Non-polar capacitor voltage reducing and dividing rectification linear light-emitting diode (LED) driving circuit

A technology of LED drive and voltage divider circuit, which is applied in the field of converters and LED drive circuits, can solve the problems of large output power changes of LED lighting lamps, affect the stability of LED lighting lamps, and short service life, and achieve obvious energy-saving effects. Improve work efficiency and power factor, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

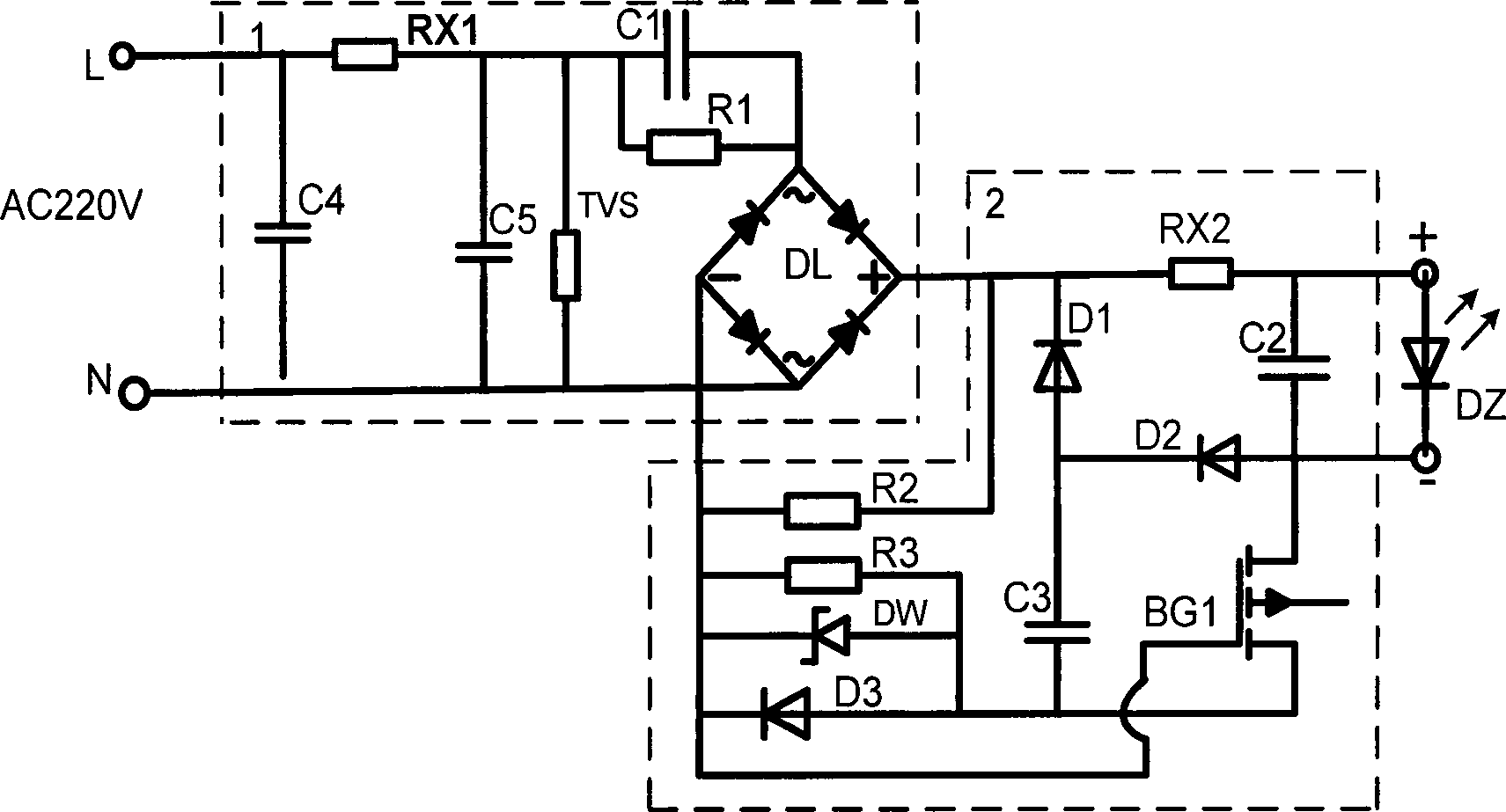

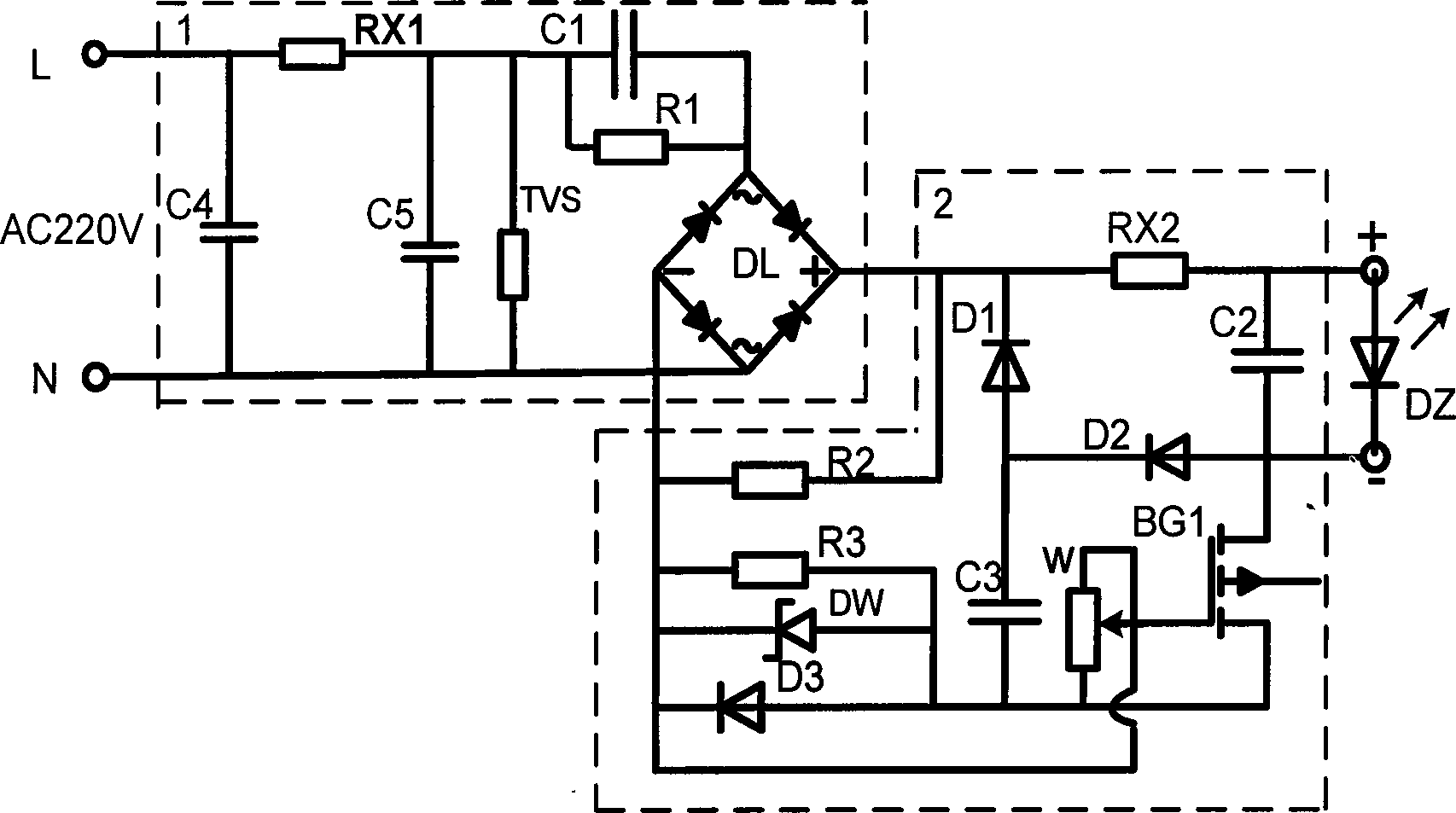

[0023] The present invention is a non-polar capacitor step-down voltage division rectification linear LED drive circuit, figure 1 It is a schematic diagram of a non-polar capacitor step-down voltage divider rectifier linear LED drive circuit. The power supply is composed of input terminals L and N, a step-down rectifier circuit 1, a voltage divider circuit 2, output terminals + and -, and a load (luminescent tube group) DZ. The step-down rectification circuit 1 is composed of filter capacitors C4 and C5, current limiting resistor RX1, overvoltage protection transient absorbing element TVS, step-down capacitor C1, discharge resistor R1 and rectifier bridge DL; the voltage divider circuit 2 It is composed of discharge diode D1, charge diode D2 and isolation diode D3, capacitors C2 and C3, drive resistor R2 and release resistor R3, voltage regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com