Upward-overturning protective door of machine tool

A protective door and flip-type technology, which is applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of coolant splashing, chips flying out of the half protective door, etc., to protect the safety of the operator and the structure Simple, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

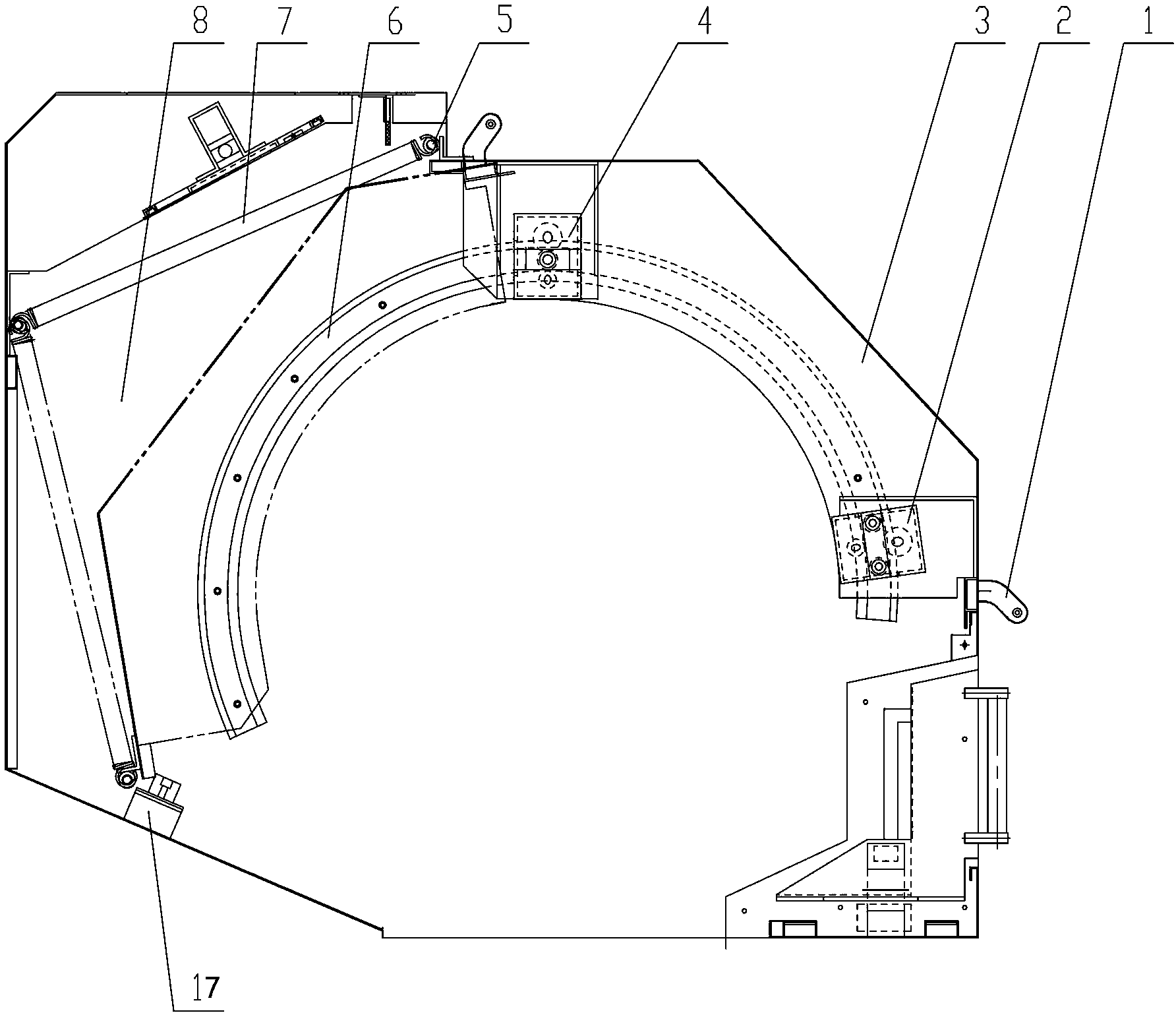

[0019] The present invention as figure 1 as shown,

