Connection element

A technology for connecting components and connecting components, which is applied to electrical components, parts of connecting devices, connections, etc., can solve the problems of unstable contact parts, no resistance to shearing force, etc., and achieve the effect of high weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

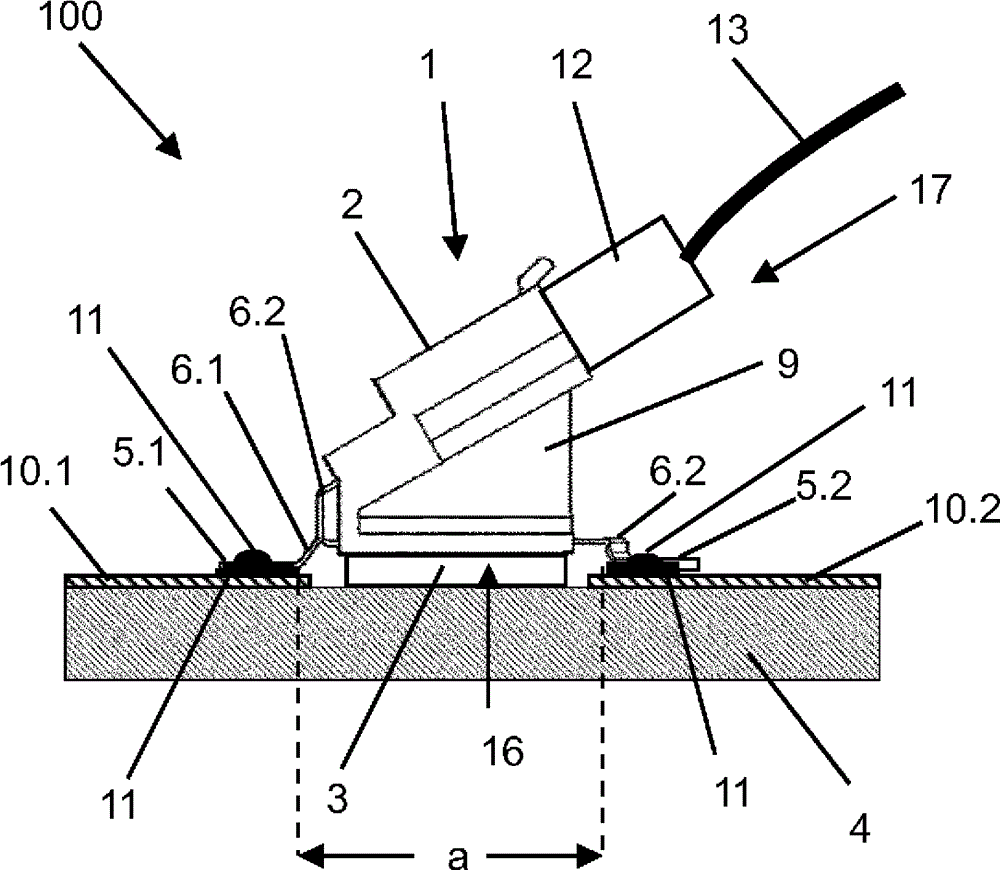

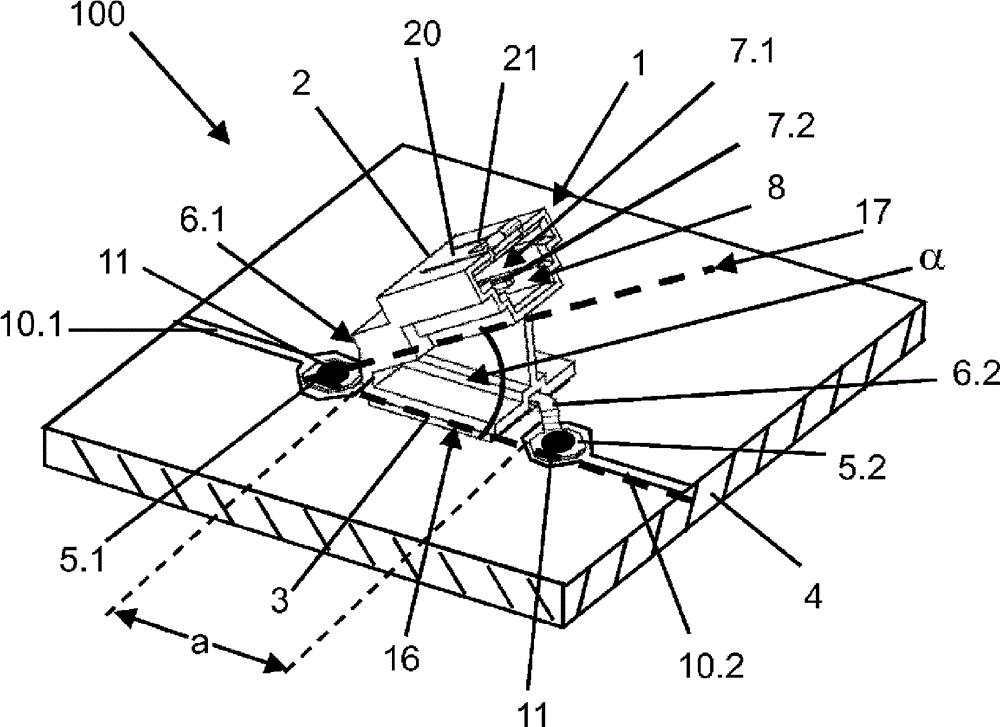

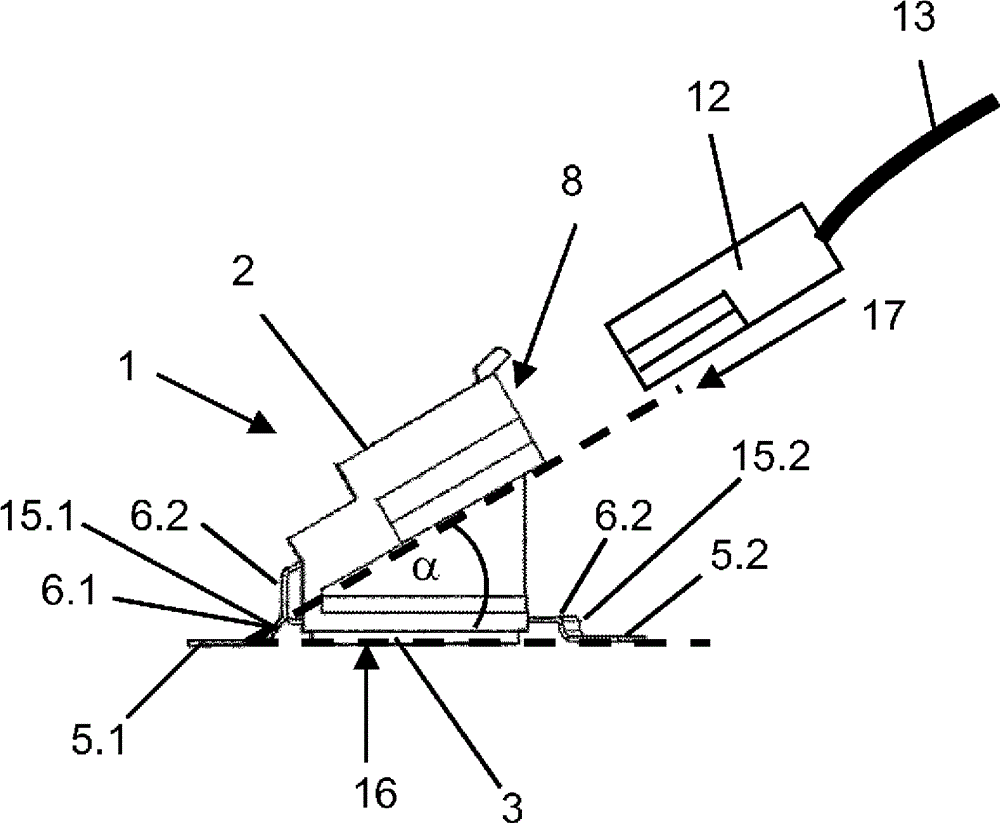

[0069] figure 1 A schematic illustration of a coupling assembly constructed in accordance with the present invention is shown, indicated at reference numeral 100 . The coupling element 1 according to the invention comprises a housing 2 which is connected to a base 4 via an adhesive fastening 3 .

[0070] The substrate 4 is in this example a transparent disk comprising 3 mm thick, thermally prestressed, single-layer safety glass containing soda lime glass. The base 4 has a width of 150 cm and a height of 80 cm, wherein, in figure 1Only a fragment is shown. Conductive structures 10.1, 10.2 in the form of heat conductor loops are printed on the substrate. With regard to the conductive structures 10.1, 10.2, only the ends and connection points are shown. The conductive structures 10.1, 10.2 contain printed and fired silver particles and glass frit.

[0071] The housing has, for example, a base area of 12 mm×12 mm and a height of 15 mm. The housing contains, for example, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com