Heat dissipation module

A heat dissipation module and heat dissipation layer technology, which is applied in the field of heat dissipation modules, can solve the problems of complex heat dissipation device design and overall setting, increase process and operation time, increase time and cost, etc., to improve space utilization, increase installation space, The effect of good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A heat dissipation module according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

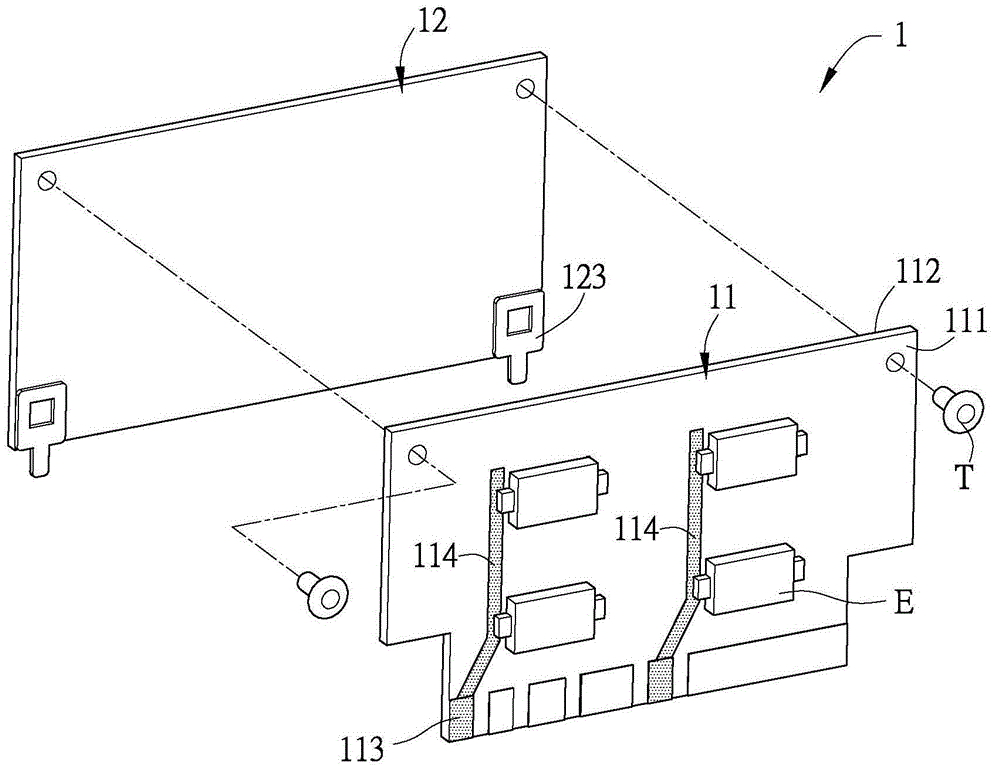

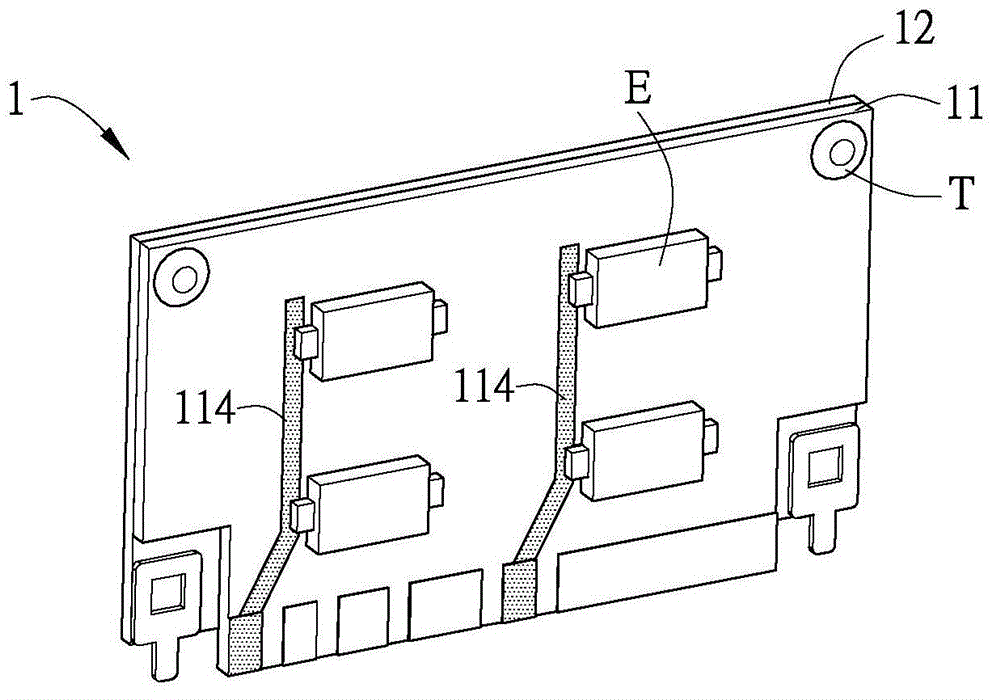

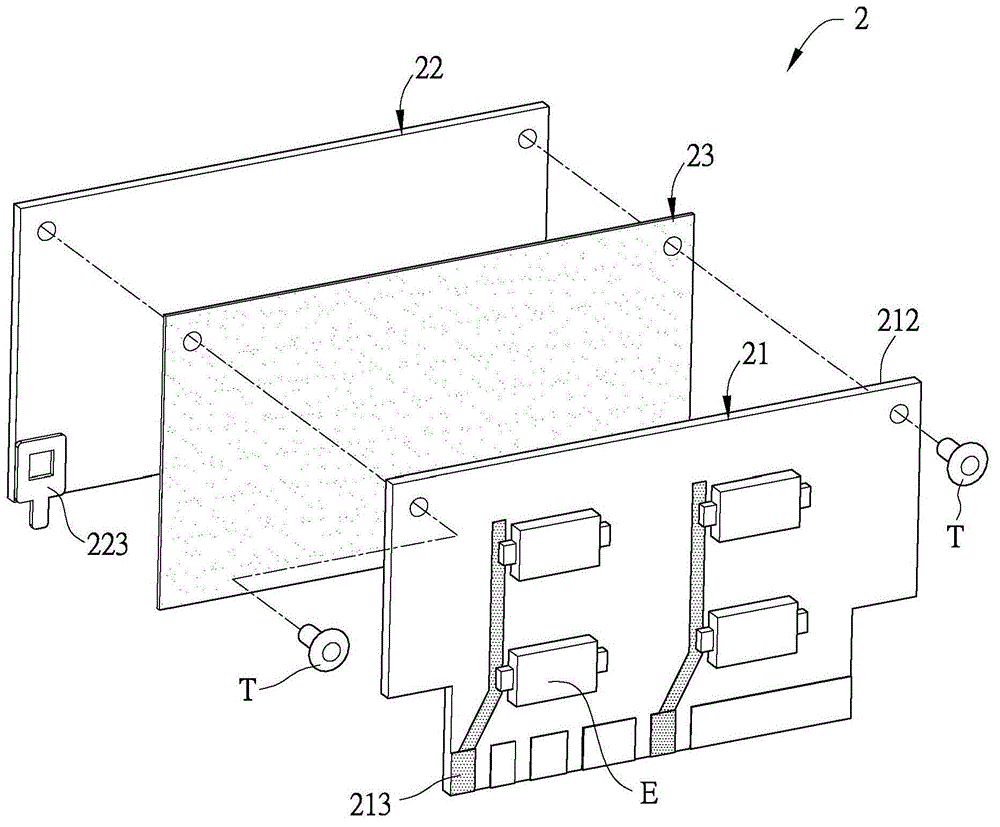

[0042] Figure 1A It is an exploded schematic diagram of a heat dissipation module in a preferred embodiment of the present invention, Figure 1B for Figure 1A A combined schematic diagram of a cooling module. Please also refer to Figure 1A and Figure 1B As shown, the heat dissipation module 1 includes at least one substrate 11 and a heat dissipation layer 12 , wherein the heat dissipation module 1 is vertically arranged on a main board (not shown). In detail, the cooling module 1 is installed on the main board through pin through hole (PTH) or surface mount technology (SMT), and the "main board" referred to here can be a main board. This is not limited. However, the above-mentioned connection methods are understood by those with ordinary k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com