Diversion-type gas-liquid separation unit, gas-liquid separation device and multi-phase flow reactor

A gas-liquid separation device and gas-liquid separation technology, which is applied in the field of diversion type gas-liquid separation unit, gas-liquid separation unit, and gas-liquid separation device, can solve the problem of excessive liquid in the purified gas, and achieve sufficient and thorough separation and discharge. Adaptable, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

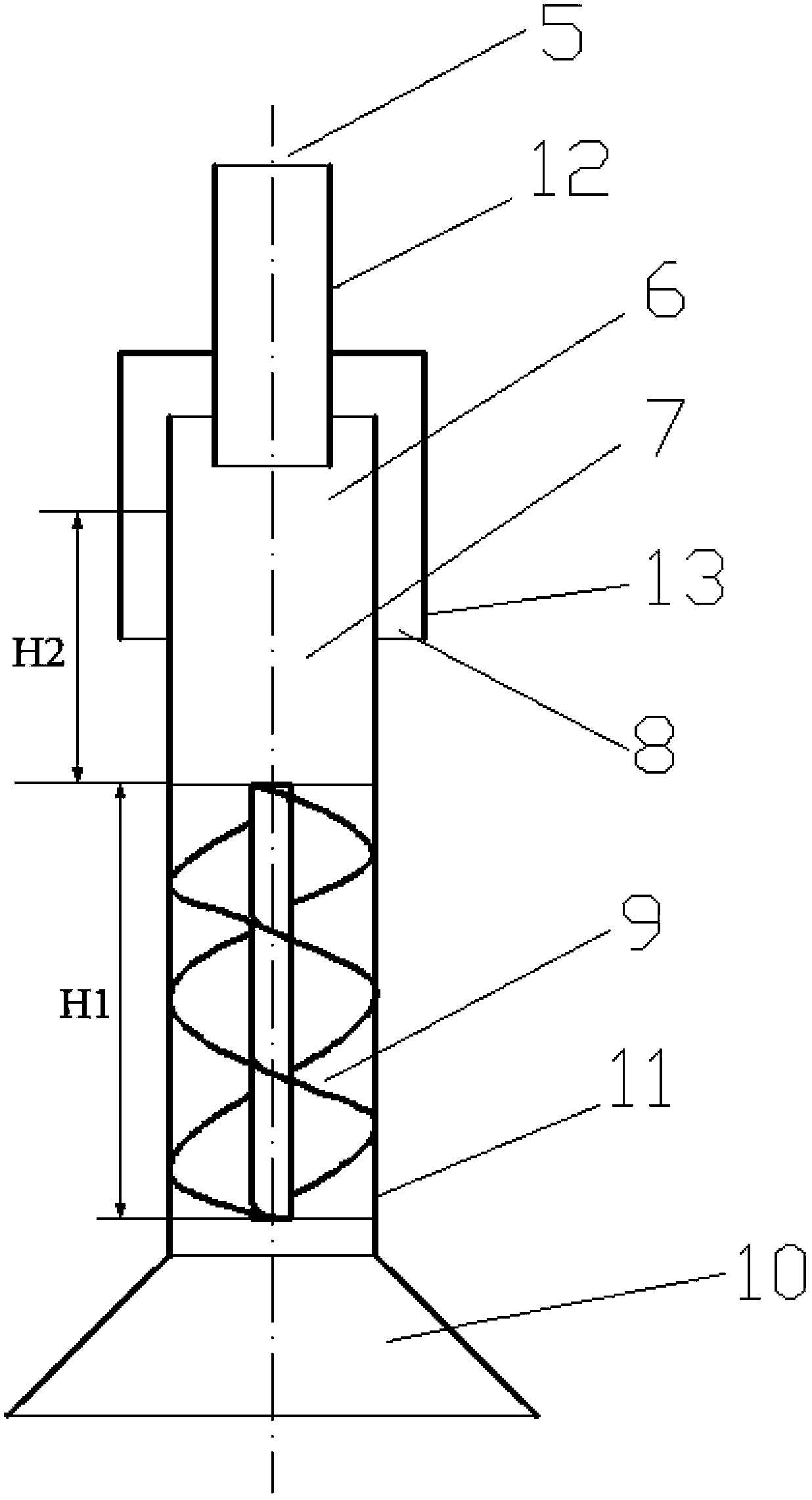

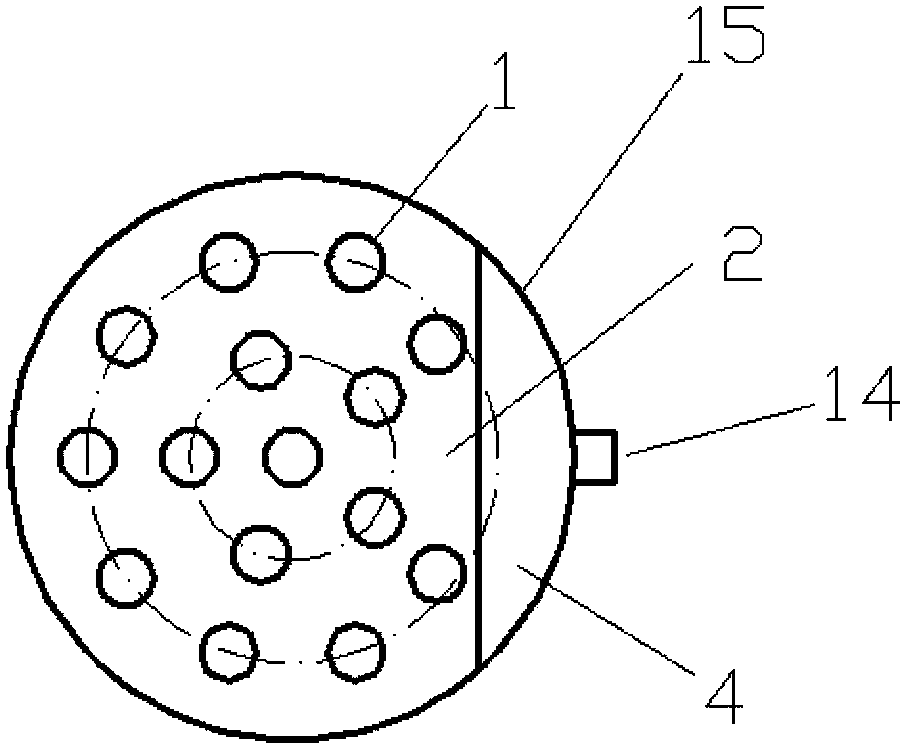

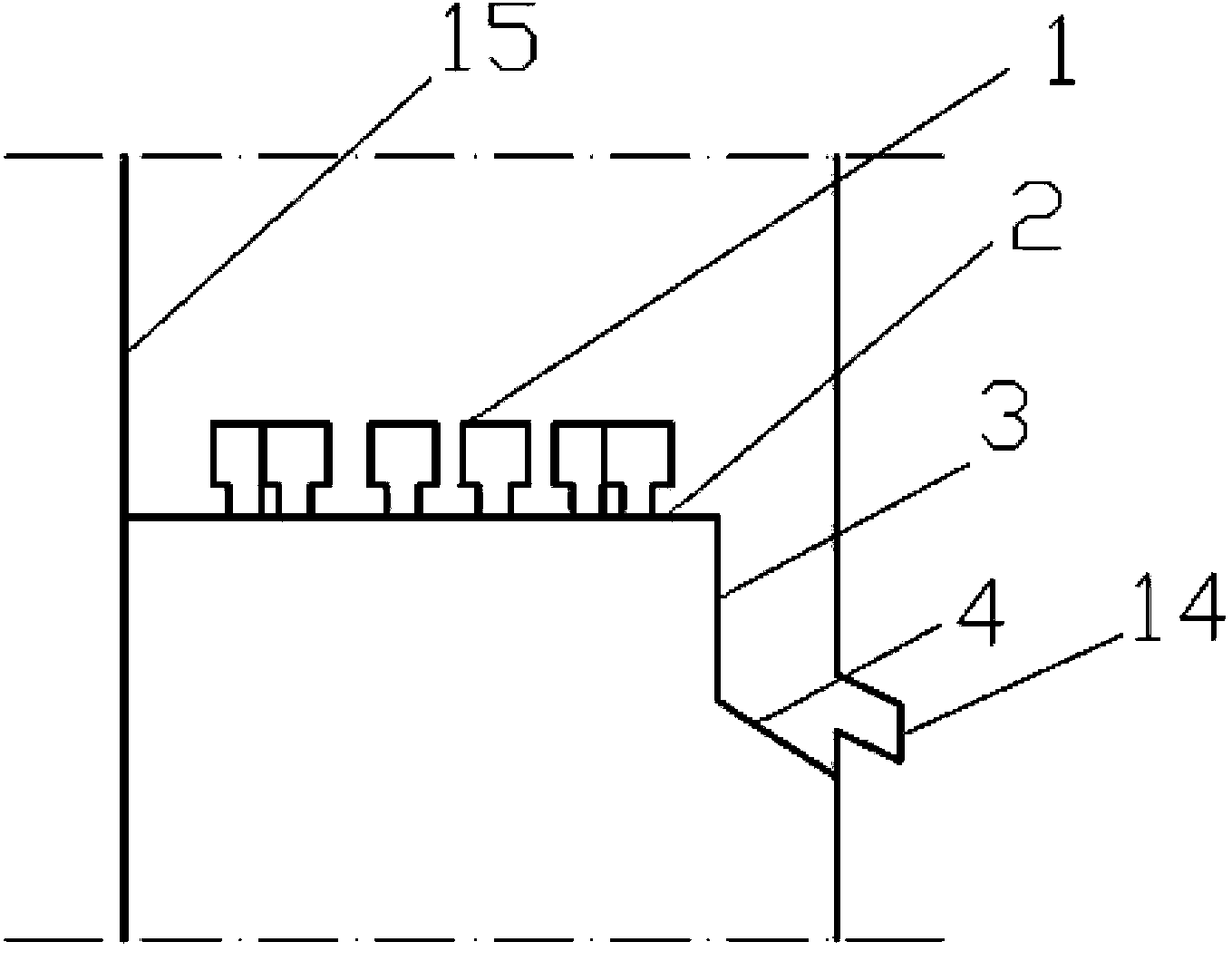

[0034] see figure 1As shown, the diversion type gas-liquid separation unit of a specific embodiment of the present invention comprises a hollow unit body, the unit body has an inlet area 10, a purified gas outlet area 5, and a gas outlet between the inlet area 10 and the purified gas outlet area 5. The liquid outlet area 8. Wherein, the internal space of the unit main body includes in turn a flow guide area 9 for receiving the gas-liquid mixture input from the inlet area 10, a liquid particle size increasing gathering area 7, and a gas-liquid separation area 6, wherein the flow guide area 9 is provided fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap