com