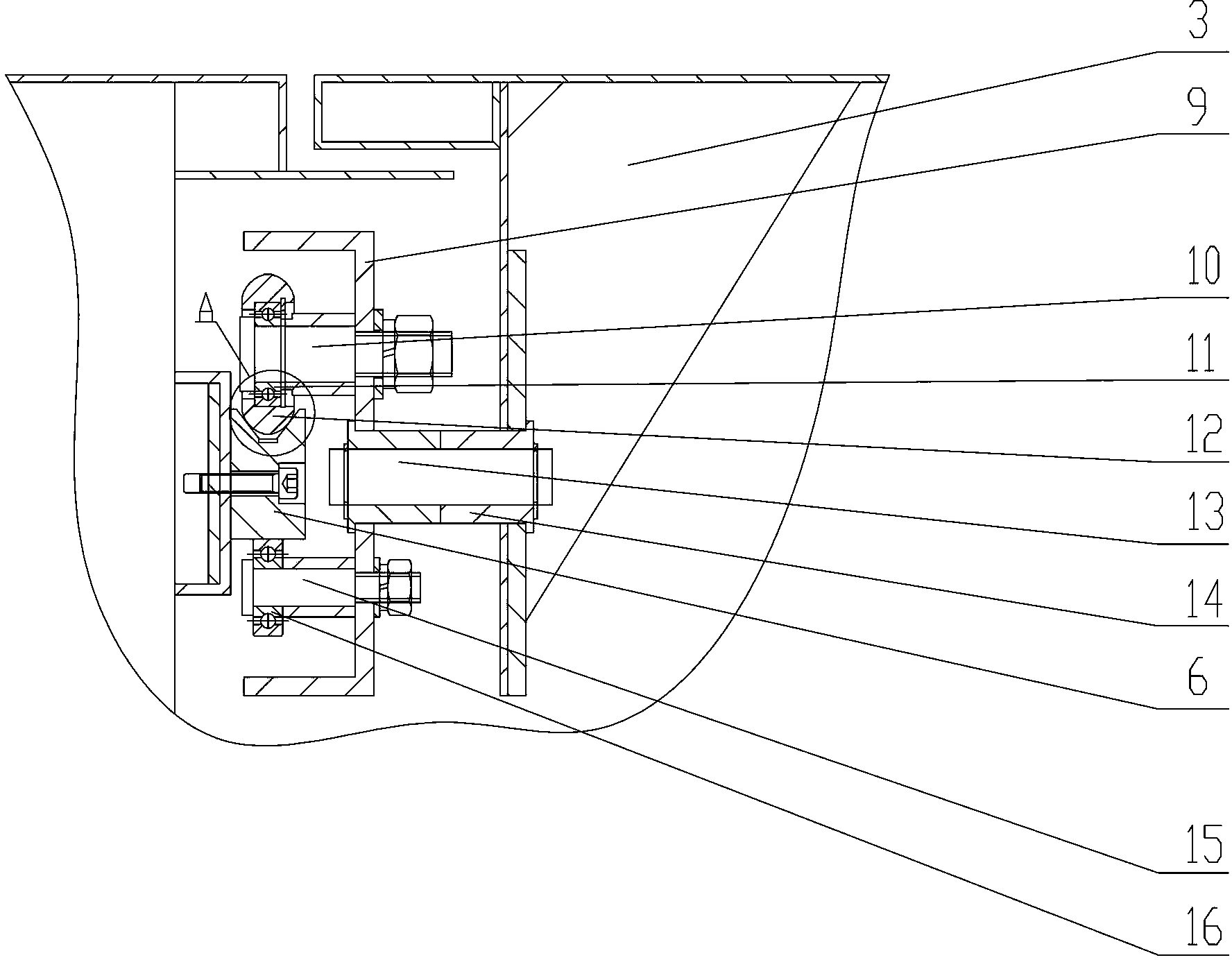

[0020] A flip-type protective door on a machine tool, including a circular arc guide rail 6 fixed on the protective body of the machine tool, a protective door 3 with a hand push handle 1, and is characterized in that it also includes an elastic buffer structure and a guide wheel group. The arc guide rail 6 is installed on the inner two sides of the machine tool protection body 8;

