Electric driving and braking integrated device

An electric drive and body technology, applied in the field of electric drive and brake integration, can solve the problems of large friction loss, uneven braking, environmental pollution, etc., and achieve the effects of low maintenance cost, stable operation, and reduced weight and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

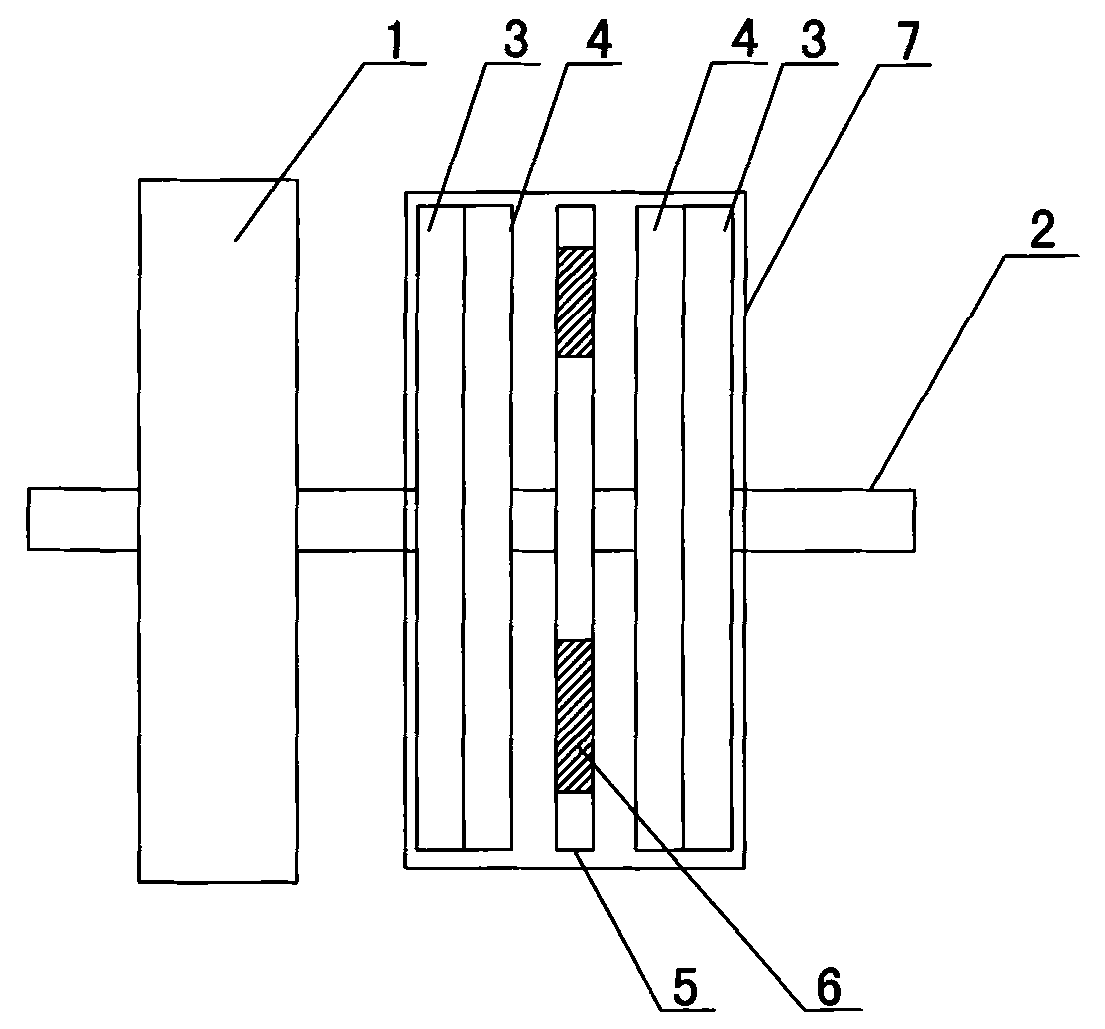

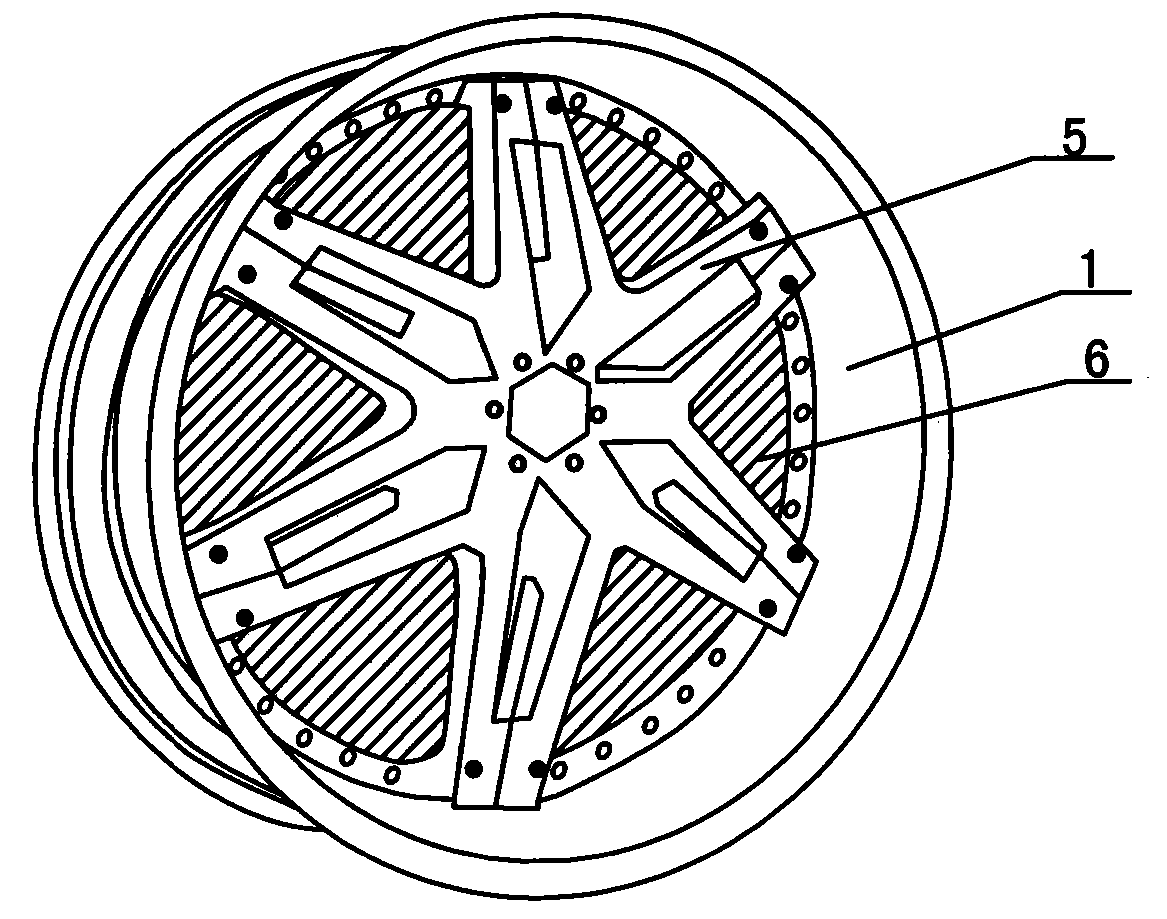

[0018] Such as Figure 1-2 As shown, the electric drive and brake integrated device according to the embodiment of the present invention includes a tire body 1, and a rotating support structure 5 is sleeved on the central rotating shaft 2 on the inner side of the tire body 1, and the rotating support structure 5 is a circle The disk structure is composed of several fan-shaped areas, and a magnetic steel 6 is fixedly installed in each fan-shaped area, and a silicon steel sheet 3 is arranged on both sides of the rotating support structure 5, and a coil 4 is fixedly installed on the inner surface of each silicon steel sheet 3, and at the same time After the rotating support structure 5, the magnetic steel 6, the silicon steel sheet 3, and the coil 4 are installed, an outer sealing frame 7 is wrapped around the silicon steel sheet 3, the coil 4, the rotating support structure 5, and the magnetic steel 6, and these Each part is packaged inside the outer layer sealing frame 7. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com