[0021] The upper side of the arc guide rail 6 is a roller grooved rail, and the lower side is a smooth rail;

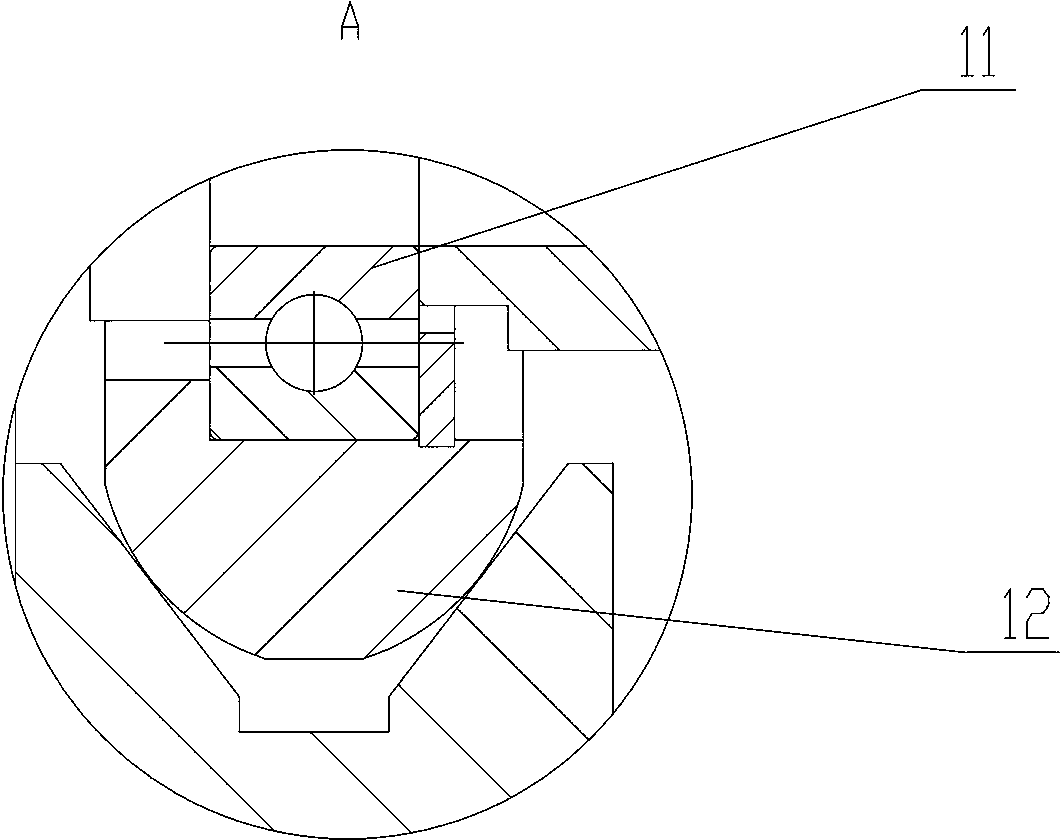

[0022] The guide wheel set includes two sets of guide wheel sets 1, 4, the upper and lower sets of guide wheels include roller brackets that are rotatably arranged on both sides of the protective door, upper rollers and lower rollers fixed on the roller brackets;

[0023] The elastic buffer structure include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com